Thingiverse

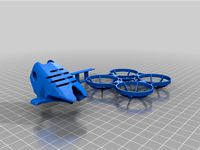

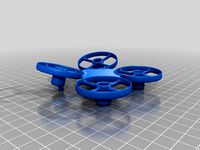

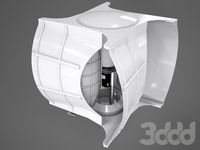

X-129R "Monster Whoop" - Micro Brushless 3D Printed FPV Quadcopter Drone Frame Kit by Karamvir_Bhagat

by Thingiverse

Last crawled date: 3 years ago

X-129R

Frame Specifications:

Frame: True X

Motor to motor: 129 mm

Motor mount configuration: 9 mm – 12 mm in M2 hardware

Recommended Motors: 11xx – 14xx

Propeller: Clearance for 3" propellers

Stack mounting:

X-129 & X-129 both accept 16 mm x 16 mm in M2

X-129 is for 20 x 20 up to M3. Adapters can be used for M2.5

X-129R is specifically for M2 in particular the Emax Magnum Mini F3 stack

Camera Mounting:

19 x 19 cameras and Tiny Whoop Cameras up to 13.8 mm lens diameter with use of adapter piece.

File Designation & Selection - IMPORTANT:

Please kindly familiarize yourself with the build guide below for a full understanding.

For M2 hardware use only files labelled X-129R.

For hardware up to M3 use files labelled X-129

DO NOT MIX FILES FOR YOUR BUILDS. THEY ARE LABELLED SO THAT THEY WILL SELF ORDER IN YOUR FILE BROWSER FOR EASE OF SELECTION.

Facebook Group: https://www.facebook.com/groups/254825821981391/

Build & Parts Guide:

This quad like all other Monster Whoops is designed to be flexible and accommodating to allow you to utilize the maximum number of components with ease and to build in various configurations.

There is no “strict” build instruction. It is a case of understanding how the parts function together to allow you to build a quad.

This frame was intended to allow people to transfer their parts directly across a Babyhawk R. Therefore, all the hardware is in M2, save for the camera mount slot which is in M3.

I wanted the designed to be versatile so I created two versions. The X-129 and the X-129R. The X-129 is for M3 hardware and with adapters can utilizes M2 AND M2.5 hardware also. The X-129R is specifically for use with the BabyHawk R parts and is therefore only takes hardware in M2.

DO NOT MIX FILES IN YOUR BUILD THEY ARE LABELLED CLEARLY.

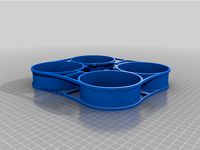

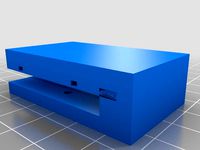

To build, mount 4 arms to the body plate by use of the adequate hardware. You will need to secure this via two points to lock in place. If you choose to keep your stack straight you will need to mount through into the bottom of the stack. If you wish to separate your stack for additional protection you can rotate it corner forward like a Tiny Whoop.

You can use a second body plate as a top plate and then mount arms off this to modify your configuration. Otherwise you can utilize the provided Top Plate to keep AUW to a minimum.

You will note that body, top plates and arm plates come in variety of thicknesses.

These are 2.8 mm, 1.7 mm and 1.1 mm.

This is to allow you to stack plates together to make up a single piece. This adds flexibility and shock resistance and also allows you to experiment with different colours and materials.

Recommend combinations are listed below:

Structural pieces:

You should use thicknesses of 2.8 mm or that equate to at least this. You should not exceed a maximum of 3.3 mm

Open Sandwich: For example, one 1.7 mm piece + one 1.1 mm piece.

Classic Sandwich: 1.1 x 3.

A TPU core flanked by PLA or PETG has been quite durable and makes a good combination and prevents tearing off of electronic components in hard impacts.

Hybrid:

There are three kinds of hybrids that you can make.

The first involves placing a 1.1 mm plate on top of 2.8 mm core structural piece or on top of a three-dimensional piece such as arm. In different colours and different piece combinations this can appear quite attractive.

The second is for added protection and vibration reduction. You can do the same as above and print in TPU. This will prevent parts from getting ripped off during very hard impacts and will additionally provide inherent dampening and “soft mounting” to motors and the flight stack.

The third is for anyone who wishes to utilize the plate files and have them cut in carbon. They can then utilize the printed parts as the wish to add decoration or strength.

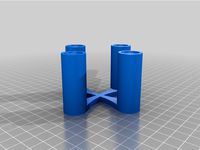

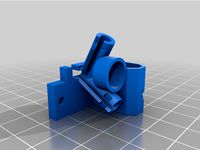

Arms:

The arms come in “Plate” form in the same designation as above and also in a three-dimensional form. Of the latter there are 4 types.

Arm: This is the standard arm and is the heaviest but strongest of all the pieces. It is recommended for more powerful setups and 13xx + motors.

Arm Lite: This is the same as the standard arm but is slightly shorter in height and therefore also lighter. This is recommended for 11xx motors.

Arm Vertical: This is the same in dimension as the regular arm with the plate section cut away. This is to allow greater airflow and to reduce weight. This is recommended for use with 13xx + motors.

Arm Vertical Lite: This is the same as the Arm Vertical but is slightly shorter in height and therefore also lighter. This is recommended for 11xx motors.

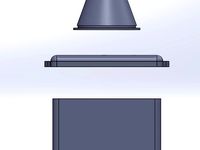

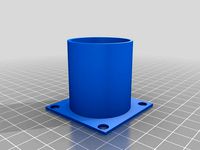

Camera Mounting:

X-129 & X-129 will require M3 hardware to secure the camera mount to frame in the slot. The slot is to allow you to adjust your camera position to suit your liking.

The camera mounts have been given extra clearance at 20 mm so that 19 x 19 cameras can fit with ease. You will need M2 hardware to mount your camera.

There 5 main camera mount pieces you can use.

The first is the main camera mount and it can be it is the tallest with holes on either side to mount the camera.

The second camera mount is the same as the first but has a slot to allow you to adjust your vertical camera position.

The “Drop Head” mount allows you to mount down off the Top Plate and again the same as the main mount in appearance but is a shorter mount with holes in M2.

The Universal Camera Mount Adapter will accommodate lenses up to 13.8 mm in diameter. This is meant for Tiny Whoop style, de-cased or separated camera units. To mount your camera, begin by getting a small elastic/rubber band, looping it over the lens and putting one twist in it to look like an 8. Take the other loop, pull it up and over the back of your camera and hook it over the lens to secure. Be careful of your wires and your lens when installing to avoid any damage.

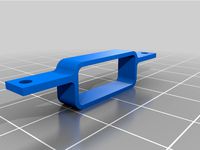

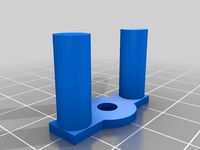

Soft Mounts & Shims:

Depending on the material that you use to print these, these can be either shims or soft mounts (or both). There are different thicknesses for you to choose from so that you can get the best fit for your motors.

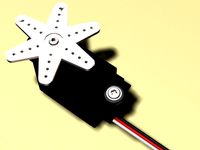

Motor Mounting:

YOU MUST USE AT LEAST 3 BOLTS FOR YOUR MOTORS! USING 2 BOLTS WILL CAUSE A MID AIR MOTOR DETACHMENT IF YOU ARE NOT CAREFUL!

Important Notes:

I have not been able to source parts from any companies to help me develop my frames.

I ensure to use the listed measurements and to check for fitment where I can with parts I have to hand. I try very hard to ensure that fitment is the best that I can achieve without physically having the parts to verify this. I have used my friend's Babyhawk R to test for fitment and it appears that there are no issues.

I must therefore state that since I have not personally tested this frame in flight, that it is a "beta" version. Once someone can kindly confirm by way of a flight DVR I will remove this label. I wanted to inform you the user so that at least you are aware of this before you invest any of your time or money.

Using and creating third party parts:

This frame was made like the other Monster Whoops frames to be easily customized and to accept additional parts easily. The standard hole mounts have been included in X and + configurations to allow for maximum versatility. These can be used for accessory mounting or allow antennas, wires or zip ties to pass through.

Since the holes are using the standard patterns it should be easy for you to make add on parts that fit easily to customise your build.

Tuning:

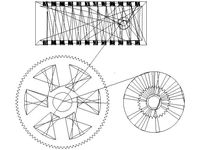

One concept I am exploring is how the proportions of the frame and its dimensions relative to each other can be used to naturally cancel out and inhibit/dampen inherent vibration.

I call this concept active geometry. It is based on the principles that form can tune vibration, for example in a pitch fork and that opposing kinetic vectors (vibrations) can cancel each other.

Every part of this frame is in perfect proportion and the dimensions are governed by a formula that I created. This is why the frames have their unique appearance.

I have noted that I have less inherent vibration in my frames, less “jello” and a minimal need to tune, if any, to get good performance.

The most prominent thing that I notice is that my frames seem to have a unique tone.

I normally just transfer my parts from frame to frame as I design. I didn’t notice this at first, but one day I was watching some line of sight footage of the same parts on a carbon frame and noticed a surprising difference. Since then I have tried to pay close attention and do indeed feel that there is a noticeable silencing/muffling effect.

It’s hard to describe, but I think once you notice it, it of stands out.

In the mid to high throttle range there seems to be less inherent jumpiness where you should normally expect to see it. It is in this throttle range where you also normally hear your quadcopter start to “scream”.

Somehow in my printed frame, the tone remains tight? I also note less twitchy response in general.

I would appreciate if anyone else could kindly pay attention to this and see if they too note can note this difference or anything in general when using this frame. I had made modifications to my frame mapping equation and want to see if this has any effect.

Flying advice:

Printed frames are not carbon frames, it’s easy to forget that when you are flying. It is advised to treat a printed frame like that of a Tiny Whoop and to avoid landing on the motor bottoms or corners of the arms.

When you first get it into the air, treat it gently until you get used to it. Since there frames are designed to balance perfectly and are actually “true X” this may feel a little strange at first. You may note that your sticks will be more even across all the axis of movement.

It is recommended to bottom mount the battery for the longevity of the frame and arms. Of course, once you are proficient and comfortable flying with the frame mount as you wish.

Plastic frames will protect your components very well, particularly from current and voltage spikes that normally kill components during crashes. Secondarily the frame breaking during an impact absorbs a great deal energy which would otherwise damage your components. The frames are designed to fully enclose the key components as much as possible of the drone so you should hopefully enjoy parts that last for a long time.

ALWAYS CHECK FLYING REGULATIONS AND RESTRICTIONS LOCAL TO YOU BEFORE ATTEMPTING TO FLY YOUR CRAFT.

Originality of Design

Of key importance to me is that my designs are original works. I always make my designs from scratch and try and make them as distinct as possible.

I have taken great care make sure that my design does not take directly from anyone else’s work or infringes on any copyrights or patents.

The unique geometry of this design alongside its unique design features identifies it as an original design and also builds in copy protection. If there is any duplication of any part of this design, a measurement can be taken of any two points and by simple calculation it can be proved.

I am a British citizen and this design was produced in the United Kingdom. The natural design rights reside with me as accorded by European Union law.

Just as a polite warning to anyone, I am legally trained.

Legal Disclaimer:

In no event shall I the designer be liable for any direct, indirect, punitive, incidental, special consequential damages, to property or life, whatsoever arising out of or connected with the use or misuse of any of my designs.

In using my work you acknowledge that any and all liability is with you the user.

You use this design at your own risk and are responsible for any consequences as such.

Frame Specifications:

Frame: True X

Motor to motor: 129 mm

Motor mount configuration: 9 mm – 12 mm in M2 hardware

Recommended Motors: 11xx – 14xx

Propeller: Clearance for 3" propellers

Stack mounting:

X-129 & X-129 both accept 16 mm x 16 mm in M2

X-129 is for 20 x 20 up to M3. Adapters can be used for M2.5

X-129R is specifically for M2 in particular the Emax Magnum Mini F3 stack

Camera Mounting:

19 x 19 cameras and Tiny Whoop Cameras up to 13.8 mm lens diameter with use of adapter piece.

File Designation & Selection - IMPORTANT:

Please kindly familiarize yourself with the build guide below for a full understanding.

For M2 hardware use only files labelled X-129R.

For hardware up to M3 use files labelled X-129

DO NOT MIX FILES FOR YOUR BUILDS. THEY ARE LABELLED SO THAT THEY WILL SELF ORDER IN YOUR FILE BROWSER FOR EASE OF SELECTION.

Facebook Group: https://www.facebook.com/groups/254825821981391/

Build & Parts Guide:

This quad like all other Monster Whoops is designed to be flexible and accommodating to allow you to utilize the maximum number of components with ease and to build in various configurations.

There is no “strict” build instruction. It is a case of understanding how the parts function together to allow you to build a quad.

This frame was intended to allow people to transfer their parts directly across a Babyhawk R. Therefore, all the hardware is in M2, save for the camera mount slot which is in M3.

I wanted the designed to be versatile so I created two versions. The X-129 and the X-129R. The X-129 is for M3 hardware and with adapters can utilizes M2 AND M2.5 hardware also. The X-129R is specifically for use with the BabyHawk R parts and is therefore only takes hardware in M2.

DO NOT MIX FILES IN YOUR BUILD THEY ARE LABELLED CLEARLY.

To build, mount 4 arms to the body plate by use of the adequate hardware. You will need to secure this via two points to lock in place. If you choose to keep your stack straight you will need to mount through into the bottom of the stack. If you wish to separate your stack for additional protection you can rotate it corner forward like a Tiny Whoop.

You can use a second body plate as a top plate and then mount arms off this to modify your configuration. Otherwise you can utilize the provided Top Plate to keep AUW to a minimum.

You will note that body, top plates and arm plates come in variety of thicknesses.

These are 2.8 mm, 1.7 mm and 1.1 mm.

This is to allow you to stack plates together to make up a single piece. This adds flexibility and shock resistance and also allows you to experiment with different colours and materials.

Recommend combinations are listed below:

Structural pieces:

You should use thicknesses of 2.8 mm or that equate to at least this. You should not exceed a maximum of 3.3 mm

Open Sandwich: For example, one 1.7 mm piece + one 1.1 mm piece.

Classic Sandwich: 1.1 x 3.

A TPU core flanked by PLA or PETG has been quite durable and makes a good combination and prevents tearing off of electronic components in hard impacts.

Hybrid:

There are three kinds of hybrids that you can make.

The first involves placing a 1.1 mm plate on top of 2.8 mm core structural piece or on top of a three-dimensional piece such as arm. In different colours and different piece combinations this can appear quite attractive.

The second is for added protection and vibration reduction. You can do the same as above and print in TPU. This will prevent parts from getting ripped off during very hard impacts and will additionally provide inherent dampening and “soft mounting” to motors and the flight stack.

The third is for anyone who wishes to utilize the plate files and have them cut in carbon. They can then utilize the printed parts as the wish to add decoration or strength.

Arms:

The arms come in “Plate” form in the same designation as above and also in a three-dimensional form. Of the latter there are 4 types.

Arm: This is the standard arm and is the heaviest but strongest of all the pieces. It is recommended for more powerful setups and 13xx + motors.

Arm Lite: This is the same as the standard arm but is slightly shorter in height and therefore also lighter. This is recommended for 11xx motors.

Arm Vertical: This is the same in dimension as the regular arm with the plate section cut away. This is to allow greater airflow and to reduce weight. This is recommended for use with 13xx + motors.

Arm Vertical Lite: This is the same as the Arm Vertical but is slightly shorter in height and therefore also lighter. This is recommended for 11xx motors.

Camera Mounting:

X-129 & X-129 will require M3 hardware to secure the camera mount to frame in the slot. The slot is to allow you to adjust your camera position to suit your liking.

The camera mounts have been given extra clearance at 20 mm so that 19 x 19 cameras can fit with ease. You will need M2 hardware to mount your camera.

There 5 main camera mount pieces you can use.

The first is the main camera mount and it can be it is the tallest with holes on either side to mount the camera.

The second camera mount is the same as the first but has a slot to allow you to adjust your vertical camera position.

The “Drop Head” mount allows you to mount down off the Top Plate and again the same as the main mount in appearance but is a shorter mount with holes in M2.

The Universal Camera Mount Adapter will accommodate lenses up to 13.8 mm in diameter. This is meant for Tiny Whoop style, de-cased or separated camera units. To mount your camera, begin by getting a small elastic/rubber band, looping it over the lens and putting one twist in it to look like an 8. Take the other loop, pull it up and over the back of your camera and hook it over the lens to secure. Be careful of your wires and your lens when installing to avoid any damage.

Soft Mounts & Shims:

Depending on the material that you use to print these, these can be either shims or soft mounts (or both). There are different thicknesses for you to choose from so that you can get the best fit for your motors.

Motor Mounting:

YOU MUST USE AT LEAST 3 BOLTS FOR YOUR MOTORS! USING 2 BOLTS WILL CAUSE A MID AIR MOTOR DETACHMENT IF YOU ARE NOT CAREFUL!

Important Notes:

I have not been able to source parts from any companies to help me develop my frames.

I ensure to use the listed measurements and to check for fitment where I can with parts I have to hand. I try very hard to ensure that fitment is the best that I can achieve without physically having the parts to verify this. I have used my friend's Babyhawk R to test for fitment and it appears that there are no issues.

I must therefore state that since I have not personally tested this frame in flight, that it is a "beta" version. Once someone can kindly confirm by way of a flight DVR I will remove this label. I wanted to inform you the user so that at least you are aware of this before you invest any of your time or money.

Using and creating third party parts:

This frame was made like the other Monster Whoops frames to be easily customized and to accept additional parts easily. The standard hole mounts have been included in X and + configurations to allow for maximum versatility. These can be used for accessory mounting or allow antennas, wires or zip ties to pass through.

Since the holes are using the standard patterns it should be easy for you to make add on parts that fit easily to customise your build.

Tuning:

One concept I am exploring is how the proportions of the frame and its dimensions relative to each other can be used to naturally cancel out and inhibit/dampen inherent vibration.

I call this concept active geometry. It is based on the principles that form can tune vibration, for example in a pitch fork and that opposing kinetic vectors (vibrations) can cancel each other.

Every part of this frame is in perfect proportion and the dimensions are governed by a formula that I created. This is why the frames have their unique appearance.

I have noted that I have less inherent vibration in my frames, less “jello” and a minimal need to tune, if any, to get good performance.

The most prominent thing that I notice is that my frames seem to have a unique tone.

I normally just transfer my parts from frame to frame as I design. I didn’t notice this at first, but one day I was watching some line of sight footage of the same parts on a carbon frame and noticed a surprising difference. Since then I have tried to pay close attention and do indeed feel that there is a noticeable silencing/muffling effect.

It’s hard to describe, but I think once you notice it, it of stands out.

In the mid to high throttle range there seems to be less inherent jumpiness where you should normally expect to see it. It is in this throttle range where you also normally hear your quadcopter start to “scream”.

Somehow in my printed frame, the tone remains tight? I also note less twitchy response in general.

I would appreciate if anyone else could kindly pay attention to this and see if they too note can note this difference or anything in general when using this frame. I had made modifications to my frame mapping equation and want to see if this has any effect.

Flying advice:

Printed frames are not carbon frames, it’s easy to forget that when you are flying. It is advised to treat a printed frame like that of a Tiny Whoop and to avoid landing on the motor bottoms or corners of the arms.

When you first get it into the air, treat it gently until you get used to it. Since there frames are designed to balance perfectly and are actually “true X” this may feel a little strange at first. You may note that your sticks will be more even across all the axis of movement.

It is recommended to bottom mount the battery for the longevity of the frame and arms. Of course, once you are proficient and comfortable flying with the frame mount as you wish.

Plastic frames will protect your components very well, particularly from current and voltage spikes that normally kill components during crashes. Secondarily the frame breaking during an impact absorbs a great deal energy which would otherwise damage your components. The frames are designed to fully enclose the key components as much as possible of the drone so you should hopefully enjoy parts that last for a long time.

ALWAYS CHECK FLYING REGULATIONS AND RESTRICTIONS LOCAL TO YOU BEFORE ATTEMPTING TO FLY YOUR CRAFT.

Originality of Design

Of key importance to me is that my designs are original works. I always make my designs from scratch and try and make them as distinct as possible.

I have taken great care make sure that my design does not take directly from anyone else’s work or infringes on any copyrights or patents.

The unique geometry of this design alongside its unique design features identifies it as an original design and also builds in copy protection. If there is any duplication of any part of this design, a measurement can be taken of any two points and by simple calculation it can be proved.

I am a British citizen and this design was produced in the United Kingdom. The natural design rights reside with me as accorded by European Union law.

Just as a polite warning to anyone, I am legally trained.

Legal Disclaimer:

In no event shall I the designer be liable for any direct, indirect, punitive, incidental, special consequential damages, to property or life, whatsoever arising out of or connected with the use or misuse of any of my designs.

In using my work you acknowledge that any and all liability is with you the user.

You use this design at your own risk and are responsible for any consequences as such.

Similar models

thingiverse

free

X-814 Singularity Master Monster Whoop by Karamvir_Bhagat

... builds.

fully enclosed stack.

height adjustable 19 x 19 camera compatible with 1 mm clearance added.

beast mode built in.

thingiverse

free

X-82 "Monster Whoop" - 1.9 - 2.5 Inch Micro Brushless FPV Racing Drone Quadcopter by Karamvir_Bhagat

...y and all liability is with you the user.

you use this design at your own risk and are responsible for any consequences as such.

thingiverse

free

X-120 - 2 Inch "Monster Whoop" Micro Brushless Racing Drone Quadcopter by Karamvir_Bhagat

...just quickly and easily sketch something up for yourself. similary, if you want to have holes instead of slots...

thingiverse

free

M2 & M2.5 to M3 Adapters & Soft Mounts (20 x 20 mm Flight Controllers) by Karamvir_Bhagat

... rotate and mount the stack like a tiny whoop with a corner facing forward to in the regular manner by mounting through the arms.

thingiverse

free

Joza TX130 quadcopter frame

...are to be threaded m2.

i have had the plates cut out of 3mm carbon fiber plates. 1,5mm for the top plate. stand offs are printed.

thingiverse

free

XC-120 Patriot - Micro Brushless 2.5 inch "Monster Whoop" 3D Printable Quadcopter Drone by Karamvir_Bhagat

...just quickly and easily sketch something up for yourself. similary, if you want to have holes instead of slots...

thingiverse

free

X-107 - 2" Micro Brushless Drone Beta Testing by Karamvir_Bhagat

...ers note:

thank you very much your interest and for your participation should you wish to engage in the project!

karamvir bhagat

thingiverse

free

SPDVL3 - 3" Super light and Durable Freestyle Frame by Flowr

...ck, motors

20x20mm stack / 16x16mm stack / aio whoop board 25.5x25.5mm

110x - 140x (4x m2 hole pattern) motors

3" propellers

thingiverse

free

Axel's modular 3D printed quadcopter (wooden arms) by Axbri

...the same as my other quadcopter design with carbon fibre motor arms. check it out here: https://www.thingiverse.com/thing:2427724

thingiverse

free

"Monster Whoop" 19 x 19 & RunCam Camera Mount by Karamvir_Bhagat

...e long edge of the piece where the camera bolts in.

for the adapter print vertically with the lock points point up off the bed.

129R

thingiverse

free

ALEXANDER 129R GT3 by miketulen123

...alexander 129r gt3 by miketulen123

thingiverse

alexander 129r gt3

you are this car schel kleiner maken

thingiverse

free

Harness clamp for Brush Cutter by Arndmp3

...by arndmp3 thingiverse harness clamp for husqvarna brush cutters 129r or every bush cutter with tube 25,4mm replacement for...

thingiverse

free

X-814 Singularity Master Monster Whoop by Karamvir_Bhagat

...rip all. micro monster powerhouse. follow basic guide in x-129r to build. same principals apply. quick specs: fully modular....

Karamvir

thingiverse

free

Runcam Micro Sparrow Holder for X-153 and other similar Frames by real_darKing

...the x-153 abd x-132, a 3d printable frame by karamvir bhagat https://www.thingiverse.com/thing:3079727https://www.thingiverse.com/thing:2956351 thank you! about the thing: i wanted...

thingiverse

free

X-107 - 2" Micro Brushless Drone Beta Testing by Karamvir_Bhagat

...ers note:

thank you very much your interest and for your participation should you wish to engage in the project!

karamvir bhagat

thingiverse

free

X-120 - 2 Inch "Monster Whoop" Micro Brushless Racing Drone Quadcopter by Karamvir_Bhagat

... you the user.

you use this design at your own risk and are responsible for any consequences as such.

with love - karamvir bhagat

thingiverse

free

XC-120 Patriot - Micro Brushless 2.5 inch "Monster Whoop" 3D Printable Quadcopter Drone by Karamvir_Bhagat

... you the user.

you use this design at your own risk and are responsible for any consequences as such.

with love - karamvir bhagat

Bhagat

3d_sky

$8

Roman shades of velvet

...fill your room and provide its originality and splendor bhagat ...

thingiverse

free

Runcam Micro Sparrow Holder for X-153 and other similar Frames by real_darKing

...x-153 abd x-132, a 3d printable frame by karamvir bhagat https://www.thingiverse.com/thing:3079727https://www.thingiverse.com/thing:2956351 thank you! about the thing: i wanted to...

thingiverse

free

X-107 - 2" Micro Brushless Drone Beta Testing by Karamvir_Bhagat

...ers note:

thank you very much your interest and for your participation should you wish to engage in the project!

karamvir bhagat

thingiverse

free

X-120 - 2 Inch "Monster Whoop" Micro Brushless Racing Drone Quadcopter by Karamvir_Bhagat

... you the user.

you use this design at your own risk and are responsible for any consequences as such.

with love - karamvir bhagat

thingiverse

free

XC-120 Patriot - Micro Brushless 2.5 inch "Monster Whoop" 3D Printable Quadcopter Drone by Karamvir_Bhagat

... you the user.

you use this design at your own risk and are responsible for any consequences as such.

with love - karamvir bhagat

cg_trader

$20

Bhagat Singh | 3D

...3d print, bhagat singh figurine. bhagat singh bust. bhagat singh stl bhagat singh bhagatsingh revolutionary indian art sculptures

grabcad

free

Logo SD Bhagat

...logo sd bhagat

grabcad

that is my logo, for my vehicle.

grabcad

free

SCREW JACK By Dipraj Bhagat

...

to remove tyre it needs to lift vehicle upwards this jack helps to lift the vehicle upwards and makes tyre removal process easy

3dwarehouse

free

bhautik bhagat fc

...bhautik bhagat fc

3dwarehouse

3dwarehouse

free

bhautik bhagat 2

...bhautik bhagat 2

3dwarehouse

Whoop

thingiverse

free

whoop by MichaelJFPV

...whoop by michaeljfpv

thingiverse

whoop

thingiverse

free

Tiny Whoop holder for 2 whoops by d2000

...tiny whoop holder for 2 whoops by d2000

thingiverse

tiny whoop holder for 2 whoop mini drones and battery

thingiverse

free

Whoop frame by Brassekongo

...whoop frame by brassekongo

thingiverse

a tiny whoop frame

thingiverse

free

Whoop frame by Brassekongo

...whoop frame by brassekongo

thingiverse

my first whoop frame.

thingiverse

free

WHOOPS 4

...

whoops is another

big cinewhoop as addon for hyperlite tooth fairy race frame 4"

first flight https://youtu.be/xm9afwiiass

thingiverse

free

Tiny Whoop 65mm by binaryfpv

...tiny whoop 65mm by binaryfpv

thingiverse

tiny whoop 65mm

thingiverse

free

V-Tail Whoop by Mystereon

...v-tail whoop by mystereon

thingiverse

v-tail whoop .. wip

thingiverse

free

Tiny Whoop Case by 3DRCStore

...tiny whoop case by 3drcstore

thingiverse

tiny whoop case for transport.

thingiverse

free

Tiny Whoop Calibration Base

...tiny whoop calibration base

thingiverse

a base usefull to calibrate your tiny whoop

thingiverse

free

Tiny Whoop Gate by Imozeb

...tiny whoop gate by imozeb

thingiverse

custom tiny whoop gate. requires hot glue for assembly.

Brushless

turbosquid

$4

Brushless motor

...r download as 3ds, dxf, obj, xsi, wrl, fbx, dwg, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1366202)

3d_export

$10

wheel and motor for mars rover

...last project: a mars rover concept. complete wheel and brushless electrical motor designed to attach to an atv or...

3d_export

$100

the volt futuristic ev hypercar

...future ! some design aspects : this is in-wheel (brushless hub) motors vehicle, for each motor the core part...

3d_export

$20

si cantik cargo plane for humanity medicine kit

...used for the tailboom. the electronic components used are brushless motor os 1000kv which can produce thrust 3kgas a...

free3d

free

N6375 Brushless Motor

...n6375 brushless motor

free3d

n6375 brushless motor

thingiverse

free

Tyro 79 brushless key

...tyro 79 brushless key

thingiverse

tyro 79 brushless key

thingiverse

free

Propeller antirotation brushless lock

...propeller antirotation brushless lock

thingiverse

propeller antirotation brushless lock

thingiverse

free

Brushless motor holder by NukeCraft

...brushless motor holder by nukecraft

thingiverse

brushless motor holder for bl3650

thingiverse

free

Brushless motor mount by robotbuilders

...brushless motor mount by robotbuilders

thingiverse

replacement mount for brushless motor.

thingiverse

free

Brushless motor mount by TarsVH

...brushless motor mount by tarsvh

thingiverse

a mount for a 2830 size brushless motor

Quadcopter

3d_export

$5

quadcopter

...quadcopter

3dexport

futuristic quadcopter design.<br>original design davidflo 77

turbosquid

$19

quadcopter

...lty free 3d model quadcopter for download as max, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1591426)

turbosquid

$25

QuadCopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter studio shaders

quadcopter 3d model vortex333 93968 3dexport

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter aircraft helicopter

quadcopter 3d model greatghost 94019 3dexport

3d_export

$18

passenger quadcopter

... a multicopter is an aircraft built according to a helicopter scheme, with three or more rotors. previews rendered with redshift.

turbosquid

$159

Quadcopter Animated.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$29

Quadcopter

...

questions about the continuation of the collection or the model can be asked here:<br>https://www.artstation.com/evgen_beg

Fpv

turbosquid

$1

FPV VTX Antenna

...e 3d model fpv vtx antenna for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1230317)

3d_export

$9

Fpv logo 3D Model

...onogram vehicle part of auto transport 3d model logo emblem detailed high quality badge

fpv logo 3d model rmodeler 59628 3dexport

3d_export

$8

dji fpv battery slot holder

...er for 3 dji fpv batteries. holds perfectly without shaking. need 1 m3 countersunk head bolt. need to print 6 pin, 1 case, 1 cap.

3d_export

$10

fpv camera hd 700tvl

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

thingiverse

free

FpV Mount (SOPORTE FPV) by elborjas1987

...fpv mount (soporte fpv) by elborjas1987

thingiverse

this is a fpv mount with the same holes of naza base.

thingiverse

free

fpv by tbutera

...fpv by tbutera

thingiverse

fpv

thingiverse

free

fpv by tbutera

...fpv by tbutera

thingiverse

fpv

thingiverse

free

FPV DRONE ROOSTER DJI FPV PART

...fpv drone rooster dji fpv part

thingiverse

fpv drone rooster dji fpv install part

thingiverse

free

FPV monitor

...tml?rmmds=myorder&cur_warehouse=cn

link for download : https://cults3d.com/fr/mod%c3%a8le-3d/divers/fpv-monitor-ecran-fpv-faf

thingiverse

free

FPV receiver mount for FPV display by petrex

...eceiver mount for fpv display by petrex

thingiverse

aomway receiver mount for field view 777 fpv monitor. with small cable tray.

Drone

3d_export

$12

Drones

...drones

3dexport

drones

3d_export

$5

drone

...drone

3dexport

drone

3d_export

$6

drone

...drone

3dexport

high poly model of dji phantom 4 (drone)

3d_export

$5

drone

...drone

3dexport

drone military flight, sizes are in mm, modeled in fision 360

3d_export

free

drone

...drone

3dexport

drone de uso tactico, creado en blender version 2.79

3d_export

$35

DRONE

...drone

3dexport

turkey drone alpagu kamikaze foldable wing 3ds max 2019,2020,2021,2022 vray 5.00 rendered

3d_ocean

$29

Drone

...drone camera drone electronics justtomas military parrot plane robot sci-fi spy toy vehicle

drone by justtomas .c4d r16 .obj .3ds

turbosquid

$6

Drone

...rone

turbosquid

royalty free 3d model drone for download as on turbosquid: 3d models for games, architecture, videos. (1347051)

turbosquid

free

Drone

...drone

turbosquid

free 3d model drone for download as blend on turbosquid: 3d models for games, architecture, videos. (1688993)

turbosquid

$69

Drone

...e

turbosquid

royalty free 3d model drone for download as max on turbosquid: 3d models for games, architecture, videos. (1232508)

Monster

3d_export

$5

monster

...monster

3dexport

very realistic monster

3d_export

free

monster

...monster

3dexport

bloody monster! (looks terrifying)

3d_ocean

$12

Monster

... this code “envatoguest2016” . visit our store high details 3d character model for small monster , useful for animations, movi...

3d_ocean

$15

Monster

...monster

3docean

android game ios java main model monster playdesign

polycount :1118 texture :1024×1024png

3d_ocean

$8

Monster Man

...monster man

3docean

giant monster

monster man software: 3ds max, mental ray.

turbosquid

$60

MONSTER

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1220728)

turbosquid

$60

Monster

...turbosquid

royalty free 3d model monster for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320840)

turbosquid

$19

Monster

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1248452)

turbosquid

$15

Monster

...turbosquid

royalty free 3d model monster for download as ztl on turbosquid: 3d models for games, architecture, videos. (1417804)

turbosquid

$15

Monster

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1293042)

Micro

3ddd

$1

Micro

...micro

3ddd

автобус

turbosquid

$80

MICRO

...ty free 3d model micro for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1700743)

3ddd

$1

JBL Micro Wireless

... micro , колонка , плеер

jbl micro wireless

turbosquid

$10

Suppressor Micro

...quid

royalty free 3d model suppressor micro for download as on turbosquid: 3d models for games, architecture, videos. (1380433)

turbosquid

$20

Micro Meter

...osquid

royalty free 3d model micro meter for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350448)

turbosquid

$7

NIghtstand Micro

...d

royalty free 3d model nightstand micro for download as max on turbosquid: 3d models for games, architecture, videos. (1248117)

3ddd

$1

Micro wind turbine

...micro wind turbine

3ddd

турбина

micro wind turbine for your green building projects

turbosquid

$29

Micro Speakers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Micro Servo.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Micro cells

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Kit

turbosquid

$3

Bathroom Kit Baño kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Drift Kit

...drift kit

3dexport

turbosquid

$40

BitCoin Kit

...urbosquid

royalty free 3d model bitcoin kit for download as on turbosquid: 3d models for games, architecture, videos. (1519068)

turbosquid

$9

Industrial kit

...osquid

royalty free 3d model industrial kit for download as on turbosquid: 3d models for games, architecture, videos. (1144117)

turbosquid

$6

Kit Vases

...

turbosquid

royalty free 3d model kit vases for download as on turbosquid: 3d models for games, architecture, videos. (1285114)

turbosquid

free

Survival Kit

...rbosquid

royalty free 3d model survival kit for download as on turbosquid: 3d models for games, architecture, videos. (1637721)

turbosquid

$50

Ninja Kit

...rbosquid

royalty free 3d model ninja kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1672364)

turbosquid

$35

Brushes Kit

...osquid

royalty free 3d model brushes kit for download as max on turbosquid: 3d models for games, architecture, videos. (1216721)

turbosquid

$19

Medical kit

...osquid

royalty free 3d model medical kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486089)

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints