Thingiverse

Extrusion Calibration by Calipers by sinned6915

by Thingiverse

Last crawled date: 3 years ago

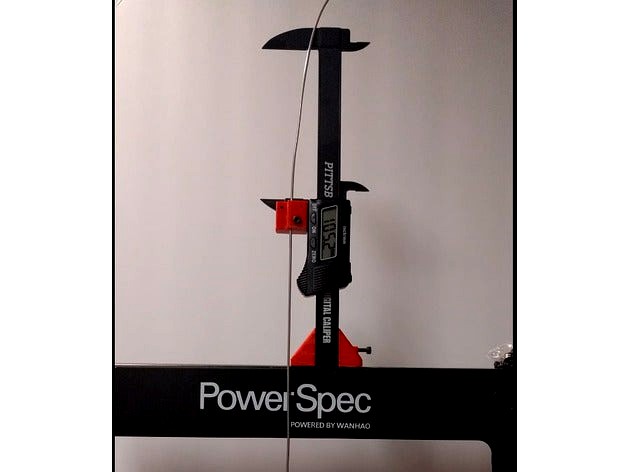

I needed to recalibrate my extruder steps and wanted to try the SublimeLayers method using calipers attached to the filament. My inexpensive calipers lacked a depth rod so I was unable to use the originally designed holder. They also have a goofy boss at the bottom that will not let them sit flat against a surface (It's the pair that you regret buying even though they were like $4 and you just hold on to hoping that there is something that you can use them for.. this is THAT!). Pretty much any 16m wide standard caliper will do, they can be dial type or electronic. They do not need a depth rod to work.

These calipers would loose count if the caliper body was anywhere near the extruder motor. (I suspect that the reinforced plastic body acts as an antenna and the EM pulses of the motor interfere with the caliper encoder).

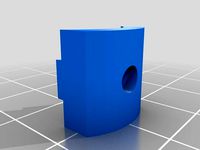

So I remixed this so that the caliper holder sits on top of my Di3 sheet metal frame and gets secured with a binder clip. The caliper in turn gets secured with a M3x25 grubscrew.

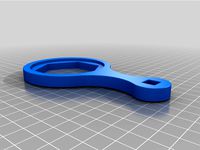

The clip that captures the filament is similarly secured to the lower jaw of the caliper with 2- M3x10 grub screws. The filament clamp uses an M3x15 screw. I changed the position of the screw so that you do not have to unload the filament from the printer or remove the clamp screw to thread the filament in.

I tweaked the original gcode script, so that the hotend heats up, beeps, displays a countdown and then extrudes 100mm of filament. The extrusion starts off slow and then speeds up then ramps down. See the linked video.

https://youtu.be/RxmVA18I0-0

Tips: Filament is best fed from the top of the printer, or use a short length. It helps if you straighten your filament by running it through your fingers a few times.

If the lower caliper jaw drops a bit after securing the filament and zero'g out the caliper, don't worry about it. The extruder will take up the slack and pull the assembly downwards and it will catch up on the dropped amount.

Remember to calculate the steps per mm and store it to the EEPROM of your printer. Octoprint make this easy for the major firmware flavors. If you are not using already, you should, and if you are, throw a few duckets Gina's way...

These calipers would loose count if the caliper body was anywhere near the extruder motor. (I suspect that the reinforced plastic body acts as an antenna and the EM pulses of the motor interfere with the caliper encoder).

So I remixed this so that the caliper holder sits on top of my Di3 sheet metal frame and gets secured with a binder clip. The caliper in turn gets secured with a M3x25 grubscrew.

The clip that captures the filament is similarly secured to the lower jaw of the caliper with 2- M3x10 grub screws. The filament clamp uses an M3x15 screw. I changed the position of the screw so that you do not have to unload the filament from the printer or remove the clamp screw to thread the filament in.

I tweaked the original gcode script, so that the hotend heats up, beeps, displays a countdown and then extrudes 100mm of filament. The extrusion starts off slow and then speeds up then ramps down. See the linked video.

https://youtu.be/RxmVA18I0-0

Tips: Filament is best fed from the top of the printer, or use a short length. It helps if you straighten your filament by running it through your fingers a few times.

If the lower caliper jaw drops a bit after securing the filament and zero'g out the caliper, don't worry about it. The extruder will take up the slack and pull the assembly downwards and it will catch up on the dropped amount.

Remember to calculate the steps per mm and store it to the EEPROM of your printer. Octoprint make this easy for the major firmware flavors. If you are not using already, you should, and if you are, throw a few duckets Gina's way...

Similar models

thingiverse

free

Anycubic Kossel Extruder Motor Clamp by nIMrOD888

...p over.

to remove:

slide the clip off either side.

when not in use:

sit the clamp on the top bracket of the extruder motor lever.

thingiverse

free

PCB clamp by Karlosek

...it but i had to use few drops of superglue.

jaws are pulled together with rubber band, secured in place with a piece of filament.

thingiverse

free

Extruder Calibration Aid by pkemp

...un 50mm of filament as the calipers (well, the ones i have) will have a max travel of about 105mm with the parts clamped to them.

thingiverse

free

2020 extrusion + captive nut + clamp by Porkstone

... m5 10mm bolt.

i tinker cadded this into existence so that i could design the clamp to secure my anet a2 printer to a base board.

thingiverse

free

Bowden Extruder for Nema 17 w. Planetary Gearbox by robkar

... knob can be used to manually extrude filament.

here is a link to the complete printer: http://www.thingiverse.com/thing:923830

thingiverse

free

Extruder mounting plate for 2020 extrusion by dc42

...e plate (you need 35mm length cap head screws for a 34mm long motor). then secure the plate to the extrusion using two m4 screws.

thingiverse

free

Pitan Bowden Modified Gear and Mount by shreddedbacon

...e small gear.

use 3x m3x40mm screws instead of the 3x m3x30mm (from the original pitan) screws to secure it to the stepper motor.

thingiverse

free

Extruder Alignment Clip by ColdCanuck

...igned and 100% secure......no more wobbling.

a simple effective solution!!!

can also be used with the tronxy xy-100 and anet a8.

thingiverse

free

2020 Extruder Motor Mount (for E3D Titan) by thnikk

...a 40mm motor so the cutout won't work if you're using a pancake motor, but you can still rotate the motor to make it fit.

thingiverse

free

Anycubic I3 Mega top extruder clamp/mount by Aspectus0

...or fits in and shouldn't move much. you can use the original wire for the motor.

i used petg, but it should be fine with pla.

Sinned6915

thingiverse

free

i3 OEM Thumbwheel cover by sinned6915

...e weight and feel of the oem thumbwheel over the thin wheel with lock nut insert. remixed with openscad source and ms 3d builder.

thingiverse

free

LED Indicator bar by sinned6915

...al to tone down the brightness.

the screw holes are pilot hole sized for the original m3 screws that mounted to the fan bracket.

thingiverse

free

Wanhao Duplicator i3 Cable Grommet Rear Rail by sinned6915

... zip tie holding the existing wires in place, move down and slide grommet into place. install a new zip tie to secure everything.

thingiverse

free

Coronavirus Ornament 2020 by sinned6915

...s of the pegs with a file or emery board to make them fit. a 2mm or 5/64 drill can be used to clean up the hex holes if need be.

thingiverse

free

OBDII Break Out box by sinned6915

...oles sized for big box store gardner bender grommets.

print it out, zippity zappity, bob is not uncle, now he's your bitch!

thingiverse

free

Powerstroke Oil Pan Bung Wrench by sinned6915

...ll.

wes did a good overview of fixing his truck, musch better than i could have done.https://www.youtube.com/watch?v=onqrhkuo2z4

thingiverse

free

Fabrikator Mini 1.5 Multi-Fan base by sinned6915

...the larger ones.

mi mini is quite happy with a 12v 70mm cpu fan, and it is quiet!

not all fans sizes have been tried/fit, ymmv.

thingiverse

free

Tuna Can Parts Washer by sinned6915

... umph than petg.

use a piece of filament as a rivet to clinch the basket springs together- see assembly illustrations in photos.

thingiverse

free

Tinyboy / Fabricator Mini 1.5 Part Cooling Fan by sinned6915

... on your additional fan, you might have to trim the fan duct a bit to get it to fit. the center tab should hold the fan in place.

Calipers

turbosquid

$7

CALIPER

...

royalty free 3d model caliper for download as stl and sldas on turbosquid: 3d models for games, architecture, videos. (1249938)

3d_export

$5

caliper

...caliper

3dexport

turbosquid

$15

Caliper

...ree 3d model caliper for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1653770)

turbosquid

$79

Caliper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Caliper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Caliper 3D Model

...caliper 3d model

3dexport

caliper paquimetro dimension dimens??o

caliper 3d model tlsurf 21469 3dexport

turbosquid

$5

Vernier Caliper

...lty free 3d model vernier caliper for download as 3ds and obj on turbosquid: 3d models for games, architecture, videos. (1604280)

turbosquid

$40

Vernier Caliper

...ee 3d model vernier caliper for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298113)

turbosquid

$15

Vernier caliper

... 3d model vernier caliper for download as ige, obj, and sldas on turbosquid: 3d models for games, architecture, videos. (1227110)

turbosquid

$15

Castroviejo Caliper

... castroviejo caliper for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1649701)

Calibration

turbosquid

$15

DEFIBRILLATOR CALIBRATORS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Calibration Test Benches

...libration test benches for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1355804)

turbosquid

$79

Tag Heuer Monaco Calibre 11

...free 3d model tag heuer monaco calibre 11 for download as max on turbosquid: 3d models for games, architecture, videos. (1634427)

turbosquid

$50

Smith & Wesson 50 Calibre Magnum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

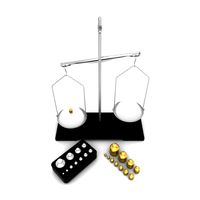

Laboratory Calibration Weight Set 1 3D Model

... 3d model

3dexport

laboratory lab science equipment weight set

laboratory calibration weight set 1 3d model bessoo 88084 3dexport

3d_export

$15

Laboratory Scale and Calibration Weight Set 3D Model

...port

laboratory lab science equipment weight set scale

laboratory scale and calibration weight set 3d model bessoo 88203 3dexport

3d_export

$5

3D printer filament calibration tool 3D Model

...ernier

3d printer filament calibration tool 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl locoman 107942 3dexport

3d_export

$59

tag heuer link calibre 16 watch

...built to real-world scale. units used: centimeters. model is 18 centimeters tall.<br>scene objects are organized by groups.

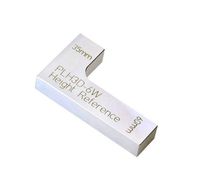

3d_export

free

laser height reference calibration tool opt lasers

...ind out more about the engraving and cutting laser heads, this item was designed to work with, take a look at the following page:

3d_export

$99

Patek Philippe White Gold Calibre 89

...br>please note: this 3d model like all my other models cannot be used as nft, as is or modified<br>thank you for reading

Extrusion

turbosquid

free

aluminum extrusion profiles

...free 3d model aluminum extrusion profiles for download as max on turbosquid: 3d models for games, architecture, videos. (1381707)

turbosquid

$5

Cable Cover Extrusion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

30 x 30 extrusion

... x 30 x 40.sldprt<br>30 x 30 x 50.sldprt<br>30 x 30 x 606.sldprt<br>the sketch.sldprt<br>30 x 30 x 40.stl

3d_export

$300

melt-blown fabric extrusion molding machine

...an email to me.<br>designed with solidworks 2017, render with photoview 360<br>**************************************

3d_export

$5

Spaceship - Galaxy Crusher

...with a more ominous twist. it has lots of extrusion and cubes and comes with a whopping 4k texture,...

3d_export

$20

1600 Meltblown cloth production line set drawing CAD

...width of 1600mm. the steel structure frame, feeding host, extrusion screw, heating system, screen changer, metering pump, melting it...

3d_export

$5

one-eyed scary virus

...cinema, the body relief is formed by the standard extrusion noise. the eye texture is...

3d_export

$20

GE TF34 Fan Blade and Nose Cone

...and appropriately sized fillet features are provided.<br>also, a threaded extrusion profile is provided on the fan blade component and...

3d_export

$10

glue injection machine

...injection technology. the ordinary glue injection machine is screw extrusion type, and its instantaneous pressure can reach more than...

3d_export

$1000

bead triangle adhesive laminating machine

...a triangular rubber head with the shape required for extrusion the rear end of the extruder is also provided...