Thingiverse

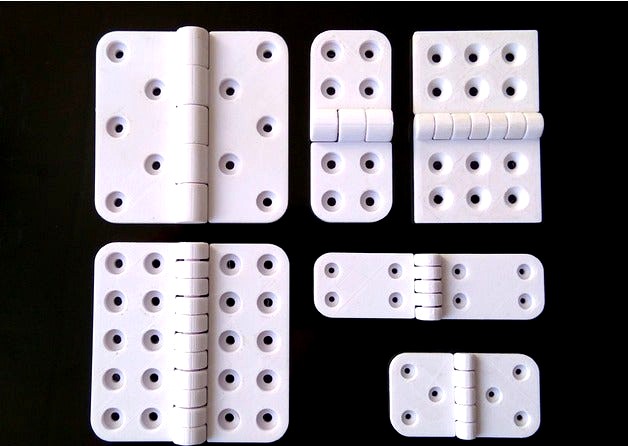

Parametric Hinge by rohingosling

by Thingiverse

Last crawled date: 3 years ago

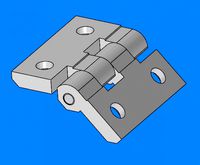

Parametric Butt Hinge

This is a parametric butt hinge designed in OpenSCAD, offering a wide range of parameters for customization. The hinge is designed to be printed in one step, but the individual leaves can be printed independently if desired. And in the case of applications that require an external pin, the default fused pin may be disabled, to leave a pin shaft ready to accept an external pin, during post printing assembly.

Note:

In the event that the Thingiverse Customizer is not working, which happens from time to time, you can still open and edit SCAD files directly in an SCAD editor, like OpenSCAD.

Experimental Version:

An experimental version of this model may be found here, https://www.thingiverse.com/thing:2351153

The experimental version includes additional features that are still being developed, or would otherwise over complicate the base model. I have made the experimental version available for those who would like to brave early access to some of the features that will possibly find there way into the base model, eventually. Please note, the experimental version is not updated as often as the base model, and may still include bugs and untested configurations.

Parameter Overview

Assembly Options

Male Leaf Enabled

Print the male leaf if true, otherwise omit it from the print.

Female Leaf Enabled

Print the female leaf if true, otherwise omit it from the print.

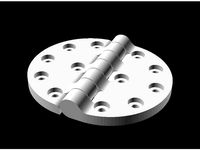

Leaf Fillet Enabled

Enable filleted leaf corners. Aside from aesthetic value, filleted corners can help with warping to a degree.

Pin Enabled

By default, the hinge is designed to be printed in one go, with a hinge pin fused to the female leaf. However, there may be applications where one may prefer to use an external pin. For instance, in the case where a metal pin is preferred for the sake of strength. In applications where an external pin is to be used, the pin may be omitted from the female leaf, by setting "Pin Enabled" to false.

Pin Auto Size Enabled

If true, this will set the pin diameter to the leaf gauge.

If false, the pin diameter may be specified by the "Pin Diameter" parameter.

Pin Shaft Counterbore Enabled

Cut a counterbore into the end caps of the knuckle joints if true.

While the pin shaft counterbore may be added even when the internal fused pin is enabled, the primary purpose of the pin shaft counterbore is to allow what ever external pin or bolt is being used in the case of an external pin, to be set flush with the top and bottom edges of the hinge, in the case where the internal pin is disabled, i.e. "Pin Enabled" is false.

Fasteners Enabled

Include fastener holes if true.

If false, leave the leaves free of fastener holes.

Knuckle Gusset Type

Select whether or not to use knuckle gussets, and if so what type. Knuckle gussets add strength to the transition between the knuckles and the leaves. The length of the knuckle gussets is equal to the fastener margin size, so that the gussets will never overlap any fastener holes.

There are four styles of knuckle gusset to choose from.

None: No knuckle gussets.

Linear: Straight edge gusset projected from a tangent on the knuckle down to the fastener margin on the leaf.

Circular: Basically a simple fillet, tangential to both the knuckle cylinder and the surface of the leaf.

Parabolic: A vertex form parabola, tangential to the knuckle cylinder, with its turning point tangential to the surface of the leaf at the fastener margin.

Throw Angle

The angle of the hinge joint. The hinge joint range is from +180 degrees fully closed, to -90 degrees fully opened. The default throw angle is 0 degrees, ie. opened flat.

This can be used either for assembly analysis, or in the case where one wishes to print the hinge standing vertically, it can be used to set a partially closed angle to keep the hinge stable during printing. For vertical printing, an angle of 120 degrees should keep the hinge stable during printing.

If you just want to print the hinge flat on the build plate, then keep the throw angle at 0 degrees for your printable model.

Flip Model

Rotate the model 180 degrees about the z-axis. This is useful for viewing the top and bottom pin shaft counterbore parameters.

Resolution

The geometric model resolution. Corresponds to the number of sides used to construct cylindrical parts of the model, like the knuckle joint segments, and the leaf fillets.

For example, a "Resolution" of 8, would specify cylindrical component elements to be constructed from 8 sides. a "Resolution" of 32 would result in 32 sided cylindrical component elements, and so forth.

For a smooth model, a "Resolution" of 64 and above is recommended. By default "Resolution" is set to 128.

Component Color

This is used purely to color the model in the Thingiverse Customizer. It should not affect the color of the model, printed from a color printer.

Hinge Parameters:

Hinge Width

The width in millimeters, of the entire hinge, from the outer edge of the left leaf, to the outer edge of the right leaf.

Leaf Height

The height in millimeters, of the hinge along the knuckle joint axis.

Leaf Gauge

Defines the thickness in millimeters, of the leaves and the radius of the knuckle joint.

Component Clearance

The inter-component gap in millimeters.

Recommended values range from 0.3mm for a tight fit, to 0.5mm for easy-er manipulation after printing. Clearance values of 0.3 or below can be challenging to print. I have succeeded in printing a few of these hinges with component clearances of 0.2mm and 0.25mm. However, quite often, sub 0.3mm clearance results in a locked up knuckle joint, where the leaves break before the hinge loosens up. A clearance of 0.4 or greater should release without to much trouble.

Note: The more knuckle segments there are, the greater the initial joint friction strait off the build plate. So for higher knuckle counts (7 or greater), component clearances of 0.4 or higher, may be required.

If the knuckle joint is not moving free at 0.4mm or higher, try re-printing slower at a higher resolution, in particular z resolution. Lower temperatures can help as well.

For PLA, a resolution of x=0.3, y=0.3, and z=0.15, at a speed of 6mm/s or less, with temperature 190 degrees C, seems to support a component clearances of 0.3mm to 0.4mm relatively well.

All of the sample STL files in the "Thing Files" section, are set to 0.3mm component clearance.

Knuckle Count

The number of knuckle segments in the knuckle joint.

This number should be an odd number.

For most applications, a knuckle count of 3 or 5 should suffice. However, higher knuckle counts can offer increases in strength relative to gauge size and hinge dimensions.

Pin Diameter

Manually specified pin diameter. This value is only used by the model, if "Pin Auto Size Enabled" is set to false.

If "Pin Auto Size Enabled" is true, then the pin diameter is automatically set to the leaf gauge size.

Pin Shaft Counterbore Parameters:

(Top or Bottom) Pin Shaft Counterbore Diameter

The diameter of the pin shaft counterbore. The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

(Top or Bottom) Pin Shaft Counterbore Depth

The depth of the pin shaft counterbore cut. The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

(Top or Bottom) Pin Shaft Counterbore Shape

The shape of the pin shaft counterbore hole. Currently circular, square and hexagonal are supported. In the case of square and hexagonal, the parameter "Pin Shaft Counterbore Diameter", refers to the diameter of a circle inscribed inside the square of hexagon.

For the square shaped counterbore, this means that the diameter of the counterbore is equal to the size of the sides of the square.

For the hexagon, the counterbore diameter is equal to the perpendicular distance between any two parallel sides of the hexagon.

The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

Fastener Hole Parameters:

Fastener Head Type

Can be set to either counterbore for pan head machine screws, or countersunk for flat countersunk screws.

The chamfer angle for flat countersunk may be adjusted by varying the other fastener hole parameters. For instance, a thread diameter of 3mm (e.g. M3 machine screws), a head diameter of 9mm, and a countersink depth of 3mm, with give a chamfer angle of 45 degrees.

Counter Sink Depth

The depth below the surface of the leaves to sink the fastener heads.

For M3 machine screws 2.5 to 2.6 is usually enough.

If the fastener holes are not countersunk, then there will be mechanical interference between the fastener heads the the opposing leaves when the hinge is closed.

Fastener Thread Diameter

The diameter of the threaded portion of the fastener hole.

This can be made smaller than the fastener thread in order to support self tapping screws, or larger to give machine screws enough room to pass through.

Fastener Head Diameter

The diameter of the counter sunk head portion of the fastener hole.

Usually a good idea to make this diameter 0.5mm to 1.0mm larger than the actual fastener head diameter. For M3 machine screws, which typically have 6mm diameter pan heads, an "Fastener Head Diameter" of 7mm works well.

Fastener Count

The number of fastener holes per leaf. The total number of fastener holes in the entire hinge will be "2 x Fastener Count".

Fastener holes are arranged in one or two columns along the height of the hinge, as specified by "Fastener Column Count".

Fastener Column Count

Specify whether to arrange the fastener holes on a leaf, in one or two columns.

Fastener Margin

The distance from the circumference of the fastener head, to the edge of the leaf.

Values between 3mm and 5mm are recommended for small to medium gauge hinges.

This is a parametric butt hinge designed in OpenSCAD, offering a wide range of parameters for customization. The hinge is designed to be printed in one step, but the individual leaves can be printed independently if desired. And in the case of applications that require an external pin, the default fused pin may be disabled, to leave a pin shaft ready to accept an external pin, during post printing assembly.

Note:

In the event that the Thingiverse Customizer is not working, which happens from time to time, you can still open and edit SCAD files directly in an SCAD editor, like OpenSCAD.

Experimental Version:

An experimental version of this model may be found here, https://www.thingiverse.com/thing:2351153

The experimental version includes additional features that are still being developed, or would otherwise over complicate the base model. I have made the experimental version available for those who would like to brave early access to some of the features that will possibly find there way into the base model, eventually. Please note, the experimental version is not updated as often as the base model, and may still include bugs and untested configurations.

Parameter Overview

Assembly Options

Male Leaf Enabled

Print the male leaf if true, otherwise omit it from the print.

Female Leaf Enabled

Print the female leaf if true, otherwise omit it from the print.

Leaf Fillet Enabled

Enable filleted leaf corners. Aside from aesthetic value, filleted corners can help with warping to a degree.

Pin Enabled

By default, the hinge is designed to be printed in one go, with a hinge pin fused to the female leaf. However, there may be applications where one may prefer to use an external pin. For instance, in the case where a metal pin is preferred for the sake of strength. In applications where an external pin is to be used, the pin may be omitted from the female leaf, by setting "Pin Enabled" to false.

Pin Auto Size Enabled

If true, this will set the pin diameter to the leaf gauge.

If false, the pin diameter may be specified by the "Pin Diameter" parameter.

Pin Shaft Counterbore Enabled

Cut a counterbore into the end caps of the knuckle joints if true.

While the pin shaft counterbore may be added even when the internal fused pin is enabled, the primary purpose of the pin shaft counterbore is to allow what ever external pin or bolt is being used in the case of an external pin, to be set flush with the top and bottom edges of the hinge, in the case where the internal pin is disabled, i.e. "Pin Enabled" is false.

Fasteners Enabled

Include fastener holes if true.

If false, leave the leaves free of fastener holes.

Knuckle Gusset Type

Select whether or not to use knuckle gussets, and if so what type. Knuckle gussets add strength to the transition between the knuckles and the leaves. The length of the knuckle gussets is equal to the fastener margin size, so that the gussets will never overlap any fastener holes.

There are four styles of knuckle gusset to choose from.

None: No knuckle gussets.

Linear: Straight edge gusset projected from a tangent on the knuckle down to the fastener margin on the leaf.

Circular: Basically a simple fillet, tangential to both the knuckle cylinder and the surface of the leaf.

Parabolic: A vertex form parabola, tangential to the knuckle cylinder, with its turning point tangential to the surface of the leaf at the fastener margin.

Throw Angle

The angle of the hinge joint. The hinge joint range is from +180 degrees fully closed, to -90 degrees fully opened. The default throw angle is 0 degrees, ie. opened flat.

This can be used either for assembly analysis, or in the case where one wishes to print the hinge standing vertically, it can be used to set a partially closed angle to keep the hinge stable during printing. For vertical printing, an angle of 120 degrees should keep the hinge stable during printing.

If you just want to print the hinge flat on the build plate, then keep the throw angle at 0 degrees for your printable model.

Flip Model

Rotate the model 180 degrees about the z-axis. This is useful for viewing the top and bottom pin shaft counterbore parameters.

Resolution

The geometric model resolution. Corresponds to the number of sides used to construct cylindrical parts of the model, like the knuckle joint segments, and the leaf fillets.

For example, a "Resolution" of 8, would specify cylindrical component elements to be constructed from 8 sides. a "Resolution" of 32 would result in 32 sided cylindrical component elements, and so forth.

For a smooth model, a "Resolution" of 64 and above is recommended. By default "Resolution" is set to 128.

Component Color

This is used purely to color the model in the Thingiverse Customizer. It should not affect the color of the model, printed from a color printer.

Hinge Parameters:

Hinge Width

The width in millimeters, of the entire hinge, from the outer edge of the left leaf, to the outer edge of the right leaf.

Leaf Height

The height in millimeters, of the hinge along the knuckle joint axis.

Leaf Gauge

Defines the thickness in millimeters, of the leaves and the radius of the knuckle joint.

Component Clearance

The inter-component gap in millimeters.

Recommended values range from 0.3mm for a tight fit, to 0.5mm for easy-er manipulation after printing. Clearance values of 0.3 or below can be challenging to print. I have succeeded in printing a few of these hinges with component clearances of 0.2mm and 0.25mm. However, quite often, sub 0.3mm clearance results in a locked up knuckle joint, where the leaves break before the hinge loosens up. A clearance of 0.4 or greater should release without to much trouble.

Note: The more knuckle segments there are, the greater the initial joint friction strait off the build plate. So for higher knuckle counts (7 or greater), component clearances of 0.4 or higher, may be required.

If the knuckle joint is not moving free at 0.4mm or higher, try re-printing slower at a higher resolution, in particular z resolution. Lower temperatures can help as well.

For PLA, a resolution of x=0.3, y=0.3, and z=0.15, at a speed of 6mm/s or less, with temperature 190 degrees C, seems to support a component clearances of 0.3mm to 0.4mm relatively well.

All of the sample STL files in the "Thing Files" section, are set to 0.3mm component clearance.

Knuckle Count

The number of knuckle segments in the knuckle joint.

This number should be an odd number.

For most applications, a knuckle count of 3 or 5 should suffice. However, higher knuckle counts can offer increases in strength relative to gauge size and hinge dimensions.

Pin Diameter

Manually specified pin diameter. This value is only used by the model, if "Pin Auto Size Enabled" is set to false.

If "Pin Auto Size Enabled" is true, then the pin diameter is automatically set to the leaf gauge size.

Pin Shaft Counterbore Parameters:

(Top or Bottom) Pin Shaft Counterbore Diameter

The diameter of the pin shaft counterbore. The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

(Top or Bottom) Pin Shaft Counterbore Depth

The depth of the pin shaft counterbore cut. The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

(Top or Bottom) Pin Shaft Counterbore Shape

The shape of the pin shaft counterbore hole. Currently circular, square and hexagonal are supported. In the case of square and hexagonal, the parameter "Pin Shaft Counterbore Diameter", refers to the diameter of a circle inscribed inside the square of hexagon.

For the square shaped counterbore, this means that the diameter of the counterbore is equal to the size of the sides of the square.

For the hexagon, the counterbore diameter is equal to the perpendicular distance between any two parallel sides of the hexagon.

The counterbore is only added if "Pin Shaft Counterbore Enabled" is set to YES.

Fastener Hole Parameters:

Fastener Head Type

Can be set to either counterbore for pan head machine screws, or countersunk for flat countersunk screws.

The chamfer angle for flat countersunk may be adjusted by varying the other fastener hole parameters. For instance, a thread diameter of 3mm (e.g. M3 machine screws), a head diameter of 9mm, and a countersink depth of 3mm, with give a chamfer angle of 45 degrees.

Counter Sink Depth

The depth below the surface of the leaves to sink the fastener heads.

For M3 machine screws 2.5 to 2.6 is usually enough.

If the fastener holes are not countersunk, then there will be mechanical interference between the fastener heads the the opposing leaves when the hinge is closed.

Fastener Thread Diameter

The diameter of the threaded portion of the fastener hole.

This can be made smaller than the fastener thread in order to support self tapping screws, or larger to give machine screws enough room to pass through.

Fastener Head Diameter

The diameter of the counter sunk head portion of the fastener hole.

Usually a good idea to make this diameter 0.5mm to 1.0mm larger than the actual fastener head diameter. For M3 machine screws, which typically have 6mm diameter pan heads, an "Fastener Head Diameter" of 7mm works well.

Fastener Count

The number of fastener holes per leaf. The total number of fastener holes in the entire hinge will be "2 x Fastener Count".

Fastener holes are arranged in one or two columns along the height of the hinge, as specified by "Fastener Column Count".

Fastener Column Count

Specify whether to arrange the fastener holes on a leaf, in one or two columns.

Fastener Margin

The distance from the circumference of the fastener head, to the edge of the leaf.

Values between 3mm and 5mm are recommended for small to medium gauge hinges.

Similar models

grabcad

free

Hinge

...d when the leaves are joined together. a pin is a solid metal rod that's inserted through the knuckle to interlock the leafs.

grabcad

free

Hinge

...d when the leaves are joined together. a pin is a solid metal rod that's inserted through the knuckle to interlock the leafs.

thingiverse

free

Parametric Magnet Strike by allanoepping

...strike plate, with zero it is centered

magnet diameter

the diameter of the magnet

magnet thickness

the thickness of the magnet

grabcad

free

knuckle/pin joint

...knuckle/pin joint

grabcad

it helps to join two shafts. both can be connected at any angle but they should be in the same plane.

grabcad

free

knuckle joint

... which a pin fastens the ends of two rods, one of which has an eye that fits between the two perforated projections of the other.

grabcad

free

Knuckle Joint

... which a pin fastens the ends of two rods, one of which has an eye that fits between the two perforated projections of the other.

grabcad

free

Knuckle Joint

...knuckle joint

grabcad

knuckle joint assembly with its components eye, fork and pin.

grabcad

free

Knuckle Joint

...nents used to create a knuckle joint after assembly. the components include a collar, a pin, a taper pin, a fork, and an eye end.

thingiverse

free

Adjustment Knob - Parametric by markcr

...ex nut size and shift clearance hole

shaft option - with flatted shaft parameters (0 hex diameter to enable shaft hole) (updated)

grabcad

free

Knuckle Joint

... is a mechanical component that is used to join the two components under tensile loads. it is also known as the forked pin joint.

Rohingosling

thingiverse

free

Test Block by rohingosling

...test block by rohingosling

thingiverse

general purpose parametric test and calibration part.

use the customizer to configure.

thingiverse

free

Heat Insert Test Panel by rohingosling

...ing

thingiverse

heat insert test panel. use this to test various heat insert hole sizes, or to practice installing heat inserts.

thingiverse

free

Experimental Parametric Hinge by rohingosling

...ove. the original is less likely to have bugs, and is also maintained and updated more frequently than this experimental version.

thingiverse

free

Toy Dog Crate by CKetner

...baby pound puppies. credit for the hinges goes to rohingosling https://www.thingiverse.com/thing:2187167. and credit for the snap shut locks goes...

thingiverse

free

Parametric Caged Ball Bearing by rohingosling

...ors" is set to yes.

cage color

the color to render the bearing cage, when "enable multiple colors" is set to yes.

thingiverse

free

Parametric Butt Hinge by z3d

...by z3d thingiverse the parametric butt hinge design from @rohingosling is awesome. original here's an online version that doesn't...

thingiverse

free

t-slot hinge by spacesaver

...the door of my eustathios v2. so i used rohingosling#39;s hinge generator and made the center of rotation as...

thingiverse

free

Fiskars Easy Action Micro-tip Scissors Guard by knowledgecravings

...will come up with a better idea. thanks to rohingosling for the hinge design https://www.thingiverse.com/thing:2187167, as i don't yet...

thingiverse

free

Puzzle of Evil

...joe larson's 3d printed puzzle of evil, combined with rohingosling#39;s parametric...

Parametric

turbosquid

$25

Parametric

...oyalty free 3d model parametric for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1683196)

3ddd

$1

Parametric Wall

...parametric wall

3ddd

панель

parametric wall with shelf

3d_export

$5

parametric table

...parametric table

3dexport

parametric table model created on rhinoceros 6. this 3d model includes: .gh, .3dm files

turbosquid

$2

parametrical chandelier

...lty free 3d model parametrical chandelier for download as dxf on turbosquid: 3d models for games, architecture, videos. (1257635)

turbosquid

$2

Parametric Seat

...id

royalty free 3d model parametric seat for download as max on turbosquid: 3d models for games, architecture, videos. (1691557)

turbosquid

$2

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1690373)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691303)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691148)

turbosquid

free

Parametric wall

...ee 3d model parametric wall for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1356869)

turbosquid

$23

Parametric Bench

...model parametric bench for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1393644)

Hinge

3d_export

$10

hinge and hinge 148 specifications

...hinge and hinge 148 specifications

3dexport

hinge and hinge (148 specifications)

3d_export

free

hinge

...hinge

3dexport

hinge model

3ddd

free

hinges

...hinges

3ddd

крепление

two types of hinge for furniture.

3d_export

$6

Hinge

...hinge

3dexport

hinge assembly render 3d modelling design

turbosquid

$19

Hinges

...

turbosquid

royalty free 3d model hinges for download as max on turbosquid: 3d models for games, architecture, videos. (1453553)

turbosquid

$19

Hinges

...

turbosquid

royalty free 3d model hinges for download as max on turbosquid: 3d models for games, architecture, videos. (1447125)

3d_export

$5

hinge 1

...hinge 1

3dexport

hinge 1

3d_export

$5

hinge 2

...hinge 2

3dexport

hinge 2

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4