Thingiverse

Anet A8 X Belt holder and tensionner by Miranina

by Thingiverse

Last crawled date: 3 years ago

If you love this design and it help you, consider tipping me as I spent a good amount of time on this design. Thanks in advance !

Anet A8 PLUS : Since the stock belt is held by the top belt to use my design you'll need to reverse the x motor direction. Either in firmware or by reversing one coil of the stepper motor.

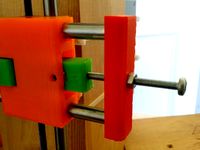

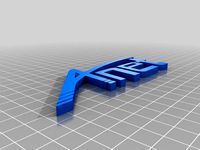

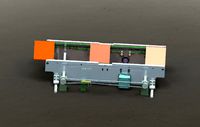

Remixed Kenneth Jiang version to add a tensionner on the setup. There is a screw ( M3x30 that come with the Anet ) that go thru the body and attach to the nut that with in the tighter.

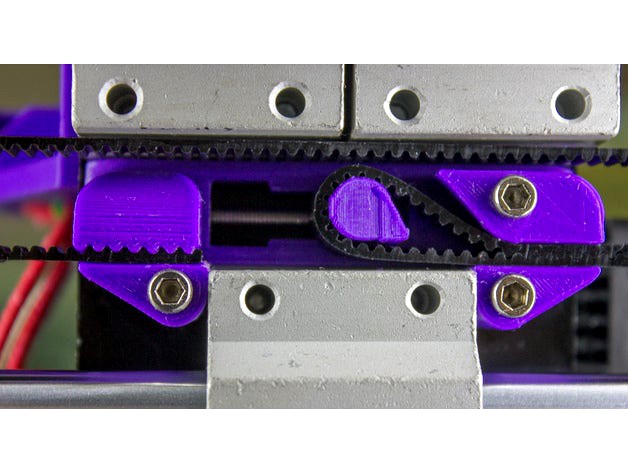

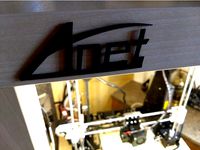

You install the belt, as shown in the picture and then you tighten the belt with the screw.

I wanted to use the lenght of the x_belt you end up with after the first built of the Anet. It was too short for most of the tensionner. This one fit perfect and you can get the belt pretty darn tight. I ended up loosing it up a bit to not put too much force on the Z axis.

File to print

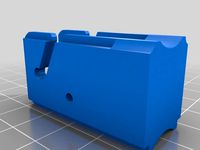

you need one tighter part

for the body, measure your belt, dimensions are as follow

-- body : 1.65mm toothed groove and 2.35mm folded groove

-- thin belt : 1.5mm toothed groove and 2.2mm folded groove

-- gates fiberglass : 1.3mm toothed groove and 2mm folded groove

V2

I added a little more structure to the upper part. Also revised the tooth a little They are still pretty darn tight and I have to push the belt with a little screw driver to get to the bottom of the groove. Might be a good thing though, as I definitly don't want any play here.

V3

First thanks for the comments and likes it's appreciated !

I had a failure of the tighter part. It just broke at the nut. So I went back and increased the size of the section were it broke. Hopefully now it will be correct. I'll print a second one as a spare if it break again.

Increased the space for the tooths and now the belt slide in easy enough, but is still snug.

Rotated the stl so that the correct print orientation is native. No more turning the part for print.

Removed one screw that was basically useless and was just adding weight to the carriage.

With the new orientation, I didn't had issue with the slide portion, so didn't changed this one. It is still very snug, but that's what you want !

Added a version for thin belt as when I upgraded my GT2 belt, the new one with fiberglass core was thinner than the steelcore that come with the Anet. It slipped and I wasn't able to thight the belt.

V4

I've narrowed a little bit the thin belt version. Now toothed groove is 1.5mm and folded groove 2.2mm

With recommendation of bASHer91 I've also uploaded an even thinner design for gate fibercore belt which is 1.3mm and 2mm respectively.

Print service

My Print service : If you're insterested contact me directly on thingiverse. Treatstock is not a sustainable and there is a void in the market for a platform.

Anet A8 PLUS : Since the stock belt is held by the top belt to use my design you'll need to reverse the x motor direction. Either in firmware or by reversing one coil of the stepper motor.

Remixed Kenneth Jiang version to add a tensionner on the setup. There is a screw ( M3x30 that come with the Anet ) that go thru the body and attach to the nut that with in the tighter.

You install the belt, as shown in the picture and then you tighten the belt with the screw.

I wanted to use the lenght of the x_belt you end up with after the first built of the Anet. It was too short for most of the tensionner. This one fit perfect and you can get the belt pretty darn tight. I ended up loosing it up a bit to not put too much force on the Z axis.

File to print

you need one tighter part

for the body, measure your belt, dimensions are as follow

-- body : 1.65mm toothed groove and 2.35mm folded groove

-- thin belt : 1.5mm toothed groove and 2.2mm folded groove

-- gates fiberglass : 1.3mm toothed groove and 2mm folded groove

V2

I added a little more structure to the upper part. Also revised the tooth a little They are still pretty darn tight and I have to push the belt with a little screw driver to get to the bottom of the groove. Might be a good thing though, as I definitly don't want any play here.

V3

First thanks for the comments and likes it's appreciated !

I had a failure of the tighter part. It just broke at the nut. So I went back and increased the size of the section were it broke. Hopefully now it will be correct. I'll print a second one as a spare if it break again.

Increased the space for the tooths and now the belt slide in easy enough, but is still snug.

Rotated the stl so that the correct print orientation is native. No more turning the part for print.

Removed one screw that was basically useless and was just adding weight to the carriage.

With the new orientation, I didn't had issue with the slide portion, so didn't changed this one. It is still very snug, but that's what you want !

Added a version for thin belt as when I upgraded my GT2 belt, the new one with fiberglass core was thinner than the steelcore that come with the Anet. It slipped and I wasn't able to thight the belt.

V4

I've narrowed a little bit the thin belt version. Now toothed groove is 1.5mm and folded groove 2.2mm

With recommendation of bASHer91 I've also uploaded an even thinner design for gate fibercore belt which is 1.3mm and 2mm respectively.

Print service

My Print service : If you're insterested contact me directly on thingiverse. Treatstock is not a sustainable and there is a void in the market for a platform.

Similar models

thingiverse

free

Anet A8 X Belt holder and tensionner by delian2

...and thinner.

i did not change the tighter, even if the belt is still touching a little bit but a little bit of sanding is enough.

thingiverse

free

Anet A8, Y BELT grip. by Wisnaeme

...n that has been marked as "thin"

a thinner z axis and narrower version, that has been marked as "narrow-thin"

thingiverse

free

GT2 belt turn bearing for Anet A8 by Wisnaeme

...at 100% infill to make it the strongest possible.

the yellow belt clip part is over here:http://www.thingiverse.com/thing:2088345

thingiverse

free

TronXY P802M / Anet A8 X-belt Toothed Idler Tensioner by HenryLoenwind

...tronxy p802m you also need a matching idler, e.g. mine: http://www.thingiverse.com/thing:2122224 (the black one in the pictures).

thingiverse

free

Anet A8 Y-Axis Belt Holder by handsomemanrob

...holder gt2. i was informed there is another very similar thing here https://www.thingiverse.com/thing:2249112. so if mine doesn't work for...

thingiverse

free

Antenna Bracket for Painter Pole Or Military Pole by JWJacobs

...s fit perfect.

-thinner wall to save on supplies and print time

-slot for diamond antenna is a bit tighter, no need for set screw

thingiverse

free

Adjustable belt tensionner M6 screw by wroux

...ble belt tensionner m6 screw by wroux

thingiverse

i remixed xifle tensionner for using with m6 socket set screw cup point i own.

thingiverse

free

X-carriage belt attachment for BLV mgn12 3D Printer (thin 1.3mm belt) by ostapoff

... my belt slept out of it as it was designed for 2mm belts.

i included the fusion 360 project file if you would like to adjust it.

thingiverse

free

ANet LCD cover FOR AFTER FEB 2017 versions by 3DTSUJ

...e tabs r super thin.

new update its thinner now and tabs are thinner and fit easier

enjoy leave a comment on how it works for you

thingiverse

free

Anet A8 X-belt tensioner for GT2 pulley by Kommander92

...ied by with freemark's thing.

a big thank you to mtepedino who provided measures and help in testing the 20 tooth prototypes.

Miranina

thingiverse

free

Anet A8 T Corners Branded by Miranina

...they are intended to be printed vertically, i turn the text so it will give a better chance for the text to be printed correctly.

thingiverse

free

Anet A8 improved y-chain by Miranina

...e same time.

print service

my print service can be found there : https://www.treatstock.com/3d-printing-services/miranio-printing

thingiverse

free

Pills Organiser by Miranina

...ed the single day pillbox and 4 different holder with either 1,2,3 or 4 slot depending the amount of time you take pills per day.

thingiverse

free

Anet A8 open frame motherboard fan mount by Miranina

...u remix thanks : https://cad.onshape.com/documents/3344cda09bbb1e40a22ea094/w/cdf06d70013d6d178c9eeae9/e/c1b0596520d979756f4c083d

thingiverse

free

Anet A8 Power Supply fast fan bracket by Miranina

...u remix thanks : https://cad.onshape.com/documents/3344cda09bbb1e40a22ea094/w/dabe15396eae112b5522938d/e/c1b0596520d979756f4c083d

thingiverse

free

Modular wades extruder - fully enclosed filament by Miranina

... message me !

finally : you'll need to be happy !

simply because it's a waste of lifetime not to be ;)

keep on printing !

thingiverse

free

ANET A8 | Customizable Dual E3D v6 Carriage / Bowden Mount

...3mm nuts to the correct locations. i currently use miraninahttps://www.thingiverse.com/thing:2425783) design and it works great with this. includes mounting...

Tensionner

thingiverse

free

y Bracket with built in tensionner by jfpion

...y bracket with built in tensionner by jfpion

thingiverse

y bracket for prusa with built in tensionner

thingiverse

free

X axis belt tensionner for Da Vinci printers

...x axis belt tensionner for da vinci printers

thingiverse

this is the replacement part for the belt tensionner on the x axis

thingiverse

free

Adjustable belt tensionner M6 screw by wroux

...ble belt tensionner m6 screw by wroux

thingiverse

i remixed xifle tensionner for using with m6 socket set screw cup point i own.

thingiverse

free

Mingda X-Axis Tensionner by tilange

...mingda x-axis tensionner by tilange

thingiverse

2 or 4 m3 bolt needed .. !

thingiverse

free

Horizontal pulley tensionner by Jcauet

... lenght (this part is optional)

p.s.:i've included the solidworks parts so feel free to use them and modify the measurements.

thingiverse

free

Mingda X-Axis Tensionner by tilange

...command to thread them with a bolt before installation.

you need to unscrew the bolt and pulley to be able to add the tensionner.

thingiverse

free

Prusa i3 x-belt tensionner remix by mokash770

... x-belt tensionner remix by mokash770

thingiverse

modified for protruding rods from thinghttp://www.thingiverse.com/thing:160636

thingiverse

free

Anet A8 X Belt holder and tensionner by delian2

...and thinner.

i did not change the tighter, even if the belt is still touching a little bit but a little bit of sanding is enough.

thingiverse

free

Anet E10 Y Belt Tensionner for by babounx

...plate can go to the end of the bed.

my youtube french channel https://www.youtube.com/user/babounx

my blog : babounx.blogspot.com

thingiverse

free

Boucle de sac à dos - Backpak belt tensionner by gprint3d

...impression3dfr

this is my own design you can sell it ! you can't share it if you don't give the link of the file.

thanks.

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.