Thingiverse

WLToys A959/979 Outcast Parts

by Thingiverse

Last crawled date: 4 years, 3 months ago

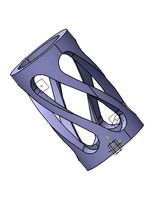

Update: I added the long awaited drive shaft extender for use with the plastic stock driveshaft. I included a tight and loose fitting version for use with the 90mm chassis extender plate in this thing. The tight version may require a bit of rotary tool massaging on the plastic stock drive shaft (Took me 5min) but the fit ends up being really good. Be sure to measure your gap before you print and stretch the part accordingly. The pockets are 12.5mm so it should work fine as long as everything is fitted reasonably well when you do your mods, but , you know, measure twice, print once.

This is a chassis extender and body mounts to allow using an Arrma Outcast 4S body with the WLToys A959/979 RC Car. You need to cut the chassis and the drive shaft, so use caution. I used some M3 screws to attach the chassis halves to the extender and added a wood brace across the top to stiffen it up a bit. Despite doing my test runs with PLA, there has been no breakage despite quite a few crashes (One body post sheered off in a head-on, but I think that drilling the holes for clips weakened it). I ran the stock electronics first and then have tried a few brushless setups without any breakage. The fastest has been a 2845 motor using the A959/979-B gearing, but that only got about 50 kph. It doesn't handle too bad and strangely got worse after I added the stiffener. I haven't modded the center drive shaft yet but my plan is to make a 3D printed coupler so I'll post that when I get around to making it.

Link to the car running: https://www.youtube.com/watch?v=ERNCA6yfuoQ

You'll need to drill holes for body clips or alter the STL files with holes of your choosing. 3D Builder in Windows 10 is pretty easy to figure out if you don't have any other software.

You will also need some touring car wheels and tires. I bought a set for less than 10 bucks off Ebay (pictured).

Steps:

Print parts.

Cut chassis/brace/center drive shaft in half (I did it without taking anything apart but if that scares you, use your own judgement).

Line up chassis halves and mark extender piece for holes (I test fitted everything using two sided tape).

Drill holes 1 size smaller than the screws you're using and assemble.

Drill holes for clips in body mounts (or use velcro).

Add a brace to the top of the chassis if desired (I used some dollar store wood planks).

Jerry Rig your drive shaft if you don't want to run in 2WD.

As always, proceed at you own risk. I offer no promises or warranty.

Wrench to drive or drive to wrench?

This is a chassis extender and body mounts to allow using an Arrma Outcast 4S body with the WLToys A959/979 RC Car. You need to cut the chassis and the drive shaft, so use caution. I used some M3 screws to attach the chassis halves to the extender and added a wood brace across the top to stiffen it up a bit. Despite doing my test runs with PLA, there has been no breakage despite quite a few crashes (One body post sheered off in a head-on, but I think that drilling the holes for clips weakened it). I ran the stock electronics first and then have tried a few brushless setups without any breakage. The fastest has been a 2845 motor using the A959/979-B gearing, but that only got about 50 kph. It doesn't handle too bad and strangely got worse after I added the stiffener. I haven't modded the center drive shaft yet but my plan is to make a 3D printed coupler so I'll post that when I get around to making it.

Link to the car running: https://www.youtube.com/watch?v=ERNCA6yfuoQ

You'll need to drill holes for body clips or alter the STL files with holes of your choosing. 3D Builder in Windows 10 is pretty easy to figure out if you don't have any other software.

You will also need some touring car wheels and tires. I bought a set for less than 10 bucks off Ebay (pictured).

Steps:

Print parts.

Cut chassis/brace/center drive shaft in half (I did it without taking anything apart but if that scares you, use your own judgement).

Line up chassis halves and mark extender piece for holes (I test fitted everything using two sided tape).

Drill holes 1 size smaller than the screws you're using and assemble.

Drill holes for clips in body mounts (or use velcro).

Add a brace to the top of the chassis if desired (I used some dollar store wood planks).

Jerry Rig your drive shaft if you don't want to run in 2WD.

As always, proceed at you own risk. I offer no promises or warranty.

Wrench to drive or drive to wrench?

Similar models

thingiverse

free

WLToys A979/A959/A969 Suspension Arms

...th your wltoys: https://www.youtube.com/watch?v=ernca6yfuoq

as always, use at your own risk.

drive to wrench or wrench to drive?

thingiverse

free

WLtoys a959 979 suspension preload clip by MTFPV

...port needed.

can be printed out within 4 min per clip.

this is a remix from wltoys 10428 shock clip

by erics89 february 01, 2021

thingiverse

free

RC Lancia Delta S4

...a959, also i have mz gs1004 buggy which very similar with wltoys. original chassis cutted in the middle and...

thingiverse

free

Diff lock for WlToys A959/979/949 by Kharakhorin

...a959/979/949 by kharakhorin

thingiverse

my stock differential is broken and i has designed this simple diff lock to replace him.

thingiverse

free

rubicon short for wltoys vortex A959/979 by rossitamiya

...rubicon short for wltoys vortex a959/979 by rossitamiya

thingiverse

enjoy it......

thingiverse

free

Traxxas Summit GoPro Rack by SgtWoody

...and there are four posts that extend down to the body where you can drill holes and use m3 hardware to stiffen the mount further.

thingiverse

free

shaft for WLtoys A959, A969, A979 A959 by Pelesepefe

...shaft for wltoys a959, a969, a979 a959 by pelesepefe

thingiverse

yes

thingiverse

free

Arrma Outcast 4S Chassis Brace Extender to Kraton 4S Length by WrenchToDrive

...possibly bend more than compress), so do what you think will work best.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Wltoys A959 Snow/Sand Wheel (7mm hex) by kryuchok

...wltoys a959 snow/sand wheel (7mm hex) by kryuchok

thingiverse

wheels for wltoys a959 on snow or sand.

7mm hex (stock).

thingiverse

free

Wltoys 70mm extention kit by emil2rs1

...stealt, but think any 1:10 axel cup should fit)

you will also need two 5 x 10 x 4 bearigs

hope you can get some use out of it. :)

A959

thingiverse

free

shaft for WLtoys A959, A969, A979 A959 by Pelesepefe

...shaft for wltoys a959, a969, a979 a959 by pelesepefe

thingiverse

yes

thingiverse

free

Strong Wheel holder for a959

...strong wheel holder for a959

thingiverse

strong wheel holder for a959

thingiverse

free

A959 Aerodynamic Nose And Shell

...a959 aerodynamic nose and shell

thingiverse

an aerodynamic shell for an wltoys a959 or a959b.

thingiverse

free

A959 A979 Diff Cup by pee581

...a959 a979 diff cup by pee581

thingiverse

a959 a979 diff cup

thingiverse

free

Wing for WL Toys A959 by rossitamiya

...wing for wl toys a959 by rossitamiya

thingiverse

wing replacement for wl toys a959

thingiverse

free

Camera support FPV for WLtoys A959, A959-B by GTDrone

...drone

thingiverse

parts used for the conception :

fpv camera - eachine 1000tvl

vtx - eachine tx801

cable - xh2.54 3p plug female

thingiverse

free

Wltoys A959 Aerodynamic pack 1 by Yeps

...wltoys a959 aerodynamic pack 1 by yeps

thingiverse

wltoys a959 aerodynamic pack

thingiverse

free

beadlock for wltoys a959 by rossitamiya

...beadlock for wltoys a959 by rossitamiya

thingiverse

enjoy it!

thingiverse

free

A959 A979 Expander Body Post by pee581

...a959 a979 expander body post by pee581

thingiverse

a959 a979 expander body post

thingiverse

free

wltoys a959 bumper by djfilton

...wltoys a959 bumper by djfilton

thingiverse

reinforced shock

Outcast

3d_export

free

The warlock is an outcast

...the warlock is an outcast

3dexport

thingiverse

free

Outcast by airdronez

...outcast by airdronez

thingiverse

outcast

thingiverse

free

outcast by lamerhouse

...outcast by lamerhouse

thingiverse

outcast

thingiverse

free

Malifaux Outcasts Marker by Altner

...malifaux outcasts marker by altner

thingiverse

a marker with outcasts symbol on it.

thingiverse

free

ARRMA OUTCAST 4S WING

... and a wall width of 2.8, with a 15% infill... this makes the winglets and base solid.. firmer tpu is the best for this...

enjoy!

thingiverse

free

Arrma Outcast grill (calandre Arrma) by somethingsbyj

...arrma outcast grill (calandre arrma) by somethingsbyj

thingiverse

this is arrma oucast 6s grill with 22mm light

thingiverse

free

ARRMA OUTCAST / KRATON 4S HUB NUT COVER

...ses over the 8mm hub nut.. fit should be snug.. made to look like an old manual locking hub...

print upright with support

enjoy!

thingiverse

free

outcast necromancer by rockgnome

...efore prining !!!!!!!!

aditional mini for cot warhammerquest

remix of wizard from hq and evil necromancer from wizards of morcar

thingiverse

free

Roof Skid Rail for Outcast 6S and others by sebcbien

...dimensions

if you need other dimensions, please do not hesitate to ask me.

screw i use: m4 x 9 (filet) / m4 x 11,8 (total length)

thingiverse

free

Arrma Outcast Spring Perch by Rbsmakn

...e part that drove me to buying my first 3d printer and introduced me to cad. this $10 piece of plastic and several days downtime.

979

3d_export

$50

3D Home 979 3D Model

... chair furniture texture table lamp apartment rug carpet restaurant hotel sitting

3d home 979 3d model richard3015 47443 3dexport

3d_export

$16

reeds in a rusty flowerpot for the interior 979

...pa pot houseplants exotic plants tropical plants pennisetum alopecuroides scirpus - reeds tussock - grass ornamental grass fescue

3d_export

$7

bathroomset108

...vray and corona formats: 3ds max 2015, fbx polys: 979 ...

3ddd

$1

Caprigo / Fresco 120

.../ fresco 120 3ddd caprigo 65292 polys 1204 х 979 х 510 мм модель по...

3ddd

$1

Шоколадный торт

...2016 и 2013 версий макса + obj polys: 234 979 ...

3d_export

$9

Skullgate

...polygon. ...............2991. vertices. skull_gate_lod_1................3623 polygon. ................1842. vertices. skull_gate_lod_2.................1897 polygon. ................979 vertices. 4096 * 4096 texture obj,fbx,blend format model. uv...

3d_export

$9

Skullgate

...polygon. ...............2991. vertices. skull_gate_lod_1................3623 polygon. ................1842. vertices. skull_gate_lod_2.................1897 polygon. ................979 vertices. 4096 * 4096 texture obj,fbx,blend format model. uv...

3d_export

$9

Skullgate

...polygon. ...............2991. vertices. skull_gate_lod_1................3623 polygon. ................1842. vertices. skull_gate_lod_2.................1897 polygon. ................979 vertices. 4096 * 4096 texture obj,fbx,blend format model. uv...

3d_export

$9

Skullgate

...polygon. ...............2991. vertices. skull_gate_lod_1................3623 polygon. ................1842. vertices. skull_gate_lod_2.................1897 polygon. ................979 vertices. 4096 * 4096 texture obj,fbx,blend format model. uv...

3d_export

$9

Skullgate

...polygon. ...............2991. vertices. skull_gate_lod_1................3623 polygon. ................1842. vertices. skull_gate_lod_2.................1897 polygon. ................979 vertices. 4096 * 4096 texture obj,fbx,blend format model. uv...

Wltoys

3ddd

free

Квадрокоптер Cyclone

...квадрокоптер cyclone 3ddd квадрокоптер , cyclone , wltoys квадрокоптер cyclone. текстуры в комплекте. модель с...

thingiverse

free

Wltoys K989 drift

...wltoys k989 drift

thingiverse

wltoys k989

thingiverse

free

Wltoys A979 Stand

...wltoys a979 stand

thingiverse

wltoys a979 stand

thingiverse

free

wltoys k989 Wing by NBdesigns

...wltoys k989 wing by nbdesigns

thingiverse

wltoys k989 wing

thingiverse

free

Wheel WLtoys A979 by Mitka

...wheel wltoys a979 by mitka

thingiverse

wheel wltoys a979

thingiverse

free

Connector - Wltoys by AndreChies

...ile included for customization.

peça para carro rc. conector do wltoys offroad 1:12.

arquivo freecad incluso para personalização.

thingiverse

free

WLtoys k989 suspension bracket

...wltoys k989 suspension bracket

thingiverse

spare suspension bracket for wltoys k989 1/28 rc car

thingiverse

free

Wltoys 12428 Bumper protection by Afterhender

...wltoys 12428 bumper protection by afterhender

thingiverse

bumper protection for wltoys 12428

thingiverse

free

f949 main gear wltoys by driekes1984

...f949 main gear wltoys by driekes1984

thingiverse

the main gear of the wltoys f949

thingiverse

free

Wltoys K989 by burtendco

...wltoys k989 by burtendco

thingiverse

diffuseur rc car

Parts

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)