Thingiverse

Vertex Delta K8800-EXA Enhanced Run-out Detection by ThyWhiteHawk

by Thingiverse

Last crawled date: 3 years, 3 months ago

Having had my Vertex Delta for only a few weeks and after having several false "run-out" alarms from the filament run-out detector I tried to find a solution. I wasn't happy with Velleman's answer to someone else with the same problem (i.e. if it stops working just unplug it and don't use it) - especially since I am using Velleman's own filament - So I decided, why not just fix it?! :-)

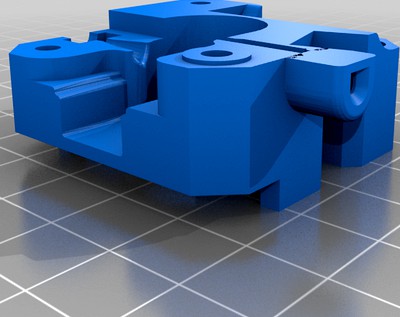

So I tweaked the extruder design (well the printer is open source after all), specifically the K8800-EXA part onto which the filament run-out detector attaches.

Basically what I found was that the friction of filament passing through the part was wearing flat surfaces in the steel pins which meant that hairline trigger of the micro-switch was not quite making it. Perhaps simply replacing these pins with tool steel (or even ceramic) may work, but that sounds too easy!

There are dedicated micro-switches with roller levers available which are more suited to this job.

The Vertex Delta (K8800) uses a Dongnan KW-10 micro-switch. The one that I picked as a roller lever replacement (which has the same external dimensions as the KW10) is Omron D2F-FL2 (note that the default part shown isn't the roller lever). The 3D model is available here. It can be bought from various places, but I bought it from RS.

I also extended the filament guide to fill the void in between it and the roller to prevent the filament falling off the roller.

So I tweaked the extruder design (well the printer is open source after all), specifically the K8800-EXA part onto which the filament run-out detector attaches.

Basically what I found was that the friction of filament passing through the part was wearing flat surfaces in the steel pins which meant that hairline trigger of the micro-switch was not quite making it. Perhaps simply replacing these pins with tool steel (or even ceramic) may work, but that sounds too easy!

There are dedicated micro-switches with roller levers available which are more suited to this job.

The Vertex Delta (K8800) uses a Dongnan KW-10 micro-switch. The one that I picked as a roller lever replacement (which has the same external dimensions as the KW10) is Omron D2F-FL2 (note that the default part shown isn't the roller lever). The 3D model is available here. It can be bought from various places, but I bought it from RS.

I also extended the filament guide to fill the void in between it and the roller to prevent the filament falling off the roller.

Similar models

thingiverse

free

Makerbot Replicator 2 Out Of Filament detector by Deepsiks

...p-stop function:http://www.extrud3d.com/p-stop

*a version with an oiler/cleaner is here:http://www.thingiverse.com/thing:297865

thingiverse

free

Roller mechanical switch filament detector

...iverse

designed an easy-load filament detector to work with roller microswitch (i think its the stock anet a8 axis limit switch)

thingiverse

free

Extruder Mount with Runout Sensor for Extrusion Mounting by KerseyFabrications

... switch for filament run-out detection. it has a filament guide and is easy to load.

roller micro switch: https://amzn.to/33n80we

thingiverse

free

Alfawise U30 filament guide

...olved. i used some thin oil (from my bike) to grease the axes at the beginning and all is neat and quite for a few weeks already.

thingiverse

free

Replicator 2 Out Of Filament Detector with Cleaner/Oilier by Deepsiks

...ting:

sailfish firmware:http://jettyfirmware.yolasite.com/v76-v45.php

use of the p-stop function:http://www.extrud3d.com/p-stop

thingiverse

free

Power cord connector and switch for Velleman Vertex K8400 by M_I_A

... velleman to replace the small corner brackets. like this you don't need to drill any holes or modify the original structure.

thingiverse

free

Motor protection K8800 by uvens

...the motors to prevent support parts from falling down to the belt wheels.

print details:

no support

layer 0.2

filling 40%

shell 2

thingiverse

free

Ender 3 -Filament Runout Sensor for larger roller switch

...ance on the filament and thus smoother extrusion.

fyi, the switches are the same as this one.https://www.adafruit.com/product/819

thingiverse

free

Ender 6 filament detector by snebragd

...t you need to break off the lever from your original switch. the positive would be that you don't need to do any electronics.

thingiverse

free

Vertex Delta 3D extruder upgrade by Psychokiller1888

...ure it correctly and adjust the model accordingly before printing! mine is 85.87mm. it is printed a bit longer so it fits.

enjoy!

K8800

thingiverse

free

Motor protection K8800 by uvens

...the motors to prevent support parts from falling down to the belt wheels.

print details:

no support

layer 0.2

filling 40%

shell 2

thingiverse

free

K8800 Cable Holder by kaimimue

...k8800 cable holder by kaimimue

thingiverse

cable holder for end stop cable at step motor.

designed with freecad.

thingiverse

free

Klammer für Vertex K8800 Rahmenprofil by StoniXX

...used, the wall should be sufficiently thick, i printed with 4 layers = 1.6mm wall thickness, so that the inserts get enough hold.

thingiverse

free

filament return pulley for Vellemann Vertex 3D Delta K8800 by shelxle

...proved version better for large spools. it reduces the problem that the filament stays in the gap between pulley and printer top.

thingiverse

free

Riemenspanner für Vertex K8800 by StoniXX

...olts

6 x m5 washers

3 x m6x50 (or shorter => 35 or 40 should be good) allen bolts

6 x m6 nuts

3 x m6 washers

thanks to him ;-)

thingiverse

free

Velleman K8800 Delta LM10UU Linear Bearing Upgrade by DrVegetable

...et me know how these work for you.

full write-up: https://forum.vellemanprojects.eu/t/the-solution-for-all-your-delta-woes/29088

thingiverse

free

Vertex Delta 3D extruder upgrade by Psychokiller1888

...upgrade by psychokiller1888 thingiverse the velleman vertex delta 3d k8800 comes with a filament spool holder on its top,...

Exa

design_connected

$7

Exa

...exa

designconnected

lapalma exa computer generated 3d model. designed by cazzaniga, piergiorgio.

turbosquid

$45

Vintage camera Exa Ihagee Dresden

... ihagee dresden for download as max, blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1536251)

3d_ocean

$4

Eye Glasses Version 3 (High-Poly)

...wish to change the color of the lenses, for exa.. ...

thingiverse

free

exa 1a by Buyan7

...exa 1a by buyan7

thingiverse

thingiverse

free

EXA Led lamp multicolor or white

...exa led lamp multicolor or white

thingiverse

just anoter lamp

thingiverse

free

Execution Agent (EXA) by FindMeAUserName

...nics for some of the most entertaining games for people who enjoy systems, programming, and design games.

have fun and stay safe.

thingiverse

free

winder for analog camera by Waterbob

...a winder with foldable lever for an analog camera (exa 1b but will fit to other models) to rewind...

thingiverse

free

Inception Spinner, Spinception (Spinners within spinner) by adonfff

...center and mr115 for the 3 others with 8mm exa nuts. still work in progress print part 1 x...

thingiverse

free

Exakta lenses to Pentax Q adapter with IHAGEE M40 macro tube by Oscarko

... other side to accommodate the few sections of ihagee tubes that have exakta mount at the end.

i am very pleased with the result!

Detection

turbosquid

$99

Detective

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Noir Detective

...uid

royalty free 3d model noir detective for download as fbx on turbosquid: 3d models for games, architecture, videos. (1334585)

turbosquid

$7

Hat Detective

...ree 3d model hat detective for download as obj, fbx, and gltf on turbosquid: 3d models for games, architecture, videos. (1643999)

turbosquid

$39

Detective Character

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$146

detective karan

...

detective karan is a 3d model which you can use for your animations or in your 3d games so why are you waiting just get it fast!

3d_export

$50

Detective Holms 3D Model

...odel

3dexport

man figure human detective mystery male character rigged max

detective holms 3d model vanishingpoint 73358 3dexport

turbosquid

$25

Detection wire LG.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

cartoon detective office

...als, so you can easily import and configure the scene in another program. i hope these models will help you to realize your idea.

3d_export

$49

detective

...ith your projects. please let us know if you have any questions or need assistance. if you like our model please rate it! thanks!

3d_export

$31

game-ready detective rigged and animated

...y rigged and animated 3d model of a detective character. model can be used in games developments, films, cartoons and so on. this

Delta

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

Enhanced

turbosquid

free

Enhance Flame.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Enhanced Arwing with Original

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Airbus A380 aircraft enhanced

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Rapidlash Eyelash Enhancing Serum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$119

Sig Sauer P226 Enhanced Elite 9mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$119

Sig Sauer P229 Enhanced Elite 9mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$23

bio-enhanced soldier

... shoulders_roughness stuff_base_color stuff_height stuff_metallic stuff_mixed_ao stuff_normal stuff_normal_opengl stuff_roughness

humster3d

$75

3D model of Mk 14 Enhanced Battle Rifle

... 3d model of mk 14 enhanced battle rifle in various file formats. all our 3d models were created maximally close to the original.

turbosquid

$29

Star Trek TNG Voyager Transporter Pattern Enhancers

...rter pattern enhancers for download as max, dwg, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1629422)

turbosquid

$165

Alvar Aalto's Furnitures Collection 1 Enhanced Edition

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Vertex

3d_export

$10

vertex decorative003

...vertex decorative003

3dexport

vertex decorative_003

3d_export

$10

vertex decorative001

...vertex decorative001

3dexport

vertex decorative_001

turbosquid

$5

Vertex Pendant

...uid

royalty free 3d model vertex pendant for download as stl on turbosquid: 3d models for games, architecture, videos. (1565161)

turbosquid

$5

Vertex Coaster

...uid

royalty free 3d model vertex coaster for download as stl on turbosquid: 3d models for games, architecture, videos. (1565158)

3ddd

$1

Vertex von Vondom

...vertex von vondom

3ddd

vondom

vertex von vondomhttp://www.vondom.com/producto/52/0/vertex/

turbosquid

$3

Vertex Set

...d model vertex vondom set for download as usdz, gltf, and fbx on turbosquid: 3d models for games, architecture, videos. (1599323)

3ddd

$1

VONDOM / VERTEX

...vondom / vertex

3ddd

karim rashid , vondom

designer - karim rashid

3d_export

$15

Vondom Vertex 3D Model

...d model

3dexport

vondom vertex table chair plastic seat furniture furnishing

vondom vertex 3d model rogojin.denis 87870 3dexport

3ddd

$1

VONDOM / VERTEX

..., karim rashid , vondom

designer - karim rashid

3ddd

$1

BUFFET VERTEX

...nical specification :

height 65 cm , width 150 cm , depth 43 cmhttp://www.oppa.com.br/buffet-vertice-4-portas-amarelo

Run

turbosquid

$2

Run

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$20

Run Personal

...run personal

designconnected

technogym run personal computer generated 3d model. designed by citterio, antonio.

turbosquid

$49

Elf running

...osquid

royalty free 3d model elf running for download as fbx on turbosquid: 3d models for games, architecture, videos. (1500360)

turbosquid

$20

running machine

...id

royalty free 3d model running machine for download as fbx on turbosquid: 3d models for games, architecture, videos. (1207171)

turbosquid

$4

Zombie Running

...uid

royalty free 3d model zombie running for download as obj on turbosquid: 3d models for games, architecture, videos. (1241889)

turbosquid

$40

Fox, Running

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Soldier run

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Running Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Skeleton Running

...eleton running for download as blend, fbx, obj, gltf, and dae on turbosquid: 3d models for games, architecture, videos. (1589546)

3d_ocean

$19

Running shoes

...imated .textures and materials are included in (others jpg file) the snapshots was rendered using the vray version of the file...