Thingiverse

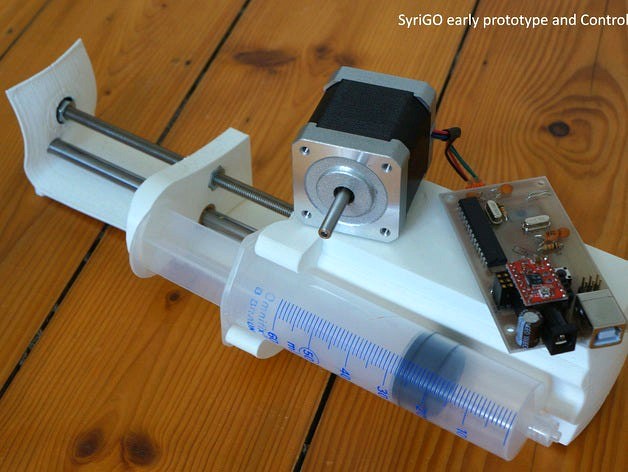

SyriGo - Open Hardware Programmable Syringe Pump by Ocram

by Thingiverse

Last crawled date: 3 years ago

PLEASE NOTICE: This is a work in progress and not meant for rebuilding yet!!Update 03.11.16: The SyriCtrl Board v1.1 is fully tested and working now. You can prebuilt it, or use it for other projects. It is basically an arduino with integrated stepper driver! You can find all files (including BOM) in the download section.

Check out the regular updates on project progress in the "custom" section below.

Our Lab was purchasing a programmable syringe pump and I was amazed at the exorbitant prices of such devices (more than 2000€ for an entry-level pump).

I searched for Open Hardware solutions, but no published pump seemed to be really suitable for laboratory use. Existing pumps are often bulky, not fully contained from the enviroment (and thus hard to clean) and unpleasant to the eye or impractical to use.

I therefore tried to design my own pump, based on a Nema17 Stepper motor, controlled by a standardized Pololu(-like) shield, an ATmega8 and full USB-support via a MCP2200.

This pump features:-Very small bench-size of only 28 x 7 cm (lab space is money!)-Fully contained, seal-able unit including the control PCB-Easy and fast 3D printing of all plastic parts (you can print all parts in one afernoon)-Mechanical parts are readily available-Total cost under 100€ (probably under 50€ if you are good)-Control (of multiple pumps) by a PC-Is fully programmable since it understands Gcode-Takes any syringe between 0.8 and 3.3 cm outer diameter (and thus anything from µl Hamilton to 60 ml Braun!)-Fully modular for later updates

All plastic parts are easily printable with almost any FDM printer without the use of support material. Mechanical parts are readily available online, as well as the electronic parts. The PCB is designed to 8 mil spacing and can be produced by etching or ordered online for under 20€.

The ATmega is programmed with an ISP programmer or via an arduino bootloader by USB serial. If you don't have an ISP programmer, you can buy an ATmega8 with a pre-installed bootloader. The MCP2200 can be used "as is" and does not need programming. It is natively supported by Windows and Linux and there are drivers easily aviable for Mac.

The pump is controlled by a serial port over a PC. Its firmware is capable of interpreting basic Gcode (like a 3D printer). On the hardware-site, the pump only features a "pause"-button and a "fast-forward" and "fast-reverse" for mounting the syringe.

The pump also features an universal syringe mount, which can take syringes with a diameter between 0.8 an 3.3 cm.

Maximum extrusion (pump) rates and accuracy depend on the used syringe and the hardware configuration.

PLEASE NOTE AGAIN: This is a work in progress and NOT meant for reproduction yet!!!

Please stay tuned for updates. Email me if you have further questions.

The following will need to be done to finish the project:-Finalize the 3D parts design.-Fully implement firmware Gcode capability. Fix minor bugs in firmware.-Finalize the PCB design.-Write a dedicated manual for the pump including building instructions.-Program or find a Gcode host-Add a BOM

Disclaimer: This device is intended for research or hobby use only. Not for medical use.

Check out the regular updates on project progress in the "custom" section below.

Our Lab was purchasing a programmable syringe pump and I was amazed at the exorbitant prices of such devices (more than 2000€ for an entry-level pump).

I searched for Open Hardware solutions, but no published pump seemed to be really suitable for laboratory use. Existing pumps are often bulky, not fully contained from the enviroment (and thus hard to clean) and unpleasant to the eye or impractical to use.

I therefore tried to design my own pump, based on a Nema17 Stepper motor, controlled by a standardized Pololu(-like) shield, an ATmega8 and full USB-support via a MCP2200.

This pump features:-Very small bench-size of only 28 x 7 cm (lab space is money!)-Fully contained, seal-able unit including the control PCB-Easy and fast 3D printing of all plastic parts (you can print all parts in one afernoon)-Mechanical parts are readily available-Total cost under 100€ (probably under 50€ if you are good)-Control (of multiple pumps) by a PC-Is fully programmable since it understands Gcode-Takes any syringe between 0.8 and 3.3 cm outer diameter (and thus anything from µl Hamilton to 60 ml Braun!)-Fully modular for later updates

All plastic parts are easily printable with almost any FDM printer without the use of support material. Mechanical parts are readily available online, as well as the electronic parts. The PCB is designed to 8 mil spacing and can be produced by etching or ordered online for under 20€.

The ATmega is programmed with an ISP programmer or via an arduino bootloader by USB serial. If you don't have an ISP programmer, you can buy an ATmega8 with a pre-installed bootloader. The MCP2200 can be used "as is" and does not need programming. It is natively supported by Windows and Linux and there are drivers easily aviable for Mac.

The pump is controlled by a serial port over a PC. Its firmware is capable of interpreting basic Gcode (like a 3D printer). On the hardware-site, the pump only features a "pause"-button and a "fast-forward" and "fast-reverse" for mounting the syringe.

The pump also features an universal syringe mount, which can take syringes with a diameter between 0.8 an 3.3 cm.

Maximum extrusion (pump) rates and accuracy depend on the used syringe and the hardware configuration.

PLEASE NOTE AGAIN: This is a work in progress and NOT meant for reproduction yet!!!

Please stay tuned for updates. Email me if you have further questions.

The following will need to be done to finish the project:-Finalize the 3D parts design.-Fully implement firmware Gcode capability. Fix minor bugs in firmware.-Finalize the PCB design.-Write a dedicated manual for the pump including building instructions.-Program or find a Gcode host-Add a BOM

Disclaimer: This device is intended for research or hobby use only. Not for medical use.

Similar models

thingiverse

free

USBTinyISP AVR ISP Programmer Case by Aegys3D

... avrdude supports ( as atmel chips )

suscribe my facebook page for the next releases : https://www.facebook.com/aegys3d

thank you

thingiverse

free

Syringe pump by Daniele_Dondi

...syringe pump by daniele_dondi

thingiverse

syringe pump controller for laboratory use

part of a thesis work by othman kerroumi

grabcad

free

Arduino Nano ISP

... used as isp (in-circuit serial programmer)

the case is optimized for 3d printing.

https://www.arduino.cc/en/tutorial/arduinoisp

thingiverse

free

Tronxy BootLoader Install & Software Update Guide by EE_Maker

...nd they worked for me. i am posting them with the idea that they may help others as well.

take care, go slow, and best of luck!.

thingiverse

free

Experiment PCB Holder by lex_ph2lb

... holder. allowing the experiment to be placed on any surface without the risk of shorts. for example on my atmega328p programmer.

grabcad

free

PCB USB ASP

...pcb usb asp

grabcad

perfect pcb model isp programing for microcontroller

thingiverse

free

Anet A8 Controller's Microprocessor Replacement by chkmailroot

...o xtal1 pin of chip while re-flash the fuse byte. pls cmt if you had this problem!

finish! goodluck

if have any problem, pls cmt!

thingiverse

free

ISP-10p-6p AMTEK adapter suite e.g. for Ender3

...peel wire end 5-7mm, bend j-form, put pure wire end in to the hole and pull unpeeled section via outer side track under the cap.

thingiverse

free

Arduino AVR Programmer Enclosure, customizable by jonsag

...328p, attiny85 and attiny2313.

note that you will have to have additional libraries to use the scad in full.

check the code.

/jon

grabcad

free

LVE Syringe Pump Updated

...lve syringe pump updated

grabcad

lve 3d printed syringe pump, updated for pulleys, belting

Ocram

thingiverse

free

Car Cigar Jack Cover by Ocram

... cover by ocram

thingiverse

cover your ugly cigarette lighter jack up with this nice little thing! prints fast and looks good ;)

thingiverse

free

ANTI-IL4 DARPIN 44C12V5 PDB 4YDW by Ocram

...anti-il4 darpin 44c12v5 pdb 4ydw by ocram

thingiverse

exported as .stl from chimera, printed with cura.

thingiverse

free

Apollo Astronaut without support by Ocram

...d the support structures so people can generate their own support. i kept the orientation as it seems to be the optimal solution.

thingiverse

free

IKEA shutter replacement endcap by Ocram

... designed for my ikea shutter. its the endcap of the shutter-rod, making the connection between the rod and its mounting bracket.

thingiverse

free

Egg pricker, small by Ocram

...etimes... so i designed this little buddy!

just print it out real fast and drive a small nail through it and you are ready to go!

thingiverse

free

Volkswagen T4 Replacement Water Knob by Ocram

...e water faucet of the famous volkswagen t4 westfalia camper wich likes to break apart over the years. it is tested and fits 100%.

thingiverse

free

Drinking Bottle concept study 0.5l by Ocram

...lfriend. use a nestle nestea cap with it. print it only with foodsafe materials (foodsave pet e.g.)!

mind printing instructions

thingiverse

free

Filament Spool Holder, universal Mount by Ocram

...100% infill (less might be possible, too). it needs no support and is designed to be material -saving while maintaining strength.

thingiverse

free

Screw-On Filament Cleaner by Ocram

...n adjust pressure on the filament by screwing the counter-part on it.

apply a little amount of oil to the sponge for lubrication.

thingiverse

free

DARPin in Complex with IL-4 (two models, snap together) PDB 4YDY by Ocram

...ported as .stl from chimera, printed with cura.

for me proteins print best with support structure type "lines" in cura.

Syringe

3d_export

$5

syringe

...syringe

3dexport

medical syringe with vaccine

3d_export

$5

syringe

...syringe

3dexport

3d model of syringe. make in blender

3d_export

$5

Syringe

...syringe

3dexport

the model of the syringe for filling the background and other needs :)

3d_export

$12

syringe

...age steampunk syringe.<br>syringe is unwrapped, but there is no texture, only material.<br>texture is only for gamut.

3d_ocean

$5

Syringe

...dical needle plastic plunger syringe tube vaccine

realistic plastic syringe with needle. if you like it, please rate it thanks…

turbosquid

$15

Syringe

...rbosquid

royalty free 3d model syringe for download as blend on turbosquid: 3d models for games, architecture, videos. (1644609)

turbosquid

$6

syringe

...turbosquid

royalty free 3d model syringe for download as max on turbosquid: 3d models for games, architecture, videos. (1259601)

turbosquid

$5

Syringe

...

turbosquid

royalty free 3d model syringe for download as ma on turbosquid: 3d models for games, architecture, videos. (1515300)

turbosquid

$3

syringe

...turbosquid

royalty free 3d model syringe for download as max on turbosquid: 3d models for games, architecture, videos. (1613235)

turbosquid

$2

Syringe

...rbosquid

royalty free 3d model syringe for download as blend on turbosquid: 3d models for games, architecture, videos. (1660892)

Programmable

3d_export

$5

vitsoe 620 programme

...vitsoe 620 programme

3dexport

vitsoe 620 programme lounge chair

turbosquid

$20

Yamaha RX11 Digital Rhythm Programmer

...1 digital rhythm programmer for download as fbx, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1690517)

3d_export

$39

astronaut suit nasa artemis programme

...ax 2017 and exported as fbx so you can use it in any software the model is made on real scale and also placed in the world center

3d_export

$25

2000pcs 2d jali cutting files for artcam and aspire programmes

...will be able to see attached stl or pdf file with for downloading the model. if there is no access to the file please contact me.

3d_export

$15

Microchip 3D Model

...electronic component silicon chip micro microprocessor monolithic ic semiconductor programmable computer programmer multi microchip 3d model download .c4d .max...

3d_export

$60

Griffon 3D Model

...l

3dexport

griffon decorative element model for tool with numeric programme management

griffon 3d model stameska62 30305 3dexport

3d_export

$5

Mcafee activate 25 digit code

...it code

3dexport

your pc will receive continuous and continuing protection from internet threats thanks to the mcafee programme.

3d_export

$30

Rosette 3D Model

...corative element model for tool with numeric programme management rosette architectral

rosette 3d model stameska62 30226 3dexport

3ddd

$1

Диван Альба

... ангстрем

диван "альба"

фабрика мебели ангстремhttp://www.angstrem-mebel.ru/catalog/programms/divaldi/

3d_export

$120

Frame for mirror 3D Model

...orative element model for tool with numeric programme management frame mirror

frame for mirror 3d model stameska62 30228 3dexport

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

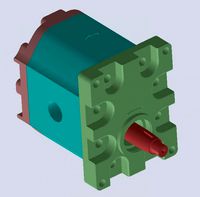

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)

Hardware

3ddd

$1

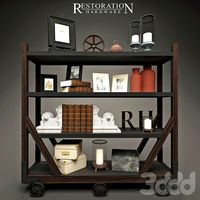

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware

3ddd

$1

RESTORATION HARDWARE

...restoration hardware

3ddd

restoration hardware , телескоп

restoration hardware

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware, кресло,

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware , декоративный набор

restoration hardware

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware , декоративный набор

restoration hardware

3ddd

$1

Restoration Hardware

... hardware , боров , свинья

restoration hardware

3ddd

$1

Restoration Hardware

...ardware , корона , медведь

restoration hardware

3ddd

$1

Restoration Hardware

...ation hardware

3ddd

restoration hardware , тумба

тумба прикроватная restoration hardware

3ddd

free

Restoration Hardware

... кашпо , куст , свеча

restoration hardware

3ddd

free

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware menlo table lamp

Open

3d_export

free

Opener

...r

3dexport

3d model of can opener. its my first work, if u can please show me my mistakes. this 3d model was created in autocad.

3d_export

free

Cap opener

...cap opener

3dexport

handy cap opener, more files/formats here:

3ddd

$1

Кресло, Open Oreon.

...кресло, open oreon.

3ddd

open , oreon

кресло, open oreon.

3d_ocean

$4

Open Book

...r interior max mental model open ray reading shelf text vray

open hardcover book with unique texture map on front and back cover.

turbosquid

$6

Opening Flag

...squid

royalty free 3d model opening flag for download as c4d on turbosquid: 3d models for games, architecture, videos. (1593555)

turbosquid

$10

Open book

...

royalty free 3d model open book for download as skp and obj on turbosquid: 3d models for games, architecture, videos. (1690781)

turbosquid

$2

bottle opener

...lty free 3d model bottle opener for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1621201)

turbosquid

$24

Bottle Opener

...free 3d model bottle opener for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1300948)

turbosquid

$20

Open Box

...yalty free 3d model open box for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1481218)

turbosquid

$10

Wine Opener

...ty free 3d model wine opener for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1240730)