Thingiverse

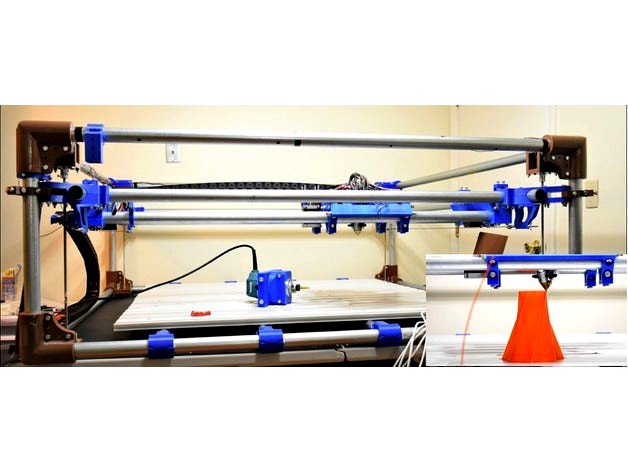

XLNC 2 - All in One Mill, 3D printer with custom Repetier Host CNC plugin and SolidWorks HSM post by crunchysann

by Thingiverse

Last crawled date: 3 years ago

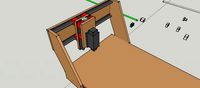

Details of XLNC Rev 2.

If you are looking for the original XLNC - Rev 1, click here https://www.thingiverse.com/thing:1855391

Follow project updates on https://crunchysann.com/

Assembly videos in change-log below or click on any video to jump to the youtube playlist:

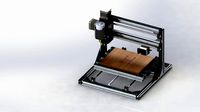

Basic final specs as pictured.

Machine footprint: 5'-5'-2.2'(L-W-H) (You can simply use shorter tubing to make a smaller, much more rigid machine)

Very large Build Volume when 3D printing: 32in-40in-12in(L-W-H) or 800mm X 800mm X 305mm

Very large Area when Milling: 32in-40in-Tool length (~4" +)

Motion: 1.25in ID (38.3mm)OD. Electrical conduit with user adjustable roller bearings

Use these SS tubes instead if you want to expand your machine cutting/ printing area past the specs above and for smoother finish on prints. Direct swap with no additional modifications. 1.5" OD 304 stainless steel rails. https://www.speedymetals.com/pc-4485-8276-1-12-od-x-065-wall-tube-304-stainless-steel-annealed.aspx

Materials supported: Cutting medium to soft grade aluminum and other softer materials

Intended usage CNC milling, Laser etching/cutting. 3D printing multiple objects simultaneously

Design Features:

Gantry on Z axis: The Gantry goes up and down on this design.

Steel re-enforced belts: Use 9 -10mm wide T5 - 5mm pitch (best) or GT3 spec belts and pulleys (MXL belts will fail very early ~ 10hrs use).

Stackable: Many of these machines can be stacked on top of one another

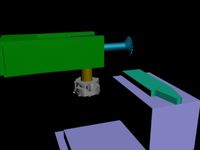

Support for toolset expansion: The gantry is made to support Wood routers, Dremels, heavy spindles, 3D printing filament Extruders (1 and up using mounting brackets), and is intended to support future robotic arm addition for hybrid 3D printing and finish milling operations.

Enclosure friendly: Since all movements are constrained within the machine's footprint, a full enclosure can be made for it.

Stiffer XY gantry: Future tests will be performed to get some actual numbers as to how accurately this particular design can cut hard materials. Since 3D printed parts are not well suited for FEA simulations, do not expect such testing to occur.

Adjustable Belt and Bearings: Belt tension is achieve using off the shelf products you can source at your local hardware store.

INSTRUCTIONS:

Download the following items:

"Rev 2.ZIP": This contains all mechanical STL and SolidWorks Part files for this machine. This is all you need in case you plan to use your own motion controllers (electronics) other than what is listed on this page.

"BOM.XLS": Bill of Materials (Mechanical BOM is posted with McMaster Part numbers where appropriate).

"XLNC PANEL BETA 1.ZIP": This is the XLNC plugin for Repetier Host (Extract and see installation instructions.docx file for install instructions)

"HSMWorks_3_Axis_Repetier_Rev5.js": Custom post-processor for SolidWorks HSMWorks (currently limited to 3 Axis X,Y,Z).

If using Vectric Aspire, download the Vectric Post for XLNC (Pending Upload).

Watch assembly instructions

Build your own enclosure or the one that will be uploaded

Update 1/14/2018: - Part 1 video added

https://www.youtube.com/watch?v=hzuDyIrcUQg&index=2&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/15/2018: - Part 2 video added

https://www.youtube.com/watch?v=tO6ayekEFwg&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

-Assembling XY gantry

-Lastest STL files uploaded.

Update 1/16/2018: - Part 3 video added

https://www.youtube.com/watch?v=f6cAQV4VIGY&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

Update 1/16/2018: - Part 4 video added

https://www.youtube.com/watch?v=wPU8iiuRFs8&index=1&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/16/2018: - Part 5 video added (updated video)

https://www.youtube.com/watch?v=5u6sC4Ff8es&t=25s&index=1&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/17/2018:

New set of files uploaded (Includes fix for Z-axis roller couplers and new belt anchors)

Update 1/20/2018: - Part 6 video added

https://www.youtube.com/watch?v=ZNme7Kf5HWQ&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

Frame assembly completed successfully

Repetier CNC Plugin updated (GUI, DB backend)

Main frame design frozen. now routing belts

Update 1/28/2018: - Part 6B video added

Upgraded belt idler pulleys

Adjusted X axis belt anchor height to keep belts parallel to tubing

Rev 2. ZIP updated with new files

https://www.youtube.com/watch?v=ripbuyeqBGg

Update 1/30/2018: - Part 7 video added

Rev 2.ZIP updated: Added solidworks Part files

https://www.youtube.com/watch?v=X2mzTKvzbjw

Update 1/31/2018:

Rev 2.ZIP updated: Added Wire guide chain anchors for X / Y axis

Update 2/9/2018:

Rev 2.ZIP updated: Added Bed pipe holders

Update 2/23/2018:

Rev 2.ZIP updated: Added revised Bed pipe holders motors have been wired. adjusting repetier firmware

XLNC panel plugin status: Adjusting for execution on AMDx64 processors.

Update 3/11/2018:

Added 3D models for Diamond hot-end mount

Upgraded bed mounting brackets for stronger parts

Fixed panel compatibility with AMDx64 processors

Packaging XLNC Panel public Beta 1.

Parts Zip file updated.

Update 3/13/2018:

Snowed in sooooooo ¯_(ツ)_/¯

Shortened diamond hot-end spacer length

Updated REV2.ZIP file with latest models.

HSMWorks BETA post-processor added (3-Axis initially), generates Repetier and Marlin compatible G-code --Install HSMWorks (or free version) in solidworks and load this custom G-code (maybe video will follow once XLNC panel is released).

Update 3/17/2018:

Updated Diamond hotend mount to hold direct bowden style motors closer to extruder.

Assembly video: https://youtu.be/Vfb4KvHMQag

Update 4/1/2018:

Uploaded rudimentary mechanical BOM: QTY is for each piece (Not Packs). McMaster part numbers are added where appropriate, but feel free to source parts elsewhere.

Uploaded Solidworks source files and Mechanical assembly in MainFrame.Zip file.

Update 4/22/2018:

Uploaded XLNC Panel Beta 1 -- See File named XLNC PANEL BETA 1.ZIP

--Description: Built-in user interface for users of Repetier Host and Repetier/Marlin firmware to streamline usage of their printers as CNC mills or Laser cutters.

-- Currently Limited to 3 Axes but plans for 4 Axes may happen.

Installation instructions:

extract or unzip XLNC PANEL BETA 1.ZIP and read the installation instruction doc file

Update 4/25/2018:

Added basic wiring diagram explaining how to connect RADDS board to multiple GRBL shields, see file named "High level wiring diagram.pptx".

Update 5/9/2018:

printing calibration cubes with diamond hotend.

And a vase: https://youtu.be/9yQQ-uZJ8BM

Update 5/27/2018:

Calibration completed

Uploaded new Mixing extruder mount. Allows usage of Bstruder bowden style filament drive (https://www.thingiverse.com/thing:711401) with the diamond hotend. Instructions: Download zip file Rev2.zip..print the parts inside Rev2.zip/New Parts/Diamond Extruder Mount. Assembly is very simple (see instructions and screw dimensions on thing 711401)

Update 6/5/2018:

Well, the MXL belts broke (they weren't adequate either way) -- time for 9mm wide HTD steel fiber reinforced belts and pulleys (5mm pitch)

Pending update to XLNC Panel app to allow external gcode file execution

Started planning camera based tool offset alignment ad-don.

Update 6/25/2018

upgraded belts to 9mm wide 5mm pitch htd belts with 12 tooth pulleys

upgrading all steppers to nema 23 260oz for all around faster acceleration and cutting.

Potential upgrade to 1.5" OD 304 stainless steel rails for smoother finish on prints. https://www.speedymetals.com/pc-4485-8276-1-12-od-x-065-wall-tube-304-stainless-steel-annealed.aspx

pending upload of revised yx belt tensioner anchors

Sick of corner braces cracking during assembly...redesigning the 8 frame corner braces.

Update 6/30/2018

Testing new frame coupling design, see thing https://www.thingiverse.com/thing:2984817

The idea is to get a strong grip on electrical conduit without cracking the plastic pieces. --

This requires new Z axis motor mount for NEMA 17/23

Added bed leveling clamps for use on Glass bed when using as 3D printer.

Update 7/20/2018

re-enabling work in progress indicator due to upcoming upgrades to the z axis

apparently underestimated the thursts/forces applied to lower bearings and cheaping out on these leads to failed bearings on the z axis.

remodeling z axis frame supports so they can be attached to thing 2984817

searching for heavy duty drop in replacement lower thrust bearings

upgraded grbl shields to tb6560 boards for the time being (highly recommend 4 nema 23 motors for z axis and heavy duty drivers.)

Update 8/4/2018

Testing new Z axis mounts and drive nut mount

All printed parts can now be assembled without worrying about breaking plastic parts

All X,Y,Z Motor drivers upgraded to DM542T (RADDS board remains the motion controller)

Planing a new site to host projects and updates...Look forward to XLNC REV 3 (hopefully the last one :)

Update 2/20/2019

Planning project migration to its own website.

Project updates will be posted on this site from here on.

Follow my project here: https://crunchysann.com/BL/projects/

If you are looking for the original XLNC - Rev 1, click here https://www.thingiverse.com/thing:1855391

Follow project updates on https://crunchysann.com/

Assembly videos in change-log below or click on any video to jump to the youtube playlist:

Basic final specs as pictured.

Machine footprint: 5'-5'-2.2'(L-W-H) (You can simply use shorter tubing to make a smaller, much more rigid machine)

Very large Build Volume when 3D printing: 32in-40in-12in(L-W-H) or 800mm X 800mm X 305mm

Very large Area when Milling: 32in-40in-Tool length (~4" +)

Motion: 1.25in ID (38.3mm)OD. Electrical conduit with user adjustable roller bearings

Use these SS tubes instead if you want to expand your machine cutting/ printing area past the specs above and for smoother finish on prints. Direct swap with no additional modifications. 1.5" OD 304 stainless steel rails. https://www.speedymetals.com/pc-4485-8276-1-12-od-x-065-wall-tube-304-stainless-steel-annealed.aspx

Materials supported: Cutting medium to soft grade aluminum and other softer materials

Intended usage CNC milling, Laser etching/cutting. 3D printing multiple objects simultaneously

Design Features:

Gantry on Z axis: The Gantry goes up and down on this design.

Steel re-enforced belts: Use 9 -10mm wide T5 - 5mm pitch (best) or GT3 spec belts and pulleys (MXL belts will fail very early ~ 10hrs use).

Stackable: Many of these machines can be stacked on top of one another

Support for toolset expansion: The gantry is made to support Wood routers, Dremels, heavy spindles, 3D printing filament Extruders (1 and up using mounting brackets), and is intended to support future robotic arm addition for hybrid 3D printing and finish milling operations.

Enclosure friendly: Since all movements are constrained within the machine's footprint, a full enclosure can be made for it.

Stiffer XY gantry: Future tests will be performed to get some actual numbers as to how accurately this particular design can cut hard materials. Since 3D printed parts are not well suited for FEA simulations, do not expect such testing to occur.

Adjustable Belt and Bearings: Belt tension is achieve using off the shelf products you can source at your local hardware store.

INSTRUCTIONS:

Download the following items:

"Rev 2.ZIP": This contains all mechanical STL and SolidWorks Part files for this machine. This is all you need in case you plan to use your own motion controllers (electronics) other than what is listed on this page.

"BOM.XLS": Bill of Materials (Mechanical BOM is posted with McMaster Part numbers where appropriate).

"XLNC PANEL BETA 1.ZIP": This is the XLNC plugin for Repetier Host (Extract and see installation instructions.docx file for install instructions)

"HSMWorks_3_Axis_Repetier_Rev5.js": Custom post-processor for SolidWorks HSMWorks (currently limited to 3 Axis X,Y,Z).

If using Vectric Aspire, download the Vectric Post for XLNC (Pending Upload).

Watch assembly instructions

Build your own enclosure or the one that will be uploaded

Update 1/14/2018: - Part 1 video added

https://www.youtube.com/watch?v=hzuDyIrcUQg&index=2&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/15/2018: - Part 2 video added

https://www.youtube.com/watch?v=tO6ayekEFwg&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

-Assembling XY gantry

-Lastest STL files uploaded.

Update 1/16/2018: - Part 3 video added

https://www.youtube.com/watch?v=f6cAQV4VIGY&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

Update 1/16/2018: - Part 4 video added

https://www.youtube.com/watch?v=wPU8iiuRFs8&index=1&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/16/2018: - Part 5 video added (updated video)

https://www.youtube.com/watch?v=5u6sC4Ff8es&t=25s&index=1&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm

Update 1/17/2018:

New set of files uploaded (Includes fix for Z-axis roller couplers and new belt anchors)

Update 1/20/2018: - Part 6 video added

https://www.youtube.com/watch?v=ZNme7Kf5HWQ&list=PL0kmIN05eLBDeOtj7yNt0PjGFq_5XDcCm&index=1

Frame assembly completed successfully

Repetier CNC Plugin updated (GUI, DB backend)

Main frame design frozen. now routing belts

Update 1/28/2018: - Part 6B video added

Upgraded belt idler pulleys

Adjusted X axis belt anchor height to keep belts parallel to tubing

Rev 2. ZIP updated with new files

https://www.youtube.com/watch?v=ripbuyeqBGg

Update 1/30/2018: - Part 7 video added

Rev 2.ZIP updated: Added solidworks Part files

https://www.youtube.com/watch?v=X2mzTKvzbjw

Update 1/31/2018:

Rev 2.ZIP updated: Added Wire guide chain anchors for X / Y axis

Update 2/9/2018:

Rev 2.ZIP updated: Added Bed pipe holders

Update 2/23/2018:

Rev 2.ZIP updated: Added revised Bed pipe holders motors have been wired. adjusting repetier firmware

XLNC panel plugin status: Adjusting for execution on AMDx64 processors.

Update 3/11/2018:

Added 3D models for Diamond hot-end mount

Upgraded bed mounting brackets for stronger parts

Fixed panel compatibility with AMDx64 processors

Packaging XLNC Panel public Beta 1.

Parts Zip file updated.

Update 3/13/2018:

Snowed in sooooooo ¯_(ツ)_/¯

Shortened diamond hot-end spacer length

Updated REV2.ZIP file with latest models.

HSMWorks BETA post-processor added (3-Axis initially), generates Repetier and Marlin compatible G-code --Install HSMWorks (or free version) in solidworks and load this custom G-code (maybe video will follow once XLNC panel is released).

Update 3/17/2018:

Updated Diamond hotend mount to hold direct bowden style motors closer to extruder.

Assembly video: https://youtu.be/Vfb4KvHMQag

Update 4/1/2018:

Uploaded rudimentary mechanical BOM: QTY is for each piece (Not Packs). McMaster part numbers are added where appropriate, but feel free to source parts elsewhere.

Uploaded Solidworks source files and Mechanical assembly in MainFrame.Zip file.

Update 4/22/2018:

Uploaded XLNC Panel Beta 1 -- See File named XLNC PANEL BETA 1.ZIP

--Description: Built-in user interface for users of Repetier Host and Repetier/Marlin firmware to streamline usage of their printers as CNC mills or Laser cutters.

-- Currently Limited to 3 Axes but plans for 4 Axes may happen.

Installation instructions:

extract or unzip XLNC PANEL BETA 1.ZIP and read the installation instruction doc file

Update 4/25/2018:

Added basic wiring diagram explaining how to connect RADDS board to multiple GRBL shields, see file named "High level wiring diagram.pptx".

Update 5/9/2018:

printing calibration cubes with diamond hotend.

And a vase: https://youtu.be/9yQQ-uZJ8BM

Update 5/27/2018:

Calibration completed

Uploaded new Mixing extruder mount. Allows usage of Bstruder bowden style filament drive (https://www.thingiverse.com/thing:711401) with the diamond hotend. Instructions: Download zip file Rev2.zip..print the parts inside Rev2.zip/New Parts/Diamond Extruder Mount. Assembly is very simple (see instructions and screw dimensions on thing 711401)

Update 6/5/2018:

Well, the MXL belts broke (they weren't adequate either way) -- time for 9mm wide HTD steel fiber reinforced belts and pulleys (5mm pitch)

Pending update to XLNC Panel app to allow external gcode file execution

Started planning camera based tool offset alignment ad-don.

Update 6/25/2018

upgraded belts to 9mm wide 5mm pitch htd belts with 12 tooth pulleys

upgrading all steppers to nema 23 260oz for all around faster acceleration and cutting.

Potential upgrade to 1.5" OD 304 stainless steel rails for smoother finish on prints. https://www.speedymetals.com/pc-4485-8276-1-12-od-x-065-wall-tube-304-stainless-steel-annealed.aspx

pending upload of revised yx belt tensioner anchors

Sick of corner braces cracking during assembly...redesigning the 8 frame corner braces.

Update 6/30/2018

Testing new frame coupling design, see thing https://www.thingiverse.com/thing:2984817

The idea is to get a strong grip on electrical conduit without cracking the plastic pieces. --

This requires new Z axis motor mount for NEMA 17/23

Added bed leveling clamps for use on Glass bed when using as 3D printer.

Update 7/20/2018

re-enabling work in progress indicator due to upcoming upgrades to the z axis

apparently underestimated the thursts/forces applied to lower bearings and cheaping out on these leads to failed bearings on the z axis.

remodeling z axis frame supports so they can be attached to thing 2984817

searching for heavy duty drop in replacement lower thrust bearings

upgraded grbl shields to tb6560 boards for the time being (highly recommend 4 nema 23 motors for z axis and heavy duty drivers.)

Update 8/4/2018

Testing new Z axis mounts and drive nut mount

All printed parts can now be assembled without worrying about breaking plastic parts

All X,Y,Z Motor drivers upgraded to DM542T (RADDS board remains the motion controller)

Planing a new site to host projects and updates...Look forward to XLNC REV 3 (hopefully the last one :)

Update 2/20/2019

Planning project migration to its own website.

Project updates will be posted on this site from here on.

Follow my project here: https://crunchysann.com/BL/projects/

Similar models

grabcad

free

6 DoF Robotic Arm & Tutorials

...ith tutorials if allah wishes

-

i'm interested in this projects

from an educational point of view

more than the design itself

thingiverse

free

CoreXY nozzle bracket parts

...ssemble manual video >>

https://www.youtube.com/watch?v=wbkbhfhttru&list=plo1yu3ldklualka_uhxuzh_hsbroluydw&index=3

thingiverse

free

Eon - SCARA Printer by KoalDesigns

...i

first print - https://www.youtube.com/watch?v=x69hjbc8okc

harmonic drive progress - https://www.youtube.com/watch?v=kowa8qmoj_k

thingiverse

free

A parts by havefun199902

...ube&list=plukc3b1mamaupeyzjyaxm7yfqup-rji7z&index=6

a parts.

all assembly parts:https://www.thingiverse.com/thing:4558592

thingiverse

free

XLNC 1 - Xtra Large CNC Machine - Mill/3DPrint/Laser etch w/Custom GUI - OBSOLETE - SEE REV 2 by crunchysann

...motor mounts. y carriage is being modified to use similar parts. update 11/14/16: updated x and y carriage 3d...

thingiverse

free

RC plane fuselage - Eclipson model Z by Eclipson

...amp;list=plbdvqnriqyopko62ncf060sprphxwppp4

-have a look our latest design: https://www.youtube.com/watch?v=jirakadhzey&t=15s

thingiverse

free

Drawing Machine Grbl CoreXY 0.9j with Axis Ends by IuriiKashitsin

... draw.

this project include all files: stl + video + grbl09_corexy.rar + photos

updated 28.08.2017

add kernel_holder_with_springs

thingiverse

free

B parts by havefun199902

...s://www.youtube.com/watch?v=blctbzim4le&feature=youtu.be

b parts

all assembly parts:https://www.thingiverse.com/thing:4558592

grabcad

free

Robotic Arm (Solidworks)

...w.youtube.com/watch?v=w5vg4sndxp8&list=wl&index=5

3-- https://www.youtube.com/watch?v=aquagphplkq&list=wl&index=6

grabcad

free

Pipe wrench

.... design by video tutorial

https://www.youtube.com/watch?v=za-8maaz1yu&list=plkwx3xup3ppo77gfcyy669si76qja5jkw&index=29

Crunchysann

thingiverse

free

Shelish Lamp by crunchysann

...odologies at this point and seeing what can be produced. stay tuned.

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Tear lamp by crunchysann

...odel, the better. this model is in mm and almost 90 mm high. enjoy:)

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

LED curved lamp by crunchysann

...mp to shine the led light through the top or bottom opening.

enjoy

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Spiral Lamps by crunchysann

...ot; tab.

http://youtu.be/qvbz4btnjtwhttp://youtu.be/elo-dct9ro0

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Vw speaker grill adapter by crunchysann

...use 1.5" long philips head screws and nuts to hold it in place.

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Shapeoko 2 NEMA 23 Motor spacer and stabilizer by crunchysann

...

this plate is 6.15mm thick. use to offset your nema size 23 motors

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

XY Light duty stage - for Cartersian 3D printer by crunchysann

...ww.youtube.com/watch?v=lpnraxckp40&list=uuvtjj6q_ism1z9sjlrm3krg

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Shapeoko 2 Ryobi TR45 router mount REV2 with hose mount - adjustable by crunchysann

... allows the drill bits to reach all the way down to the waste-board.

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

Z axis mount plate upgrade for Shapeoko by crunchysann

... and is designed to accomodate both nema 17 and 23 motors. have fun.

follow my project here: https://crunchysann.com/bl/projects/

thingiverse

free

3DHUBS Alternative Quality Test Model by crunchysann

... orientations and include supports to see how your printer performs.

follow my project here: https://crunchysann.com/bl/projects/

Hsm

turbosquid

$10

Sigma 40mm F1 4 DG HSM

...model sigma 40mm f1 4 dg hsm for download as ma, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1554511)

3dfindit

free

HSM

...hsm

3dfind.it

catalog: festo

3dfindit

free

HSM

...hsm

3dfind.it

catalog: festo

3dfindit

free

HSM

...hsm

3dfind.it

catalog: festo

thingiverse

free

Replacement Switch for HSM Card Shredder by Maesmelan

...replacement switch for hsm card shredder by maesmelan

thingiverse

replacement switch for hsm shredder.

3dfindit

free

Hand control HSM-OD-2LD Rev 6

...hand control hsm-od-2ld rev 6

3dfind.it

catalog: tec24

3dfindit

free

Hand control HSM-OD-2LD Rev 6

...hand control hsm-od-2ld rev 6

3dfind.it

catalog: tec24

thingiverse

free

Panasonic 25mm Hair-Tool for Panasonic ER-GP80 and Panasonic HSM ER-DGP82 by LoetziOetzi

...p80 and panasonic hsm er-dgp82 by loetzioetzi

thingiverse

this is my 25mm tool for panasonic er-gp80 and panasonic hsm er-dgp82.

thingiverse

free

Second generation Sigma 70-200 f2.8 APO DG HSM by Ballistyx

... the sigma 70-200 f2.8 apo dg hsm and to add dimples on each side so it's easy to see when the hood is aligned with the lens.

thingiverse

free

Lenshood for Sigma 18-35mm F1,8 DC HSM Art (like LH780-06)

...i lost my original one, so i don't have the original sizes of the hood.

it fits perfectly on my lens with the given settings.

Repetier

thingiverse

free

Rostock max models for Repetier-Host by BrOncO

...rostock max models for repetier-host by bronco

thingiverse

rostock max models for repetier-host view

thingiverse

free

ATOM Proton/Neutron print bed for Repetier setting by philxing

...atom proton/neutron print bed for repetier setting by philxing

thingiverse

stls for repetier-host printer setting.

thingiverse

free

Hatchbox Alpha Repetier 1.0.0 by Masterkookus

...the ui.cpp included instead.

--final--

i have moved to marlin due to stability issues, i won't be updating this configuration

thingiverse

free

Alfawise U30 - Skin - printer model for repetier host by douglasperaza1

...t - data - models

2- abrir repetier host

3- ir a configuracion

configurar impresora

dimensiones impresora - printer visualization

thingiverse

free

skyrim Daedric Bow to pieces (escale 6/7 in repetier) by Dante9666

...skyrim daedric bow to pieces (escale 6/7 in repetier) by dante9666

thingiverse

daedric bow, prusa i3 escale 6 / 7 in repetier

thingiverse

free

TronXY X5S Repetier 0.92.6 Firmware by The_Wizard

...nt to run marlin.. :)

enjoy!

rep 1.0 to come as soon as i can get it to fit the 1284p. this may require disabling some features.

thingiverse

free

Duplicator 3 stl to use in repetier host by r0naldo

...ere is the option to add a stl with the design of your printer, then i put it from mine, and i thought it was nice, see the photo

thingiverse

free

Hephestos Repetier Firmware by Wingman94

...www.repetier.com/firmware/v092/index.html

disclaimer: use at your own risk! i am not reponsible for any damage to your printer.

thingiverse

free

Repetier Raspberry pi server by wezze

...berry-pi/easy-install.

updated 2017-02-05

new font

optional bottom stl with 7mm hole for button to activate safe shutdown script.

thingiverse

free

Repetier 1.0.3 firmware for Zonestar P802N by salvogi

...used.

i posted only the configuration and language files, you need to download the rest of the firmware from the repeater wesite.

Host

3ddd

$1

SWAN Host sofa L206

...st l206

ширина: 100 см.

длина: 250 см.

высота: 80 см.

в архиве 2 вида ткани.http://www.swanitaly.com/category/divani/

3ddd

$1

Ralph Lauren CONSERVATORY GARDEN HOST CHAIR

... conservatory , garden host

ralph lauren conservatory garden host chair

turbosquid

$39

simple host character for presentations

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

кресло Bernhardt Marquesa Host Dining Chair

...ресло bernhardt marquesa host dining chair

3ddd

bernhardt

кресло bernhardt marquesa host dining chair:

l- 68см, w- 78см, h-116см.

3ddd

$1

Hickory Chair Martin Host With Loose Cushion

...artin host with loose cushion

3ddd

hickory

hickory chair_martin host with loose cushion and arms ash-art 150-01 (d.76 w.64 h.116)

3ddd

$1

Lexington Talbott Upholstered Host Chair

...sions:

24w x 26½d x 40h in.

inside width: 20½ in.

inside depth: 19¼ in.

seat height: 19¼ in.

3d_export

$14

icons data center and hosting

...ender. there are 10 icons in the collection. for your concepts as well as the icons on your website. vertices 46.865 faces 43.055

3d_export

$12

tropical - balfour host chair

...export

dimensions: 28.5w x 31d x 45.5h in. arm height: 24.75 in. seat height: 19.5 in. inside width: 23 in. inside depth: 21 in.

3ddd

$1

Радиусный диван SWAN Host

...одителя: www.swanitaly.com

диванная группа состоит из трех модулей. диаметр: 5360 мм. файл закачки содержит 2015.max и 2012.max

3ddd

$1

Hickory Martin Host Chair 150-02

...ot; h \ 55cm h

для fbx прилагается библиотека материалов.

здесь другие мои модели:http://3ddd.ru/users/jekson777/models

Mill

design_connected

$18

Mills

...mills

designconnected

minotti mills computer generated 3d model. designed by dordoni, rodolfo.

3ddd

$1

Mille Nuits

...mille nuits

3ddd

mille nuits

люстра из коллекции mille nuits

turbosquid

$25

Mill

...ll

turbosquid

royalty free 3d model mill for download as fbx on turbosquid: 3d models for games, architecture, videos. (1292872)

turbosquid

$15

The Mill

...urbosquid

royalty free 3d model the mill for download as obj on turbosquid: 3d models for games, architecture, videos. (1459219)

turbosquid

$3

Mill

...ll

turbosquid

royalty free 3d model mill for download as max on turbosquid: 3d models for games, architecture, videos. (1233201)

turbosquid

$1

mill

...

turbosquid

royalty free 3d model mill for download as blend on turbosquid: 3d models for games, architecture, videos. (1613409)

3d_export

$10

Coffee Mill

...coffee mill

3dexport

coffee mill

3d_export

$5

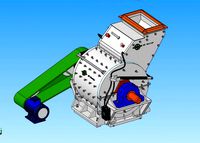

impact mill

...impact mill

3dexport

impact mill

archibase_planet

free

Milling machine

...base planet

milling machine miller milling-machine

milling machine vhf-680 n250413 - 3d model (*.gsm+*.3ds) for 3d visualization.

3ddd

$1

Minotti / Mills

...minotti / mills

3ddd

minotti

minotti / mills

Plugin

turbosquid

$6

Switches & Plugins collection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Water Shader (No Plugins) 3ds Max

... 3ds max

3docean

photo realistic 3ds max water shader requiring no 3rd party plug-ins or renderers. contains preview scene file.

3d_export

$5

Contemporary Brushed Nickel Finish Plugin Sconce 3D Model

...ntemporary brushed nickel finish plug-in sconce

contemporary brushed nickel finish plugin sconce 3d model render74 52146 3dexport

3d_export

$59

Rayfire plugins fragmention wall on car 3D Model

...eck break down wreak havoc blow up burst detonate

rayfire plugins fragmention wall on car 3d model rahman.najafian 87890 3dexport

3d_export

$5

four swords lightsaber battered lightsaber steel sword battered steel sword with plugins

...d steel sword with plugins

3dexport

four swords, lightsaber, battered lightsaber, steel sword, battered steel sword with plugins

3d_export

$99

3D Model Toyota Prius PHV 2012 Plugin Purius 3D Model

...12 2013 gs max 3ds fbx obj dxf sport coupe phv plug-in

3d model toyota prius phv 2012 plugin purius 3d model poal7 51644 3dexport

turbosquid

$899

Rotors II - 7 Pre-Rigged Helicopters for Craft Director Studio and 1 Premium Plugin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Иисус

...3ddd статуэтка для правильного отображения текстуры установите бесплатные плагины siger:http://www.sigerstudio.eu/shop/plugin-free/sigertexmap-complexfresnel/ http://www.sigerstudio.eu/shop/plugins-free/sigertexmaps-sigernoise/ http://www.sigerstudio.eu/shop/plugins-free/sigertexmaps-sigerscratches/ http://www.sigerstudio.eu/shop/plugins-free/sigertexmap-thinfilm/ ...

3d_export

$5

Office Restroom

...scene, you need download and install very useful free plugin colorcorrect for your version 3dsmax (2008-2022): https://cuneytozdas.com/3ds-max-plugins/ there is...

3d_ocean

$6

Minion model no texture

...minion model no texture 3docean no plugin ...

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Post

archibase_planet

free

Post

...post

archibase planet

barrier pole post pillar

fence post 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$1

Post-it

...emporary website: http://marcinbauer.com ) features: - easy switch of post-it texture and color - you can very easily change t...

3d_ocean

$2

Post-It

...st-it tack tic work

*originally created in blender 3d. exported to different formats: .obj;.3ds;.blend;.dae;.fbx;.ply;.x3d;.mtl .

3d_export

free

Post

...post

3dexport

turbosquid

$7

Post

...lty free 3d model post for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1150679)

3d_export

$5

sidewalk post

...sidewalk post

3dexport

sidewalk post

turbosquid

free

Post

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

post box

...post box

3dexport

american post box

archibase_planet

free

Steel Post

...steel post

archibase planet

fence balustrade

balustrade steel post

archibase_planet

free

Guard post

...base planet

guard post checkpoint building check point

guard post n191015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Custom

3ddd

free

Customized

...customized

3ddd

комод

customized, chest, cabinet

3d_export

$50

Custom motorcycle

...custom motorcycle

3dexport

custom motorcycle

3d_export

$21

Funko custom

...funko custom

3dexport

funko custom

turbosquid

$2

Customs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Customs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Custom Car

...turbosquid

royalty free 3d model custom car for download as on turbosquid: 3d models for games, architecture, videos. (1584212)

3d_export

$7

Custom glasses

...custom glasses

3dexport

3d custom glasses;<br>textured with non overlapping<br>rigged: yes

turbosquid

$80

Custom sportbike

...d

royalty free 3d model custom sportbike for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313435)

turbosquid

$30

custom truck

...squid

royalty free 3d model custom truck for download as max on turbosquid: 3d models for games, architecture, videos. (1329357)

turbosquid

$10

custom alien

...squid

royalty free 3d model custom alien for download as fbx on turbosquid: 3d models for games, architecture, videos. (1244065)

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Solidworks

turbosquid

$6

Practice in SolidWorks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Pillar staircase solidworks

...ar staircase solidworks for download as stl, sldpr, and sldas on turbosquid: 3d models for games, architecture, videos. (1149346)

turbosquid

$40

Light bulb Solidworks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Barbuta helmet - Solidworks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

Solidworks Parts Collection

...ollection for download as sldpr, sldas, sldpr, ige, and sldpr on turbosquid: 3d models for games, architecture, videos. (1638624)

turbosquid

$13

Metal workbench for garage. Solidworks

...el metal workbench for garage. solidworks for download as obj on turbosquid: 3d models for games, architecture, videos. (1478129)

turbosquid

$4

6 Nations Trophy SolidWorks

...ee 3d model 6 nations trophy solidworks for download as sldas on turbosquid: 3d models for games, architecture, videos. (1363060)

turbosquid

$20

METAL CHAIR SOLIDWORKS 2017

...del metal chair solidworks 2017 for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1226511)

turbosquid

$14

Metal Fence with spears solidworks

...etal fence with spears solidworks for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1478085)

turbosquid

$10

SolidWorks Standard wall bracket

...orks standard wall bracket for download as , sldpr, and sldas on turbosquid: 3d models for games, architecture, videos. (1241419)

One

turbosquid

$2

one plus one

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

One

...one

3ddd

стул

офисный стул one

3ddd

free

one

...

palazetti one ,http://palazzetti.ca/index.php/component/virtuemart/seating/armchairs-lounges/one-chair-detail?itemid=0

turbosquid

$35

One A

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

One

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Стул One

...стул one

3ddd

one , magis

кресло magis s.p.a , one

3ddd

$1

Стул One

...стул one

3ddd

one , magis

кресло one chair (4star), magis s.p.a.

3d_export

$20

xbox one

...xbox one

3dexport

xbox one

3ddd

$1

xbox one

... консоль , джойстик

xbox one + kinect + gamepad

3ddd

free

One

...nstantin grcic

артикул ct-284 (cosmorelax.ru)

размер l36xw41xh82.5, sh 77cm

цвет черный, красный

материал алюминий

вес 2,5 кг

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.