Thingiverse

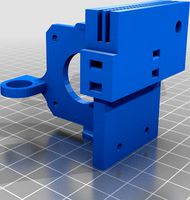

Z-axis_linear_rails_MGN12H by Far_a_way

by Thingiverse

Last crawled date: 3 years, 1 month ago

Conversion of the Z-axis with linear rails MGN12H

Anet E10 MGN12H; 300mm lg

Anet E12 MGN12H; 400mm lg

As part of the renovation, I moved the extruder motor upwards so that one

Filament change the Z-axis can no longer be accidentally adjusted.

For the extruder motor mount above you need a ball bearing 688ZZ (8x16x5mm), which is pressed in.

For people who do not want this, I have also provided a solution.

Print required components, I printed my parts with 15% support. The X-axis motor mount

was printed with 60% infill, the other parts only with 30% infill.

The Z-axis conversion can be used with original X-carriages and when converting to MGN12 linear rails, followed by a conversion of the X-axis to beltless.

After printing out the required components, the X-carriage must be dismantled. It is best to start with the right side, where there is no motor bracket, as follows, move the Z-axis as high as possible, dismantle the X-axis, dismantle the Z-slide on the right-hand side, dismantle the trapezoidal thread spindle guide at the top right, trapezoidal thread nut as well Place the new component, mount the linear rail with the fixed carriage (!! fix otherwise the balls will fall out of the guide), I have attached the linear rail at the top so that the air gap remains at the bottom, screw the printed Z-axis guide onto the threaded spindle and fix it with 4 screws M3x6mm on the linear rail carriage. Place the X-axis loosely between the Z-axis carriages (1 screw on each side), Carefully lower the Z-axis and only screw the X-axis down at the bottom, so the distance between the Z-spindles is not adjusted much. Move the Z-axis back up and only now screw on the loose threaded spindle guide on top. The same is done on the left-hand side, but before the X-axis is set here, the X-axis motor mount is attached to the stop on the X-axis. If you now push the fastening strap of the motor bracket to the linear rail carriage, the X-axis limit switch is back in its original position.

There is an M3 threaded opening on the underside of the X-axis motor bracket, where a M3x20 flat head screw can be used as a stop adjustment.

If necessary, extend the cable and tube.

Reattach the dismantled components of the X-axis, lower the X-axis and adjust.

Anet E10 MGN12H; 300mm lg

Anet E12 MGN12H; 400mm lg

As part of the renovation, I moved the extruder motor upwards so that one

Filament change the Z-axis can no longer be accidentally adjusted.

For the extruder motor mount above you need a ball bearing 688ZZ (8x16x5mm), which is pressed in.

For people who do not want this, I have also provided a solution.

Print required components, I printed my parts with 15% support. The X-axis motor mount

was printed with 60% infill, the other parts only with 30% infill.

The Z-axis conversion can be used with original X-carriages and when converting to MGN12 linear rails, followed by a conversion of the X-axis to beltless.

After printing out the required components, the X-carriage must be dismantled. It is best to start with the right side, where there is no motor bracket, as follows, move the Z-axis as high as possible, dismantle the X-axis, dismantle the Z-slide on the right-hand side, dismantle the trapezoidal thread spindle guide at the top right, trapezoidal thread nut as well Place the new component, mount the linear rail with the fixed carriage (!! fix otherwise the balls will fall out of the guide), I have attached the linear rail at the top so that the air gap remains at the bottom, screw the printed Z-axis guide onto the threaded spindle and fix it with 4 screws M3x6mm on the linear rail carriage. Place the X-axis loosely between the Z-axis carriages (1 screw on each side), Carefully lower the Z-axis and only screw the X-axis down at the bottom, so the distance between the Z-spindles is not adjusted much. Move the Z-axis back up and only now screw on the loose threaded spindle guide on top. The same is done on the left-hand side, but before the X-axis is set here, the X-axis motor mount is attached to the stop on the X-axis. If you now push the fastening strap of the motor bracket to the linear rail carriage, the X-axis limit switch is back in its original position.

There is an M3 threaded opening on the underside of the X-axis motor bracket, where a M3x20 flat head screw can be used as a stop adjustment.

If necessary, extend the cable and tube.

Reattach the dismantled components of the X-axis, lower the X-axis and adjust.

Similar models

thingiverse

free

Tronxy X5SA linear guides by Far_a_way

... the y-limit switch, print out the modified retaining bracket, dismantle the limit switch, relocate and reassemble on the inside.

3dwarehouse

free

SolidCore CoreXY Y-Carriage Assembly

...y carriage and z-axis. the y-axis assembly components mount to a mgn12h linear rail. https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

X-Z axis plate -right side - with DC motor mount by unix_guru

...ount by unix_guru

thingiverse

right side x/z axis plate to mount z-axis linear bearings, x-axis rods, and x-axis dc servo motor.

thingiverse

free

Tevo Tarantula Z-Axis MGN12 Rail Brackets/Mounts by evil_k

...

you will need to change the belt drive for the x-axis. the parts i used are on thingiverse. check the tevo tarantula collection.

thingiverse

free

Dual Z axis MGN12H linear rails kit Print parts by HoganZeng

... reduces the z-axis layer pattern, offset, and distortion of higher models, and improves the surface effect of the printed model.

thingiverse

free

Y-Axis Linear Bearing Mod MGN12H for Ender 3 V2 by ngungbi

... then tighten the rail screw at the rear.

make sure the carriage can move freely with very little resistance.

reassemble the bed.

grabcad

free

tevo tarantula aluminum parts all axis linear rail.

... parts all axis linear rail.

grabcad

the axis has mgn12h rail

the z axis has mgn12h rail (dual z axis)

the x axis has mgn9c rail

thingiverse

free

Carriage for MGN12H and Bondtech BMG by 3ddruckqueck

...e carriage has lots of mounting points designed to take cheap 4mm x 3mm m3 bronze inserts.

i included a bltouch mounting bracket.

thingiverse

free

BD's Tarantula Z Motor and Nut Mounts by bdwalker1

... print bed. it moves things far enough back to allow the x-axis carriage to pass between the lead screw and the x-axis extrusion.

thingiverse

free

Dremel CNC X-carriage redesign by mgreven

...er than the original design to mount it to the mgn12 sliding block and the moter of the z-axis is mounted on top of the carriage.

Mgn12H

thingiverse

free

Mount 775 motor mgn12h by crazysova

...mount 775 motor mgn12h by crazysova

thingiverse

mount 775 motor mgn12h

thingiverse

free

Servo mount for MGN12H rail by Kieranod

...servo mount for mgn12h rail by kieranod

thingiverse

servo mount for mgn12h rail

thingiverse

free

MGN12H Titan Mount Vfire by 3DPrintingEverything

...mgn12h titan mount vfire by 3dprintingeverything

thingiverse

mgn12h mount for a titan e3d extuder

thingiverse

free

Kossel Mini carriage for MGN12H by gnahz

...kossel mini carriage for mgn12h by gnahz

thingiverse

kossel mini carriage for mgn12h with end stop

thingiverse

free

Tarantula Y carriage for MGN12H by ikong

...tarantula y carriage for mgn12h by ikong

thingiverse

tevo tarantula y carriage for mgn12h (of mgn12 rail).

thingiverse

free

MGN12H clamping V-slot by SviatoslavWolf

...mgn12h clamping v-slot by sviatoslavwolf

thingiverse

создал крепление для напрявляющих mgn12h под профиль v-slot

thingiverse

free

MGN12H aero p3steel v18 campy by maskeperro

...eperro

thingiverse

mgn12h aero p3steel v18 campy , pieza modificada para usar con mgn12h ....la original de campy es para mgn12c

thingiverse

free

MGN12H to 2020 and belt holder for x Axis by Kieranod

...epper.

mgn12h without belts.stl has no belt i used it on the side of the nema17 stepper.https://www.thingiverse.com/thing:2959042

thingiverse

free

MGN12C and MGN12H adapter plate by 3r4th

...h

thingiverse

i created a adapter plate for the y axis from mgn12c and mgn12h to a hole pattern of the sc8uu.

best regards 3r4th

thingiverse

free

MGN12H linear rail 20x20 adapter by Goretec

... linear rail 20x20 adapter by goretec

thingiverse

mgn12h linear rail adapter for mounting 20x20 extrusion to the linear guide.

Linear

3ddd

$1

Linear Diffusers

...linear diffusers

3ddd

диффузор

set of linear diffusers for ceiling.

design_connected

$27

Linear Sofa

...linear sofa

designconnected

scp linear sofa computer generated 3d model.

design_connected

$18

Atlantis linear

...atlantis linear

designconnected

terzani atlantis linear pendant lights computer generated 3d model. designed by barlas baylar.

3d_export

$5

light linear unit

...light linear unit

3dexport

light linear unit

turbosquid

$5

Linear Actuator

...

royalty free 3d model linear actuator for download as blend on turbosquid: 3d models for games, architecture, videos. (1589061)

turbosquid

$29

Linear panel

...oyalty free 3d model linear panel for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1391254)

turbosquid

$12

Linear Chandelier

...y free 3d model linear chandelier for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1574289)

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Grohe Lineare

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Linear Unit 3D Model

...linear unit 3d model

3dexport

linear unit force torque velocity

linear unit 3d model fau 71218 3dexport

Far

3d_export

$10

far west buildings

...far west buildings

3dexport

some far west buildings like saloon, sheriff office...

3ddd

free

Bellavista - Dolce far niente pleated

... dolce , банкетка

bellavista - dolce far niente pleated

turbosquid

$9

Chandra rugs FAR-6207

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

water collector far art-3822-3412tp bonus

...le includes next models:<br>1) water collector far art-3822-3412tp<br>2) metal bracket with fasteners far.art-7480-34

3d_export

$5

mysterio - spdierman far from home

...from home

3dexport

excellent for small size 3d printing.<br>simple sketchup modeling.<br>ideal model for papercraft.

3d_export

$5

spiderman - spiderman far from home

...from home

3dexport

excellent for small size 3d printing.<br>simple sketchup modeling.<br>ideal model for papercraft.

turbosquid

free

Water Collector FAR Art-3822-3412TP plus Bonus

...ollector far art-3822-3412tp plus bonus for download as blend on turbosquid: 3d models for games, architecture, videos. (1639022)

3d_export

$41

Iranian Khalij Fars Cruise Missile 3D Model

...range up to 300km.nose fins designed for animations.2048x2048 texture map & bump map provided.1024x1024 texture maps for fins

3d_export

$5

spiderman stealth suit - spiderman far from home

...from home

3dexport

excellent for small size 3d printing.<br>simple sketchup modeling.<br>ideal model for papercraft.

3d_export

$40

R2D2 Star Wars

...a plucky little astromech droid from a galaxy far, far away. he is an ally to the rebel alliance,...

Rails

3d_ocean

$5

rails

...rails

3docean

old rails rails sleepers

old rails

archibase_planet

free

Rail

...chibase planet

rail railing handrail guard-rail

rail forged fence n310814 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

handrail railing guard-rail

rail n220914 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

railing hand-rail banisters

rail n130309 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

railing hand-rail banisters

rail n270510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...

archibase planet

railing handrail fence guard-rail

railing n140314 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing

railing- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing enclosure barrier

light railing - 3d model for interior 3d visualization.

archibase_planet

free

Rail

...rail

archibase planet

metal railing

rail n280608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Railing

...railing

archibase planet

railing kitchen ware

railing 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Way

3ddd

$1

Backhausen Fabric WAY

...x 2014, 2013, 2011,

obj

__________________________________________http://www.backhausen.com/en/products/fabric-catalog/

design_connected

$16

Way Turqoise

...way turqoise

designconnected

way turqoise computer generated 3d model. designed by gemvall, karin.

turbosquid

$9

Gerard Way

...

royalty free 3d model gerard way for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1682114)

3ddd

$1

Formerin - MY WAY

... my way , угловой

диван formerin - my way, в размере, с текстурами.

turbosquid

$7

End Way

...ty free 3d model end way for download as ma, ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1688865)

turbosquid

$15

American way

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

sub way

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Pregno / WAY OF LIFE

...pregno / way of life

3ddd

гардероб , pregno

гардероб pregno way of life

design_connected

$16

Team - 4 ways

...team - 4 ways

designconnected

arper team - 4 ways computer generated 3d model. designed by lievore, alberto.

design_connected

$11

Wai Highboy Highboard

...wai highboy highboard

designconnected

bonaldo wai highboy highboard computer generated 3d model. designed by mazzer, mario.