Thingiverse

Vixen GP Goto Conversion Using Meade DS Motors by wt808

by Thingiverse

Last crawled date: 3 years, 3 months ago

Brackets and adapters for installing Meade DS motors on a Vixen Great Polaris telescope equatorial mount. May fit other Vixen equatorial mount models and clones such as:

Vixen SP, SP-DX, GP-E, GP-DX

Celestron CG-5

Synta EQ-4, EQ-5

Skywatcher EQ-4, EQ-5

Orion SkyView Pro

Jinghua HD (Apogee Inc.)

Or make your own brackets for your mount to fit the motor adapter and ring.

Installation on a Vixen GP

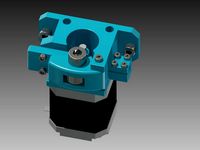

Remove the lock ring and threaded collar from both DS motors. Thread on the 3D-printed motor ring until nearly fully seated on the motor threads.

Note the orientation of the ring with the 3D-printed mounting bracket and where the M3 nuts will need to go. Turn the ring as needed until the holes of the ring and bracket line up properly. Make note the holes on the ring where the M3 nuts need to be pressed in.

Remove the ring, press in the three M3 nuts, and reinstall the ring in the proper orientation again.

Press a MF85ZZ bearing into the recess inside each motor. Finger pressure should be enough to seat both bearings.

Press a 635ZZ bearing into each end of the 3D-printed nose piece adapter.

Cut a small flat into the 5mm shaft for the set screw of the 22T gear to prevent the gear from rotating on the shaft when locked. I allowed 4mm of the shaft to protrude from the bottom of the gear to fit in the MF85ZZ bearing in the motor.

Install the 22T gear on the shaft lining up the set screw with the flat. If the underside of the gear is hollow, 3D-print the gear spacer and press it into the gear. This prevents the MF85ZZ bearing from unseating from the motor housing during operation.

Slide the longer end of the shaft through the nose piece and attach the 40T 5mm ID pulley. Check for free rotation and excessive play.

Apply grease to the 22T gear and carefully slide the nose piece into the motor. Note the alignment nubs on the nose that mate with the notches on the motor. Rotate the pulley/gear as needed to align the gear teeth with the nylon gear in the motor as you slide the assembly into the motor.

Fasten the motor assembly to the 3D-printed mounting bracket using three M3 screws and washers. Press an M6 nut into the base of the bracket.

Repeat for the other DS motor. At this point, you might want to connect both motors, power supply, and the Autostar controller to the jack panel, power the system on, and test for proper operation.

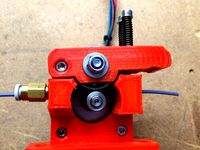

Install the 40T 6mm ID pulleys on both worm screws of the mount. Do not tighten fully yet.

Carefully install the belt simultaneously as you position the bracket for installation. Once the bracket is positioned properly, insert an M6 bolt through the corresponding opening in the mount and tighten to secure the bracket.

Verify the belt alignment and tighten set screws on the mount pulleys. If the belt alignment cannot be corrected by adjusting the mount-side pulley, you can also shim M5 washers between the motor-side pulley and outboard 635ZZ bearing. Note that you will have to remove the motor from the bracket to access the pulley set screws.

Install the 3D-printed jack panel housing on the RA motor bracket using the two M3 wood screws. Install the jack panel with the 4 screws provided with the panel, or use 4 more wood screws like the ones you used to mount the housing.

Connect the motors and Autostar hand controllers to the jack panel, connect the power supply, and verify proper operation. Note positions where the motor might hit the other motor, mount, jack panel cables, or where the telescope might hit either motor or jack panel.

Notable Autostar configuration parameters

Telescope - 4504/114EQ if FW patched, otherwise DS-127

Alt/Dec Ratio = -03.28533 (1:144 worm ratio)

Az/RA Ratio = +03.28533 (1:144 worm ratio)

Alt/Dec Percent = 75%

Az/RA Percent = 75%

Parts list

2x Meade DS motors (492 or 493)

1x Meade Computer Control jack panel

1x Autostar hand controller (495 or 497) + coil cable

1x 5.5x2.5mm 12VDC power supply, center-positive, 1.5A minimum (preferably with a right-angle DC connector)

1x Meade 505 RS-232 serial interface (optional, RJ11 on handset end, DB9 or USB on computer end)

2x 22T pinion gear, mod1, 5mm ID bore (used for RC cars)

4x 635ZZ ball bearing, double shielded, 5x19x6mm

2x MF85ZZ ball bearing, flanged, double shielded, 5x8x2.5mm

2x 5mm OD x 60mm L stainless round shaft

2x GT2 timing belt, 180mm circumference, 6mm width

2x 40T GT2 timing pulley, 5mm ID bore, 6mm width

2x 40T GT2 timing pulley, 6mm ID bore, 6mm width (I bought four of the 5mm ID pulleys and reamed two to 6mm)

6x M3 x 20mm bolt

6x M3 nuts

6x M3 flat washers

2x M3 x 8mm wood or self-tapping sheet metal screws (6x if the jack panel didn't include screws)

M5 washers (optional, for spacing timing pulleys for belt alignment)

1x M6 x 20mm bolt

1x M6 x 45mm bolt

2x M6 hex nuts

References

"Retrofitting Autostar GOTO control to the Vixen SP and GP style GEM mounts using Meade DS-Series motors", v1.2 2/14/2003https://www.cloudynights.com/ubbthreads/attachments/677648-Retrofit_v1.2.pdf

"Adding Autostar GOTO functionality to your existing telescope", Christopher Ericksonhttp://data-plumber.com/autostarupgrade.htm

Vixen SP, SP-DX, GP-E, GP-DX

Celestron CG-5

Synta EQ-4, EQ-5

Skywatcher EQ-4, EQ-5

Orion SkyView Pro

Jinghua HD (Apogee Inc.)

Or make your own brackets for your mount to fit the motor adapter and ring.

Installation on a Vixen GP

Remove the lock ring and threaded collar from both DS motors. Thread on the 3D-printed motor ring until nearly fully seated on the motor threads.

Note the orientation of the ring with the 3D-printed mounting bracket and where the M3 nuts will need to go. Turn the ring as needed until the holes of the ring and bracket line up properly. Make note the holes on the ring where the M3 nuts need to be pressed in.

Remove the ring, press in the three M3 nuts, and reinstall the ring in the proper orientation again.

Press a MF85ZZ bearing into the recess inside each motor. Finger pressure should be enough to seat both bearings.

Press a 635ZZ bearing into each end of the 3D-printed nose piece adapter.

Cut a small flat into the 5mm shaft for the set screw of the 22T gear to prevent the gear from rotating on the shaft when locked. I allowed 4mm of the shaft to protrude from the bottom of the gear to fit in the MF85ZZ bearing in the motor.

Install the 22T gear on the shaft lining up the set screw with the flat. If the underside of the gear is hollow, 3D-print the gear spacer and press it into the gear. This prevents the MF85ZZ bearing from unseating from the motor housing during operation.

Slide the longer end of the shaft through the nose piece and attach the 40T 5mm ID pulley. Check for free rotation and excessive play.

Apply grease to the 22T gear and carefully slide the nose piece into the motor. Note the alignment nubs on the nose that mate with the notches on the motor. Rotate the pulley/gear as needed to align the gear teeth with the nylon gear in the motor as you slide the assembly into the motor.

Fasten the motor assembly to the 3D-printed mounting bracket using three M3 screws and washers. Press an M6 nut into the base of the bracket.

Repeat for the other DS motor. At this point, you might want to connect both motors, power supply, and the Autostar controller to the jack panel, power the system on, and test for proper operation.

Install the 40T 6mm ID pulleys on both worm screws of the mount. Do not tighten fully yet.

Carefully install the belt simultaneously as you position the bracket for installation. Once the bracket is positioned properly, insert an M6 bolt through the corresponding opening in the mount and tighten to secure the bracket.

Verify the belt alignment and tighten set screws on the mount pulleys. If the belt alignment cannot be corrected by adjusting the mount-side pulley, you can also shim M5 washers between the motor-side pulley and outboard 635ZZ bearing. Note that you will have to remove the motor from the bracket to access the pulley set screws.

Install the 3D-printed jack panel housing on the RA motor bracket using the two M3 wood screws. Install the jack panel with the 4 screws provided with the panel, or use 4 more wood screws like the ones you used to mount the housing.

Connect the motors and Autostar hand controllers to the jack panel, connect the power supply, and verify proper operation. Note positions where the motor might hit the other motor, mount, jack panel cables, or where the telescope might hit either motor or jack panel.

Notable Autostar configuration parameters

Telescope - 4504/114EQ if FW patched, otherwise DS-127

Alt/Dec Ratio = -03.28533 (1:144 worm ratio)

Az/RA Ratio = +03.28533 (1:144 worm ratio)

Alt/Dec Percent = 75%

Az/RA Percent = 75%

Parts list

2x Meade DS motors (492 or 493)

1x Meade Computer Control jack panel

1x Autostar hand controller (495 or 497) + coil cable

1x 5.5x2.5mm 12VDC power supply, center-positive, 1.5A minimum (preferably with a right-angle DC connector)

1x Meade 505 RS-232 serial interface (optional, RJ11 on handset end, DB9 or USB on computer end)

2x 22T pinion gear, mod1, 5mm ID bore (used for RC cars)

4x 635ZZ ball bearing, double shielded, 5x19x6mm

2x MF85ZZ ball bearing, flanged, double shielded, 5x8x2.5mm

2x 5mm OD x 60mm L stainless round shaft

2x GT2 timing belt, 180mm circumference, 6mm width

2x 40T GT2 timing pulley, 5mm ID bore, 6mm width

2x 40T GT2 timing pulley, 6mm ID bore, 6mm width (I bought four of the 5mm ID pulleys and reamed two to 6mm)

6x M3 x 20mm bolt

6x M3 nuts

6x M3 flat washers

2x M3 x 8mm wood or self-tapping sheet metal screws (6x if the jack panel didn't include screws)

M5 washers (optional, for spacing timing pulleys for belt alignment)

1x M6 x 20mm bolt

1x M6 x 45mm bolt

2x M6 hex nuts

References

"Retrofitting Autostar GOTO control to the Vixen SP and GP style GEM mounts using Meade DS-Series motors", v1.2 2/14/2003https://www.cloudynights.com/ubbthreads/attachments/677648-Retrofit_v1.2.pdf

"Adding Autostar GOTO functionality to your existing telescope", Christopher Ericksonhttp://data-plumber.com/autostarupgrade.htm

Similar models

thingiverse

free

Flex / Solid Connector 5/6mm by kubik88

... motor shaft)

motor with 5mm shaft

another 6mm shaft

m3x15 screws (2x)

m3 washers (4x)

m3 safety nuts (2x)

m3x12 set screw (worm)

thingiverse

free

NEMA17 Universal Belted 2:1 Reduction Drive by mildw4ve

...rews

2x m3x25 socket hex screws

4x m3x25 or longer socket hex screws for mounting the top plate and anything that might be on it.

thingiverse

free

Camera Pan/Tilt Head by suromark

...gs

30mm x 5mm ø steel shaft

55mm x 8mm ø steel shaft

keystone network wiring module

m8 screw 60-100mm

m4 screws

m3 screws

washers

thingiverse

free

UM reduced extruder for 3.0mm filament by EazyBreezy

... bearing 3x10x4

2x - 625 bearings 5x16x5

5x - m3 nuts

5x - m3x30 screws

1x - m3x12 screw

1x - little spring to the clamp filament

thingiverse

free

Nema 17 motor mount bracket P3Steel by jusebago

...thingiverse

nema 17 motor mount bracket for bowden extruder p3steel

3x m3 nuts.

2x m3 12mm screws..

1x m3 15mm screw, or longer.

thingiverse

free

backlash free gearbox for nema 17 stepper motor by hamid8Sadra

...(or cnc) for 2mm iron bracket (or plexiglass)

video in youtube channel "learn,make,forget"https://youtu.be/mpu_jl-h0qi

thingiverse

free

VEE CORE XY by maxdesign1990

...h - 300mm 2x

linear shaft

12mm dia shaft length - 400mm 2x

linear bearing

linear bearing 12mm lm12uu 4x

thingiverse

free

Nema 17 belted reduction gear by D14

...earance for bolt and bearing to sit tighter. so, you need to adjust them.

links:

gt2-80t http://www.thingiverse.com/thing:1812138

thingiverse

free

Rackprint Bowden Extruder by Alex_RP

...x m3 screw ~20mm and nuts

2x m3 screw 15mm

bearing 608zz

mk8 drive gear

2x spring ~20mm with ~3mm inner diameter

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

Wt808

thingiverse

free

Li'l Crenellated Pumpkin Puncher by wt808

...li'l crenellated pumpkin puncher by wt808

thingiverse

scale up or down to fit snugly, ie. on 7/16" - 1/2" od

thingiverse

free

Dust Cap, Crosman 22xx PowerMax-HiPAC Fill Nipple Cover by wt808

...rse

dust cap for the integral 8mm foster fill nipple of a powermax-hipac pcp conversion kit for crosman 22xx pistols and rifles.

thingiverse

free

Single Shot Tray, Benjamin Marauder .22 Rifle by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Dust Cover/Cap, Battery Charger SAE Connector by wt808

...out of connectors that are exposed to the elements. lanyard loop for keeping the cover tethered to the cord or for wall mounting.

thingiverse

free

Single Shot Tray, Benjamin Marauder .22 Pistol by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Single Shot Tray, Benjamin Marauder .25 Rifle by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Single Shot Tray, Benjamin Marauder .177 Rifle by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Single Shot Tray, Benjamin Marauder .30 Rifle by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Single Shot Tray, Benjamin Marauder .357 Rifle by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

thingiverse

free

Single Shot Tray, Benjamin Marauder .177 Pistol by wt808

....

i modified these trays to fit tighter than the original. sand the back and bottom sides as needed to get the fit that you want.

Vixen

turbosquid

$100

De Haviland Sea Vixen FAW2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

De Haviland Sea Vixen FAW2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$22

telescope3d model

...universe astrologie tripod observatory lunette glass optic astro monocular vixen magnify magnifier spy space zoom .max .mb .fbx .c4d...

thingiverse

free

Vixen by speedtwin69

...vixen by speedtwin69

thingiverse

vixen

3d_sky

$8

Vixen Chandelier

...vixen chandelier

3dsky

vixen chandelier

thingiverse

free

Vixen to mini vixen clamp by Rob94

...vixen to mini vixen clamp by rob94

thingiverse

thingiverse

free

Vixen Dovetail by icimdengelen

...vixen dovetail by icimdengelen

thingiverse

vixen dovetail

thingiverse

free

Vixen Kit by eeprof

...vixen kit by eeprof

thingiverse

vixen kit

thingiverse

free

Vixen 2 mini vixen guiding scope by frondot

...se it with canon l 70-200 f/2,8 is and other lens and svbony vixen, svbony 30x120 mini vixen guiding scope and a asi120mm camera.

thingiverse

free

Arca To Vixen/Synta Finder by Jimmyjamjoejoe

...arca to vixen/synta finder by jimmyjamjoejoe

thingiverse

for attaching a vixen/synta style finder to a tripod head.

Meade

3ddd

$1

Телескоп Meade LX 200

...аботка материалов в 2014 г.

габариты: 845 х 2400 мм

аналогhttp://www.telescopeplanet.co.uk/meade-lx200-acf-gps/20168

turbosquid

free

Syd Mead Entertainment center Home

...yd mead entertainment center home for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1523167)

3ddd

$1

Axel Occasional Table Belle Meade

...ble belle meade

•dimensions: 24d 22h

•features: acrylic base with satin brass hub

•starphire glass top with flat polished edge

3d_export

$200

Telescope 3D Model

...model 3dexport telescope telescop scop scope lunette glass astronomy meade space star stars galaxy observatory zoom optic detail detailed...

3d_export

$7

brooklyn museum

...tain its building and collection, only to be revitalized in the late 20th century, thanks to major renovations. source: wikipedia

unrealengine

$35

Mead Hall UE5

...mead hall ue5

unreal engine marketplace

mead hall. 44 unique assets + interior

thingiverse

free

Meade Eyepiece Cover by lanemaxwell

...meade eyepiece cover by lanemaxwell

thingiverse

eyepiece dust cap for meade etx telescopes

3dcadbrowser

free

MEADS

...e system.this 3d object can be downloaded in .max, .obj, .3ds, .fbx, .dxf, .lwo, .stl, .wrl, .ma, .dae, .x and .asc file formats.

thingiverse

free

Meade Spotting Scope Mount by RobertCL

...potting scope on the side of the meade etx125 scope body rather than using the standard mount point that tends to get in the way.

sketchfab

$10

Ornate Medieval Mead Tankard

...

polygons 3,602

vertices 3,600

textures png 4k - ornate medieval mead tankard - buy royalty free 3d model by getdeadentertainment

Goto

3ddd

free

Tod von mertens

...mertens , тумба , лампа bed king size:http://todvon.com/?goto=view§ion;=portfolio&portfolio;=110&cat;=22 night stand:http://todvon.com/?gotoview§ion;=portfolio&portfolio;=108&cat;=17 ...

thingiverse

free

Goto by alberton

...a body in the form of a drop (gota=goto).goto is a bioindicator for water and environment purity. it can be printed in any color.

thingiverse

free

Case for my Rduinoscope goto system by Slim65

...to system by dessislav http://rduinoscope.byethost24.com/index.html

there is still some hole missing for the stepper motor cables

thingiverse

free

The Micro Scope | A Miniture GOTO Telescope. by GregoryHolloway

...tes.

21/03/2021 - added filament weights to the bom and released the universal tripod fixture. details on the instructables page.

thingiverse

free

Sky-Watcher 200P 8" Dobsonian GoTo using OnStep by xlnzee

...odded to fit the 200p dob. the rest of the required files are found on his thingy here: https://www.thingiverse.com/thing:3942813

thingiverse

free

Remix of OpenAstroTracker - DSLR tracking & GoTo mount MEGA CASE Lid With GPS by Shadowolf13

...t you want it tight.

thanks

remix of openastrotracker - dslr tracking & goto mount https://www.thingiverse.com/thing:4472727

thingiverse

free

EQ5 GoTo Nema17 Motor Bracket Set for RJ45 Connector by oddvarness

... as part of rebuilding my old manual sky-watcher eq5 mount to a onstep goto system: https://onstep.groups.io/g/main/message/33535

thingiverse

free

Belt hanger for Kore Trakline, GoTo track belts

...n, but hey, i like mine better and it's much cheaper. also holds belts better and is attached to a regular shirt wood hanger.

thingiverse

free

EQ telescope mount II. for OnStep goto controller by RomanHujer

...d tripod upgrade for telescope with eyepiece plate

my onstep for seben eq3 mount

note:

use stones and cement to fill the weights.

thingiverse

free

Orion XT10 Plus GoTo using OnStep

...s and nuts.

the electronics enclosure is designed for the mks gen l board, a wemos d1 mini wifi board, and a 40x40x20 blower fan.

Ds

3ddd

$1

DS-277

...ds-277

3ddd

desede

ds-277

3ddd

$1

DS-47_Sofas

...ds-47_sofas

3ddd

desede

ds-47_sofas

3ddd

$1

DS-3_Sofas

...ds-3_sofas

3ddd

desede

ds-3_sofas from desede

design_connected

$27

DS-152

...ds-152

designconnected

de sede ds-152 computer generated 3d model.

design_connected

$9

DS 9045

...ds 9045

designconnected

de sede ds 9045 computer generated 3d model. designed by bestenheider, philippe.

design_connected

$16

DS 315

...ds 315

designconnected

de sede ds 315 armchairs computer generated 3d model. designed by philippe bestenheider.

design_connected

$20

DS 166

...ds 166

designconnected

de sede ds 166 armchairs computer generated 3d model. designed by hugo de ruiter.

design_connected

$18

DS-9090

...ds-9090

designconnected

de sede ds-9090 computer generated 3d model. designed by de sede design-team.

3ddd

$1

DS-278-chair

...ds-278-chair

3ddd

desede

ds-278-chair

design_connected

$20

DS-220

...ds-220

designconnected

de sede ds 220 armchairs computer generated 3d model. designed by de sede design-team.

Gp

3ddd

free

Подавитель GPS

...подавитель gps

3ddd

подавитель gps

3ddd

free

Подавитель GPS

...подавитель gps

3ddd

подавитель gps

3ddd

free

Cтол GP

...cтол gp

3ddd

обеденный , giorgio piotto

cтол gp

turbosquid

$5

GPS navigation

...e 3d model gps navigation for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1636695)

turbosquid

$4

GP-5

...lty free 3d model gp-5 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1160699)

turbosquid

$60

TomTom GPS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

GPS/TV

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Battery GP 3D Model

...battery gp 3d model

3dexport

battery gp

battery gp 3d model wasiliy 40319 3dexport

3d_export

$5

gas mask gp-5

...gas mask gp-5

3dexport

gas mask gp-5

cg_studio

$36

Gps device3d model

...ice3d model

cgstudio

.3ds .c4d .dxf .obj - gps device 3d model, royalty free license available, instant download after purchase.

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

Motors

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Using

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...among us

3dexport

this 3d-model of a character from the game "among us". it can be used as a toy or decoration.

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us

3dexport

turbosmooth modifier can be used to increase mesh resolution if necessary

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation