Thingiverse

Ribbon Microphone Corrugator by guitartoys

by Thingiverse

Last crawled date: 3 years ago

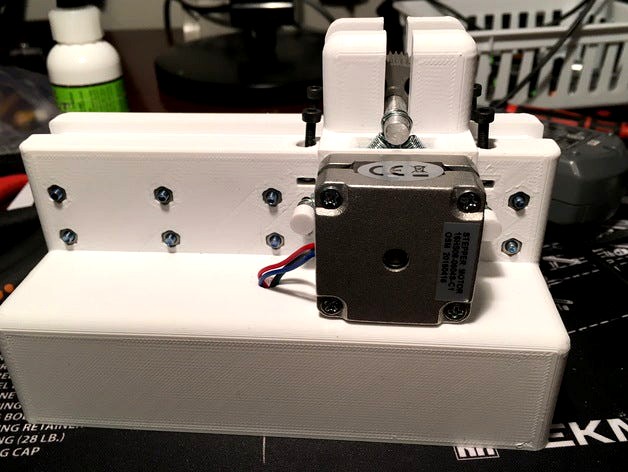

In my never ending quest for a high quality ribbon microphone in every studio locker (chicken in every pot), I designed a tool to help corrugate ribbons for ribbon microphones.

In order to make a ribbon microphone element, you need to corrugate it, putting small folds in the ribbon, to give it flexibility, and allow you to put proper tension on it, when you mount the ribbon into the truss. Many ways to do this, but ultimately everyone uses gears. I wanted a fancy table top unit that was automated, to keep my hands free to feed the ribbon in, and catch it on the way out.

Using some gears, I fashioned a 3-D printed frame, a stepper and Arduino and a footswitch to allow you to corrugate your ribbon microphone elements easily and consistently.

(Crafters can use it too for crimping ribbons)

The full project is up on Instructables, along with parts sources, and Arduino code. Please check it out.

http://www.instructables.com/id/Ribbon-Corrugator-crimper-for-Ribbon-Microphones-A/

Next project in the queue is a fully automated Ribbon element tuner. Basically put a ribbon microphone truss into a carrier, lay the ribbon in, fix one end of the ribbon, and the other will be held down on a sliding part. It will automatically inject a (user selectable) frequency at (user selectable) amplitude and a stepper will adjust the tension for optimal gain. Then fix the other end of the ribbon.

You should then have a nicely tuned ribbon element. Well at least that's the plan, but I'm sure I will face a number of challenges.

Trick here, is I’m designing a set of interchangeable carriers for a variety of different ribbon microphone trusses. So pick the carrier for your mic truss, such as an MXL R80, put the truss in the carrier, and the carrier in the tuner, and you are ready to go.

Once done with that, I'm going to revisit this corrugator, modifying it for 1" wide gears with a diametrical pitch of 64 and a larger stepper. But since custom made gears are so costly this will take some time to get back to.

I hope you find it useful, and look forward to any suggestions you might have.

In order to make a ribbon microphone element, you need to corrugate it, putting small folds in the ribbon, to give it flexibility, and allow you to put proper tension on it, when you mount the ribbon into the truss. Many ways to do this, but ultimately everyone uses gears. I wanted a fancy table top unit that was automated, to keep my hands free to feed the ribbon in, and catch it on the way out.

Using some gears, I fashioned a 3-D printed frame, a stepper and Arduino and a footswitch to allow you to corrugate your ribbon microphone elements easily and consistently.

(Crafters can use it too for crimping ribbons)

The full project is up on Instructables, along with parts sources, and Arduino code. Please check it out.

http://www.instructables.com/id/Ribbon-Corrugator-crimper-for-Ribbon-Microphones-A/

Next project in the queue is a fully automated Ribbon element tuner. Basically put a ribbon microphone truss into a carrier, lay the ribbon in, fix one end of the ribbon, and the other will be held down on a sliding part. It will automatically inject a (user selectable) frequency at (user selectable) amplitude and a stepper will adjust the tension for optimal gain. Then fix the other end of the ribbon.

You should then have a nicely tuned ribbon element. Well at least that's the plan, but I'm sure I will face a number of challenges.

Trick here, is I’m designing a set of interchangeable carriers for a variety of different ribbon microphone trusses. So pick the carrier for your mic truss, such as an MXL R80, put the truss in the carrier, and the carrier in the tuner, and you are ready to go.

Once done with that, I'm going to revisit this corrugator, modifying it for 1" wide gears with a diametrical pitch of 64 and a larger stepper. But since custom made gears are so costly this will take some time to get back to.

I hope you find it useful, and look forward to any suggestions you might have.

Similar models

thingiverse

free

Ribbon Microphone Tuner Tensioner by guitartoys

...e element.

for more info, please check out my instructable at

http://www.instructables.com/id/ribbon-microphone-tuner-tensioner/

3dwarehouse

free

Rotery Ribbon Corrugater

...n or standard corrugation types. #audio #corrugate #corrugating #corrugation #foil #mic #microphone #piston #ribbon #sound #stack

thingiverse

free

MXL R80 Ribbon Upgrade and Alignment Jig by guitartoys

...r complete instructions, check out my instructable here:

http://www.instructables.com/id/ribbon-microphone-upgrade-for-mxl-r80/

thingiverse

free

Austin Ribbon Microphone Alignment Jig by guitartoys

... end at a time.

see my ribbon microphone upgrade for the mxl 990 mic below for full instructions.

cad work done in fusion 360

thingiverse

free

Ribbon Microphone Upgrade for MXL 990 Mic by guitartoys

...ng. i've got a ribbon alignment jig for an mxl r80, and an mxl r144, in addition to some enhancements to those mics.

enjoy.

3dwarehouse

free

STack Sound Ribbon Corrugator 2x¼

...9; and conventional corrugation. ready to be 3d printed. #3d_print #audio #diy #mic #microphone #piston #recording #ribbon #sound

thingiverse

free

Ribbon Cable Clamp by waynestronach

... to fix 10 way ribbon cable to 8mm extruder rod and convert from flat to round format. i use this for connection to my extruder.

thingiverse

free

MXL R144 Ribbon Upgrade and Alignment Jig by guitartoys

...om/id/ribbon-microphone-upgrade-for-mxl-r144-re-ribbon-n

yes, the ribbon shown in the alignment jig is too loose. i replaced it.

thingiverse

free

PrintrBot Jr X Axis Tensioner by Ridgeback

...t hand twisted the screws in. i tightened the tension nice and snug. i'm using gt2 gears (20 tooth) and matching timing belt.

thingiverse

free

3G 6D Shield by cpt_caveman

...

the unused scl and sda pins are used for the fifth stepper.

major work in progress, tell me what is unclear and i will fix it.

Guitartoys

thingiverse

free

Reel Mod by guitartoys

... mod by guitartoys

thingiverse

this is an adjustment to the base to make the opening at the bottom match the opening at the top.

thingiverse

free

Ribbon Microphone Tuner Tensioner by guitartoys

...e element.

for more info, please check out my instructable at

http://www.instructables.com/id/ribbon-microphone-tuner-tensioner/

thingiverse

free

Austin Ribbon Microphone Alignment Jig by guitartoys

... end at a time.

see my ribbon microphone upgrade for the mxl 990 mic below for full instructions.

cad work done in fusion 360

thingiverse

free

9V Battery Cap by guitartoys

...lso included a version with holes in them so you can test them with a battery tester, without having to take to caps off.

enjoy.

thingiverse

free

Kitchen Sink Wash Cloth dryer by guitartoys

...n diameter and just shy of 180mm long

don't forget to print 2 of the triangle parts.

some super glue and you are done.

enjoy

thingiverse

free

Spektrum Video Monitor Stand by guitartoys

...t fall over. so this is a nice stable stand, it fits well, and is simple to print.

print bottom down, no support needed.

enjoy.

thingiverse

free

MXL R144 Ribbon Upgrade and Alignment Jig by guitartoys

...om/id/ribbon-microphone-upgrade-for-mxl-r144-re-ribbon-n

yes, the ribbon shown in the alignment jig is too loose. i replaced it.

thingiverse

free

Blade Inductrix FPV Plus Case by guitartoys

... should print solid with shells and not need any infill. i also print 4 top and bottom layers.

fits the fpv plus perfectly

enjoy

thingiverse

free

Protein Skimmer Cup with drain for Aquatic Life 115 by guitartoys

...a bucket.

the drain port is to the right, but if you need it on the back or left, just let me know, and i'll mod it for you.

thingiverse

free

H4N Mic Stand Remix with Knobs by guitartoys

...t, and you will find that here as well.

works pretty well.

i haven't printed the thicker piece yet, but the other print ok.

Corrugator

3ddd

free

Cosmorelax Corrugated

...cosmorelax corrugated

3ddd

cosmorelax , corrugated

cosmorelax corrugated

3d_export

$7

corrugated glass

...corrugated glass

3dexport

turbosquid

$10

Corrugated door

...id

royalty free 3d model corrugated door for download as max on turbosquid: 3d models for games, architecture, videos. (1651509)

turbosquid

$1

Corrugated sheets

...

royalty free 3d model corrugated sheets for download as obj on turbosquid: 3d models for games, architecture, videos. (1380247)

turbosquid

$30

Corrugated Metal

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Corrugated Iron

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$4

Cardboard Corrugated Surface Textures

...ackgrounds. cardboard corrugated styles. great for your creativity for 3d programs and more. about files png/jpg seampless, ti...

3d_ocean

$5

Corrugated Iron Seamless Texture

...ated from photographs. texture, displacement, normal, occlusion and specular jpg maps are all included in this download! displ...

3d_export

$13

Corrugated galvanized sheets

...alvanized sheets

3dexport

corrugateed galvanized sheets 3d lowpoly model. multiple import formats<br>thank you for reading

3d_ocean

$2

Corrugated Metal Seamless Texture

...corrugated metal seamless texture

3docean

grunge metal old rust texture

seamless metal texture, ideal for uv mapping in 3d.

Microphone

3ddd

$1

microphone

...microphone

3ddd

microphone , микрофон

microphone

3d_ocean

$7

Microphone

...microphone

3docean

mic microphone mike

microphone

3d_ocean

$4

Microphone

...microphone

3docean

mic microphone mike

microphone with spherical grill

archibase_planet

free

Microphone

...hone conference microphone

digital conference selector microphone n170912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$7

microphone

...microphone

3dexport

black microphone

3d_export

$5

microphone

...microphone

3dexport

black modern microphone for streaming

archibase_planet

free

Microphone

...microphone

archibase planet

microphone audio equipment

microphone n260809 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Microphone

...microphone

archibase planet

equipment microphone

microphone n230410 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Microphone

...microphone

archibase planet

microphone audio equipment

microphone n250608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Microphone

...microphone

archibase planet

microphone audio equipment

microphone n160309 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Ribbon

3ddd

$1

Ribbon

...house , круглое

зеркало "ribbon", teakhouse, art.bf9-rb02rl, ш/в/г 140/140/5см

design_connected

$11

Ribbon

...ribbon

designconnected

bonaldo ribbon computer generated 3d model. designed by lipparini, mauro.

3ddd

$1

MARK - Ribbon

...mark - ribbon

3ddd

mark , ribbon

mark - ribbon

design_connected

$16

Ribbon

...ribbon

designconnected

artifort ribbon armchairs computer generated 3d model. designed by pierre paulin.

3d_export

$10

order on the ribbon

...order on the ribbon

3dexport

order on the ribbon memorial date

turbosquid

$10

Ribbon

...y free 3d model ribbon for download as max, c4d, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1401548)

turbosquid

$3

Ribbon

...3d model ribbon for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1494272)

turbosquid

$1

Ribbon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

stgeorges ribbon

...stgeorges ribbon

3dexport

st. george's memorial ribbon

design_connected

$10

Ribbon Low

...ribbon low

designconnected

cappellini ribbon low computer generated 3d model. designed by nendo.