Thingiverse

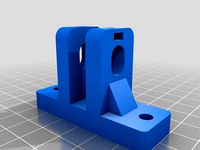

VertexEvo (Rev.1) - Vertex K8400 Evolution by Bo_Ris

by Thingiverse

Last crawled date: 3 years ago

This is the initial version of VertexEvo. Newer and improved version is published here.

Please check also my Vertex-H MOD, which is the next step after VertexEvo.

Before you start making such a major modification to your Vertex printer please be aware about Cons:

Properly assembled and tuned K8400 can produce rather good printouts and it is unlikely that this upgrade will further improve print quality

VertexEvo works in CoreXY printing mode that requires firmware upgrade to the latest Marlin version 1.1.5. As the result you will loose K8400-specific menu items like filament loading/unloading, LED light control, etc. Entire menu structure will be different and it may take you some time to get used to it.

Front and side panels of K8400 are not strong enough to hold the amount of load produced in CoreXY mode. As the result the panels wobble and this in some cases may slightly degrade print quality. To address this you will need to attach 25mm x 3mm aluminium bars along the top of front and side panels.

Having polyurethane GT2 belts with steal threads is the must, however the threads eventually break, belts stretch and will need to be replaces 2-3 times a year.

You may need to adjust (lower) the speed and acceleration to retain original quality, i.e. overall printing time will increase. At certain speeds side panels start to resonate, which causes additional noise.

This mod requires soldering. You will need to relocate X-stop sensor from back panel to the print-head, extend and re-route X-stop wires.

You will need to drill a hole in aluminium plate supporting the print-bed to move it forward and down as described here.

and Pros:

Printer has much simpler mechanics, only linear bearings and is easier to tune and maintain.

There are only 2 belts instead of 6 in the original design.

The carriage outer shape is very simple, which makes it easy to change the print-head. You can even design and attach your own print-head, for example single e3D with proximity sensor, etc.

When using dual e3D, there is no need to cut heat sinks as in my other designs published here and here.

Dual e3D mount can be tilted along Y-axis that makes it very easy to level nozzles.

Overall print volume increases from the original 6840 cm³ to over 7414 cm³.

This design is completely revertible, i.e. you can always roll back to the old configuration.

Other considerations:

STL files posted here were designed for 0.35mm nozzles (wall thickness 0.7, 1.05 and 1.4mm). They were printed with e3D hotend on K8400 that has all my mods posted earlier on Thingiverse. Unfortunately I have no way of testing how well the things posted here will print with the original hotend from Velleman.

You will need to use the latest Arduino version to compile and install the latest firmware.

Having 2 Carbon-fiber 8mm rods for X-axis is highly recommended. Each weights about 14 grams versus 200 grams of steel equivalent.

The print volume with dual e3D print-head and MK3 heated bed is X=182mm, Y=210mm and Z=194mm.

Bill of Materials

Left Motor and rear-left Y-rod mount

4 x M3 x 8mm screws for motor mount

2 x M3 x 12mm screws for Y-rod

4 x M5 x 16mm socket-cup screws

4 x M5 self locking nuts

1 x GT20 pulley with 5mm bore

Right Motor and rear-right Y-rod mount

4 x M3 x 8mm screws for motor mount

1 x M3 x 12mm screw for Y-rod

4 x M5 x 16mm socket-cup screws

4 x M5 self locking nuts

1 x GT20 pulley with 5mm bore

Left Front Corner with front-left Y-rod mount

1 x M5 x 50mm socket-cup screw

5 x M5 x 16mm socket-cup screws

6 x M5 self locking nuts

2 x GT2 idler pulleys with teeth and 5mm bore

2 x M3 x 12mm screws for Y-rod

Right Front Corner with front-right Y-rod mount

1 x M5 x 50mm socket-cup screw

5 x M5 x 16mm socket-cup screws

6 x M5 self locking nuts

2 x GT2 idler pulleys with teeth and 5mm bore

2 x M3 x 12mm screws for Y-rod

Left XY Clamp

2 x M3 x 16mm screws for Y-rods

6 x M3 x 12mm screws for X-rods

2 x M5 x 25mm socket head button screws

1 x GT2 idler pulley with teeth and 5mm bore

1 x GT2 idler toothless pulley with 5mm bore

1 x 8mm tube bearing

Right XY Clamp

2 x M3 x 16mm screws for Y-rods

6 x M3 x 12mm screws for X-rods

2 x M5 x 25mm socket head button screws

1 x GT2 idler pulley with teeth and 5mm bore

1 x GT2 idler toothless pulley with 5mm bore

1 x 8mm tube bearing

Rods

2 x 8mm x 315mm steel rods for Y-axis

2 x 8mm x 320mm carbon-fiber rods for X-axis

Print head

4 x 8mm IGLIDUR linear bearings

2 x e3d v6 original hotends (clones will not fit)

5 x M4 x 20mm socket cup screws for dual e3d holder and filament fan

8 x M3 x 15mm screws for dual e3d fan mount and for carriage corners

5 x M3 x 12mm screws mounting dual e3d holder and pcb with cable holder

2 x M3 washers (optional but recommended)

14 x M3 self locking nuts

9 x M3 x 8mm screws for X-stop sensor, filament fan mount, pcb mount

4 x M3 x 30mm socket cup screws for belt ends

1 x filament fan

Belts

2 x 1.5 meters of polyurethane belt with steel enforcement

Other

1 paper clip to hold belt ends

All bearings, filament fan and many screws and nuts can be reused from the original printer.

Please check also my Vertex-H MOD, which is the next step after VertexEvo.

Before you start making such a major modification to your Vertex printer please be aware about Cons:

Properly assembled and tuned K8400 can produce rather good printouts and it is unlikely that this upgrade will further improve print quality

VertexEvo works in CoreXY printing mode that requires firmware upgrade to the latest Marlin version 1.1.5. As the result you will loose K8400-specific menu items like filament loading/unloading, LED light control, etc. Entire menu structure will be different and it may take you some time to get used to it.

Front and side panels of K8400 are not strong enough to hold the amount of load produced in CoreXY mode. As the result the panels wobble and this in some cases may slightly degrade print quality. To address this you will need to attach 25mm x 3mm aluminium bars along the top of front and side panels.

Having polyurethane GT2 belts with steal threads is the must, however the threads eventually break, belts stretch and will need to be replaces 2-3 times a year.

You may need to adjust (lower) the speed and acceleration to retain original quality, i.e. overall printing time will increase. At certain speeds side panels start to resonate, which causes additional noise.

This mod requires soldering. You will need to relocate X-stop sensor from back panel to the print-head, extend and re-route X-stop wires.

You will need to drill a hole in aluminium plate supporting the print-bed to move it forward and down as described here.

and Pros:

Printer has much simpler mechanics, only linear bearings and is easier to tune and maintain.

There are only 2 belts instead of 6 in the original design.

The carriage outer shape is very simple, which makes it easy to change the print-head. You can even design and attach your own print-head, for example single e3D with proximity sensor, etc.

When using dual e3D, there is no need to cut heat sinks as in my other designs published here and here.

Dual e3D mount can be tilted along Y-axis that makes it very easy to level nozzles.

Overall print volume increases from the original 6840 cm³ to over 7414 cm³.

This design is completely revertible, i.e. you can always roll back to the old configuration.

Other considerations:

STL files posted here were designed for 0.35mm nozzles (wall thickness 0.7, 1.05 and 1.4mm). They were printed with e3D hotend on K8400 that has all my mods posted earlier on Thingiverse. Unfortunately I have no way of testing how well the things posted here will print with the original hotend from Velleman.

You will need to use the latest Arduino version to compile and install the latest firmware.

Having 2 Carbon-fiber 8mm rods for X-axis is highly recommended. Each weights about 14 grams versus 200 grams of steel equivalent.

The print volume with dual e3D print-head and MK3 heated bed is X=182mm, Y=210mm and Z=194mm.

Bill of Materials

Left Motor and rear-left Y-rod mount

4 x M3 x 8mm screws for motor mount

2 x M3 x 12mm screws for Y-rod

4 x M5 x 16mm socket-cup screws

4 x M5 self locking nuts

1 x GT20 pulley with 5mm bore

Right Motor and rear-right Y-rod mount

4 x M3 x 8mm screws for motor mount

1 x M3 x 12mm screw for Y-rod

4 x M5 x 16mm socket-cup screws

4 x M5 self locking nuts

1 x GT20 pulley with 5mm bore

Left Front Corner with front-left Y-rod mount

1 x M5 x 50mm socket-cup screw

5 x M5 x 16mm socket-cup screws

6 x M5 self locking nuts

2 x GT2 idler pulleys with teeth and 5mm bore

2 x M3 x 12mm screws for Y-rod

Right Front Corner with front-right Y-rod mount

1 x M5 x 50mm socket-cup screw

5 x M5 x 16mm socket-cup screws

6 x M5 self locking nuts

2 x GT2 idler pulleys with teeth and 5mm bore

2 x M3 x 12mm screws for Y-rod

Left XY Clamp

2 x M3 x 16mm screws for Y-rods

6 x M3 x 12mm screws for X-rods

2 x M5 x 25mm socket head button screws

1 x GT2 idler pulley with teeth and 5mm bore

1 x GT2 idler toothless pulley with 5mm bore

1 x 8mm tube bearing

Right XY Clamp

2 x M3 x 16mm screws for Y-rods

6 x M3 x 12mm screws for X-rods

2 x M5 x 25mm socket head button screws

1 x GT2 idler pulley with teeth and 5mm bore

1 x GT2 idler toothless pulley with 5mm bore

1 x 8mm tube bearing

Rods

2 x 8mm x 315mm steel rods for Y-axis

2 x 8mm x 320mm carbon-fiber rods for X-axis

Print head

4 x 8mm IGLIDUR linear bearings

2 x e3d v6 original hotends (clones will not fit)

5 x M4 x 20mm socket cup screws for dual e3d holder and filament fan

8 x M3 x 15mm screws for dual e3d fan mount and for carriage corners

5 x M3 x 12mm screws mounting dual e3d holder and pcb with cable holder

2 x M3 washers (optional but recommended)

14 x M3 self locking nuts

9 x M3 x 8mm screws for X-stop sensor, filament fan mount, pcb mount

4 x M3 x 30mm socket cup screws for belt ends

1 x filament fan

Belts

2 x 1.5 meters of polyurethane belt with steel enforcement

Other

1 paper clip to hold belt ends

All bearings, filament fan and many screws and nuts can be reused from the original printer.

Similar models

grabcad

free

GT2 idler pulley, 10mm belt, 8mm bore.

...gt2 idler pulley, 10mm belt, 8mm bore.

grabcad

smooth idler pulley for 10mm gt2 belt. 8mm internal bore.

grabcad

free

GT2 5mm bore idler pulley

...gt2 5mm bore idler pulley

grabcad

just a simple idler pulley file for gt2 x 6mm belts.

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount 2.0 by SaberShip

...ler pulley for 6mm wide gt2 belt

1x m5 x30 bolt

1x m5 nylon lock insert nut (regular m5 nut may work)

2x m3 x10 screws

2x m3 nuts

thingiverse

free

Belt driven Z pulley mount w/ GT2 6mm belt 5mm bore 20t idler by Evilkoal

...e idler mount to fit the idlers i have.

gt2 20t 6mm belt, 5mm bore idler.

printed with 50% "archimedian chords" infill.

thingiverse

free

Elbow belt tensioner suitable for 2020 frame

...allbearing x 2

5mm id 20 tooth gt2 idler pulley

feature:

easy to print,easy to adjust,fit for various system,fit for closed belt.

3dwarehouse

free

Idler Pulley 8mm x 21mm x 11mm for GT2, T5, T2.5 belt

... for gt2, t5, t2.5 belt

3dwarehouse

8mm bore, 21mm inner(belt mount) diameter, 27mm outer diameter, 11mm width #cnc #gt2 #t2 #t5

thingiverse

free

Anet A8 single motor Z axis drive by osadchy

...he original 400 to 800)

hope i included everything here. if you find anything missing, please comment and i'll answer/update.

thingiverse

free

TRONXY X5S - Z motor sync by WT1704

...e platform on the stepper and 3 * m5 screws and nuts for the pulley

1 * m3 screw and nut to hold the tension stick with the block

thingiverse

free

M3 to M5 spacer hülse 3mm to 5mm for e.g. belt pulley by TimJuPe

...spacer for using m5 holes with m3 screws. designed this for fitting gt2 belt pulley wit m3 skrews. 8.5mm long (belt pulley width)

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount by SaberShip

...rts:

x1 stock 608zz idler bearing

x1 stock m3 bolt and nut

x2 stock m5 bolts

x2 stock m5 t-slot nuts

x2 m3 x 10 screws

x2 m3 nuts

Vertexevo

thingiverse

free

Side Support for VertexEvo by Bo_Ris

...escription and remaining stl files.

note: this design requires drilling 4 additional 5mm holes in each side panel of the printer.

thingiverse

free

VertexEvo Y-visor by Bo_Ris

... make sure that y-visor_part3 moves freely and closes y-stop sensor only when pushed towards the back of the printer by xy_clamp.

thingiverse

free

Raspberry Pi Fish Eye Camera for VertexEvo by Bo_Ris

...3 x 6mm screws

2 x m5 x 16mm socket head screws

2 x m5 self locking nuts.

update 29-nov-2017 added flat cable holders and images.

thingiverse

free

VertexEvo with Ultimaker glass by Bo_Ris

...edesign things to make sure they all fit together.

update 8-feb-2018: new y-visor solving aforementioned issue is published here.

thingiverse

free

VertexEvo (K8400) Z-axis Support by Bo_Ris

...here. don't forget to place spacers between clamps and the bearing. wider side of each spacer should face its adjacent clamp.

thingiverse

free

VertexEvo Rev.2 by Bo_Ris

...018 vertex-h project was a success. please read the description here and choose which of these 2 mods will work the best for you.

thingiverse

free

"Brake" for K8400 VERTEX Universal Spool Holder by Bo_Ris

...part2.stl is for the original vertex, part2evo.stl is for vertexevo with 3mm thick aluminium enforcement bars. part3 is designed...

thingiverse

free

Anti-spill Cup Holder by Bo_Ris

...designed to utilize the maximum print space of my vertexevo printer and can fit up-to 15 cm high cups....

K8400

thingiverse

free

Vertex K8400 Small Corner part (K8400-HQP-SC) by Hest

...vertex k8400 small corner part (k8400-hqp-sc) by hest

thingiverse

vertex k8400 small corner part (k8400-hqp-sc)

thingiverse

free

Base for K8400 by Hitty

...base for k8400 by hitty

thingiverse

just a base for your k8400 to extend the space for the power adapter.

thingiverse

free

K8400 Fan tool by dergringo

...k8400 fan tool by dergringo

thingiverse

k8400 fan tool

thingiverse

free

Support ventilateur K8400 / Fan support K8400 by ldellanna

........................

fan support for velleman vertex k8400

minimum layer : 0.2mm

printing time in 0.1mm -> max 20 minutes

thingiverse

free

K8400 Scraper holder by Storm67

...k8400 scraper holder by storm67

thingiverse

scraber holder for velleman k8400 vertex

thingiverse

free

Fan Tool K8400 Velleman by dergringo

...fan tool k8400 velleman by dergringo

thingiverse

fan tool velleman k8400

thingiverse

free

Endcap Custom for Vertex K8400 by olechristiandalseth

...endcap custom for vertex k8400 by olechristiandalseth

thingiverse

endcap for vertex k8400

left and right.

thingiverse

free

Vertex K8400 spool holder by simersion

...vertex k8400 spool holder by simersion

thingiverse

spoolholder for vertex k8400

100mm length and 35mm diameter.

thingiverse

free

E3D dual head K8400 by hexxter

...e3d dual head k8400 by hexxter

thingiverse

holder for the e3d hot end on the vertex k8400 printer.

thingiverse

free

Vertex K8400 power switch by Zannddor

...vertex k8400 power switch by zannddor

thingiverse

alternative power switch to the 3d printer vertex k8400

Ris

turbosquid

$20

ris

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Лампа Настольная Vita Ri 22163

...лампа настольная vita ri 22163

3ddd

vita , ri

лампа настольная vita ri 22163

3ddd

$1

Кресло JUMBO RIS-41b

...hymia

стиль: классика

длина: 80

глубина: 85

высота: 155

артикул: ris-41b

варианты отделки: орех, крашенный, с золотом, с серебром

3ddd

free

Диван JUMBO RIS-42b

...hymia

стиль: классика

длина: 155

глубина: 85

высота: 155

артикул: ris-42

варианты отделки: орех, крашенный, с золотом, с серебром

3d_export

$25

Parth 11 riing 3D Model

...ing 3d model

3dexport

parth 11 riing 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 109549 3dexport

3d_export

$10

M4A1 rifle RIS version 3D Model

...m4a1 rifle ris version 3d model

3dexport

rifle gun weapon

m4a1 rifle ris version 3d model figlif 1347 3dexport

3ddd

$1

Centennial Regulation Pool Table by RI Anderson

...by ri anderson

3ddd

brunswick

бильярдный стол в стиле ар-деко centennial regulation pool table by ri anderson

размеры 264x147x81h

turbosquid

$2

KWA SR5 RIS - 4inch HandGuard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$199

Tank Type 5 Chi-Ri Japan

...el tank type 5 chi-ri japan for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1640853)

cg_studio

$59

Colt M4A1 Carbine RIS Assault rifle3d model

...s .c4d .lwo .obj - colt m4a1 carbine ris assault rifle 3d model, royalty free license available, instant download after purchase.

Bo

3d_export

$5

boing

...boing

3dexport

boing plane

turbosquid

$19

Boing boing Park

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Boing 747

...boing 747

3ddd

boing 747 без текстур

3ddd

$1

Bo concept

...bo concept

3ddd

boconcept , декоративный набор

bo concept

3ddd

$1

Bo Concept / Pinto

...bo concept / pinto

3ddd

boconcept

bo concept pinto

3ddd

$1

кровать bo concept

...кровать bo concept

3ddd

boconcept

кровать bo concept

3ddd

$1

Bo concept sidebroad

...bo concept sidebroad

3ddd

тумба , boconcept

bo concept

3ddd

$1

Bo-box / Ирис

...bo-box / ирис

3ddd

bo-box

кресло ирис, пр-ль bo-box, коллекция soul. габариты (мм): 720x900x880

3ddd

free

Bo Concept

... ковер

сборник ковров от bo concept

размер - 200х300см, 170х240 см

10 шт.http://www.boconcept.ru

turbosquid

$5

Bo Shuriken

...y free 3d model bo shuriken for download as obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1412495)

Rev

3d_export

$5

Rev Gun 3D Model

...rev gun 3d model

3dexport

rev gun

rev gun 3d model sone93 52014 3dexport

3d_export

$15

Maverick REV-6

...n act as the main blaster of a nerfer, but due to the short range, it is recommended to use it as a secondary, additional weapon.

turbosquid

$84

Euro Pallet rev 2009

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Chandra rugs REV-15802

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

rev"s drum set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Sova Design/Rev coffee table

... table

3ddd

журнальный

https://www.facebook.com/media/set/?set=a.514295972031044.1073741841.343660145761295&type;=3

turbosquid

$30

Yak-44 (Rev) AEW Aircraft Solid Assembly Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Mitsubishi Mu-2 Aircraft Solid Assembly Model(Rev)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

An-71 Madcap (Rev) AEW Aircraft Solid Assembly Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Antonov An-74 (Rev} STOL Transport Aircraft Solid Assembly Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Evolution

3ddd

$1

Evolution

... evolution , комод

комод из каталога emmemobili модель evolution

design_connected

$18

Evolution

...evolution

designconnected

zanotta evolution computer generated 3d model. designed by ïto, ora.

design_connected

$11

Evolute

...evolute

designconnected

danese evolute computer generated 3d model. designed by crasset, matali.

design_connected

$22

Evolution

...evolution

designconnected

emmemobili evolution shelves and storage computer generated 3d model. designed by ferruccio laviani.

3ddd

$1

Zanotta / EVOLUTION

...zanotta / evolution

3ddd

zanotta

zanotta

884 evolution

3ddd

free

Simas Evolution

...simas evolution

3ddd

simas

раковина simas evolution

3ddd

$1

Lancer Evolution

...lancer evolution

3ddd

автомобиль , машина

lancer evolution viii

3ddd

$1

Zanotta Evolution

...zanotta evolution

3ddd

zanotta

современное кресло evolution фабрики zanotta

turbosquid

$25

Evolution Dragon

...d

royalty free 3d model evolution dragon for download as obj on turbosquid: 3d models for games, architecture, videos. (1212928)

turbosquid

$6

Flowers Evolution

...

royalty free 3d model flowers evolution for download as obj on turbosquid: 3d models for games, architecture, videos. (1214159)

Vertex

3d_export

$10

vertex decorative003

...vertex decorative003

3dexport

vertex decorative_003

3d_export

$10

vertex decorative001

...vertex decorative001

3dexport

vertex decorative_001

turbosquid

$5

Vertex Pendant

...uid

royalty free 3d model vertex pendant for download as stl on turbosquid: 3d models for games, architecture, videos. (1565161)

turbosquid

$5

Vertex Coaster

...uid

royalty free 3d model vertex coaster for download as stl on turbosquid: 3d models for games, architecture, videos. (1565158)

3ddd

$1

Vertex von Vondom

...vertex von vondom

3ddd

vondom

vertex von vondomhttp://www.vondom.com/producto/52/0/vertex/

turbosquid

$3

Vertex Set

...d model vertex vondom set for download as usdz, gltf, and fbx on turbosquid: 3d models for games, architecture, videos. (1599323)

3ddd

$1

VONDOM / VERTEX

...vondom / vertex

3ddd

karim rashid , vondom

designer - karim rashid

3d_export

$15

Vondom Vertex 3D Model

...d model

3dexport

vondom vertex table chair plastic seat furniture furnishing

vondom vertex 3d model rogojin.denis 87870 3dexport

3ddd

$1

VONDOM / VERTEX

..., karim rashid , vondom

designer - karim rashid

3ddd

$1

BUFFET VERTEX

...nical specification :

height 65 cm , width 150 cm , depth 43 cmhttp://www.oppa.com.br/buffet-vertice-4-portas-amarelo

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)