Thingiverse

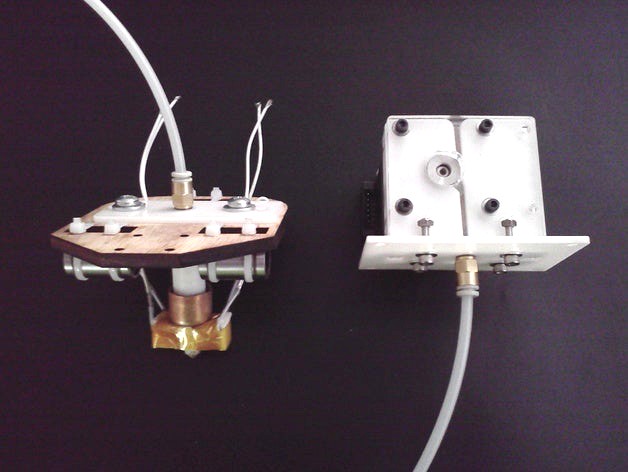

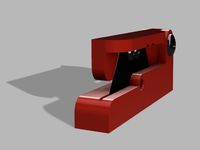

Minimalistic MK6 Bowden Rework by ohioplastics

by Thingiverse

Last crawled date: 3 years ago

The MK6 was Makerbot's first attempt at building an extruder that supported 1.75mm filament. It was a great step forward for 3d printing. It was easy to construct and had no moving parts. However it did have some major drawbacks.

Primarily, there was an almost complete lack of accessibility to the drive system. You literally had to disassemble the entire thing if there was a jam, or just to do simple maintenance. Also, the design of the acrylic housing unit was not entirely optimized for 1.75mm filament. Parts of the acrylic were still meant to support 3mm filament, which means there were gaps that 1.75mm filament could curl into.

This rework attempts to mitigate these problems through a redesign of the acrylic housing and delrin tensioner. It also uses the bowden drive method to increase accessibility and compatibility with today's hot ends.

Along with this drive system is an x-carriage designed to work with the J-head Lite hot end and the Mendel style printer. Some of these parts are available on my ebay store: http://stores.ebay.com/ohpakron. This project is at an early stage, so check back for updates.

Primarily, there was an almost complete lack of accessibility to the drive system. You literally had to disassemble the entire thing if there was a jam, or just to do simple maintenance. Also, the design of the acrylic housing unit was not entirely optimized for 1.75mm filament. Parts of the acrylic were still meant to support 3mm filament, which means there were gaps that 1.75mm filament could curl into.

This rework attempts to mitigate these problems through a redesign of the acrylic housing and delrin tensioner. It also uses the bowden drive method to increase accessibility and compatibility with today's hot ends.

Along with this drive system is an x-carriage designed to work with the J-head Lite hot end and the Mendel style printer. Some of these parts are available on my ebay store: http://stores.ebay.com/ohpakron. This project is at an early stage, so check back for updates.

Similar models

thingiverse

free

MK6 Extruder Drive 1.75mm by Shaputer

...mk6 extruder drive 1.75mm by shaputer

thingiverse

i modified the stl file so this part will accomodate 1.75mm filament

thingiverse

free

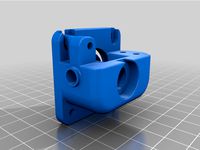

Mini-OwlExtruder 1.75mm direct drive bowden by eMotion-Tech

... 1.75mm filament, direct drive for bowden systems.

could be used for instance for delta style printers or any bowden application.

thingiverse

free

Compact Bowden Extruder, 1.75mm Filament for MK7 Drive Gear V2 by Hiselrya

...lament for mk7 drive gear v2 by hiselrya

thingiverse

a remix of the, compact bowden extruder, 1.75mm filament for mk7 drive gear

thingiverse

free

3D Printable Replacement Parts for Plastruder MK6 Support 1.75mm (plate D) by Anais25

...t parts for plastruder mk6 support 1.75mm (plate d) by anais25

thingiverse

to replace a cracked plate d for the 1.75mm filament.

thingiverse

free

CR-10 Direct Drive by s_gutz

...xis limit switch. this is necessary due to the added thickness of the direct drive plate so it can make contact with the switch.

thingiverse

free

Compact Bowden Extruder MK8 drive gear IR gate by sailorpete

...lity is limited due to the two bsp fittings.

-1.75mm filaments

(more photos to follow)

update 1:

added a panel mount flush option

thingiverse

free

Bowden Extruder M8 Clamp by sdaf2

... with mounting clamp. also includes some other changes to take the bowden tube (3mm od) and work with a 1.75mm diameter filament.

thingiverse

free

Titan direct drive carriage front plate for C-Bot by ian_in_the_midlands

...owden option\c-bot bowden carriage rear plate (x1) ).

for the cooling fan ducts and bracket to mount the fans, see thing 2830838.

thingiverse

free

prusa i3 rework budashnozzle extruder 1.75mm with support by ufra

...rk budashnozzle extruder 1.75mm with support

first attempt to regain 3 cm i've loste muonting a budaschnozzle with an adapter

thingiverse

free

Creality CR-10 hot end bowden tube socket hex extension by nCoco

....

this part also provides extra support to the bowden tube.

the part shown in my images is printed in black pla with 100% infill.

Ohioplastics

thingiverse

free

charpy by ohioplastics

...charpy by ohioplastics

thingiverse

this is used for a charpy test to analyze strength.

thingiverse

free

StepstickA4984 by ohioplastics

...

a stepper motor driver that uses the a4984 instead of the a4988. please note that the a4984 is only capable of 1/8th step mode.

thingiverse

free

Directional Fan Duct by ohioplastics

... a 40mm fan into a directional blower. laser cut out of 1/32" vulcanized fiber. loosely based off of the ultimaker fan duct.

thingiverse

free

Universal 3D Printer Filament Spool Holder, Laser Cut by ohioplastics

...eter.

parts:

2- 608zz bearings

2- m8 nuts

4- m8 washers

1- 6" m8 thread rod

2- birch wood spool holders

2- 3d printed arbors

thingiverse

free

J-Head Lite V1.0 Hot End by ohioplastics

...ers. a bit pricey for my taste, but without their dedication to open source tech, my business would not be possible. thanks bros.

thingiverse

free

The J-Head Lite V2 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...759/16-22-9)

copper heat sink (zoro # g1445893)

brass nut (zoro # g3497794)

start the revolution: http://stores.ebay.com/ohpakron

thingiverse

free

The J-Head Lite V2.1 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...ng plate (lowes)

for sale: http://www.ebay.com/itm/the-j-head-lite-v2-1-ultimate-economy-reprap-3d-printer-hot-end-/261607085522?

thingiverse

free

Airtripper Jhead-Lite Remix by madmike8

...from openhardwarecoza to work with my jhead-lite hotend from ohioplastics the first one i printed didn't have the relief...

Mk6

turbosquid

$5

MK6 Helmet

...6 helmet for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1595020)

3d_export

$25

Bentley mk6 3D Model

...bentley mk6 3d model

3dexport

bentley mk6 car old retro

bentley mk6 3d model godzik 3334 3dexport

3d_export

$99

Reloop RP6000 MK6 3D Model

...reloop rp6000 mk6 3d model

3dexport

reloop rp 6000 mk6 turntable music dj

reloop rp6000 mk6 3d model aerog 22475 3dexport

3d_export

$57

Suzuki Swift Mk6 3D Model

...suzuki swift mk6 3d model

3dexport

suzukiswiftmk

suzuki swift mk6 3d model evermotion 92536 3dexport

3d_export

$39

Reloop turntable RP6000 MK6 3D Model

... 3d model

3dexport

reloop vynil turntable rp-6000 mk6 dj music 3dvynil

reloop turntable rp6000 mk6 3d model godzik 14115 3dexport

humster3d

$75

3D model of Ford Mustang (Mk6) Shelby GT350R 2015

...of ford mustang (mk6) shelby gt350r 2015 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$6

War machine mk6 and ironpatriot v2 - avengers endgame

...s endgame

3dexport

excellent for small size 3d printing.<br>simple sketchup modeling.<br>ideal model for papercraft.

3d_export

$49

Vynil turntable with mixer 3D Model

...3d model 3dexport vynil turntable mixer reloop pioneer djm-600 mk6 rp-6000 dj music crossfade vynil turntable with mixer 3d...

3d_export

$59

Vinyl Cd turntable mixer 3D Model

...3d model 3dexport vynil turntable mixer reloop pioneer djm-600 mk6 rp-6000 dj music crossfade cd dvj-x1 dvj vinyl cd...

3d_ocean

$89

Volkswagen Golf 5door 2009

...doors 5door caribe city euro germany golf hatch hatchback mk6 rabbit urban volkswagen volkswagen golf vw volkswagen golf 5door...

Rework

3d_export

$25

riva aquarama 1970

...visualization, as well as, if desired, it can be reworkd for 3d printing. in the near future, a model...

3d_export

$8

Mosaic 1 3D Model

...outdoor indoor vector ceramic glass mosaic decorative mosaic manually reworkd into a vector. the image is then modified in...

3d_export

$65

sci-fi scene for rendering restyling - tesla

...colors with the name, metal, light metal, dark metal, reworkd renders for preview and processed in photoshop using a...

3d_export

$22

a filter assembly and inspection line

...laser marking station (op40), one packaging station (op50), one rework and pump water detection station (op60), and two assembly...

3d_export

$19

muuto raw chair

...the muuto raw chair.<br>raw chair is a striking functional reworkng of a recognizable everyday object. a part of the...

3d_export

$12

desert rocks stock in blender

...in obj format (non-textured), together with the textures, for reworkng them in other programs.<br>notes: the scene include 12 simple...

3d_export

$10

arclinea principia

...the essence, with the basic principles of the kitchen, reworkd: new steel technology and natural wood cutting. the extraordinary...

thingiverse

free

Doughnut Rework by Johhnny

...doughnut rework by johhnny

thingiverse

i reworked tzani's mobius doughnut for dual extrusion.

thingiverse

free

Beanie the Transformer rework by Whirl55

...beanie the transformer rework by whirl55

thingiverse

found and reworked head pin

and all files

thingiverse

free

AM10 - am8 rework Y

...am10 - am8 rework y

thingiverse

totaly rework to turn your am8 into an am10 with only 2 pieces

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Minimalistic

3d_export

$20

minimalist rings

...minimalist rings

3dexport

minimalist rings

3d_export

$5

minimalistic beach

...minimalistic beach

3dexport

minimalistic scenes for your symbols or other ideas

3d_ocean

$2

Minimalist Ring

...ring 3docean fish minimalist ring this is a very minimalistic ring design. its shape is inspired by a fish...

3d_ocean

$15

minimalist house

...minimalist house

3docean

architecture minimalist modern

a simple modern house, ready to render in mental ray

3d_export

$15

minimalist table

...list table

3dexport

this is a minimalist table with wood and aluminum materials. in the rar file i've included .stl and .obj

3d_export

$7

modern minimalist bedroom

...modern minimalist bedroom

3dexport

modern minimalist bedroom

turbosquid

$100

Minimalist homes

...d

royalty free 3d model minimalist homes for download as rvt on turbosquid: 3d models for games, architecture, videos. (1253698)

turbosquid

$70

minimalist apartment

...oyalty free 3d model minimalist apartment for download as max on turbosquid: 3d models for games, architecture, videos. (1566613)

turbosquid

$25

The House is Minimalist

...lty free 3d model the house is minimalist for download as skp on turbosquid: 3d models for games, architecture, videos. (1246947)

turbosquid

$18

Tableware minimalistic

...alty free 3d model tableware minimalistic for download as max on turbosquid: 3d models for games, architecture, videos. (1545233)