Thingiverse

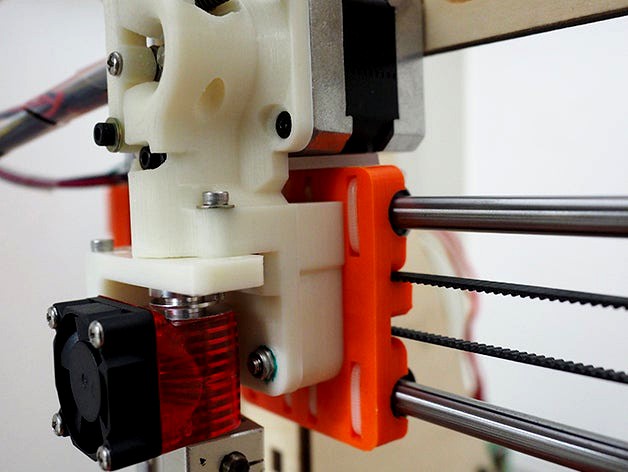

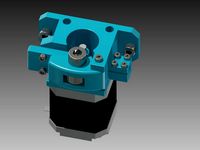

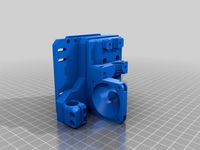

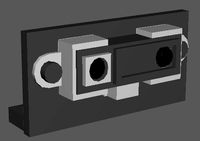

Unified Prusa i3 Extruder for Mk8 drive gear, e3d v6 hotend, and BLTouch sensor. by inornate

by Thingiverse

Last crawled date: 3 years ago

I remixed the great extruder design by coricoco (thing #755164) and applied some design improvement from Marck80's remix (thing #932386).

This design has numerous advantages.

The solid and unified design requires minimal assembly.

No Bowden.

Minimal footprint, so it does not cannibalize printing volume.

The center of weight is on the X axis.

Capable of Flexible filaments.

This design is backward compatible. You might able to use various accessories from the previous designs (#755164 and #932386).

This extruder is for Mk8 drive gear (effective diameter 7mm) and an E3Dv6 nozzle.

Also, it equips BLTouch auto leveling sensor mount ( https://www.indiegogo.com/projects/bltouch-auto-leveling-sensor-for-3d-printers ).

Required additional parts and gears

PTFE tube (o.d 4mm / i.d 2mm)

M3*7mm countersunk bolts (x4)

M3*5mm bolts (x2)

M3*20mm bolt (x2)

M3*25mm bolt (x1)

M3*50mm bolts (x2)

M4*40mm bolts (x4)

M3 & M4 Nyloc nuts

Washers

Springs x2 (about 15mm)

3mm&4mm drills

M3 Tap

623 or 624 bearing 1ea

Mk8 drive gear

E3Dv6 hotend (or lite ver.)

NEMA17 & 31mm stepper motor.

(Optional) BLTouch sensor

Printing Instruction

I recommend using high infill rate (above 40%) and 3 perimeters. I used ABS but PLA probably works fine. Reorient parts if required.

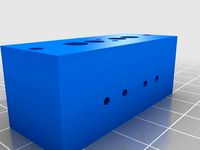

Print [Extruder_mk8]. It's designed to be printed without raft and supports, however, choose decent bed adhesion option if needed.

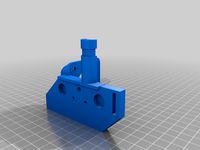

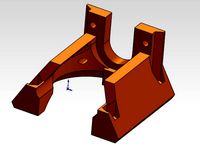

Print [Extruder_fixer]. If you want to use BLTouch sensor, print the _BLTouch ver. Otherwise, print the _normal version.

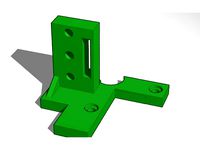

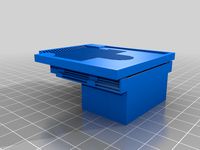

Print [Extruder_tensioner] for your bearing size.

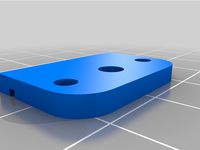

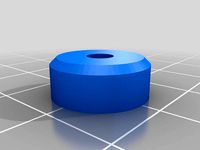

Print [Spacer] and [TubeClamp].

Assembly Instruction

For better vibration resistance. use Nyloc nuts for every possible place.

Remove the pre-designed supports.

Clean the holes using drills.

Tap two M3 threads at the center of the extruder.

Test mount an E3D nozzle. Cut the PTFE tube to be placed just below the drive gear.

Mount a stepper motor using M3*7mm countersunk bolts

Mount a bearing to the [Extruder_tensioner]. For 623 bearing, use M3x20mm bolt. For 624 bearing, use M4x25mm bolt. If you're using 624 bearing, place the bolt head toward the stepper.

Mount the [Extruder_tensioner] assembly to the extruder body. Use M3*25mm bolt and add some washers for clearance. Tightening the bolt is tricky here. Use a long-nose plier to fix a nut. Make sure the tensioner is moving freely.

Mount the Mk8 drive gear to the stepper.

Using two M3*50mm bolts, springs, and nut, push the bearing against the drive gear. Refer the picture.

Place four M4 Nyloc nuts to the extruder body. Apply a drop of super glue to avoid falloff during assembly.

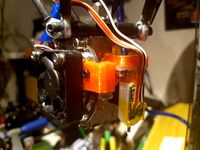

Using [Extruder_fixer] and two M3x20mm bolts, mount the E3Dv6 hotend.

If your hotend has PTFE tube clamp, just go to next step. Otherwise, clamp the PTFE tube using TubeClamp part & two M3*5mm bolts.

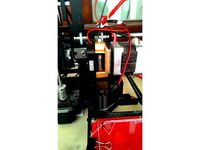

(Optional) Mount the BLTouch sensor. The X-offset between the nozzle and sensor probe is 23mm. Y-offset is zero. Z-offset is required to be calibrated for your parts.

Mount the extruder assembly to the carriage using four M4*40mm bolts. Sandwich [Spacer] between them.

If you have some rubbery material, place it between the stepper motor and carriage. This will greatly reduce the vibration during print.

This design has numerous advantages.

The solid and unified design requires minimal assembly.

No Bowden.

Minimal footprint, so it does not cannibalize printing volume.

The center of weight is on the X axis.

Capable of Flexible filaments.

This design is backward compatible. You might able to use various accessories from the previous designs (#755164 and #932386).

This extruder is for Mk8 drive gear (effective diameter 7mm) and an E3Dv6 nozzle.

Also, it equips BLTouch auto leveling sensor mount ( https://www.indiegogo.com/projects/bltouch-auto-leveling-sensor-for-3d-printers ).

Required additional parts and gears

PTFE tube (o.d 4mm / i.d 2mm)

M3*7mm countersunk bolts (x4)

M3*5mm bolts (x2)

M3*20mm bolt (x2)

M3*25mm bolt (x1)

M3*50mm bolts (x2)

M4*40mm bolts (x4)

M3 & M4 Nyloc nuts

Washers

Springs x2 (about 15mm)

3mm&4mm drills

M3 Tap

623 or 624 bearing 1ea

Mk8 drive gear

E3Dv6 hotend (or lite ver.)

NEMA17 & 31mm stepper motor.

(Optional) BLTouch sensor

Printing Instruction

I recommend using high infill rate (above 40%) and 3 perimeters. I used ABS but PLA probably works fine. Reorient parts if required.

Print [Extruder_mk8]. It's designed to be printed without raft and supports, however, choose decent bed adhesion option if needed.

Print [Extruder_fixer]. If you want to use BLTouch sensor, print the _BLTouch ver. Otherwise, print the _normal version.

Print [Extruder_tensioner] for your bearing size.

Print [Spacer] and [TubeClamp].

Assembly Instruction

For better vibration resistance. use Nyloc nuts for every possible place.

Remove the pre-designed supports.

Clean the holes using drills.

Tap two M3 threads at the center of the extruder.

Test mount an E3D nozzle. Cut the PTFE tube to be placed just below the drive gear.

Mount a stepper motor using M3*7mm countersunk bolts

Mount a bearing to the [Extruder_tensioner]. For 623 bearing, use M3x20mm bolt. For 624 bearing, use M4x25mm bolt. If you're using 624 bearing, place the bolt head toward the stepper.

Mount the [Extruder_tensioner] assembly to the extruder body. Use M3*25mm bolt and add some washers for clearance. Tightening the bolt is tricky here. Use a long-nose plier to fix a nut. Make sure the tensioner is moving freely.

Mount the Mk8 drive gear to the stepper.

Using two M3*50mm bolts, springs, and nut, push the bearing against the drive gear. Refer the picture.

Place four M4 Nyloc nuts to the extruder body. Apply a drop of super glue to avoid falloff during assembly.

Using [Extruder_fixer] and two M3x20mm bolts, mount the E3Dv6 hotend.

If your hotend has PTFE tube clamp, just go to next step. Otherwise, clamp the PTFE tube using TubeClamp part & two M3*5mm bolts.

(Optional) Mount the BLTouch sensor. The X-offset between the nozzle and sensor probe is 23mm. Y-offset is zero. Z-offset is required to be calibrated for your parts.

Mount the extruder assembly to the carriage using four M4*40mm bolts. Sandwich [Spacer] between them.

If you have some rubbery material, place it between the stepper motor and carriage. This will greatly reduce the vibration during print.

Similar models

thingiverse

free

7:32 Compact Geared Extruder Nema17 and 14 by ryannining

...haft bearing

1x 624 for idler.

1xm4 nut

to make tensior, i use steel from peg to clamphttps://www.youtube.com/watch?v=-7bpu9pbq18

thingiverse

free

Schematix: Dual Drive Extruder (Fits E3D v6) by Schematix

....d 4mm o.d

springs (some experimentation may be required) however i use the following:

wire diameter: 0.7mm x 6mm o.d x 18mm long

thingiverse

free

Tentacles Cooler for MK8 extruder adjustable mount

... mount to fit different hotend lengths.

thread m4 holes in fan mount, or drill it and use m4 nuts, or just use m3 bolts and nuts.

thingiverse

free

Dual stepper MK8 gear direct drive bowden extruder

...

2x m3 washer for holding the bearings in place

2x pneumatic push-in fittings with m5 threads for the bowden tube diameter in use

thingiverse

free

Alpha Direct Drive Extruder by engineglue

...upply list; this is a minimal design. you can use m4 bolts and nuts to mount it. it mounts to a standard aluminum mounting plate.

thingiverse

free

Prusa I3 Direct Drive Extruder 3mm by alphapilot

...aliexpress.com/item/mk7-bore-8mm-extruder-drive-gear-for-3mm-hobbed-gear-for-makerbot-reprap-mendel-high-quality/32462285369.html

thingiverse

free

Extruder Nema23 MK8 by fawan21

...cs

bolt jp m4 x 16, 1 pc

bolt jp m4 x 50, 4 pcs

bearing 624zz, 1 pc

hex nut m3, 1 pc

hex nut m4, pcs

https://youtu.be/44dng7swzc8

thingiverse

free

1.75mm Direct Drive Extruder by tosjduenfs

... to use ptfe tubing to guide filament to the extruder you can print the ptc (push-to-connect) holder for the top of the extruder.

thingiverse

free

Rackprint Bowden Extruder by Alex_RP

...x m3 screw ~20mm and nuts

2x m3 screw 15mm

bearing 608zz

mk8 drive gear

2x spring ~20mm with ~3mm inner diameter

thingiverse

free

Rusa bowden extruder gear by urusa

...tes the m5 bolts.

the shaft is fixed to the motor rotation.

secure the mk7 extrusion gear to the m5 bolts.

the gear ratio is 1/3.

Inornate

thingiverse

free

White Mage Minion by inornate

...inornate

thingiverse

white mage derived from "black mage minion from final fantasy xiv" by panini.

no need of support.

thingiverse

free

Prusa i3 Frame Fixing Mounts by inornate

...prusa i3 frame fixing mounts by inornate

thingiverse

immobilize your frame!

your printer will be rock solid after this mod.

thingiverse

free

Flying Spaghetti Monster (FSM) Emblem by inornate

...aghetti monster (fsm) emblem by inornate

thingiverse

it's a high-quality version of fsm emblem for your any purposes.

ramen!

thingiverse

free

KAIST character by inornate

...ch require lots of support) and another one is a flattened and lay downed model for 3d printing.

earphone winder version added.

thingiverse

free

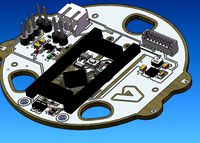

E3D Hemera extruder indicator by inornate

...and it's good to rotate!

best print with two colors (filament change method).

working in action: https://youtu.be/c8hmqkz_fmc

thingiverse

free

BLTouch auto leveling sensor (dummy prop) by inornate

...ensor virtually in your design.

dimensions from https://www.indiegogo.com/projects/bltouch-auto-leveling-sensor-for-3d-printers#/

thingiverse

free

Printable tatting shuttle by inornate

...ts for the center column, which relieve the stress of the plate. also, there is "big" version for bigger tatting piece.

thingiverse

free

Auto bed leveling using piezo discs - Remixed by inornate

...r transfers the force to the piezo disc.

the original design was done by elenhinan, thing http://www.thingiverse.com/thing:707392

thingiverse

free

ImmersionRC rapidFIRE module door (cover) for FatShark goggles by inornate

...'t design this and all the rights are deserved by immersionrc.

not suitable for fdm printers.

recommend resin-based printing.

thingiverse

free

Kleenex Tissue Box Holder by inornate

...work with any tissue box with 11cm~12cm height. four pyramids inside the clip will hold the box tightly. it will never slip away.

Unified

3ddd

$1

Душевой Смеситель

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3ddd

$1

Зеркало в санузел

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3ddd

$1

Набор гостиничной мебели

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3ddd

$1

Сушка для тарелок

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3ddd

free

энергосберегающий контроллер "SALTO"

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3d_export

$15

PKP Pecheneg

...pkp pecheneg 3dexport the unified russian pkp "pecheneg" (6541) 7.62 mm is widely known...

3d_export

$79

Female Muscular System

...female muscular system 3dexport this model is a unified muscle textured to a male 3d model, this includes...

3d_export

$15

Masculine Female

...masculine female 3dexport this model is a unified muscle textured to a male 3d model, this includes...

3ddd

$1

Диван "БОСТОН"

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

3ddd

$1

Стол на опоре Spartak-light с табуретами

...сэмплов всех a&d; материалов равно 1 для использования с unified sampling. для глобального изменения сэмплов в материалах можно воспользоваться...

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Bltouch

thingiverse

free

Support bltouch by TonyJ

...support bltouch by tonyj

thingiverse

support bltouch

thingiverse

free

BLTOUCH for MICRON3DP by lamerhouse

...bltouch for micron3dp by lamerhouse

thingiverse

bltouch for micron3dp

thingiverse

free

SapphirePro mount for Bltouch

...sapphirepro mount for bltouch

thingiverse

sapphirepro mount for bltouch

thingiverse

free

ender6 BLtouch by chimaer

...ender6 bltouch by chimaer

thingiverse

ender6 bltouch

this is an external bracket

thingiverse

free

BLTouch KP3s by 1devilman1

...bltouch kp3s by 1devilman1

thingiverse

bltouch mount for kingroon kp3s

thingiverse

free

Bltouch support adjustable

...bltouch support adjustable

thingiverse

adjustable support for bltouch, p3steel.

thingiverse

free

BMG NEREUS BLTOUCH

...bmg nereus bltouch

thingiverse

petg

m3 screws and nuts for the bltouch

thingiverse

free

BLTouch Bracket by tidh666

...bltouch bracket by tidh666

thingiverse

serves to attach the bltouch sensor to the extruders

thingiverse

free

bltouch mount by wars

...bltouch mount by wars

thingiverse

reinforced bracket for bltouch cooperates with high_clearance_cr10_oem_fang_mod

thingiverse

free

BLTouch Holder by Jonthan06

...bltouch holder by jonthan06

thingiverse

support bltouch pour wanhao d12

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

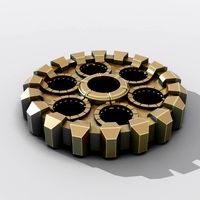

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)