Thingiverse

Hard Shell Basic Mask by ksihota

by Thingiverse

Last crawled date: 4 years, 1 month ago

Update31/03/2020 (2)

I have uploaded a few new picts of the latest design.

I do not recommend printing the bottom section (part with threads) in TPU as the threads will tend to bind more readily than with PLA to PLA. It may work fine if the whole section can be printed in TPU but if its just the end, the TPU and PLA may separate under the pressure of threading in the filter. The TPU gasket is loose at the threads so this doesn't have the same issue. It could also be an issue of my print being done quickly and at a low resolution.

So far my silicone sealant gluing appears to be working okay. I tried using a cyanoacrylate based glue which works but is rigid. After the materials flex for some time the bond weakens. I am hoping the flexible silicone sealant won't have this issue.

31/03/2020

I have added a new version of the PLA/TPU combo mask (V3) The new design fits my wife and me pretty well.

It does need to be shifted on the face to allow it to seal properly.

I left off the upper bead as it makes the TPU less flexible. I have also added an inner (thickening) band that allows the joint (PLA//TPU) to be wider. Hopefully this will result in a stronger bond.

I have also adjusted the nose bridge area as well as the angle of the filter so the mask can be printed with a larger TPU section. It can be printed in a single piece by printing the PLA up to the top of the fastener ridge and then the remaining upper section in TPU.

I printed a the complete mask (no filter parts) in just under 2 hrs. I used 0.3 layer height but this does result in a courser thread and not as nice a finish. I would recommend a smaller layer height and/or using adaptive layers.

I do not recommend printing the bottom section (part with threads) in TPU as the threads will tend to bind more readily than with PLA to PLA. It may work fine if the whole section can be printed in TPU but if its just the end, the TPU and PLA may separate under the pressure of threading in the filter. The TPU gasket is loose at the threads so this doesn't have the same issue.

I have also included the same design split into two pieces in case you want to try and print the TPU and PLA parts separately and then try and glue them together. I am currently experimenting with using silicone sealant as a bonding agent.

30/03/2020

I have uploaded a slightly different style shell, meant to be printed in mixed materials (hard for shell and flexible edge.)

I used PLA for the shell and TPU for the flex edge. I did a 3mm initial TPU part instead of having to print a gasket then the main shell in PLA and the final upper edge in TPU. The transition heights were 3mm and 46mm.

I have not done extensive tests of the bond between PLA and TPU. The join is only 1.2mm wide but on my prints it appears to be holding up so far.

The new design has a different strap fastener and the nose (bridge) shape is slightly different. It still does not fit me well but it fits my wife perfectly.

29/03/2020

I did a test print of the mask in TPU. I had to stop after the nozzle portion, as it was definitely going to fail. Instead of wasting the print I decided to experiment with a mixed PLA/TPU print, so I swapped filament to PLA and continued printing till it got past the strap holes. I then swapped filament back to TPU. The pictures are uploaded so you can see how it did.

The bond appears strong enough. I may have to try and redesign the top edge so it is a little thicker and move the strap holes a little so I can get more TPU at the edge.

28/03/2020 (2)

For anyone who would like a slightly larger tool so its easier to turn, I have just uploaded a Filter Tool Tall.

28/03/2020 (1)

Updated a new full mask seal that is not as large as the seal previously posted.

The new seal needs to be printed in TPU and will add a little softer surface where the mask touches the face.

An alternative, to printing a TPU seal, is to take a length of small diameter silicone (or similar) tubing and cut a slit lengthwise and then place the tubing around the mask edge.

27/03/2020 (2)

Just realized I forgot to upload the filter gasket. Its now in the file list.

27/03/2020 (1)

I just uploaded an upper seal that can be printed with TPU. The mask can be moulded slightly by heating the shell with hot water or hot air and bending the edges carefully. The TPU seal can be used to fill some of the extra gap for those with smaller noses and lower bridges than mine. It can also be sliced or trimmed to help fit better.

Let me know if there are other alterations that would make it fit better.

Not sure why the STLs are not displaying. Hopefully Thingiverse will get the bugs worked out soon.

Summary

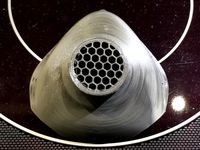

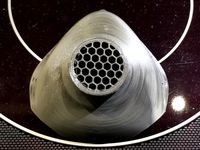

Here is my latest hard shell mask design. This is designed to be printed without any supports using PLA or other similar filaments. I did not have any success printing it with TPU but I have only just started playing with flexible filaments so it may just be me.

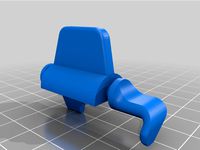

There are 3 parts to the mask that can be printed in PLA. These consist of the main shell body, the filter cartridge and the cartridge cap. There is also a cartridge tool that you can print that makes assembling the cartridge a little easier.

Note: the nose pad and copper filter are not included in the parts. They are only for visual demonstration purposes.

I just used some of my wife's make-up remover pads as the filter material.

The filter material gets inserted into the cartridge and the cartridge cap is screwed in to hold the material in place. The whole cartridge assembly is then screwed into the front of the mask. Use some TPU filament or other material as the straps to hold it on.

The shell is only 1.2 mm thick so it can be softened and reformed a little if necessary.

It fits my face but the nose bridge is quite high so it may need some foam or other padding around the upper edges. There are different types of material such as self adhesive weather stripping or soft, flexible medical tape that could be used depending on the thickness needed.

I am looking at ways to print a TPU upper seal and will update it if I come up with a simple solution.

Note: This is a dust mask and is not meant as a medical equipment replacement.

If you do succeed in printing it in TPU please let me know.

I have uploaded a few new picts of the latest design.

I do not recommend printing the bottom section (part with threads) in TPU as the threads will tend to bind more readily than with PLA to PLA. It may work fine if the whole section can be printed in TPU but if its just the end, the TPU and PLA may separate under the pressure of threading in the filter. The TPU gasket is loose at the threads so this doesn't have the same issue. It could also be an issue of my print being done quickly and at a low resolution.

So far my silicone sealant gluing appears to be working okay. I tried using a cyanoacrylate based glue which works but is rigid. After the materials flex for some time the bond weakens. I am hoping the flexible silicone sealant won't have this issue.

31/03/2020

I have added a new version of the PLA/TPU combo mask (V3) The new design fits my wife and me pretty well.

It does need to be shifted on the face to allow it to seal properly.

I left off the upper bead as it makes the TPU less flexible. I have also added an inner (thickening) band that allows the joint (PLA//TPU) to be wider. Hopefully this will result in a stronger bond.

I have also adjusted the nose bridge area as well as the angle of the filter so the mask can be printed with a larger TPU section. It can be printed in a single piece by printing the PLA up to the top of the fastener ridge and then the remaining upper section in TPU.

I printed a the complete mask (no filter parts) in just under 2 hrs. I used 0.3 layer height but this does result in a courser thread and not as nice a finish. I would recommend a smaller layer height and/or using adaptive layers.

I do not recommend printing the bottom section (part with threads) in TPU as the threads will tend to bind more readily than with PLA to PLA. It may work fine if the whole section can be printed in TPU but if its just the end, the TPU and PLA may separate under the pressure of threading in the filter. The TPU gasket is loose at the threads so this doesn't have the same issue.

I have also included the same design split into two pieces in case you want to try and print the TPU and PLA parts separately and then try and glue them together. I am currently experimenting with using silicone sealant as a bonding agent.

30/03/2020

I have uploaded a slightly different style shell, meant to be printed in mixed materials (hard for shell and flexible edge.)

I used PLA for the shell and TPU for the flex edge. I did a 3mm initial TPU part instead of having to print a gasket then the main shell in PLA and the final upper edge in TPU. The transition heights were 3mm and 46mm.

I have not done extensive tests of the bond between PLA and TPU. The join is only 1.2mm wide but on my prints it appears to be holding up so far.

The new design has a different strap fastener and the nose (bridge) shape is slightly different. It still does not fit me well but it fits my wife perfectly.

29/03/2020

I did a test print of the mask in TPU. I had to stop after the nozzle portion, as it was definitely going to fail. Instead of wasting the print I decided to experiment with a mixed PLA/TPU print, so I swapped filament to PLA and continued printing till it got past the strap holes. I then swapped filament back to TPU. The pictures are uploaded so you can see how it did.

The bond appears strong enough. I may have to try and redesign the top edge so it is a little thicker and move the strap holes a little so I can get more TPU at the edge.

28/03/2020 (2)

For anyone who would like a slightly larger tool so its easier to turn, I have just uploaded a Filter Tool Tall.

28/03/2020 (1)

Updated a new full mask seal that is not as large as the seal previously posted.

The new seal needs to be printed in TPU and will add a little softer surface where the mask touches the face.

An alternative, to printing a TPU seal, is to take a length of small diameter silicone (or similar) tubing and cut a slit lengthwise and then place the tubing around the mask edge.

27/03/2020 (2)

Just realized I forgot to upload the filter gasket. Its now in the file list.

27/03/2020 (1)

I just uploaded an upper seal that can be printed with TPU. The mask can be moulded slightly by heating the shell with hot water or hot air and bending the edges carefully. The TPU seal can be used to fill some of the extra gap for those with smaller noses and lower bridges than mine. It can also be sliced or trimmed to help fit better.

Let me know if there are other alterations that would make it fit better.

Not sure why the STLs are not displaying. Hopefully Thingiverse will get the bugs worked out soon.

Summary

Here is my latest hard shell mask design. This is designed to be printed without any supports using PLA or other similar filaments. I did not have any success printing it with TPU but I have only just started playing with flexible filaments so it may just be me.

There are 3 parts to the mask that can be printed in PLA. These consist of the main shell body, the filter cartridge and the cartridge cap. There is also a cartridge tool that you can print that makes assembling the cartridge a little easier.

Note: the nose pad and copper filter are not included in the parts. They are only for visual demonstration purposes.

I just used some of my wife's make-up remover pads as the filter material.

The filter material gets inserted into the cartridge and the cartridge cap is screwed in to hold the material in place. The whole cartridge assembly is then screwed into the front of the mask. Use some TPU filament or other material as the straps to hold it on.

The shell is only 1.2 mm thick so it can be softened and reformed a little if necessary.

It fits my face but the nose bridge is quite high so it may need some foam or other padding around the upper edges. There are different types of material such as self adhesive weather stripping or soft, flexible medical tape that could be used depending on the thickness needed.

I am looking at ways to print a TPU upper seal and will update it if I come up with a simple solution.

Note: This is a dust mask and is not meant as a medical equipment replacement.

If you do succeed in printing it in TPU please let me know.

Similar models

thingiverse

free

Unusual filter masks by ksihota

...thing down the nose. maybe an old sock?

obviously the filter aspect would require some redesigning, but it can be done if needed.

thingiverse

free

Hard Shell Filter Mask by ksihota

...hile printing you may have better success. of course by printing in tpu the print would also take quite a bit longer than in pla.

thingiverse

free

Breathing Mask (work with common cig filters 7mm) by Nakamura_Productions

...e, 1 piece, flexible material (tpu or softer material)

for a correct assembly, the component 1 must be sealed at the component 2.

thingiverse

free

Threaded cap container with TPU seal by shmitty594

...y shmitty594

thingiverse

printed in pla, no supports 20% infill.

optional gasket printed in tpu to facilitate water-tight seal.

thingiverse

free

Roomba 700 Filter Gasket by natdoggy2

...ter and a body. my specific use is to augment the covid-19 hepa mask filter created by toothharvester.

print in flexible like tpu

thingiverse

free

TPU mask by shermluge

... of abs, tpu, pla, or petg.

this seals nicely and works.

enjoy sherm

other projects:https://www.thingiverse.com/shermluge/designs

thingiverse

free

DB's Basic Respirator with replaceable filter by DanBuro

... foam

along the inside edge and edge. if you use silicone rubber,

let it cure fully otherwise you'll get a skin rash from it.

thingiverse

free

Covid19 Mask (Geminus Dual Filter) with 3M Filter Adapter by thanekew

...ume that this is for show and it is not approved by the cdc, who or anyone else who approves masks for use in medical situations.

thingiverse

free

Sew on flange for North P100 cartridges, along with a second, top flange for a good seal.

...is that the threads on the clamp together may not last, and they may fall apart after not too much use. feedback is appreciated.

thingiverse

free

100% 3D Printed COVID MASK by wildcardfox

...abs, petg, etc.

if you need to resize, use the 90% small size mask.

step file included if you need to or want to modify.

-brett

Ksihota

thingiverse

free

Predator Extruder Feed Sleeve by ksihota

... need to be sanded slightly to fit properly

if you use it, leave me a comment to indicate if it works or if it needs adjustments.

thingiverse

free

Operation Game Pieces by ksihota

...y as well as a single stl with all the parts.

i am not sure what the names are really supposed to be so i just named them myself.

thingiverse

free

1995 Volvo 850 seatbelt release button by ksihota

...riginal by filling in the centre underside. this makes for a stronger part and makes the print cleaner when printing on its edge.

thingiverse

free

Ryobi One+ Hybrid Leaf blower switch by ksihota

... canada. it is a one+ model. i have included a full picture of it for reference. the switch is a side toggle, not a slide switch.

thingiverse

free

Simple Face Shield by ksihota

... for intended use.

if you do try and like the design but find the size is not right let me know and i can resize it if necessary.

thingiverse

free

Filastruder Electronics Case by ksihota

...f the filastruder case where the switches and temp controller used to reside.

let me know if you find any issues with the design.

thingiverse

free

Unusual filter masks by ksihota

...thing down the nose. maybe an old sock?

obviously the filter aspect would require some redesigning, but it can be done if needed.

thingiverse

free

Hard Shell Filter Mask by ksihota

...hile printing you may have better success. of course by printing in tpu the print would also take quite a bit longer than in pla.

thingiverse

free

Ryobi Backpack Leaf Blower Nozzles by ksihota

...as a little wider and not quite as high.

i have not yet tested either nozzle ends yet. i will add comments about their use later.

thingiverse

free

MPMD E3D V6 Effector by ksihota

...base

rod connectors:

3 60mm m3 threaded rods (nuts and washers)

or

6 30mm m3 nuts bolts and washers

assorted wires and connectors

Shell

archibase_planet

free

Shell

...shell

archibase planet

sports shell playground

sports shell 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$16

Shell

...shell

designconnected

fasem international shell armchairs computer generated 3d model. designed by roberto lazzeroni.

3ddd

$1

Shell Chair

...shell chair

3ddd

hans wegner , shell

shell chair

design_connected

$13

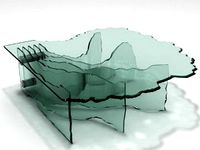

Shell

...shell

designconnected

fiam italia shell coffee tables computer generated 3d model. designed by danny lane.

3ddd

$1

Shell armchair

...shell armchair

3ddd

shell

shell armchair

designer don't remember

turbosquid

$1

Shells

...

turbosquid

royalty free 3d model shells for download as max on turbosquid: 3d models for games, architecture, videos. (1449062)

turbosquid

$10

Shell

...quid

royalty free 3d model shell for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1583461)

turbosquid

free

Shells

...uid

free 3d model shells for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1562122)

turbosquid

$49

Shell

...yalty free 3d model shell for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1569496)

turbosquid

$1

Shell

...yalty free 3d model shell for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1606504)

Mask

turbosquid

$1

Dust Mask Medical Mask Face Mask Surgical Mask

...k face mask surgical mask for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1533329)

3d_export

$5

Mask

...mask

3dexport

african mask

turbosquid

$2

Riggged Surgical mask face mask dust mask medical mask

...sk dust mask medical mask for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1536257)

archibase_planet

free

Mask

...mask

archibase planet

mask sculpture decor

mask - 3d model for interior 3d visualization.

3d_export

$19

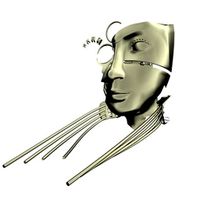

masks tech metal masks wearable futuristic masks

... tech metal masks wearable futuristic masks

3dexport

masks, tech metal masks, wearable, futuristic masks zip contain fbx obj max

archibase_planet

free

Mask

...mask

archibase planet

mask sculpture decor

mask-decor - 3d model for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask

swimming mask - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

picturesque element mask

mask n050608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask picturesque element

mask n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask ornament decoration

mask decor n240211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Hard

3d_ocean

$15

Hard Disk

...ard disk hard disk model hard disk obj high poly hard disk passport hard disk wd hard disk western digital

high poly wd hard disk

3ddd

$1

Светильник Long and Hard

...к long and hard

3ddd

flos , long and hard

светильник long and hard от flos, с текстурами

3d_export

$5

hard gauge protector

...hard gauge protector

3dexport

hard gauge protector

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$40

Hard Disc

...

royalty free 3d model hard disc for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1386268)

turbosquid

$1

Hard Hat

...d

royalty free 3d model hard hat for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1222575)

turbosquid

free

Hard Drive

...ty free 3d model hard drive for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1332637)

turbosquid

$29

hard hat

...free 3d model hard hat for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272864)

turbosquid

$29

hard HAT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Hard Drive

... model hard drive for download as max, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1630728)

Basic

3d_export

$5

basic hand

...basic hand

3dexport

basic hand, made in blender

3d_export

$10

Basic coat

...basic coat

3dexport

basic coat<br>arm and waist movement

3ddd

$1

PixMolda Basic Bed

...pixmolda basic bed

3ddd

basic bed , pixellin

pixmolda basic bed by pixellin

3ddd

free

Детский стол Basic

...етский стол basic

3ddd

basic , стол

детский стол для письма basic от производителя moll.

turbosquid

$1

Basic Chair

...urbosquid

royalty free 3d model basic chair for download as on turbosquid: 3d models for games, architecture, videos. (1269713)

turbosquid

$1

Basic Keyboard

...osquid

royalty free 3d model basic keyboard for download as on turbosquid: 3d models for games, architecture, videos. (1298685)

turbosquid

$1

basic table

...urbosquid

royalty free 3d model basic table for download as on turbosquid: 3d models for games, architecture, videos. (1271450)

turbosquid

free

Basic Bandit

...

turbosquid

free 3d model basic bandit for download as blend on turbosquid: 3d models for games, architecture, videos. (1250561)

turbosquid

free

Turret basic

...

turbosquid

free 3d model turret basic for download as blend on turbosquid: 3d models for games, architecture, videos. (1382326)

turbosquid

free

Basic Sword

...urbosquid

royalty free 3d model basic sword for download as on turbosquid: 3d models for games, architecture, videos. (1331031)