Thingiverse

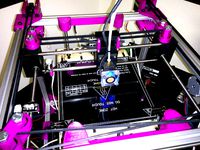

Colin's CoreXY (V-Slot) by zx81

by Thingiverse

Last crawled date: 3 years ago

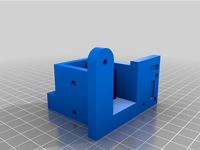

I'm Building a Custom CoreXY printer using V-Slot.

The V-Slot is reasonably priced however the Accessories for it are quite expensive and Will ADD UP! So I am going to design A lot of parts for ABS Printing.

This is an in Progress Thing!

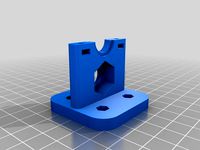

So far it's just a couple of Parts to Join the V-Slot together, The Cube part Has 3x 5mm holes for joining 3 pieces of V-Slot at the top (when you TAP the V-SLot) thus enabling you to make a Square or rectangular Frame, the 3 larger holes are so you can get the Bolt in the cube.

V2 of cube added: Rounded corners, internal countersink for CapHead Bolts

Corner Piece is pretty Self explanatory, M5 10mm Dome head Screws work best.

I've just came across this http://www.thingiverse.com/thing:105900 Which is the open builds versions, I did not copy these designs, however my design and their designs are very similar.

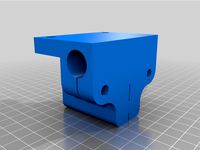

03-07-2016: Added a Nema17 Mount to attach the motor to the vslot, I still have to make a second mount that is higher than the first as I plan to use a "over and under" drive belts rather than the traditional crossed belts. this mount uses 3x M5 Cap head bolts to secure to the vslot and 4x M3 cap head's to attach the nema17

05-7-2016: Added 2nd Nema17 Mount this one is taller to raise the Gear Pulley above the first mount allowing an over under belt system, I may change this model.

06-7-2016: Added V3 of the cube, the previous 2 versions will need to be drilled to allow for a Cap Head bolt, V2 will work ok for button head bolts. V3 is optimised for button head bolts, cap head bolts are a poor choice they would require making the supporting plastic a lot thiner.

09-7-2016: changed the Nema17 Mounts from cap head bolts to button head bolts. I'm using M5 10mm Button head bolts for everything on this build now.

24-7-2016: Added RodFixing, it allows you to fit 10mm Smoth rod to the V-Slot / T-slot Extrusions.

21-11-2016 Added Custom Y-Plates the Y plate is loosely based on the Openbuilds Mini V gantry plate however the hole spacings are designed to do away with the Eccentric spacers, using mini wheels which you can get from your usual Chinese distributors, one orientation will give you a tighter fit than the other orientation (that's what the two squares are for on the top)

20-11-2016 Improved the X and Y gantry Plates, they work much better now

no adjustment or messing about is needed for use with the mini gantry wheels, just

4x m5 25mm bolts

4x m5 standard hex nuts

4x m5 washers

4x mini V wheels

8x m5 lock nuts

it is important to use lock nuts! as the inner diameter of the locking part of the nut is the perfect size to not lock up the mini wheels! put one either end of the wheel the locking part towards the wheel! (so the last lock nut is backwards)

Drill out the 4 holes with a 5mm drill bit to make sure the bolts fit through without being held by the plastic, the nuts on the rear are used to hold the bold straight and in place, if you screw the bolt through the plastic (which is very easy) it is very probable that it will be at a slight angle! (you don't want that) https://youtu.be/fFbzME6J3Ao

The V-Slot is reasonably priced however the Accessories for it are quite expensive and Will ADD UP! So I am going to design A lot of parts for ABS Printing.

This is an in Progress Thing!

So far it's just a couple of Parts to Join the V-Slot together, The Cube part Has 3x 5mm holes for joining 3 pieces of V-Slot at the top (when you TAP the V-SLot) thus enabling you to make a Square or rectangular Frame, the 3 larger holes are so you can get the Bolt in the cube.

V2 of cube added: Rounded corners, internal countersink for CapHead Bolts

Corner Piece is pretty Self explanatory, M5 10mm Dome head Screws work best.

I've just came across this http://www.thingiverse.com/thing:105900 Which is the open builds versions, I did not copy these designs, however my design and their designs are very similar.

03-07-2016: Added a Nema17 Mount to attach the motor to the vslot, I still have to make a second mount that is higher than the first as I plan to use a "over and under" drive belts rather than the traditional crossed belts. this mount uses 3x M5 Cap head bolts to secure to the vslot and 4x M3 cap head's to attach the nema17

05-7-2016: Added 2nd Nema17 Mount this one is taller to raise the Gear Pulley above the first mount allowing an over under belt system, I may change this model.

06-7-2016: Added V3 of the cube, the previous 2 versions will need to be drilled to allow for a Cap Head bolt, V2 will work ok for button head bolts. V3 is optimised for button head bolts, cap head bolts are a poor choice they would require making the supporting plastic a lot thiner.

09-7-2016: changed the Nema17 Mounts from cap head bolts to button head bolts. I'm using M5 10mm Button head bolts for everything on this build now.

24-7-2016: Added RodFixing, it allows you to fit 10mm Smoth rod to the V-Slot / T-slot Extrusions.

21-11-2016 Added Custom Y-Plates the Y plate is loosely based on the Openbuilds Mini V gantry plate however the hole spacings are designed to do away with the Eccentric spacers, using mini wheels which you can get from your usual Chinese distributors, one orientation will give you a tighter fit than the other orientation (that's what the two squares are for on the top)

20-11-2016 Improved the X and Y gantry Plates, they work much better now

no adjustment or messing about is needed for use with the mini gantry wheels, just

4x m5 25mm bolts

4x m5 standard hex nuts

4x m5 washers

4x mini V wheels

8x m5 lock nuts

it is important to use lock nuts! as the inner diameter of the locking part of the nut is the perfect size to not lock up the mini wheels! put one either end of the wheel the locking part towards the wheel! (so the last lock nut is backwards)

Drill out the 4 holes with a 5mm drill bit to make sure the bolts fit through without being held by the plastic, the nuts on the rear are used to hold the bold straight and in place, if you screw the bolt through the plastic (which is very easy) it is very probable that it will be at a slight angle! (you don't want that) https://youtu.be/fFbzME6J3Ao

Similar models

thingiverse

free

Y Gantry fo 20mm Extrusion (Core XY) by zx81

...he bolt through the plastic (which is very easy) it is very probable that it will be at a slight angle! (you don't want that)

thingiverse

free

Openbuilds v-slot X axis for Lulzbot TAZ 6 printers by piercet

...head m5 bolts and nuts 30mm (standard bolts will not fit, need the flat ones. ). longer if you plan to add the cable chain pieces

thingiverse

free

X Gantry Plate for 20mm extrusion by zx81

...hole spacing's are 15mm from the center left and right (or x axis) and 26mm up and down (y axis)

https://youtu.be/ffbzme6j3ao

thingiverse

free

Mini V Gantry to Nema Stepper Adapter - Flex3drive by berencam

...he stepper mounting holes, otherwise you will need to use a lower profile button head bolt for the mini v gantry v roller mounts.

thingiverse

free

Openbuilds v-slot X axis for Lulzbot TAZ 6 printers With integrated Z anti Wobble by piercet

...on picture is provided courtesy kam vedbrat and is used with permission, all rights for the photo remain with him. thank you kam!

thingiverse

free

Delta Carriage for 2020 Aluminum V-Slot® 20x20 Linear Rail by quadcells

...near the top of the carriage for the end stop adjusting bolt and one to lock down the end stop adjusting bolt (see the pictures).

thingiverse

free

2020 Aluminum V-Slot 60 Degree Brackets by quadcells

...al 60 degree brackets will need:

4 m5 10mm button head bolts (could use other type heads).

4 m5 t-nuts

hope this can help others.

thingiverse

free

Nema17 40mm Mount for Root 3 Lite by gerhardbooysen

...mount for the root 3 lite to first connect to the motor with 4x m3x10 bolts and them through gantry plates into m3 nuts inserted.

thingiverse

free

V-Slot Openbuilds Mini Gantry E3D V6 mount W/ 18mm Proximity Sensor by muegen

... for my modified gantry plate. uses the same cap that's supplied in source remix.

update: increased thickness of probe mount.

thingiverse

free

Anet E-10 My carriage mods - V-Slot, Titan Aero, Pinda sensor, Cooler by rings

...8

1 x m3x25

4x 6x7x2mm neodymium magnet

fan duct is a remix, link to the original below:https://www.thingiverse.com/thing:1246425

Zx81

thingiverse

free

Sinclair ZX81 by Amario57

...sinclair zx81 by amario57

thingiverse

model 1:1 computer sinclair zx81

with stickers

thingiverse

free

ZX81 Edge Connector by mcarlson_sb

...it the zx81 (10mm height)

expanded to 23x2 (46 pin)

added channel to outside holes to make bending wire and pulling tight easier.

thingiverse

free

downpipe cover by zx81

...by zx81

thingiverse

broke the old cover trying to access the pipe, can't find a replacement one so designed this.

fits well.

thingiverse

free

ZX81 / Timex Sinclair 1000 Display Stand

...ngs you want!

i have an assortment of matching stands for other computers if you want a consistent look for your display shelves.

thingiverse

free

Bulldog XL Mount by zx81

...r for clearance issues, i've included the sketchup files so you can modify it easily..

the fan bracket needs some improvment.

thingiverse

free

Sinclair ZX81, ZX Spectrum & QL Display Stands by Tom_DD

...128k toastrack

zx spectrum +2/+2ab

zx spectrum +3 with and without gotek (extra 5mm on base to give clearance for rotary knob)

ql

thingiverse

free

RJ4JP Test Fitting by zx81

...y carriage assembly around the drylin bushings.

please be aware this is not designed to be a drop-in replacement lmu10uu bearings

thingiverse

free

Spool Arm for P3Steel by zx81

...all tab with the hole in it and made the arm thicker, the screw now goes through the center of the arm with a m3 nut in the back!

thingiverse

free

X carriage for J head Hotend with inductive proximity sensor E3D / Hexagon by zx81

...ends also, you will have to glue the fan on as there wasn't enough space to put screw holes i might fix this at a later time.

thingiverse

free

X Gantry Plate for 20mm extrusion by zx81

...hole spacing's are 15mm from the center left and right (or x axis) and 26mm up and down (y axis)

https://youtu.be/ffbzme6j3ao

Colin

turbosquid

$14

chair bar colin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Colin Reid Still Life with Books

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Colin Cab Barbara Barry Baker Chair 3D Model

...r sofa

colin cab barbara barry baker chair 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl raziel3d 106811 3dexport

design_connected

$10

Capiton

...capiton computer generated 3d model. designed by garros, emilie colin ...

3ddd

$1

Zen Art

..., picture , камень , камни , ветки работы colin and linda mckie & linda...

3ddd

$1

Baker_Colin Cab Swivel Chair_No. 6712C-SW

... colin cab swivel

the barbara barry collection

detailed dimensions

width: 84 cm

depth: 99.06 cm

height: 80 cm

thingiverse

free

colin by summer3D

...colin by summer3d

thingiverse

colin's house

thingiverse

free

colin castle by summer3D

...colin castle by summer3d

thingiverse

colin's castle

thingiverse

free

Robot by Colin by SCISPD

...robot by colin by scispd

thingiverse

designed by 3rd grader, colin!

part of our 2d to 3d project.

thingiverse

free

Colin Butgereit by Staff

...colin butgereit by staff

thingiverse

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Slot

3d_export

$5

slot handle

...slot handle

3dexport

slot handle

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

... machine slot-machine one-armed bandit

slot machine novomatic gaminator n240911 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$5

narrow slot handle

...narrow slot handle

3dexport

narrow slot handle

turbosquid

$15

Slot Machine

...oyalty free 3d model slot machine for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1710861)

turbosquid

$25

Slot Machine

... free 3d model slot machine for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1649555)

turbosquid

$25

Coin Slots

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Slotted spoon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Slot Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

slotted spoon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V

design_connected

$16

V Chair

...v chair

designconnected

v chair computer generated 3d model.

design_connected

$11

V Hanglamp

...v hanglamp

designconnected

arturo alvarez v hanglamp computer generated 3d model. designed by alvarez, arturo .

turbosquid

$25

Borbet V

...v

turbosquid

royalty free 3d model borbet v for download as on turbosquid: 3d models for games, architecture, videos. (1381618)

turbosquid

free

Saturn V

...rn v

turbosquid

free 3d model saturn v for download as blend on turbosquid: 3d models for games, architecture, videos. (1651098)

turbosquid

$40

V motor

...turbosquid

royalty free 3d model v motor for download as max on turbosquid: 3d models for games, architecture, videos. (1379483)

turbosquid

$7

V for Van

...rbosquid

royalty free 3d model v for van for download as max on turbosquid: 3d models for games, architecture, videos. (1695889)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408535)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408534)

turbosquid

$15

BonePile V

...oyalty free 3d model bonepile v for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546310)

turbosquid

$2

FONT V

...quid

royalty free 3d model font v for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549450)