Thingiverse

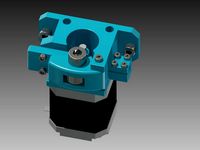

VORON Flex Bowden Extruder by russiancatfood

by Thingiverse

Last crawled date: 3 years ago

Overview: https://www.youtube.com/watch?v=8s7HgMFrdTg

UPDATE:

REV A1: Enlarged the hole for the set screw in case the motor shaft is not keyed (D shaped).

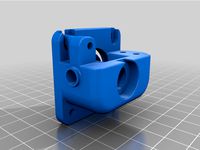

REV A: I've ran into some issues with the design when it comes to flexible filament, and fixed them. The flex filament still has some path to get around the drive gear, because the piece of PTFE tube could be pushed up. The tubes also likes to be pulled down. The solution was to shape a channel for the filament in printed plastic, and add a bolster that filled the space between the top curve of the drive gear's tooth channel. Now the flexible filament will just slip, like any filament should, instead of jamming the gear.

Also added 3mm versions of parts that needed modification

I finally have an extruder I'm happy with. Easy access, and 70mm/s retract speeds. Oh, and I can print 1.75mm Ninjaflex. :)

You are going to need the following things:

4 - M3 22mm hex head screws

1 - M3 hex nut

1 - M4 14mm hex head screw

1 - M4 hex nut

1 - MK8 Drive Gear

1 - 625-2RS ball bearing

You'll also need a BSP bowden coupling (1/8) and about 40mm of bowden tubing

Insert the bowden tubing in all the way and shape it with a razor blade using the printed body as a guide. Then pop in the screws and attach the whole thing to the motor. Line up the key on the motor with the slit, slip on and align the MK8 drive gear and tighten it

UPDATE:

REV A1: Enlarged the hole for the set screw in case the motor shaft is not keyed (D shaped).

REV A: I've ran into some issues with the design when it comes to flexible filament, and fixed them. The flex filament still has some path to get around the drive gear, because the piece of PTFE tube could be pushed up. The tubes also likes to be pulled down. The solution was to shape a channel for the filament in printed plastic, and add a bolster that filled the space between the top curve of the drive gear's tooth channel. Now the flexible filament will just slip, like any filament should, instead of jamming the gear.

Also added 3mm versions of parts that needed modification

I finally have an extruder I'm happy with. Easy access, and 70mm/s retract speeds. Oh, and I can print 1.75mm Ninjaflex. :)

You are going to need the following things:

4 - M3 22mm hex head screws

1 - M3 hex nut

1 - M4 14mm hex head screw

1 - M4 hex nut

1 - MK8 Drive Gear

1 - 625-2RS ball bearing

You'll also need a BSP bowden coupling (1/8) and about 40mm of bowden tubing

Insert the bowden tubing in all the way and shape it with a razor blade using the printed body as a guide. Then pop in the screws and attach the whole thing to the motor. Line up the key on the motor with the slit, slip on and align the MK8 drive gear and tighten it

Similar models

thingiverse

free

Compact Bowden Extruder by CaseyJohnson

...der arm

2 m3 x 25mm machine screw if you do not use springs on the extruder arm

1 m6 hex nut

1 bowden push fitting with m6 thread

thingiverse

free

VORON Extruder 1.75 for Ender 3

...ar

1 - 625-2rs ball bearing

remember what you need:

change the direction of rotation of the motor!

customize the number of steps!

thingiverse

free

7:32 Compact Geared Extruder Nema17 and 14 by ryannining

...haft bearing

1x 624 for idler.

1xm4 nut

to make tensior, i use steel from peg to clamphttps://www.youtube.com/watch?v=-7bpu9pbq18

thingiverse

free

Tiny Flex Extruder Bowden Variant by tkramm

...r-pulley-drive-gear.html

nema 17 motor

624 bearing

2x m3x12

1x m3x25

1x m4x10

4x m3 hex nut

4x m3x16

1x spring 7mm od 30mm length

thingiverse

free

Extruder / Bowden - 3mm filament by dinizhobby

...zhobby

thingiverse

extruder for bowden filament 3mm

you need mk8 driver gear and one bearing 6x13x5 and shaft 6mm with screw m4

thingiverse

free

Rackprint Bowden Extruder by Alex_RP

...x m3 screw ~20mm and nuts

2x m3 screw 15mm

bearing 608zz

mk8 drive gear

2x spring ~20mm with ~3mm inner diameter

thingiverse

free

Bowden extruder by louis2

...ament. it use an m10 pneumatic fitting for more reliability and an easier filament insertion. can be used with flexible filament.

thingiverse

free

Upgraded Bowden Extruder for flexible filament, nylon and many more by kazam_x1

... hotend.

you need:

4 x m3x10mm

1 x m3x 15mm

1 x m3 nut

1 x 608 bearing

1 x mk7 drive gear

1 x ptfe push fit connector

teflon tube

thingiverse

free

MK7 Extruder by wkkpatrick

... 5mm inner x 1

-bearing 604uu x 1

-m3 washer 8x0.8 x 2

-hex screw m3 20mm x 2

-hex screw m4 10mm x 1

-push fit connector (pc4-m6)

thingiverse

free

Bowden Extruder (Acrylic) by wkkpatrick

...0mm x 2

-hex screw m3 6mm x 2

-push fit connector (pc4-m6)

filament loading by thumb crank:-http://www.thingiverse.com/thing:7912

Russiancatfood

thingiverse

free

Parametric Linear Bearing by russiancatfood

...verse

fixed the lip on the bearings to make them more printable.

also exposed full parameters of the bearings for customization.

thingiverse

free

E3D Titan BSP Bowden adapter by russiancatfood

...e3d titan bsp bowden adapter by russiancatfood

thingiverse

needed a bsp adapter for a e3d titan, so here it is.

thingiverse

free

Maker Faire Robot Ornament by russiancatfood

...nament by russiancatfood

thingiverse

i took an existing maker faire robot action figure and added supports and an ornament loop.

thingiverse

free

R9 Antenna Protector by russiancatfood

... cmw massive droner, or you can just zip tie it to any quad.

step files included for both. enjoy modding this for your own craft.

thingiverse

free

Non-slip switch for Revlon hair drier by russiancatfood

...rror the part for the other switch.

when you are putting them in, be careful of the little tidbits that fall out of the handle.

thingiverse

free

FPV Camera mount/guard for BlackOut/ZMR250 by russiancatfood

...screws

1x m3 set screw (or another m3 screw) for locking angle of the camera.

it can be pointed straight or at 15 degree angle.

thingiverse

free

Self-Aligning PLA Linear Bearings by russiancatfood

...ignment.

if you want the actual part, they can be ordered directly from igus:http://www.igus.com/wpck/3772/igubal_flanschlager

thingiverse

free

TR8 Lead Screw Block - IGUS by russiancatfood

...round the 2 aligning protrusions.

the block is pressed into the retainer that both provides mounting options, and gives rigidity.

thingiverse

free

Voron Geared Extruder by russiancatfood

...hobbed bolt 50mm long, hobbed in the middle (sourced from lulzbot) | 1

m8 locking nut | 1

m8 washer | 2

nema 17 stepper motor | 1

Voron

thingiverse

free

VORON Tag by froggy2288

...voron tag by froggy2288

thingiverse

tag for a voron 3d printer. mounts directly to 20mm aluminum extrusion.

thingiverse

free

3D Voronization of Hand by kriffe

...3d voronization of hand by kriffe

thingiverse

3d voronization of hand.

thingiverse

free

Tool Holder Voron by Struppiboy

...ngiverse

ein praktischer zangenhalter für den voron 2.4 am gehäuse.

a practical pliers holder for the voron 2.4 on the housing.

thingiverse

free

Stand Voron 2.4 by Struppiboy

...uppiboy

thingiverse

ich habe für den voron 2.4 füße für squash bälle konstruiert.

i constructed 2.4 squash balls for the voron.

thingiverse

free

Voron Gopro Mount by JacobMakes

...filming timelape videos of my voron, i changed up the design to better match the style of the voron, also made it easier to print

thingiverse

free

Voron Switchwire - Build Log by DarekNorway

...uild bog is regularly updated on hackaday:

https://hackaday.io/project/174810-voron-switchwire-3d-printer

voron switchwire frame

thingiverse

free

Voron 2.4, Orbiter1.5 Mount by madsgadeberg

...extruder mount for the voron afterburner.

print settings same as other voron parts.

bolts: 4pcs m3x20 and regular m3 heat inserts

thingiverse

free

Voron 2.4 feet by maciek13

...voron 2.4 feet by maciek13

thingiverse

.

thingiverse

free

VORON case for Viki2 LCD by fulg

...on case for viki2 lcd by fulg

thingiverse

here is a case for the viki2 lcd. it is styled to match the rest of the voron printer.

thingiverse

free

Voron M4 Guidler with ID by falcon14141

...voron m4 guidler with id by falcon14141

thingiverse

simple remix of the voron m4 guidler to add identification of your extruder.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Flex

3ddd

$1

Flex

...flex

3ddd

flex , конференц-зал

кресло для переговоров

3ddd

$1

Flex — I Laccati

... i laccati

3ddd

flex , дверь

двери межкомнатные, окрашенные. flex, коллекция «i laccati»

3ddd

free

Flex Seating 6032

... конференц-зал , flex

кресло модульное, модель flex seating 6032

3ddd

free

TechnoGym Flex Posterior

... flex , тренажер

3ds max 2012 (v-ray) + fbx

technogym flex posterior

3ddd

$1

Банкетка Flex Team

... , flex team

http://www.abitant.com/products/banketka-flex-team-2014-kilt-pouf

3ddd

free

FLEX , I Laccati

...cati

3ddd

flex , i laccati

flex , i laccati

модель p 14 q stucco fiorentino decoro gigli

3ddd

$1

Metal lux / FLEX

...metal lux / flex

3ddd

metal lux

люстра metal lux flex.

turbosquid

$11

Stool Flex

...ty free 3d model stool flex for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1673813)

3ddd

$1

Flex by Skandiform

...flex by skandiform

3ddd

skandiform , стул

enjoy

turbosquid

$7

Flex Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.