Thingiverse

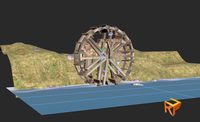

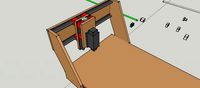

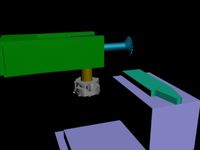

Waterbath for Carbon / Glass - fiber CNC milling by Magnus_e

by Thingiverse

Last crawled date: 3 years, 1 month ago

. 3dprint .stl files, and mill .dxf with cnc or laser.

You need

32x 4x30mm pan head wood screw.

gel / flexible glue for wather proofing. Do not use ca or anything that sets hard.

740x500x8-12mm wood plate

690x500x4mm acryl plate OR 2x 345x500x4mm acryl plate

600x400x2mm acryl wasteboard

THESE DIMENTIoNS ARE AFTER MILLING. USE A LARGER PLATE TO HAVE SOME TOLERANCES.

If you have a big enough acrylic plate, then machine AkrylicBottom and AcrylicBottomWithTap as one part.

WoodBase should be 8 - 12mm thick. Screwholes going trough the acrylic should not be drilled trough, so the glue will not leak out of the bottom. Leave ~2mm at the bottom.

Use a 600x400x2mm acrylic plate on top as the wasteboard. Replace when needed.

3dprinted parts has a slit for gluing to the bottom. Add glue and fasten with screws. When everything is assembled, then add glue to the opening in the dovetail joints. Just to leeakproof the gap betwean parts. You may need to repeat this after setting.

If using two plates as the 4mm acrylic bottom, then glue them down to the wood base for waterproofing. Use some 15x4mm wood screws to hold down the plates as the glue sets.

The Z-homie plate is so you can probe the wasteboard bead outside the waterbath. If you break a cutting steel during milling you will not be able to probe the workpease under water. Allways probe the Z-homie for consistancy. (Depending on your wood base, and thickness of glue, you might need to change the height of the Z-homie.

Hope you like, Happy milling!

You need

32x 4x30mm pan head wood screw.

gel / flexible glue for wather proofing. Do not use ca or anything that sets hard.

740x500x8-12mm wood plate

690x500x4mm acryl plate OR 2x 345x500x4mm acryl plate

600x400x2mm acryl wasteboard

THESE DIMENTIoNS ARE AFTER MILLING. USE A LARGER PLATE TO HAVE SOME TOLERANCES.

If you have a big enough acrylic plate, then machine AkrylicBottom and AcrylicBottomWithTap as one part.

WoodBase should be 8 - 12mm thick. Screwholes going trough the acrylic should not be drilled trough, so the glue will not leak out of the bottom. Leave ~2mm at the bottom.

Use a 600x400x2mm acrylic plate on top as the wasteboard. Replace when needed.

3dprinted parts has a slit for gluing to the bottom. Add glue and fasten with screws. When everything is assembled, then add glue to the opening in the dovetail joints. Just to leeakproof the gap betwean parts. You may need to repeat this after setting.

If using two plates as the 4mm acrylic bottom, then glue them down to the wood base for waterproofing. Use some 15x4mm wood screws to hold down the plates as the glue sets.

The Z-homie plate is so you can probe the wasteboard bead outside the waterbath. If you break a cutting steel during milling you will not be able to probe the workpease under water. Allways probe the Z-homie for consistancy. (Depending on your wood base, and thickness of glue, you might need to change the height of the Z-homie.

Hope you like, Happy milling!

Similar models

thingiverse

free

cnc 3018 waterbath by Bessou

...e to fix the martyr 3.5mm you can screw m4 directly or add insert m3

not perfect lot of vibration between waterbath and cnc plate

grabcad

free

Vinyl stand

...though if the thickness of the plexiglass is not consistent, some sanding might be required for a snug fit.

designed in shapr3d.

grabcad

free

CNC Z-Axis Router Mill Touch Plate Mach3 Tool Setting

...tool-setting-probe-milling-tools/253753319181?sspagename=strk%3amebidx%3ait&var=553030055984&_trksid=p2057872.m2749.l2649

thingiverse

free

Z Probe holder for TEVO Tarantula (12mm) by HS_Maker_Lab

...lab

thingiverse

simple holder for the z probe, with a diameter of 12mm, for the tevo tarantula.

you will need two 18mm m3 screw.

thingiverse

free

Acrylic Unimog Turret by MarcelloTempesta

... for milling an acrylic turret for a unimog.

the spacers are 12mm thick.

the turret plate is 20mm thick. the holes are 15mm deep.

thingiverse

free

Z Probe Trigger for Kossel by aleungyw

...ossel by aleungyw

thingiverse

only a small part designated for z probe trigger.

you need a (m3.0mm) set screw with 6mm height.

thingiverse

free

Sunhokey 3D printer Z-Probe Attachment by CuriousHatter

...d the acrylic holder, you may need to switch to a m3 x 25 or longer screw.

also helps in keeping the extruder snug and non-wobbly

thingiverse

free

Shapeoko 3 Wasteboard Workholding by clockfort

...en flipped the wasteboard around so that it was right-side-up, and then recessed the holes a bit for the preexisting screw holes.

thingiverse

free

CNC Z Probe

...cnc z probe

thingiverse

cnc z probe

hight: 30mm another 20mm

thickness: 40 mm

deepening: 38 x 2mm

thingiverse

free

clamping claws, CNC Router, Spannpratzen, CNC-Fräse by MG111

... than set, so that the clamping claws do not get stuck in it. for the pockets of the holder a 3mm cutter is needed for finishing.

Waterbath

3d_ocean

$49

Bathroom shower corners,bath corners collection 1

...3docean bath bathcorner bathroom bathroomset bathset bathtube collection volume waterbath collection 3d models of bathroom shower corner 20 pcs...

thingiverse

free

cnc 3018 waterbath by Bessou

...e to fix the martyr 3.5mm you can screw m4 directly or add insert m3

not perfect lot of vibration between waterbath and cnc plate

grabcad

free

WATERBATH

...orium yang berisi air atau cairan khusus yang

bisa mempertahankan suhu pada kondisi tertentu selama selang waktu yang ditentukan.

3dwarehouse

free

No.27 Ocean Engineering waterbath

...936m2 and is an two-story building with one-story basement. it is the waterbath for the ocean engineering. #ulsan_university #uou

Magnus

turbosquid

$14

Magnus Bronze Desk Lamp

...lty free 3d model magnus bronze desk lamp for download as max on turbosquid: 3d models for games, architecture, videos. (1561483)

turbosquid

$40

Ultra Magnus Rig G1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

i-SIT armchair by Magnus Olesen

...l i-sit armchair by magnus olesen for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1414618)

3d_export

$70

zhuchengtyrannus magnus- descendant of trex sculpt

... format= 45.923 mil 4 pieces -. check out my new a zhuchengtyrannus magnus- descendant of trex<br>thanks for your purchase!

3ddd

$1

Tint Lamp / Magnus Pettersen

...tersen

3ddd

лофт

лампа в трёх вариациях, с разными лампочками. цвет стекла может быть абсолютно любым-).

в архиве есть файл 2011.

3d_ocean

$9

Bar Stool - Contra

...bar chair bar stool chair furnishing furniture home interrior magnus metal pettersen seating stool studio whiskey wood contra bar...

design_connected

$11

Partout

...partout designconnected magnus olesen partout bar stools computer generated 3d model. designed...

3d_ocean

$6

Leimu Lamp (2013)

...3d model c4d concrete design glass iittala lamp leimu magnus pettersen vray leimu lamp (iittala, 2013) leimu lamp item...

archive3d

free

Lamp 3D Model

...model archive3d lamp table lamp reading lamp lamp by magnus pettersen n241213 - 3d model (*.gsm+*.3ds) for interior 3d...

3d_export

$150

20th Anniversary Optimus Prime 3D Model

...convoy takara hasbro 20th anniversay masterpiece transformers transformer ultra magnus megatron starscream hybrid truck vehicle robot 20th anniversary optimus...

Fiber

turbosquid

$29

fiber-cement

...squid

royalty free 3d model fiber-cement for download as obj on turbosquid: 3d models for games, architecture, videos. (1391259)

turbosquid

$59

Muscle Fiber

...royalty free 3d model muscle fiber for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1261019)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$10

fiber Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$2

Fiber Textures

...extures. tileable and editable. 512×512 pixel sized. jpg , tga image format given. unlimited color possibilities. stay connected

design_connected

$13

Fiber Wood Rug

...fiber wood rug

designconnected

ligne roset fiber wood rug computer generated 3d model. designed by ligne roset.

turbosquid

$7

Fiber Lounge Chair

...

royalty free 3d model fiber lounge chair for download as max on turbosquid: 3d models for games, architecture, videos. (1658264)

3d_export

$20

fiber optics 3D Model

...l

3dexport

light object lamp home decorative bright table element fiber optics furniture

fiber optics 3d model braz 5913 3dexport

turbosquid

$15

Solar Fibers Solarway

...l solar fibers solarway for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559873)

3d_export

$5

Carbon fiber seamless 3D Model

...carbon fiber seamless 3d model

3dexport

carbon fiber seamless texture

carbon fiber seamless 3d model gryxitl 79178 3dexport

Carbon

3d_ocean

$2

Carbon Textures

...usty shiny tga tileable

a pack of 5 carbon textures. tileable. 512×512 pixel sized. jpg , tga image format given. stay connected

design_connected

$16

Carbon Chair

...carbon chair

designconnected

moooi carbon chair chairs computer generated 3d model. designed by marcel wanders.

3ddd

$1

Carbon touring desk

... tonino lamborghini casa , стол

tonino lamborghini casa carbon touring desk

turbosquid

$1

carbonic acid

...id

royalty free 3d model carbonic acid for download as blend on turbosquid: 3d models for games, architecture, videos. (1517834)

design_connected

$7

Carbon Shagreen Box

...carbon shagreen box

designconnected

carbon shagreen box computer generated 3d model.

turbosquid

$90

Carbon NanoSheet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$90

Carbon Nanotube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

carbon nanosheet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$38

Carbon Planet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Carbon dioxide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Milling

design_connected

$18

Mills

...mills

designconnected

minotti mills computer generated 3d model. designed by dordoni, rodolfo.

3ddd

$1

Mille Nuits

...mille nuits

3ddd

mille nuits

люстра из коллекции mille nuits

turbosquid

$25

Mill

...ll

turbosquid

royalty free 3d model mill for download as fbx on turbosquid: 3d models for games, architecture, videos. (1292872)

turbosquid

$15

The Mill

...urbosquid

royalty free 3d model the mill for download as obj on turbosquid: 3d models for games, architecture, videos. (1459219)

turbosquid

$3

Mill

...ll

turbosquid

royalty free 3d model mill for download as max on turbosquid: 3d models for games, architecture, videos. (1233201)

turbosquid

$1

mill

...

turbosquid

royalty free 3d model mill for download as blend on turbosquid: 3d models for games, architecture, videos. (1613409)

3d_export

$10

Coffee Mill

...coffee mill

3dexport

coffee mill

3d_export

$5

impact mill

...impact mill

3dexport

impact mill

archibase_planet

free

Milling machine

...base planet

milling machine miller milling-machine

milling machine vhf-680 n250413 - 3d model (*.gsm+*.3ds) for 3d visualization.

3ddd

$1

Minotti / Mills

...minotti / mills

3ddd

minotti

minotti / mills

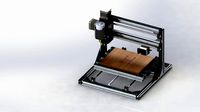

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Glass

archibase_planet

free

Glasses

...glasses

archibase planet

glass wine-glass liqueur-glass

glasses- 3d model for interior 3d visualization.

archibase_planet

free

Glass

...archibase planet

glass cocktail glass tall wine glass martini glass

glass - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass wine-glass glass-ware

glass n030209 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass-ware glass glass ware

glass n141109 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$2

Glass

...liquid container low-poly glass nice glass obj r15 water glass

3d model of a beautiful glass. created the model in cinema 4d r15.

archibase_planet

free

Glass

...glass

archibase planet

glass tall wine glass wine-glass

glass n300514 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass wine-glass tall wine glass

glass n091210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Glass

...glass

archibase planet

glass tall wine glass glass-ware

glass n081011 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$9

glasses

...glasses

3docean

glasses

max glasses v-ray

archibase_planet

free

Glass

...glass

archibase planet

glass-ware glass

glass - 3d model (*.gsm+*.3ds) for interior 3d visualization.

E

3ddd

$1

WALL-E

...wall-e

3ddd

wall-e , робот

wall-e

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw- it have 3d model of passenger e-rickshaw

3d_ocean

$12

Wall E

...wall e

3docean

character robot wall e

its a 3d model of wall e….

turbosquid

$68

Model-E Droids 2-E Q-E Star Wars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$45

Model-E Droids 2-E Q-E Star Wars3d model

....3ds .c4d .obj .vue - model-e droids 2-e q-e star wars 3d model, royalty free license available, instant download after purchase.

3d_export

$100

e-rickshaw

...e-rickshaw

3dexport

e-rickshaw design for passenger it have all mechanical component

design_connected

$7

Cone E

...cone e

designconnected

bonaldo cone e computer generated 3d model. designed by pasini, ennio.

3ddd

$1

Wall-E NEW

...wall-e new

3ddd

wall-e , робот

wall-e

design_connected

$29

Extrasoft E

...extrasoft e

designconnected

living divani extrasoft e computer generated 3d model. designed by lissoni, piero.

3ddd

$1

E-Turn

... скамейка

современная скамейка фирмы kundalini.

модель e-turn.

дизайнер brodie neil.

размеры: h 42 cm l 185 cm w 54 cm