Thingiverse

XYZ Printing daVinci Jr 1.0 - HeatBed 110w 9A @ 12V by kr15_uk

by Thingiverse

Last crawled date: 3 years ago

!!! YOU WILL BE DEALING WITH POISONOUS CHEMICALS SO I'M NOT RESPONSIBLE IF YOU KILL YOURSELF OF PEOPLE/ANIMALS AROUND YOU.

!!! DIY HEATBED COULD BE FIRE HAZARD IF NOT DONE CORRECTLY SO I'M NOT RESPONSIBLE IF YOU BURN DOWN YOUR HOUSE OR SO.

IF YOU DO NOT HAVE EXPERIENCE WITH PCB ETCHING AND ELECTRONICS - DON'T DO THIS! OR GET SOMEONE WHO HAS TO DO THIS FOR YOU.

DIY heatbed for Jr.

***Yes you can buy silicone heaters and stick them to the bottom of the glass but usually that requires some drilling/cutting into the metal base of the bed to get wires routed through.

With this solution you'll only lose 2mm of Z height if done correctly.

!!! Just to set things clear - this isn't step by step tutorial. More like brief description.

If you don't understand what I'm talking about then maybe this project isn't for you!

You'll need:

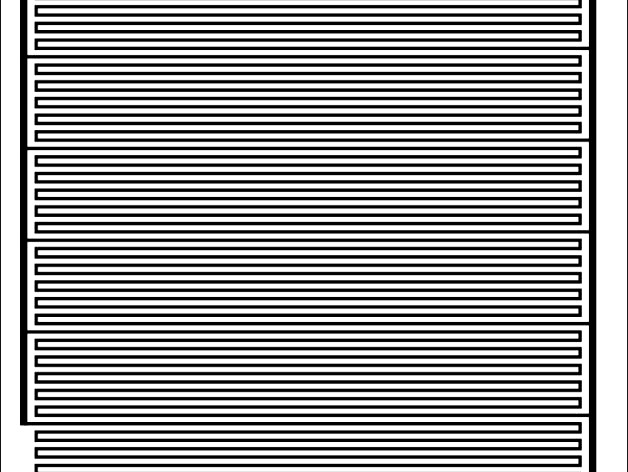

PCB Clad 165x200mm - Jr glass is 165x165, you can get ones which are 165mm wide already of eBay. You need 1x side to be 200 to cut little tab which will stick out so you can solder wires to it.

All chemicals etc for PCB etching. (Deliberately not mentioning what exactly)

Small handsaw.

Soldering iron

16-18AWG wire

12v PSU - AT LEAST 9AMP

Temperature control board

Relay.

Sharpie

Process is very simple.

Print SVG on regular 2D laser printer (laser printer is a MUST)

Transfer print to PCB clad via iron method.

Fix up imperfections with Sharpie

Draw freehand with Sharpie extension traces for the power input so it sticks out a bit on the right hand side of your Jr bed.

Etch!

I had my thermistor cartridge simply capton taped to on side. Not perfect but good enough for me.

But... You could do freehand traces on the bottom of the clad to get thermistor nicely in the middle with traces going out on the side underneath the power in (that's of course if you have double sided PCB clad)

I've covered all surface with capton tape to give it some kind of a insulation.

Wiring.

I've used cheapest available 12v temp controller board of eBay + ATX PC PSU to power it up.

And relay was wired to Jr exhaust fan to make it somewhat automated. That also ensured the bed is switched off automatically when print is done.

I hope all this makes sense.

P.S.: I'll try to find my heatbed and post some actual photos of it.

I've stopped using it only because Jr is no more. Cannibalised for parts.

!!! DIY HEATBED COULD BE FIRE HAZARD IF NOT DONE CORRECTLY SO I'M NOT RESPONSIBLE IF YOU BURN DOWN YOUR HOUSE OR SO.

IF YOU DO NOT HAVE EXPERIENCE WITH PCB ETCHING AND ELECTRONICS - DON'T DO THIS! OR GET SOMEONE WHO HAS TO DO THIS FOR YOU.

DIY heatbed for Jr.

***Yes you can buy silicone heaters and stick them to the bottom of the glass but usually that requires some drilling/cutting into the metal base of the bed to get wires routed through.

With this solution you'll only lose 2mm of Z height if done correctly.

!!! Just to set things clear - this isn't step by step tutorial. More like brief description.

If you don't understand what I'm talking about then maybe this project isn't for you!

You'll need:

PCB Clad 165x200mm - Jr glass is 165x165, you can get ones which are 165mm wide already of eBay. You need 1x side to be 200 to cut little tab which will stick out so you can solder wires to it.

All chemicals etc for PCB etching. (Deliberately not mentioning what exactly)

Small handsaw.

Soldering iron

16-18AWG wire

12v PSU - AT LEAST 9AMP

Temperature control board

Relay.

Sharpie

Process is very simple.

Print SVG on regular 2D laser printer (laser printer is a MUST)

Transfer print to PCB clad via iron method.

Fix up imperfections with Sharpie

Draw freehand with Sharpie extension traces for the power input so it sticks out a bit on the right hand side of your Jr bed.

Etch!

I had my thermistor cartridge simply capton taped to on side. Not perfect but good enough for me.

But... You could do freehand traces on the bottom of the clad to get thermistor nicely in the middle with traces going out on the side underneath the power in (that's of course if you have double sided PCB clad)

I've covered all surface with capton tape to give it some kind of a insulation.

Wiring.

I've used cheapest available 12v temp controller board of eBay + ATX PC PSU to power it up.

And relay was wired to Jr exhaust fan to make it somewhat automated. That also ensured the bed is switched off automatically when print is done.

I hope all this makes sense.

P.S.: I'll try to find my heatbed and post some actual photos of it.

I've stopped using it only because Jr is no more. Cannibalised for parts.

Similar models

thingiverse

free

PCB Heatbead for Home Etching by triffid_hunter

...my bed up to 140â°c before, and didn't want to take it higher for fear of cracking my glass or damaging the fr4 pcb material.

thingiverse

free

Dell A870P Power Supply to Bench Supply Cover by ktelep

...power supply on, you'll need to short the bottom and third from the bottom pins all the way on the right hand side to ground.

thingiverse

free

Simple Metal Sharpie Adapter by joeyballard

...lver/gold). you can print on thick objects with a flat surface. you can make pcbs if you have some copper clad and etching fluid.

thingiverse

free

Relay Housing for PSU Control

...the ac wires to one side while the control wires are soldered to a pcb and then lead out through a different hole in the housing.

thingiverse

free

Ender 3_PSU Cover Mod

...owever the pcb shows 40w, strange i know...)

https://fr.aliexpress.com/item/33042313383.html?spm=a2g0s.9042311.0.0.27426c37v0ybdo

grabcad

free

relay 12v pcb

...relay 12v pcb

grabcad

relevador de 12v para pcb

thingiverse

free

Printrbot Jr. Heated Aluminum Bed by Alaster

...thightly fix to each other, without any play in the drill holes, the resulting stress could crack and/or destroy the whole setup.

thingiverse

free

XYZ daVinci Jr - RepRapDiscount Smart Controller LCD 2004 by kr15_uk

...e. switch i had in my component draw already.

didn't bothered to trace usb cable hence all prints i did was from the sd card.

thingiverse

free

XYZ daVinci Jr - E3D V6/Lite6 Mount by kr15_uk

...his is that 1st i need to redesign x axis mount at the right. it not going to cary extra stepper early without sagging even more.

thingiverse

free

Quilted Heatbed by Legot

...

currently, the design below gets between 70c and 90c (under glass) when pulling ~5.79a @12v when etched onto 2oz/in copper clad.

Kr15

110W

3ddd

$1

Galimberti Nino_Norma

...nino , norma galimberti nino norma dimensions: 880h x 110w x 40d...

3d_sky

$8

Galimberti Nino_Norma

...galimberti nino norma galimberti nino norma dimensions: 880h x 110w x 40d...

thingiverse

free

PCB heated print bed by josefprusa

...area you can select what resistance you want 1.3ohms (110w at 12v) or 21ohms you dont need any steel...

3dbaza

$3

TILAN chandelier (139307)

...cm<br>m 85 × 52 cm<br>l 135 × 58 cm (110w<br>ceiling mount 46 × 42 cm<br>polys: 6 459<br>verts: 7...

thingiverse

free

Shower caddy mirror holder by schuy

...will secure the mirror in just fine. measures outside: 110w x 78h x 5.5d and accommodates mirror size: 107w...

3dbaza

$3

7471xx Saturno Lightstar Pendant Chandelier (103930)

...lightstar pendant chandelier 3d model<br>747122 - brass<br>747144 - chrome<br>led 110w 9900lm<br>xyz: 700x577x1198 mm<br>polys: 9,700<br>verts: 10,379<br>subdivision ready<br>recommended opensubdiv iterations:<br>0 -...

thingiverse

free

Suzo Happ arcade PSU cover

...is a cover for the suzo happ power pro 110w arcade power supply. it has a 48x28mm opening on...

thingiverse

free

OctoPi Enclosure for TAZ 6 by dkrider

...thanks to the following for the useful cad files: https://cad.onshape.com/documents/db1314645041f433a24b6dc3/w/6aee9c13ac54c11d09e02da0/e/b7de97fc974a48bdc73dd85bhttps://grabcad.com/library/raspberry-pi-3-model-b-reference-design-rpi-raspberrypi-raspberry-pi-solidworks-cad-assembly-1https://grabcad.com/library/iec-320-c14-receptacle-panel-mount-1https://grabcad.com/library/qualtec-738w-x201-plug-snap-adaptor-outlet-110w1https://grabcad.com/library/sainsmart-2-channel-relay-module-1 note that this design is or entertainment purposes only....

cg_trader

$299

JCB hydradig 110w

...dradig 110w

cg trader

3d model jcb hydradig 110w jcb loader, available formats obj, fbx, c4d, stl, ready for 3d animation and ot

9A

3ddd

free

ITALUX LISA MX09080-9A

...italux lisa mx09080-9a

3ddd

italux

светильник подвесной, фирмы italux . модель - lisa. номер по каталогу - mx09080-9a

humster3d

$75

3D model of 9A-91

...ster3d

buy a detailed 3d model of 9a-91 in various file formats. all our 3d models were created maximally close to the original.

3ddd

free

Бра - mathieu lustrerie 995036-9A

...бра - mathieu lustrerie 995036-9a

3ddd

mathieu lustrerie

бра - mathieu lustrerie 995036-9a

моделил по фото, не 100% сходство

turbosquid

$9

Classic Bed `141209`9A

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Magazine (9a-91 VSK-94)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$50

Carbine assault rifle 9a-91 3D Model

...91 carbine kbp

carbine assault rifle 9a-91 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl ronin3ds 103000 3dexport

3ddd

$1

sarri hydria 835852/9a

...lys: 216,746

verts: 220,554

краткое описание коллекции:

возможно заказать в другом размере: 835852/6a - h 98 cm, d 92 cm, 6 ламп

3ddd

$1

Люстра Illuminati Aquarius MD1100331-9A

...ti aquarius md1100331-9a

3ddd

illuminati

размеры: диаметр - 53 см, высота - 60 см. количество ламп - 9х25 вт. материалы - corona.

3d_export

$65

MQ-9 Reaper US Border Security

...mq-9 reaper us border security 3dexport the turboprop-powered, multi-mission mq-9a remotely piloted aircraft (rpa) was developed with ga-asi funding...

3ddd

$1

Люстра ILLUMINATI Corso

...corso 3ddd illuminati , corso итальянская люстра illuminati (corso md103204-9a. описание - 9*g9, d:500,...

Davinci

3ddd

$1

Torre DaVinci 03W

...: davinci 03w

dimensions:

730mm x 575mm x h770mmhttp://www.torre.it/products/contract/chairs-armchairs/da-vinci-03-112

3ddd

$1

Torre DaVinci 04W

...l: davinci 04

dimensions:

730mm x 575mm x h855mmhttp://www.torre.it/products/contract/chairs-armchairs/da-vinci-04-112

turbosquid

$9

Davinci Coin gold coin

...alty free 3d model davinci coin gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1495584)

turbosquid

$5

DaVinci Single Coffee Table

...free 3d model davinci single coffee table for download as max on turbosquid: 3d models for games, architecture, videos. (1540607)

3d_export

$10

Italdesign Davinci Asphalt 9

...at your discretion. instead of textures, blender materials are used, and the color of any part can be changed at your discretion.

3ddd

$1

Cattelan Italia / DaVinci

...75 см

глубина: 75 см

ширина: 140 см

схематичное изображениеhttp://www.ib-gallery.ru/off-line/mebel_file/25949/file.png

3d_export

$7

092 armchair davinci

...t includes four balls with different color materials (gray, brown, light brown, natural wood). on the end there is real plywood))

3d_export

$10

davinci machine

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

3ddd

free

Настенная мозаика DaVinci

...ерация turbosmooth), и простые кубики с фаской - 9000 полигонов.

габариты модели, шхвхг: 50см*50см*1,5см

размер ячейки: 2см*2см

3d_export

$29

Cryptex New 3D Model

...cryptex new 3d model 3dexport cryptex davinci da vinci code criptex enigma mystery riddle game device...

Heatbed

thingiverse

free

HeatBed by moreken

...heatbed by moreken

thingiverse

heatbed for my printer3d "moredelta"

thingiverse

free

heatbed (double heatbed) holder by Vo_Van_163

... bigger size than work desk. this holder - is good solution for me/ and also this is a good solution for double hotbed regulation

thingiverse

free

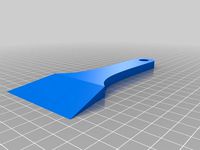

Heatbed Spatula by Brabus453

... spatula by brabus453

thingiverse

heatbed spatula

this is a simple spatula to scrape the heatbed from the first layer residues.

thingiverse

free

Heatbed Mount for round Heatbeds by OliverReinecke

...y bottom board to fix the heatbed-mount. but of coursse there are lots of alternatives to do this... its up to you. hope it helps

thingiverse

free

Heatbed plane test

...eds ... this simple object allows to see where the bonding of the object and the flatness of the heatbed might not be optimal ...

thingiverse

free

Heatbed Knob by Sp0nge

...heatbed knob by sp0nge

thingiverse

craftbot plus heatbed knob

print it in abs and put a nut inside.

thingiverse

free

Heatbed cable cover

... the heatbed when i placing the pei sheet.

so i designed this small cover, it clips right down over the +/- screws on the heatbed

thingiverse

free

Heatbed Mosfet controller by oscar_diciomma

...heatbed mosfet controller by oscar_diciomma

thingiverse

heatbed mosfet controller

thingiverse

free

Parametric Heatbed Clamp by verglor

...y verglor

thingiverse

minimalistic heatbed clamps that do not get in way of nozzle.

can be customized for any heatbed thickness.

thingiverse

free

Heatbed support

...ail

heatbed size 328mm

use m5x10 with washers or m5x8 for the 20x20 profile

m4 for heatbed

can be use with wells of 45mm of diam.

Jr

3ddd

$1

Estilo JR

...estilo jr

3ddd

jori , estilo

кресло: estilo jr-7060

бренд:jori

3ddd

$1

Acne JR Bear

...acne jr bear

3ddd

медведь

авторская мягкая игрушка - круглый мишка acne jr

turbosquid

$30

Robot Jr

... 3d model robot jr for download as ma, c4d, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1697456)

turbosquid

$49

Les Paul Jr.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mega Machine Jr

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Bathroom Set JR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Les Paul Jr Guitar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Floyd Mayweather Jr. bed

... постельное белье

floyd mayweather jr. bed

размеры: x 187см, y 238см, z 132см.

polys: 504 020

verts: 507 851

3d_export

$15

Mega Machine Jr 3D Model

...mega machine jr 3d model

3dexport

car toy wheel photorealistic racing vray model

mega machine jr 3d model eiwari 87383 3dexport

3ddd

$1

Kuppersbusch EDG 6260 JR Steamer

... пароварка

kuppersbusch edg 6260 jr steamer

hot chili edition

polys:45675

verts:48094

пароварка

Xyz

turbosquid

$7

Rusty Metal Letter XYZ

...etras de metal oxidado for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1454094)

turbosquid

$9

XYZ Glass Tube Font - Letras de cristal

...nt - letras de cristal for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1547160)

3d_export

$8

sci-fi sneakers

...located in scene xyz=0,0,0<br>.:::formats:::.<br>.obj / located in scene in xyz0,0,0 .fbx 2006 / located in scene in xyz=0,0,0 .mb...

3d_export

$18

forklift

...maya .:::formats:::. .obj / multiformat located in scene in xyz0,0,0 .fbx / autodesk fbx200611 / located in scene inxyz=0,0,0...

3d_export

$15

golf cart

...autodesk maya .obj / multiformat located in scene in xyz0,0,0 .fbx / autodesk fbx200611 / located in scene inxyz=0,0,0...

3d_export

$10

Birdhouse

...autodesk maya .obj / multiformat located in scene in xyz0,0,0 .fbx / autodesk fbx200611 / located in scene inxyz=0,0,0...

3d_export

$8

tower crane

...** .:::formats:::.** -.obj / multiformat located in scene in xyz0,0,0 -.fbx / autodesk fbx200611 / located in scene inxyz=0,0,0...

3d_export

$15

wooden pier

.../ 3ds max 2016 / located in scene in xyz0,0,0<br>.:::textures::::.<br>handled painted textures.<br>x3 - 4096x4096 / .jpg<br>-color<br>-nrm<br>-bump<br>thanks for...

3d_export

$10

wooden pier winter

.../ 3ds max 2016 / located in scene in xyz0,0,0<br>.:::textures::::.<br>handled painted textures.<br>x3 - 4096x4096 / .jpg<br>-color<br>-nrm<br>-bump<br>thanks for...

3d_export

$5

camping wood table winter

...in xyz=0,0,0<br>.blend / blender 2,79b located in scene in xyz0,0,0<br>1 material<br>.:::textures:::.<br>x2 texture 4096x4096 .jpg (snow, wood)<br>-color<br>-normal map<br>-bump...

12V

turbosquid

$6

12v battery

...royalty free 3d model 12v battery for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1355531)

3ddd

$1

Dolce Porte / Venezia 12V

...

3ddd

dolce porte , дверь

багетные межкомнатные двери dolce porte , полотно 2000х800 mm.

3d_export

$15

Aquacomputer Aquastream XT USB 12V Pump 3D Model

...

water cooling pomp aquacomputer aquastream xt computer

aquacomputer aquastream xt usb 12v pump 3d model mackandco 37582 3dexport

3d_export

$10

relay jd1912 12v 40a with connector

...lowing bodies: 1. relay jd1912 12v 40a - 1 piece; 2. connector housing - 1 piece; 3. terminal with a part of the wire - 4 pieces.

3d_export

$5

CHC3512CB fan

...chc3512cb fan 3dexport solidworks 3d model of chc3512cb 35mm 12v fan for...

3ddd

free

Люстра Quasar

...sizes: *38 x e 5/8 12v/1.2w 1 x gy6.35 12v75w l 76 x e 5/8 6v/1.2w 1 x gy6.35...

3ddd

$1

MW-LIGHT Федерика

...379013512 высота 34 см диаметр 55 см 12х20w g4 12v рекомендуемая площадь освещения: 16 кв....

3ddd

$1

ILFARI. TEARS FROM MOON H34

...munsters описание: 34 x g4 | 10w max. | 12v включительно светильники 4 x led 3.2w | 2700k |...

3ddd

$1

ILFARI. TEARS FROM MOON H22

...munsters описание: 22 x g4 | 10w max. | 12v включительно светильники 3 x led 3.2w | 2700k |...

3ddd

$1

Lightstar / Boogie Vetro OP

...источники света: 1x50wmax gu5,3 (mr16) (лампой не комплектуется) напряжение: 12v220v диаметр: 80мм высота: 70мм диаметр врезного отверстия: 55мм глубина...

Uk

turbosquid

$40

UK sockets

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Uk Map

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

UK Spitfire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

UK Flag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Диван Chesterfield UK flag

...диван chesterfield uk flag

3ddd

chesterfield

диван chesterfield uk flag

cg_studio

$15

UK Phonebooth3d model

...phonebooth3d model

cgstudio

.lws .lwo - uk phonebooth 3d model, royalty free license available, instant download after purchase.

turbosquid

$39

Woman Shoe UK

...quid

royalty free 3d model woman shoe uk for download as max on turbosquid: 3d models for games, architecture, videos. (1462477)

turbosquid

$1

UK Pound Symbol

...id

royalty free 3d model uk pound symbol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560784)

turbosquid

$19

Manhole Covers UK

...y free 3d model manhole covers uk for download as max and max on turbosquid: 3d models for games, architecture, videos. (1575421)

3d_ocean

$10

UK Road Signs

... hexagonal, triangle and double circle signs. each model is separate and named accordingly. these models are perfect for an ar...

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

1

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

turbosquid

$50

door 1 darkwood 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Printing

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints