Thingiverse

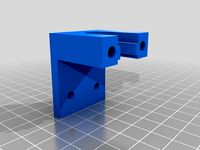

J-Head Lite V1.0 Hot End by ohioplastics

by Thingiverse

Last crawled date: 2 years, 12 months ago

The V1 is obsolete. This post is for product support and legacy.

No sugar added!

It basically combines the holder of the J-Head, the heat sink of the Budaschnozzle, and the hot end of the MK7. The J-Head Lite uses a 1/2" reprocessed PTFE holder with a 6mm stainless steal tube whereas a traditional J-head uses a 5/8 PEEK holder with an 8mm PTFE lined brass tube. The heat sink is actually just a simple plumbing cap with a hole through it and mounted with a brass nut: simple, low tech, effective. The hot end is based off of the MK7, except it uses a 3w resistor and a thermistor instead of a 40W heater and a thermocouple. I tried to take the best parts of "the big 3" hot end designs and make something that's an economical alternative for ABS/PLA printing. Did I mention it's only 1.5oz?

After probing around the hot end at 240C with a thermistor, I found the brass nut on the heat sink gets to 170C, the middle of the stainless steal tube gets to 110C and the top gets to 80C. To be on the safe side, I'll call the max temp 250C.

Made out of:

1/2" PTFE rod (McMaster-Carr # 8803K14)

Laser cut oak mounting plate (Lowes 1/4" Oak)

M6x1 stainless steal barrel (McMaster-Carr # 90024A461)

Aluminum heater block (Clinton Aluminum .3750X.5000 FLT 6061)

Vishay 6.8ohm resistor (Digikey # RWMA-6.8CT-ND)

Honeywell 100k thermistor (Digikey # 480-3135-ND)

Brass nozzle (McMaster-Carr # 8952K33)

Ceramic insulation (Mcmaster-Carr # 87575K85)

Heat Resistant Wiring (skygeek.com # M22759/16-22-0)

Copper Heat Sink (McMaster-Carr # 5520K44)

Instead of using a brass barrel, I use a stainless steal barrel, much like what is used in the current Makerbot extruder design. I, and they, did this because stainless steal has less thermal conductivity than brass. This means less heat travels up the barrel. I also added a heat sink which mounts to the top of the heater block, separated by ceramic insulation. The brass nut, which clamps the heat sink down, absorbs heat as it travels up the barrel and dissipates it through the heat sink. The PTFE is separated from the heat sink by air, which is actually a great insulator. Simply by not touching the PTFE, the heat sink is unable to transmit its thermal energy through conduction. This thermal management helps resists thermal expansion in the PTFE.

Thermal expansion is the cause of PTFE loosening during extrusion. As the amount of force required to push the filament down the barrel and through the nozzle is much less with 1.75mm filament vs. 3mm filament (2-3 times less I think), less force is ultimately required to keep the barrel in place. So, with the right thermal management and the smaller filament size, PTFE is a pretty effective and economical alternative to PEEK.

Although It doesn't look like a very complex design, it's sometimes easier to do more with less and there's quite a lot of interesting thermodynamics going on here. With this minimalist design, a respectable hot end can be made at a fraction of the cost vs. a traditional J-Head. Hence, I deemed it the J-Head Lite.

PLA USERS:

Soak a cotton ball with vegetable oil and feed the filament through it in order to stop it from sticking.http://www.makerbot.com/blog/2010/02/06/oil-helps-pla-yes/

Some of the earlier batches of heater blocks were machined a little tight. If it's too tight for the heater, either ream out the hole a little, or contact me for a replacement on ebay.

The .stl file is for reference only. Do not attempt to print your own J-Head lite. For 1.75mm filament only. Please note, the J-head Lite has not been tested on nylon or polycarbonate.

Thanks to http://alexcphoto.com for the printable mount.

Buy one: http://stores.ebay.com/ohpakron

See it in action: http://youtu.be/oHNYAnzMJ2A

Atribution! Atribution! Atribution!

Hotends.com, the original J-Head developers. a bit pricey for my taste, but without their dedication to open source tech, my business would not be possible. Thanks bros.

No sugar added!

It basically combines the holder of the J-Head, the heat sink of the Budaschnozzle, and the hot end of the MK7. The J-Head Lite uses a 1/2" reprocessed PTFE holder with a 6mm stainless steal tube whereas a traditional J-head uses a 5/8 PEEK holder with an 8mm PTFE lined brass tube. The heat sink is actually just a simple plumbing cap with a hole through it and mounted with a brass nut: simple, low tech, effective. The hot end is based off of the MK7, except it uses a 3w resistor and a thermistor instead of a 40W heater and a thermocouple. I tried to take the best parts of "the big 3" hot end designs and make something that's an economical alternative for ABS/PLA printing. Did I mention it's only 1.5oz?

After probing around the hot end at 240C with a thermistor, I found the brass nut on the heat sink gets to 170C, the middle of the stainless steal tube gets to 110C and the top gets to 80C. To be on the safe side, I'll call the max temp 250C.

Made out of:

1/2" PTFE rod (McMaster-Carr # 8803K14)

Laser cut oak mounting plate (Lowes 1/4" Oak)

M6x1 stainless steal barrel (McMaster-Carr # 90024A461)

Aluminum heater block (Clinton Aluminum .3750X.5000 FLT 6061)

Vishay 6.8ohm resistor (Digikey # RWMA-6.8CT-ND)

Honeywell 100k thermistor (Digikey # 480-3135-ND)

Brass nozzle (McMaster-Carr # 8952K33)

Ceramic insulation (Mcmaster-Carr # 87575K85)

Heat Resistant Wiring (skygeek.com # M22759/16-22-0)

Copper Heat Sink (McMaster-Carr # 5520K44)

Instead of using a brass barrel, I use a stainless steal barrel, much like what is used in the current Makerbot extruder design. I, and they, did this because stainless steal has less thermal conductivity than brass. This means less heat travels up the barrel. I also added a heat sink which mounts to the top of the heater block, separated by ceramic insulation. The brass nut, which clamps the heat sink down, absorbs heat as it travels up the barrel and dissipates it through the heat sink. The PTFE is separated from the heat sink by air, which is actually a great insulator. Simply by not touching the PTFE, the heat sink is unable to transmit its thermal energy through conduction. This thermal management helps resists thermal expansion in the PTFE.

Thermal expansion is the cause of PTFE loosening during extrusion. As the amount of force required to push the filament down the barrel and through the nozzle is much less with 1.75mm filament vs. 3mm filament (2-3 times less I think), less force is ultimately required to keep the barrel in place. So, with the right thermal management and the smaller filament size, PTFE is a pretty effective and economical alternative to PEEK.

Although It doesn't look like a very complex design, it's sometimes easier to do more with less and there's quite a lot of interesting thermodynamics going on here. With this minimalist design, a respectable hot end can be made at a fraction of the cost vs. a traditional J-Head. Hence, I deemed it the J-Head Lite.

PLA USERS:

Soak a cotton ball with vegetable oil and feed the filament through it in order to stop it from sticking.http://www.makerbot.com/blog/2010/02/06/oil-helps-pla-yes/

Some of the earlier batches of heater blocks were machined a little tight. If it's too tight for the heater, either ream out the hole a little, or contact me for a replacement on ebay.

The .stl file is for reference only. Do not attempt to print your own J-Head lite. For 1.75mm filament only. Please note, the J-head Lite has not been tested on nylon or polycarbonate.

Thanks to http://alexcphoto.com for the printable mount.

Buy one: http://stores.ebay.com/ohpakron

See it in action: http://youtu.be/oHNYAnzMJ2A

Atribution! Atribution! Atribution!

Hotends.com, the original J-Head developers. a bit pricey for my taste, but without their dedication to open source tech, my business would not be possible. Thanks bros.

Similar models

thingiverse

free

The J-Head Lite V2 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...759/16-22-9)

copper heat sink (zoro # g1445893)

brass nut (zoro # g3497794)

start the revolution: http://stores.ebay.com/ohpakron

thingiverse

free

The J-Head Lite V2.1 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...ng plate (lowes)

for sale: http://www.ebay.com/itm/the-j-head-lite-v2-1-ultimate-economy-reprap-3d-printer-hot-end-/261607085522?

thingiverse

free

bfb hot end model by BogdanKecman

...at barrel.

you can see about the hot end itself: http://www.bitsfrombytes.com/wiki/index.php?title=manualupdatesv30#head-assembly

thingiverse

free

Heater Block by rp_one_labs

...6 threaded barrels/hot ends.

diy kit - block + cartridge + thermistor + ptfe sleeves + connhttp://www.ebay.com/itm/221181798222

grabcad

free

Ender 3 Hot End

... end

grabcad

ender 3 hot end:

- heater cartridge

- radiator

- bowden pc4m6

- thermistor

- heatbreak

- heating block

- hose pipe

thingiverse

free

TefStruder by VincentJGeisler

...cal insulation, aremco cp4040 high temperature dielectric coating. overcoat, prepreg sosil/fiberglass

thermal insulation, xerogel

thingiverse

free

hot-end pieces for OpenSCAD by whosawhatsis

...reprap parts suppliers. i needed them to model an x carriage i'm working on, and thought someone else might find them useful.

thingiverse

free

Railcore2 hot end carrier for modified creality hot end by jstevewhite

...n't require the volcano mod, but right now it does require the volcano to line up with the part cooling fans and the bltouch.

thingiverse

free

Metal "MB" HotEnd for 1.75mm filament by rp_one_labs

...usa from inch size stock). ss thermal barrier also similar to one used in stepstruder. part of the credit...

thingiverse

free

Monoprice Select Mini E3D V6 heat sink adaptor by shingabiss

...mcmaster carr.

installation tool is right next to it on order page. you can also use a nut with a through drilling if you like..

Ohioplastics

thingiverse

free

charpy by ohioplastics

...charpy by ohioplastics

thingiverse

this is used for a charpy test to analyze strength.

thingiverse

free

StepstickA4984 by ohioplastics

...

a stepper motor driver that uses the a4984 instead of the a4988. please note that the a4984 is only capable of 1/8th step mode.

thingiverse

free

Directional Fan Duct by ohioplastics

... a 40mm fan into a directional blower. laser cut out of 1/32" vulcanized fiber. loosely based off of the ultimaker fan duct.

thingiverse

free

Universal 3D Printer Filament Spool Holder, Laser Cut by ohioplastics

...eter.

parts:

2- 608zz bearings

2- m8 nuts

4- m8 washers

1- 6" m8 thread rod

2- birch wood spool holders

2- 3d printed arbors

thingiverse

free

Minimalistic MK6 Bowden Rework by ohioplastics

...ts are available on my ebay store: http://stores.ebay.com/ohpakron. this project is at an early stage, so check back for updates.

thingiverse

free

The J-Head Lite V2 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...759/16-22-9)

copper heat sink (zoro # g1445893)

brass nut (zoro # g3497794)

start the revolution: http://stores.ebay.com/ohpakron

thingiverse

free

The J-Head Lite V2.1 Ultimate Economy RepRap 3D Printer Hot End by ohioplastics

...ng plate (lowes)

for sale: http://www.ebay.com/itm/the-j-head-lite-v2-1-ultimate-economy-reprap-3d-printer-hot-end-/261607085522?

thingiverse

free

Airtripper Jhead-Lite Remix by madmike8

...from openhardwarecoza to work with my jhead-lite hotend from ohioplastics the first one i printed didn't have the relief...

Lite

design_connected

$11

Lite

...lite

designconnected

sphaus lite coffee tables computer generated 3d model. designed by eero saarinen.

3ddd

$1

Foscarini_Giga-Lite

... giga-lite , лампы , light

foscarini_giga-lite

turbosquid

free

LegendarySwords - Lite

...odel legendaryswords - lite for download as dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559781)

turbosquid

$85

DS Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jet Lite

... model jet lite for download as 3ds, obj, fbx, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1476173)

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

lite on.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

Multi-Lite Pendant

...multi-lite pendant

designconnected

gubi multi-lite pendant computer generated 3d model. designed by weisdorf, louis .

turbosquid

$120

Cartoon Pack Lite

...

royalty free 3d model cartoon pack lite for download as fbx on turbosquid: 3d models for games, architecture, videos. (1255320)

turbosquid

$100

HUAWEI P3 Lite

...id

royalty free 3d model huawei p30 lite for download as c4d on turbosquid: 3d models for games, architecture, videos. (1515805)

J

3d_export

$17

J-7mg

...j-7mg

3dexport

j-7mg

3d_export

$5

j hook

...j hook

3dexport

j hook

3d_export

$17

J-21 jastreb

...j-21 jastreb

3dexport

j-21 jastreb

3d_export

$17

Chengdu J-10

...chengdu j-10

3dexport

chengdu j-10

turbosquid

$96

J-20

...20

turbosquid

royalty free 3d model j-20 for download as max on turbosquid: 3d models for games, architecture, videos. (1658873)

turbosquid

$68

J-10A

...a

turbosquid

royalty free 3d model j-10a for download as max on turbosquid: 3d models for games, architecture, videos. (1658854)

turbosquid

$30

J-7

...j-7

turbosquid

royalty free 3d model j-7 for download as max on turbosquid: 3d models for games, architecture, videos. (1538420)

turbosquid

$14

Fence J

...turbosquid

royalty free 3d model fence j for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313345)

turbosquid

$7

J for Jug

...rbosquid

royalty free 3d model j for jug for download as max on turbosquid: 3d models for games, architecture, videos. (1688347)

turbosquid

$5

Letter J

...urbosquid

royalty free 3d model letter j for download as max on turbosquid: 3d models for games, architecture, videos. (1408483)

V1

turbosquid

$35

v1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

street tree v1

...street tree v1

3dexport

street tree v1

3d_export

$5

potato v1

...potato v1

3dexport

turbosquid

$20

Kitchen V1

...bosquid

royalty free 3d model kitchen v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1153622)

turbosquid

$12

sofa v1

...turbosquid

royalty free 3d model sofa v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1283267)

turbosquid

$3

Chair V1

...urbosquid

royalty free 3d model chair v1 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486093)

turbosquid

$15

Cupboard v1

...royalty free 3d model cupboard v1 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1444568)

3d_export

$5

tram v1

...tram v1

3dexport

3d_export

$8

lumber car v1

...lumber car v1

3dexport

lumber car v1 printable, low poly model.

turbosquid

$20

DELTALIGHT v1

...free 3d model deltalight v1 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1630928)

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

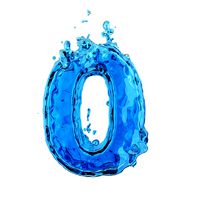

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear