Thingiverse

Zero Probe by Klave

by Thingiverse

Last crawled date: 3 years, 1 month ago

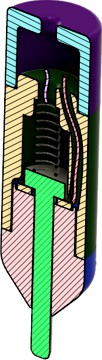

This is a very simple but very sensitive normally closed (NC) touch probe. When the tip is moved by any amount it opens the switch contacts.

You should be able to find the parts that aren't printed in you toolbox or spare parts box.

Parts not printed

Screw with a flat (not countersunk) shoulder 3.3mm diameter and a smooth shank longer than 18mm. Mine was from a PC heatsink

Washer that fits the screw loosely but has an OD of 9.4mm

Coil spring 4mm OD and about 10mm long (extended). Mine came out of a squirt bottle trigger/pump

If you don't have these parts it is easy to find similar things to fit, like using a pop-rivet head or a 3.3mm rod and glue a nut to make the head.

I have included .stp files so you can adapt the parts you have to work for this design. Failing that, these are very easy to design, even in Tinkercad and its really only the "Guide" that will need to be changed.

If you have something very close in size but too big, PLA will easily soften if you warm the metal part up and push it through before it gets too hot and warps everything.

How it works

The probe is attached to the z axis (or fixed to the focus lens in the case of a CO2 laser where the bed moves). When the probe tip touches the bed the screw "sensor" moves up against the spring pressure and no longer touches the washer.

Because wires are attached to both the washer and the spring, this movement causes normally closed contacts to open.

When the bed moves away from the probe the sensor can move back down and close the switch contact.

This action is very accurate and repeatable if the screw shank is a snug fit to the "Guide" hole and the mounting to the laser does not flex.

The device is completely passive and the tip does not retract. It does not need power to work, it is simply a switch that opens when the sensor tip touches a surface.

It is probably NOT suitable for a 3D printer bed leveling system because it could touch the model you are printing. If you added a removable cap to protrude past the print head then you could use it but there are many available options for bed leveling that don't need this.

You should be able to find the parts that aren't printed in you toolbox or spare parts box.

Parts not printed

Screw with a flat (not countersunk) shoulder 3.3mm diameter and a smooth shank longer than 18mm. Mine was from a PC heatsink

Washer that fits the screw loosely but has an OD of 9.4mm

Coil spring 4mm OD and about 10mm long (extended). Mine came out of a squirt bottle trigger/pump

If you don't have these parts it is easy to find similar things to fit, like using a pop-rivet head or a 3.3mm rod and glue a nut to make the head.

I have included .stp files so you can adapt the parts you have to work for this design. Failing that, these are very easy to design, even in Tinkercad and its really only the "Guide" that will need to be changed.

If you have something very close in size but too big, PLA will easily soften if you warm the metal part up and push it through before it gets too hot and warps everything.

How it works

The probe is attached to the z axis (or fixed to the focus lens in the case of a CO2 laser where the bed moves). When the probe tip touches the bed the screw "sensor" moves up against the spring pressure and no longer touches the washer.

Because wires are attached to both the washer and the spring, this movement causes normally closed contacts to open.

When the bed moves away from the probe the sensor can move back down and close the switch contact.

This action is very accurate and repeatable if the screw shank is a snug fit to the "Guide" hole and the mounting to the laser does not flex.

The device is completely passive and the tip does not retract. It does not need power to work, it is simply a switch that opens when the sensor tip touches a surface.

It is probably NOT suitable for a 3D printer bed leveling system because it could touch the model you are printing. If you added a removable cap to protrude past the print head then you could use it but there are many available options for bed leveling that don't need this.

Similar models

thingiverse

free

Cheap Bed Level Sensor (touch) by labidus

...vwbapv8

if you have suggestion for some type of mechanism to be able to retract this sensor without unscrew post your comment :).

thingiverse

free

3D Touch Cover / Protector by BD0G

...s so as to not need any support at all when printing. the other designs for the bl touch did require turning support material on.

thingiverse

free

Adjustable Z endstop for the Ender 3

...ge it or make alternative parts. my ender 3 is not all stock.

use the short version of the slider if you have a lower bed height.

thingiverse

free

CNC Tool Probe by Klave

...e that theirs is normally open and they had to set the probe as active low. this is not needed for my probe which is active high.

grabcad

free

CNC Tool Probe

... height (22.48mm in my case) is entered into the m31 macro in uccnc. spring od is <6.4mm and needs about 220g to open contacts

thingiverse

free

MechABL - An Affordable Auto Bed Levelling Sensor With an Automatic Retracting Probe by ArnoDorian16

... electronic noise can effect the standart deviation.

users are adviced to probe the buildplate while the heaters are not working.

grabcad

free

CNC Measurement Probe Protection Ring

...x10 socket cap screw, but we have found that it grips the shank just fine without the screw.

brought to you by emelody worldwide

thingiverse

free

CNC Touch Probe by scorch

...eded:

general purpose tap, thread size 6-32 (mcmaster 2522a717)

general purpose tap, thread size 1/4"-20 (mcmaster 2521a621)

thingiverse

free

CR-10 / CR10S Heated Bed Spring Tensioner Washers by notdave

...e bed was wobbly and print quality suffered.

these little washers increased the spring tension and made the bed much more stable.

thingiverse

free

CNC Clamp-On Surface Probe

... usefull then please click on "like"

if you print it please let me know how you got on

any comments/questions welcomed.

Klave

thingiverse

free

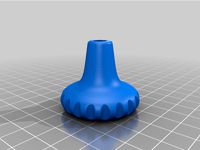

Dremel Nut by Klave

... scaled 101% in the radial directions to make the fit slightly looser but 100% threaded on fine

lay it on its front face to print

thingiverse

free

LM2596 Enclosure by Klave

...he board. the lid will fit both ways so make sure you check the pot is visible.

for the side entry the lid will only fit one way

thingiverse

free

YAFS Yet another end of of filament sensor by Klave

...x 5.7 mm like these https://www.amazon.ca/gp/product/b07dgx9b9c)

it also doubles as an equally unnecessary filament guide

ender 3

thingiverse

free

Hex bit finger wrench by Klave

...tool holder so i can easily place and remove it. i also put a magnet in the wrench top to stick it to the nearest piece of steel.

thingiverse

free

Filter Sieve by Klave

...s, the bars are an easy distance to bridge, only 3.6mm, and the sides taper at 24 degrees from vertical so no supports are needed

thingiverse

free

CNC Tool Probe by Klave

...e that theirs is normally open and they had to set the probe as active low. this is not needed for my probe which is active high.

thingiverse

free

Honda Civic 2008 Front Emblem by Klave

...ted it, i just made a curved version of the flat one and added the two pins, about 2mm long. you will need supports for this one.

thingiverse

free

K40 mA meter Bezel by Klave

...high voltage on them.

the meter face is 56mm x 64mm and the large round section has a diameter 49mm

mine is similar to this meter

thingiverse

free

K40 mirrors by Klave

... had this experience, feel free to feed back to the mirror suppliers that their compatibility with k40 is marginal and deceptive.

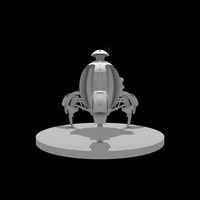

Probe

turbosquid

$25

Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

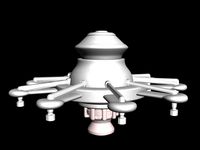

turbosquid

$12

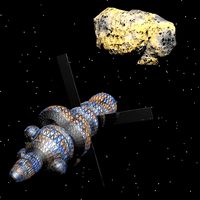

Mars probe space space exploration lunar probe

...be space space exploration lunar probe for download as max on turbosquid: 3d models for games, architecture, videos. (1630876)

turbosquid

$35

Space Probe

...osquid

royalty free 3d model space probe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1571168)

turbosquid

$15

Space Probe

...osquid

royalty free 3d model space probe for download as obj on turbosquid: 3d models for games, architecture, videos. (1314864)

turbosquid

$25

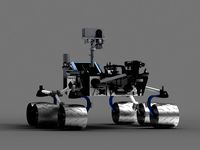

Robot Probe

...y free 3d model robot probe for download as fbx, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1537490)

turbosquid

$1

Dental Probe

...e 3d model dental probe for download as ma, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1312400)

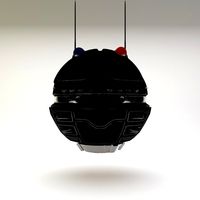

turbosquid

$60

Police Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Dental Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Space probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cassini Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Zero

3ddd

$1

ZERO, BEAM

...zero, beam

3ddd

zero

поворотная люстра zero , beam

design_connected

$9

Zero-in

...zero-in

designconnected

established & sons zero-in tables computer generated 3d model. designed by jay osgerby .

3ddd

free

Sub-Zero

...sub-zero

3ddd

sub-zero , голова

sub-zero corona render!

3ddd

$1

Metalspot / Zero

...metalspot / zero

3ddd

metalspot

metalspot zero

3ddd

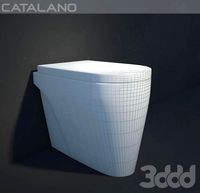

$1

Catalano Zero

...catalano zero

3ddd

catalano , унитаз

catalano zero

3ddd

$1

SUB ZERO

... sub zero

the first and only 3d model of sub zero refrigerator.

the model is very accurate.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Zero

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ZERO / Hide

...zero / hide

3ddd

zero

polys: 25486

wire-spline