Thingiverse

Watch winder for 2 automatic watches by noteasy2

by Thingiverse

Last crawled date: 3 years ago

Automatic watch winder for 2 automatic watches and powered by geared motor, servo or raspberry pi zero.

Parts list and tips:

Low noise motor (Option 1) and driving geared motor (Option 2)with 10rpm max.

Power switch On/off

Steel pins size to suit gear axle

Bearing (either printed out or steel bearing)

Screws

Motor Option:

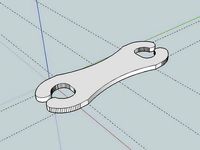

Back-gear frame.stl

8 driving gear.stl

2 Nos. 40x8 -final.stl

OR Geared Motor (1020555 3K1655)Option:

New_8_gear.stl

New_motor_frame.stl

1 No. 40x8-final.stl

Control Method 1:

Programmable timer and an USB power supplierhttp://www.dx.com/p/digital-lcd-electronic-plug-in-programmable-timer-12-24-hour-switch-socket-with-clock-summer-time-416027#.WkmJJpeYO70

Control Method 2:

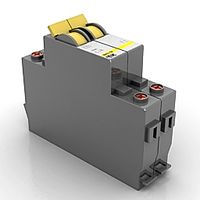

Raspberry Pi Zero with a modified relay controllerhttps://learn.adafruit.com/adafruit-power-relay-featherwing/overview?view=all

Control Method 3:

IC 555 delay timer switch

Control Method 4:

TPL5111https://learn.adafruit.com/adafruit-tpl5111-reset-enable-timer-breakout/overview?view=all

Watch cups were fixed with bearing on the back panel and rotated and guarded by front panel. To ensure prefect contact, watch cups shall be heated with hot water or hair dryer and then pull fit into panel and turned for 10+ rounds until smooth to run. Finally, some grease may add on it for easy of turning. For the watches, it was fixed into cups with oval shaped spongy material (cut from heat pipe insulation materials).

Noise may be generated during the operation, please review the specifications of the driving motor for its operation voltage. If it is possible, please use a low noise geared motor as in crystal display stand. IC, LM317 may be used to step down the voltage in order to slow down the driving motor such that noise can be reduced. In my case, 5V USB adopter of mobile phone was used as power with a LM317 to convert voltage to 3.9V with 475 ohm and 1k ohm resistors. It is programmed to run 3 times every day via 7 x 24 hrs. digital timer plug.

Optional functions such as AIY with raspberry pi and powered by USB for mobile docking or charging stand.

If you do not want to print or make one, you may buy a watch winder in below link from me in a more reasonable price.https://www.bing.com/images/search?view=detailV2&ccid=vBxTVVYc&id=08C055733F36DFBAF5C1138923631E0DB4F31873&thid=OIP.vBxTVVYckQ0p2EEptg8a7QEsEs&q=delux+watch+winder&simid=608031555680404246&selectedIndex=28&ajaxhist=0

Last update on 19 Aug 2018:

Please ensure the motor can be mounted into the T-frame. Otherwise, you must design your frame to fit into the gear system. The gear was supported by the axles (i.e. stainless steel pins for the watch or steel rods). For the long run, my motor was powered by an USB adopter and a power switch on the case. An external 7x24 stock timer and an USB adopter was controlled by it. I have 3 rotation settings on each day and only rotating the watch in one direction.

Many guy was asking for the kit or pre-built watch. Therefore, please visit http://noteasy2.kmdns.net for details.

Updated: Nov 2020

The automation interface is designed and run in a Raspberry Pi 3B web server via four GPIO controlled relays. It can be turned off/on remotely any devices (i.e. LED light of fish tank (https://www.thingiverse.com/thing:4193517)and watch winder and scheduled with crontab.

Parts list and tips:

Low noise motor (Option 1) and driving geared motor (Option 2)with 10rpm max.

Power switch On/off

Steel pins size to suit gear axle

Bearing (either printed out or steel bearing)

Screws

Motor Option:

Back-gear frame.stl

8 driving gear.stl

2 Nos. 40x8 -final.stl

OR Geared Motor (1020555 3K1655)Option:

New_8_gear.stl

New_motor_frame.stl

1 No. 40x8-final.stl

Control Method 1:

Programmable timer and an USB power supplierhttp://www.dx.com/p/digital-lcd-electronic-plug-in-programmable-timer-12-24-hour-switch-socket-with-clock-summer-time-416027#.WkmJJpeYO70

Control Method 2:

Raspberry Pi Zero with a modified relay controllerhttps://learn.adafruit.com/adafruit-power-relay-featherwing/overview?view=all

Control Method 3:

IC 555 delay timer switch

Control Method 4:

TPL5111https://learn.adafruit.com/adafruit-tpl5111-reset-enable-timer-breakout/overview?view=all

Watch cups were fixed with bearing on the back panel and rotated and guarded by front panel. To ensure prefect contact, watch cups shall be heated with hot water or hair dryer and then pull fit into panel and turned for 10+ rounds until smooth to run. Finally, some grease may add on it for easy of turning. For the watches, it was fixed into cups with oval shaped spongy material (cut from heat pipe insulation materials).

Noise may be generated during the operation, please review the specifications of the driving motor for its operation voltage. If it is possible, please use a low noise geared motor as in crystal display stand. IC, LM317 may be used to step down the voltage in order to slow down the driving motor such that noise can be reduced. In my case, 5V USB adopter of mobile phone was used as power with a LM317 to convert voltage to 3.9V with 475 ohm and 1k ohm resistors. It is programmed to run 3 times every day via 7 x 24 hrs. digital timer plug.

Optional functions such as AIY with raspberry pi and powered by USB for mobile docking or charging stand.

If you do not want to print or make one, you may buy a watch winder in below link from me in a more reasonable price.https://www.bing.com/images/search?view=detailV2&ccid=vBxTVVYc&id=08C055733F36DFBAF5C1138923631E0DB4F31873&thid=OIP.vBxTVVYckQ0p2EEptg8a7QEsEs&q=delux+watch+winder&simid=608031555680404246&selectedIndex=28&ajaxhist=0

Last update on 19 Aug 2018:

Please ensure the motor can be mounted into the T-frame. Otherwise, you must design your frame to fit into the gear system. The gear was supported by the axles (i.e. stainless steel pins for the watch or steel rods). For the long run, my motor was powered by an USB adopter and a power switch on the case. An external 7x24 stock timer and an USB adopter was controlled by it. I have 3 rotation settings on each day and only rotating the watch in one direction.

Many guy was asking for the kit or pre-built watch. Therefore, please visit http://noteasy2.kmdns.net for details.

Updated: Nov 2020

The automation interface is designed and run in a Raspberry Pi 3B web server via four GPIO controlled relays. It can be turned off/on remotely any devices (i.e. LED light of fish tank (https://www.thingiverse.com/thing:4193517)and watch winder and scheduled with crontab.

Similar models

thingiverse

free

Raspberry Pi NAS Box by khanhj

...raspberry pi nas box by khanhj

thingiverse

support raspberry pi 3, 4

usb hub

ethernet rj45

hdmi

power plug

power switch

thingiverse

free

4 Relay Raspberry Pi Enclosure by skylinrcr01

...skylinrcr01

thingiverse

this is a case for the 3 relay board for the raspberry pi to shield from the high voltage carrying pins.

thingiverse

free

Network Ethernet Relay Box (Raspberry Pi Zero) by Z__Y

...tml?spm=a2g0s.9042311.0.0.27424c4dtkppsk

5x 6mm m2 screws: (can find on ebay or hardware store)

some wires to connect relay to pi

thingiverse

free

R2D2 Servo Controller by JellyBitz

...ead board via the relay

connect all servos power cables to the breadboard.

the you can turn power offand on to them via the relay

thingiverse

free

Octoprint Printer Power Relay Box for big Power Contactor by Darkwulf3D

...a 5 volt relay which can be switched via octroprint and the raspberry pi.

to print, this box is made of fire-retardant material.

thingiverse

free

Case for USB voltage hub

...nning multiple raspberry pi computers

the pcb is designed by my brother, see https://easyeda.com/bartvangorp/usb-voltage-hub-v1-2

thingiverse

free

Hyperion ambilight box by Todely

... rs-50-5 & raspberry pi 3b+ & arduino

hole for :

power plug

round connector

usb of raspberry

micro usb power raspberry

grabcad

free

CTRL HAT - Solid State Relay HAT

...sensitive equipment such as amplifiers.

original model created in sketchup pro 2018.

© 2020 - dan jones - https://plasmadan.com

grabcad

free

Case for 3.3V Relay Module for Raspberry Pi

...ires a 220v/10a switch, a power cord and a bunch of m2.5/m3 screws and nuts. the switch can be used to enable/disable the module.

thingiverse

free

Raspberry Pi with dual relay board by steverjuk

...ual relay board by steverjuk

thingiverse

raspberry pi case with dual relay board, also designed to screw into cr-10 control box.

Noteasy2

thingiverse

free

Box by noteasy2

...box by noteasy2

thingiverse

box was created from fusion 360 as a trial

thingiverse

free

Foldable door hanger by noteasy2

...foldable door hanger by noteasy2

thingiverse

this is a replacement plastic hanger for an aluminium bi-fold door.

thingiverse

free

Bridge Segment by noteasy2

...t model of a bridge in hk. how hard to creat this bridge?https://www.theb1m.com/video/hong-kong-to-macau-bridge-passes-inspection

thingiverse

free

Key Ring - Please call (phone no.) by noteasy2

...key ring - please call (phone no.) by noteasy2

thingiverse

made to order key ring

thingiverse

free

Coffee Mug by noteasy2

...nt with suitable filament to withstand high temperature (i.e.100 deg) such as pp. otherwise, you may only use it for cold drink.

thingiverse

free

Head of Ball Jointed Doll by noteasy2

...asy2

thingiverse

this is a girl head of a ball joint doll. the frame of doll is under designed base on the smart doll in japan.

thingiverse

free

Rubber Tie for Bicycle LED Flashing Light by noteasy2

...rubber tie for bicycle led flashing light by noteasy2

thingiverse

replacement rubber tie for bicycle flashing light.

thingiverse

free

Wall unit handle (add-on hook) by noteasy2

...andle. clothes can be hanged on it easily and the location can be changed by slipping it on the handle easily. my wife loves it.

thingiverse

free

Foam Board - Corner Mount by noteasy2

...o a flat surface with double side tape or sealant. a wedge is used to hold foam board in place and can be removed when necessary.

thingiverse

free

Differential Gear Box by noteasy2

...as input. 4 sun gears(16 teeth) are rotating in the center as output. the design of casing can be designed according to the use.

Winder

turbosquid

$10

window strap winder (external)

...del window strap winder (external) for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1281687)

3d_export

$14

winder textile special equipment

...s a role of "bridge" connecting the preceding and the following, so it plays an important role in the field of textile.

3d_export

$30

gold pocket watch

...(parented to watch)<br>hour hand (parented to watch)<br>lid (parented to watch)<br>winder (parented to watch)<br>pocketwatch - 2k -<br>diffuse<br>roughness<br>normal - (opengl unity...

3d_export

$30

helmets hats pack lowpoly

...newsboy cap sun cap war guard helmet winter cap winder fold cap<br>fbx-embed texture fbx<br>mb(maya binary)<br>obj<br>blender file only exports without...

3d_export

$32

speed reducer gear box worm helical wpx

...common household uses are washing machines, food blenders and window-winder. reduction drives are also used to decrease the rotational...

thingiverse

free

Side Winder by airdronez

...side winder by airdronez

thingiverse

side winder

thingiverse

free

Earphone winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Earphone Winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Spool Winder by Verohomie

...spool winder by verohomie

thingiverse

spool winder for a cordless drill

thingiverse

free

Cable Winder by kazsoft

...cable winder by kazsoft

thingiverse

just a simple cable winder.

Automatic

archibase_planet

free

Automat

...automat

archibase planet

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$17

Automatic wire bending machine wire automatic bending machine

...atic wire bending machine wire automatic bending machine

3dexport

automatic wire bending machine, wire automatic bending machine

archive3d

free

Automat 3D Model

...ive3d

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$20

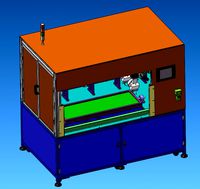

Design of automatic laminator

...design of automatic laminator

3dexport

design of automatic laminator

3d_export

$6

Automatic soldering machine

...automatic soldering machine

3dexport

automatic soldering machine

turbosquid

$20

automatic rifle

...id

royalty free 3d model automatic rifle for download as fbx on turbosquid: 3d models for games, architecture, videos. (1163137)

turbosquid

$9

automatic gun

...yalty free 3d model automatic gun for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1226948)

turbosquid

$5

Automatic Knife

...lty free 3d model automatic knife for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1378253)

turbosquid

$1

flashlight for automat

...flashlight for automat for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1314717)

3d_export

$20

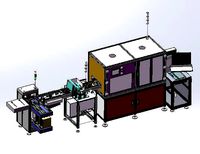

automatic pcb loading and unloading dispensing test automatic line

...ment structure is very complex. it is a very practical equipment for smt industry. the equipment is mature application equipment.

Watches

3d_ocean

$4

Watch

...watch

3docean

accessory watch

just ordinary watch

archibase_planet

free

Watch

...se planet

watch wristwatch wristlet watch wrist-watch

watch gucci n121213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n280114 - 3d model (*.3ds) for interior 3d visualization.

3d_export

free

Watch

...watch

3dexport

watch

archibase_planet

free

Watch

...watch

archibase planet

wrist-watch wrist watch wristwatch

watch n061110 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n011212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wristwatch wrist watch

watch bulova n170211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

watch

...watch

3dexport

black watch

archibase_planet

free

Watch

...chibase planet

watch wrist-watch wristwatch

watch orient titanium n090713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...planet wrist watch watch wristwatch clock watch casio g-shock wristwatches n260111 - 3d model (*.3ds) for interior 3d...

Watch

3d_ocean

$4

Watch

...watch

3docean

accessory watch

just ordinary watch

archibase_planet

free

Watch

...se planet

watch wristwatch wristlet watch wrist-watch

watch gucci n121213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n280114 - 3d model (*.3ds) for interior 3d visualization.

3d_export

free

Watch

...watch

3dexport

watch

archibase_planet

free

Watch

...watch

archibase planet

wrist-watch wrist watch wristwatch

watch n061110 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n011212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wristwatch wrist watch

watch bulova n170211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

watch

...watch

3dexport

black watch

archibase_planet

free

Watch

...chibase planet

watch wrist-watch wristwatch

watch orient titanium n090713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...net

wrist watch watch wristwatch clock

watch casio g-shock wristwatches n260111 - 3d model (*.3ds) for interior 3d visualization.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALPEREN-2

...alperen-2

3ddd

комод , alperen-2

комод с зеркалом alperen-2

design_connected

$27

Confluences 2 2-Seater Sofa

... 2-seater sofa

designconnected

ligne roset confluences 2 2-seater sofa computer generated 3d model. designed by nigro, philippe.