Thingiverse

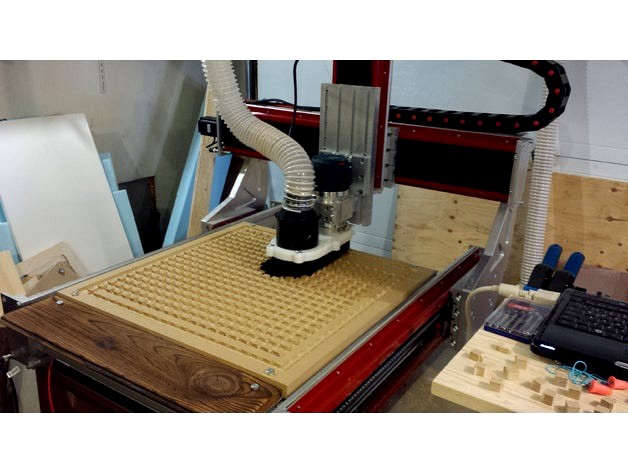

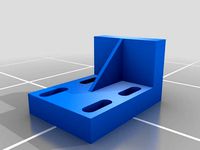

Vacuum Table for CNC Machine by infinity111

by Thingiverse

Last crawled date: 3 years ago

This is a 2ft. x 2ft. vacuum table designed for a CNCRouterparts "Benchtop Pro" CNC Router machine.

Process (in a nutshell):

Obtain your MDF wood

Load the file in Fusion 360 (free for hobbyists)

Select/create your tool and regenerate tool-paths (Note: this could take a while. Fusion 360 just does not like this tool path. My computer uses up to 5GB RAM and 5-10 minutes to make any changes to the main air chamber tool path. )

Process output files (keep operations separate)

Load the file into Mach3 (licensed)

Set your "zero" for X and Y but follow the NOTICE below for setting your Z-zero

Run operation to cut main chamber

Run operation to cut vacuum port

Flip material, re-zero

Run operation to cut "guide holes" - these holes are not through the material

Assemble using duct tape and shop vac

Fasten to work table

Selectively drill out holes for your media size using a cordless drill and drill bit

Enjoy!

NOTICE: You must cut the main air chamber using 2 passes. The file included does NOT do this automatically because my computer could not render the two passes without crashing. To achieve 2 passes, simply calibrate your Z-zero to 0.25 above your material on the first pass, and then calibrate Z-zero to true material top on your second pass.

Bolt Holes (recommended) can be added by creating a sketch on the material border, or by manually drilling. Bolts will keep both pieces of MDF square and tight to the table, while clamps may result in some slippage.

See pictures for more detail.

Required material:

air filter mask, eye and ear protection

two pieces 2x2' MDF, 1" thick

duct tape - for sealing the two tables pieces together around the outer edge

shop vac - I used a small Rigid-brand "5HP Max" shop vac

bolts, clamps or other fastening hardware

cordless drill and 1/8" drill bit - for drilling out guide holes to match your media size

Optional material:

M8x60 bolts, washers and t-slot inserts - for "Benchtop Pro" machine

glue - for gluing the two pieces of MDF together around the outer border and also across all of the inner support "cubes." This can be achieved by spreading glue, sandwiching the two pieces together and then clamping or applying even force (e.g. weight) across the entire surface on a LEVEL surface. I opted NOT to glue the two pieces at first however I did notice that the two MDF pieces have a slight air gap between them which could result in uneven cutting with vacuum pressure changes. However, I'm doing through-cutting and not engraving so I am OK with this, plus this is just an experiment for now.

Note STL file will not work, and is only uploaded to satisfy Thingiverse programming. Fusion 360 does NOT seem to export in any formats compatible with Thingiverse.

Process (in a nutshell):

Obtain your MDF wood

Load the file in Fusion 360 (free for hobbyists)

Select/create your tool and regenerate tool-paths (Note: this could take a while. Fusion 360 just does not like this tool path. My computer uses up to 5GB RAM and 5-10 minutes to make any changes to the main air chamber tool path. )

Process output files (keep operations separate)

Load the file into Mach3 (licensed)

Set your "zero" for X and Y but follow the NOTICE below for setting your Z-zero

Run operation to cut main chamber

Run operation to cut vacuum port

Flip material, re-zero

Run operation to cut "guide holes" - these holes are not through the material

Assemble using duct tape and shop vac

Fasten to work table

Selectively drill out holes for your media size using a cordless drill and drill bit

Enjoy!

NOTICE: You must cut the main air chamber using 2 passes. The file included does NOT do this automatically because my computer could not render the two passes without crashing. To achieve 2 passes, simply calibrate your Z-zero to 0.25 above your material on the first pass, and then calibrate Z-zero to true material top on your second pass.

Bolt Holes (recommended) can be added by creating a sketch on the material border, or by manually drilling. Bolts will keep both pieces of MDF square and tight to the table, while clamps may result in some slippage.

See pictures for more detail.

Required material:

air filter mask, eye and ear protection

two pieces 2x2' MDF, 1" thick

duct tape - for sealing the two tables pieces together around the outer edge

shop vac - I used a small Rigid-brand "5HP Max" shop vac

bolts, clamps or other fastening hardware

cordless drill and 1/8" drill bit - for drilling out guide holes to match your media size

Optional material:

M8x60 bolts, washers and t-slot inserts - for "Benchtop Pro" machine

glue - for gluing the two pieces of MDF together around the outer border and also across all of the inner support "cubes." This can be achieved by spreading glue, sandwiching the two pieces together and then clamping or applying even force (e.g. weight) across the entire surface on a LEVEL surface. I opted NOT to glue the two pieces at first however I did notice that the two MDF pieces have a slight air gap between them which could result in uneven cutting with vacuum pressure changes. However, I'm doing through-cutting and not engraving so I am OK with this, plus this is just an experiment for now.

Note STL file will not work, and is only uploaded to satisfy Thingiverse programming. Fusion 360 does NOT seem to export in any formats compatible with Thingiverse.

Similar models

thingiverse

free

PVC Pipe Clamp (3/4") by zim

...hose clamp and 2 1/4" lag bolts. the two holes for the lag bolts will probably need to be touched up with a 1/4" drill.

thingiverse

free

31" spoil board with dovetail clamping slots by muddyfeet

...these clamps:

oops clamps: https://www.thingiverse.com/thing:4584289

toe clamps: https://www.thingiverse.com/thing:4584288

thingiverse

free

Wire clamp tite clamp maker by rkevinball_5591

...

for making wire clamps

go to hardware store and buy a 1/4" x 5" bolt. cut off threaded part and drill a hole for bolt.

thingiverse

free

2.25" Dust Vacuum Plug by Donovan_Benoit

...r diameter

this version works with the adapter that comes attached to hose from this home depot vacuum hose extension kit vt2520.

thingiverse

free

Hole Jig for Round Stock / Dowel / Pipe by scottmi

....

note: close tolerance in hole size, and thickness of the flange for the bolts are desired for good alignment of the jig parts.

thingiverse

free

Camera Mount by vasile

...or longer bolts, or adjust

the length by placing a second nut on the bolt on the side of the

clamp where the head of the bolt is.

thingiverse

free

Prowin "Wini" Vacuum cleaner hose clamp by Acer54

...rizontal position with supports because then the clamping mechanism should be more stable an robust due to the layer orientation.

thingiverse

free

Vacuum Chamber Air Spreader (1/4") by HeavyMetalGuy

...avymetalguy

thingiverse

i designed this to prevent the air from going straight down into the vacuum chamber when repressurizing.

thingiverse

free

PRO Series "CNC Router Parts" Spoilboard by CNCRouterParts

...of f-clamps. what you'll need 3/4" thick mdf or similar material that covers the desired work area (usually matching...

thingiverse

free

Shop Vac vacuum clamp by sbeav

...thingiverse

shop vac adapter for dust collection specifically for a harbor freight belt sander.its

id is 1.75" in diameter.

Infinity111

thingiverse

free

Golf Tee Game x 4 by infinity111

...al) work best for cutting out the games.

the holes work with the following golf tees: https://www.amazon.ca/gp/product/b00y2163ke

thingiverse

free

MDF Spoilboard for Avid Benchtop Pro 2x2 by infinity111

...ps://www.amazon.ca/gp/product/b0747qx71f

this was cut using a 1/4" end mill and a bosch 1617 router on an avid benchtop pro.

Vacuum

thingiverse

free

BANDSAW VACUUM ADAPTOR TO VACUUM CLEANER

...eaner exit

inner dia: 32mm

outer dia: 36mm

max length in z-axis: 84mm

max length in x-axis: 67mm

max length in y-axis: 67mm

thingiverse

free

Vacuum Adapter

...vacuum adapter

thingiverse

just a quick model of a adapter for vacuum cleaners

thingiverse

free

Vacuum Attatchment

...vacuum attatchment

thingiverse

made this for my vacuum maybe you could use it

thingiverse

free

Vacuum couple

...vacuum couple

thingiverse

this is a couple for a kreg jig to plug a rigid vacuum cleaner.

thingiverse

free

Vacuum nozzle by mrojod

...vacuum nozzle by mrojod

thingiverse

this is a vacuum noozle to replace the stock one of 90% of vacuums

thingiverse

free

Vacuum Pump Coupler

...upler

thingiverse

-6 an to -6 an straight female coupler for diy vacuum chamber or vacuum forming with a cheap ebay vacuum pump.

thingiverse

free

Vacuum Hood by kaxorpie

...dental office. it fits nicely into a 2" vacuum tube connector--the size commonly used for household central vacuum systems.

thingiverse

free

VACUuM ATtACHMENT by theecokid

...vacuum attachment by theecokid

thingiverse

vacuum attachment

thingiverse

free

Vacuum Attachment by JamCav

...vacuum attachment by jamcav

thingiverse

vacuum attachment

thingiverse

free

Vacuum Model by CTElementalists

...vacuum model by ctelementalists

thingiverse

this is the design for robot vacuum

Cnc

thingiverse

free

CNC by Robi1602

...cnc by robi1602

thingiverse

cnc

thingiverse

free

CNC Feet - Nikodem CNC

...ixe-it, and they are a big hole for screw the aluminium profile (on the pictures).

enjoy and thanks nikodem for you amazing cnc !

thingiverse

free

CNC Case

...cnc case

thingiverse

control box to be used with rs-cnc or any other cnc you like.

thingiverse

free

Susferus CNC

...susferus cnc

thingiverse

susferus cnc testing

thingiverse

free

RS-CNC , the new model of R-CNC by RoMaker

...new model of r-cnc by romaker

thingiverse

the rs-cnc is the replacement of the r-cnc (https://www.thingiverse.com/thing:2159840)

thingiverse

free

Fixture- CNC by sidd200970

...fixture- cnc by sidd200970

thingiverse

cnc machine vise for diy cnc machines

thingiverse

free

Cnc Lazer by baymikro

...cnc lazer by baymikro

thingiverse

cnc lazer

thingiverse

free

CNC dusthood by Idegraaf

...cnc dusthood by idegraaf

thingiverse

dusthood for cnc

thingiverse

free

coupling cnc by poggia10

...coupling cnc by poggia10

thingiverse

coupling cnc

thingiverse

free

cnc square by MR_MUSTARD

...cnc square by mr_mustard

thingiverse

square for cnc

Table

thingiverse

free

table table by mertyty

...table table by mertyty

thingiverse

table table

thingiverse

free

table

...table

thingiverse

a table

thingiverse

free

table

...table

thingiverse

a table model!

thingiverse

free

Table

...table

thingiverse

sliding table extender components

thingiverse

free

Table lampshade table by PRATRIK

...table lampshade table by pratrik

thingiverse

a tablelamp that is a table. get it...

thingiverse

free

Mini Table Tennis Table by DarrenGossling

...mini table tennis table by darrengossling

thingiverse

mini table tennis table and table at 20%

thingiverse

free

table in front of table printer by DoESLiverpool

...table in front of table printer by doesliverpool

thingiverse

table in front of table printer

thingiverse

free

TROFY TABLE AND NORMAL TABLE by Santyagus

... table by santyagus

thingiverse

they are designs of tables to print as models, one is a basic table and the other a trophy table

thingiverse

free

Part of Table tennis table by LuZhiShen

...part of table tennis table by luzhishen

thingiverse

this is a part of table tennis table above

thingiverse

free

Table

...table

thingiverse

medieval style table for tabletop games. test printed on an anycubic photon

Machine

thingiverse

free

arcade machine

...arcade machine

thingiverse

miniature arcade machine

thingiverse

free

Machine by eca3d

...machine by eca3d

thingiverse

machine -> bus

thingiverse

free

machine by President909

...machine by president909

thingiverse

machine by aidan [created on 3dtin]

thingiverse

free

ink machin by bendytheprinter

...ink machin by bendytheprinter thingiverse this is the ink machine from the game of bendy and the ink...

thingiverse

free

handle washing machine / Poignée machine a laver

...handle washing machine / poignée machine a laver

thingiverse

test and work in progress

thingiverse

free

granita machine by ississ

...granita machine by ississ

thingiverse

granitas machine

thingiverse

free

DClean Machine Knob

...dclean machine knob

thingiverse

this is a knob for a machine

thingiverse

free

milling machine by arli3d

...milling machine by arli3d

thingiverse

a milling machine

thingiverse

free

game machine by max7th

...game machine by max7th

thingiverse

game machine

thingiverse

free

bucket machines by shura2000

...bucket machines by shura2000

thingiverse

bucket machines