Thingiverse

Wool winder / spool by rumbero71

by Thingiverse

Last crawled date: 3 years, 1 month ago

A major disadvantage of buying knitting wool from dope-headed hippies is the fact that it doesn't come in ready to use form. It has to be pre-washed, color-fixated and -last but not least- wound up onto spools or into the familiar playthings of the common household cat.

In order to save my son from being used as a living wool-holder by his knitting-crazy mother, I designed this thing.

Design was by myself, although I frankensteined parts from other things into it:

http://www.thingiverse.com/thing:1832235

From this one I used the rollers as a mount for the skateboard bearings.

https://www.thingiverse.com/thing:1959208

Here I used screw and screw hole of the back plate for the table mount.

Design principle is a scissor-extender on two movable mounting plates. Two, because I was too lazy to design a fix for one of them. Some fixation for the mounting plates is provided by the friction between the bearings and the aluminium rod. Important ! The aluminium rod has to be of the anodized (matte) type to fit into the holes of the bearings and provide the necessary friction !

The whole device is to be mounted on the edge of a table w/ a max thickness of 30mm (less if you want to use a rubber protector on the mount). The rod will extend horizontally from the table. However, I found this to be a bit clumsy/unstable, so I will design a vertical mount later on.

On printing: 50% is probably too much for most of the parts. However, the table mount NEEDS AT LEAST 50%. 70% is better. Ah, and use PETG for the table mount because PLA is not flexible enough.

BoM (printed):

2 Mounting Plates

Rod protector knob

Table mount

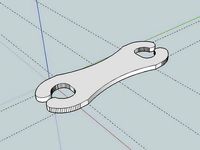

Screw

Mounting bracket

8 scissor parts w/ thick end

Thin scissor parts (count depends on desired extension)

BoM (other):

2 608 Skateboard Bearings

8mm anodized aluminium rod

M3x10 screws (lots of 'em)

M3 Nylock nuts (again: lots of 'em)

M3 screws (I think it was 16 or 18mm), new version uses 20mm

M3 Nuts

UPDATE !

I changed the design for the table mount from a horizontal rod position to a vertical one. Just choose the variant you desire.

Hint:

The plastic screw has a really tight fit. Scaling the width and height (NOT the length) of this to 99% improves usability a lot.

In order to save my son from being used as a living wool-holder by his knitting-crazy mother, I designed this thing.

Design was by myself, although I frankensteined parts from other things into it:

http://www.thingiverse.com/thing:1832235

From this one I used the rollers as a mount for the skateboard bearings.

https://www.thingiverse.com/thing:1959208

Here I used screw and screw hole of the back plate for the table mount.

Design principle is a scissor-extender on two movable mounting plates. Two, because I was too lazy to design a fix for one of them. Some fixation for the mounting plates is provided by the friction between the bearings and the aluminium rod. Important ! The aluminium rod has to be of the anodized (matte) type to fit into the holes of the bearings and provide the necessary friction !

The whole device is to be mounted on the edge of a table w/ a max thickness of 30mm (less if you want to use a rubber protector on the mount). The rod will extend horizontally from the table. However, I found this to be a bit clumsy/unstable, so I will design a vertical mount later on.

On printing: 50% is probably too much for most of the parts. However, the table mount NEEDS AT LEAST 50%. 70% is better. Ah, and use PETG for the table mount because PLA is not flexible enough.

BoM (printed):

2 Mounting Plates

Rod protector knob

Table mount

Screw

Mounting bracket

8 scissor parts w/ thick end

Thin scissor parts (count depends on desired extension)

BoM (other):

2 608 Skateboard Bearings

8mm anodized aluminium rod

M3x10 screws (lots of 'em)

M3 Nylock nuts (again: lots of 'em)

M3 screws (I think it was 16 or 18mm), new version uses 20mm

M3 Nuts

UPDATE !

I changed the design for the table mount from a horizontal rod position to a vertical one. Just choose the variant you desire.

Hint:

The plastic screw has a really tight fit. Scaling the width and height (NOT the length) of this to 99% improves usability a lot.

Similar models

thingiverse

free

reduced friction Spool Holder by Connorus

...oolholder1.stl

4 bearings 20mm diameter

8mm threaded rod

20x20mm aluminium profile

spool holder which fits into the hole of spool

thingiverse

free

Prusa i3 fixation to base plate by zea123

...ate.

i screwed the part with sink screws in the base plate and pressed the frame part from a side with a hex nut to the fixation.

thingiverse

free

Rod fixation by Trigubovich

...rod fixation by trigubovich

thingiverse

6mm, 5mm rod fixation

use

4 screws m3

1 nut m3

thingiverse

free

Bearing Mount (Pillow Block Mt) by ElectronicKit

...

the object accepts the 608 skateboard ball bearing and there are 2 mounting holes for 3mm or 4mm bolts to fasten the thing down.

thingiverse

free

T and L plates for 2020 aluminium extrusion, M3

...connecting two 2020 aluminium extrusions that uses m3 screws. design is very simple and it prints fast. i like to use 50%+ infil.

thingiverse

free

X motor mount left side for Anet A8 with z-rod bearing tightners by ZhenyaKa

... two holes for m3 bolts and nuts.

fixator for z-screw removed.

my x carriage is free for less wobbling and no need this fixation.

thingiverse

free

Nautilus Mount (RigidBot E3D v6) by walter

...nts.

the part cooling parts use a 50mm blower fan and aquarium airline tubing, and only works with the 32mm version of the mount.

thingiverse

free

Wall-mount spool holder with quick release fastener by loco

...unk screws 4mm diameter

3x m8 nuts

1x m8 threaded rod

2x 608 ball bearing

1x m3x20 screw

1x m3 nut (nyloc nut or loctite)

thingiverse

free

Mega S spool holder with bearings by muff99

... rod matching your spools width

attach the stopper on the rod

i worked better than expected, the friction is significantly lower.

grabcad

free

screw rod

...screw rod

grabcad

this is a design of a screw rod used in scissor jack

Rumbero71

thingiverse

free

Waveshare 5in LCD Stand by rumbero71

...waveshare 5in lcd stand by rumbero71

thingiverse

just a simple stand for a waveshare 5in lcd (b) display

thingiverse

free

Lack FrankenTable by rumbero71

...a set of two, a smaller one of 60x40 and a bigger one) and the legs of two additional square lack tables into an auxiliary table.

thingiverse

free

RFtoy bumper by rumbero71

...ication. unfortunately, there is no case / cover for it which makes handling it a bit cumbersome. this little bumper should help.

thingiverse

free

PlugUp U2F Key Case by rumbero71

...o71

thingiverse

a case reinforcing the flimsy plugup u2f key w/ a sleeve protecting the contacts.

print at 0.1mm w/ 0.4mm nozzle

thingiverse

free

Fitbit Flex Charge Holder by rumbero71

...antly flipping over making it impossible to see if it charges -the contact mechanism is somewhat suboptimal. now it stays put :-)

thingiverse

free

Gscheiduino Case by rumbero71

...a2-clon.html

since unfortunately the pcb does not exactly match the arduino specs, i did have to tinker esquilos design again :-)

thingiverse

free

C.H.I.P. w/ OLED HAT case by rumbero71

... some improvements on the connector side.

the eagle files for that dip can be found at https://github.com/rumbero71/chip-multidip

thingiverse

free

Long cable clips by rumbero71

... ceiling, especially when using a semi transparent cable. i printed those clips in transparent petg w/ 0.4mm nozzle, 0.15mm layer

thingiverse

free

The Button - Remix by rumbero71

...liberty of just increasing the thickness of the mounting plate since the original design seemed a bit flimsy to me at that point.

thingiverse

free

Anet A8 Webcam Mount by rumbero71

...ey are too slick and the angle was not good.

this plate is designed to be mounted on top of the right z-axis stepper motor plate.

Winder

turbosquid

$10

window strap winder (external)

...del window strap winder (external) for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1281687)

3d_export

$14

winder textile special equipment

...s a role of "bridge" connecting the preceding and the following, so it plays an important role in the field of textile.

3d_export

$30

gold pocket watch

...(parented to watch)<br>hour hand (parented to watch)<br>lid (parented to watch)<br>winder (parented to watch)<br>pocketwatch - 2k -<br>diffuse<br>roughness<br>normal - (opengl unity...

3d_export

$30

helmets hats pack lowpoly

...newsboy cap sun cap war guard helmet winter cap winder fold cap<br>fbx-embed texture fbx<br>mb(maya binary)<br>obj<br>blender file only exports without...

3d_export

$32

speed reducer gear box worm helical wpx

...common household uses are washing machines, food blenders and window-winder. reduction drives are also used to decrease the rotational...

thingiverse

free

Side Winder by airdronez

...side winder by airdronez

thingiverse

side winder

thingiverse

free

Earphone winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Earphone Winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Spool Winder by Verohomie

...spool winder by verohomie

thingiverse

spool winder for a cordless drill

thingiverse

free

Cable Winder by kazsoft

...cable winder by kazsoft

thingiverse

just a simple cable winder.

Wool

3d_ocean

$3

Wool texture

...wool texture

3docean

seamless wool texture

3d_ocean

$3

Naturally wool texture

...naturally wool texture

3docean

carpet fabric seamless textilem naturally wool

seamles texture of wool.

3d_ocean

$3

Gray wool texture

...gray wool texture

3docean

carpet chair clothes fabric furniture sofa wool

seamles texture of wool

turbosquid

$19

Wool Sofa

...rbosquid

royalty free 3d model wool sofa for download as max on turbosquid: 3d models for games, architecture, videos. (1158509)

turbosquid

$5

Wool Snowman

... 3d model wool snowman for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1264202)

design_connected

$16

Studded Wool Curtain

...studded wool curtain

designconnected

studded wool curtain computer generated 3d model.

3d_ocean

$4

Blue seamless wool

...blue seamless wool

3docean

blue seamless wool texture. diffuse and bump are included.

3d_ocean

$3

Wool seamless texture

...wool seamless texture

3docean

great seamless texture of white wool. resolution: 3000×3000px

design_connected

$16

Geo Wool Kilim

...geo wool kilim

designconnected

west elm geo wool kilim computer generated 3d model.

design_connected

$16

Asymetric Wool Rug

...asymetric wool rug

designconnected

west elm asymetric wool rug computer generated 3d model.

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)