Thingiverse

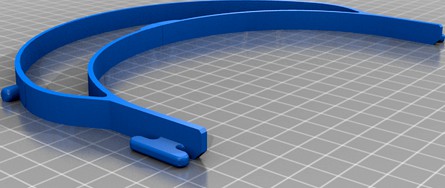

Ultra Fast and Light Consumer Face Shield by Nerys

by Thingiverse

Last crawled date: 4 years ago

I have 140 printers. but I can only run 4 or 5 at once and most are still crated up from my move. SO I can really mass produce shields for #opshieldsup etc..

My local medical facilities also are not short on PPE. (Rural New Mexico USA)

BUT. our local shop employee's are largely unprotected and they have expressed an interest in the face shields. SO I am going to make them some. I have materials for 100 (with elastic and clear plastic being my limiting factors) so over the next week Dollar Tree, Smith's, & McDonalds employee's will be getting some face shields.

The standards for these are not as stringent as hospitals its just a comfortable barrier protection that is light comfy and easy to use.

SO comfirm first but likely hospitals won't want these.

These are designed for RAW performance and frugality. 10mm tall 1.2mm nozzles 0.8mm layer height. your printer will go slow but your extruder is going to SCREAM. you might even have to slow down if your system can't melt plastic fast enough (volumetric flow) or you might be able to go faster if you have more heat capacity.

Gcode and S3D Factory file included. 200x200 bed 0.4mm nozzle. it is programed to extrude a line 1.2mm wide 0.8mm tall. do not try and go fast it just won't work. this is programmed for 19mm/s and a 25minute print (1.0 and 1.2mm nozzles can do this in 14-17 minutes if you can push enough heat) my sequential set of 4 in vase mode takes 58-61 minutes to finish for 4 shield bands.

to slice. set your nozzle to your nozzle size. set your extrusion or line width to 1.2mm set your layer height to 0.8mm 19mm/s 80% outline underspeed 240c on the nozzle (230 first layer as its slower you don't want to cook off the pla)

I doubt this will even work with PETG unless you lower the layer height or have a volcano and push 255c. your going to be extruding a silly amount of plastic! a gram a minute basically.

no top or bottom layers no infill just vase or spiralize outer contour mode. I am seeing about a 10% anomaly ratio so I may drop down to 0.7 or 0.6 layer height and just live with a 20min print instead of 17. we shall see. so far the 0.4mm is working great as long as I don't push too fast. (25-29 minutes print time on 0.4mm nozzle which is still silly fast)

about 23g of plastic each.

if using a 0.4mm nozzle and you see "tearing" in your extrusion slow it down 10% and see how it likes that.

in the picture the green one was printed on my Anycubic Chiron with 1.2mm nozzle the red one was printed on my Creality CP-01 with 0.4mm nozzle.

This is for a standard US 3 hole punch. I am tired tonight so I will upload a Euro 4 hole punch version tomorrow.

I still have a few ideas for shaving more time off the print. the trick is to remove acceleration delta's. ie no hard turns etc.. which is where things slow down.

My local medical facilities also are not short on PPE. (Rural New Mexico USA)

BUT. our local shop employee's are largely unprotected and they have expressed an interest in the face shields. SO I am going to make them some. I have materials for 100 (with elastic and clear plastic being my limiting factors) so over the next week Dollar Tree, Smith's, & McDonalds employee's will be getting some face shields.

The standards for these are not as stringent as hospitals its just a comfortable barrier protection that is light comfy and easy to use.

SO comfirm first but likely hospitals won't want these.

These are designed for RAW performance and frugality. 10mm tall 1.2mm nozzles 0.8mm layer height. your printer will go slow but your extruder is going to SCREAM. you might even have to slow down if your system can't melt plastic fast enough (volumetric flow) or you might be able to go faster if you have more heat capacity.

Gcode and S3D Factory file included. 200x200 bed 0.4mm nozzle. it is programed to extrude a line 1.2mm wide 0.8mm tall. do not try and go fast it just won't work. this is programmed for 19mm/s and a 25minute print (1.0 and 1.2mm nozzles can do this in 14-17 minutes if you can push enough heat) my sequential set of 4 in vase mode takes 58-61 minutes to finish for 4 shield bands.

to slice. set your nozzle to your nozzle size. set your extrusion or line width to 1.2mm set your layer height to 0.8mm 19mm/s 80% outline underspeed 240c on the nozzle (230 first layer as its slower you don't want to cook off the pla)

I doubt this will even work with PETG unless you lower the layer height or have a volcano and push 255c. your going to be extruding a silly amount of plastic! a gram a minute basically.

no top or bottom layers no infill just vase or spiralize outer contour mode. I am seeing about a 10% anomaly ratio so I may drop down to 0.7 or 0.6 layer height and just live with a 20min print instead of 17. we shall see. so far the 0.4mm is working great as long as I don't push too fast. (25-29 minutes print time on 0.4mm nozzle which is still silly fast)

about 23g of plastic each.

if using a 0.4mm nozzle and you see "tearing" in your extrusion slow it down 10% and see how it likes that.

in the picture the green one was printed on my Anycubic Chiron with 1.2mm nozzle the red one was printed on my Creality CP-01 with 0.4mm nozzle.

This is for a standard US 3 hole punch. I am tired tonight so I will upload a Euro 4 hole punch version tomorrow.

I still have a few ideas for shaving more time off the print. the trick is to remove acceleration delta's. ie no hard turns etc.. which is where things slow down.

Similar models

thingiverse

free

GOW Marcus Fenix by aggressivelokon

... by aggressivelokon

thingiverse

layer height: 0.12mm

nozzle: 0.4mm

perimeter: 0.8mm

speed: 60mm/s (but s3d slows it down mostly)

thingiverse

free

Protective Face Shield Frame by Nerys

...ot; at the top than the bottoms so the binder clips stay put and don't slide off easily and being steal they can be sanitized

thingiverse

free

Surgical Mask Strap for 0.8mm Nozzle Printers by makerjeff

... x/y corners have filets applied for smoother high speed prints.

thinner 2-layer main strap ( 0.8mm nozzle, 0.4mm layer height ).

thingiverse

free

Flush V-Slot Cover by Benedryl_Cucumberpatch

...nozzle, you probably won't have to change anything from your normal settings. just resize the length to fit your application.

thingiverse

free

Servo wire extension security Clip by oregondesign

...mm nozzle, 0.9mm walls for printing with 0.3mm nozzle. the thin walls allow for plenty of flexibility in pla,

tips are good :)

thingiverse

free

Race to the Treasure Card Holder by DrewTM

...lid with 1.2mm extrusion width and zero top or bottom layers. this shows off your fancy infill and lets you see the cards inside.

thingiverse

free

Face Shield Modified FAST by edwardme

...l line count: 3 layers

print speed: 100mm/s

no plate adhesion

use 3 hole punch for sheet of 8 or 10 mil clear binder covers work.

thingiverse

free

remote holder for round vertical handrail

...of 22 mm. the remotes dimensions are 37x13mm.

printing with volcano hotend 0.8mm nozzle, 0.4mm layer height took only 22 minutes!

thingiverse

free

Light 16g covid face shield no rubber by pietreksz

...

0.4mm nozzle - 54m

files with 08mm in name are optimized for 0.8mm nozzle.

file with 04mm in name is optimized for 0.4mm nozzle.

thingiverse

free

Mobula 6 HD - Case - Vase Mode by Null_Hypothesis

...too tight, you could also print the 0.8mm version with a 0.4mm nozzle.

prints in under 1h with 0.4mm nozzle or 30min with 0.8mm.

Nerys

3ddd

free

Neri

... фонарь

уличный фонарь фирмы neri

моделился по спецификации (есть на рендере)

текстуры в ахиве.

25 700 полигонов.

3ddd

free

Technolux Neri

...technolux neri

3ddd

technolux

technolux neri

3ddd

free

NERI AND HU

...neri and hu

3ddd

ковер

ковры ручной работы дизайнеров neri and hu

серия jet stream

3ddd

$1

стол neri & ho

...стол neri & ho

3ddd

neri & ho

стол neri & ho

3ddd

$1

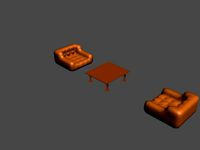

Neri & Ho

...

глубина (см): 36,2

материал каркаса: орех американский

материал обивки: кожа

все материалы и текстуры имею уникальные названия.

3ddd

$1

NERI AND HU часть 2

...neri and hu часть 2

3ddd

ковры

ковры ручной работы дизайнеров neri and hu

серия bittersweet и sweet caroline

turbosquid

free

NERY&HU Armchair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Neri & Hu Platform Sofa

...кстуры.

вес 236 000 полигонов

сайтhttp://www.thefutureperfect.com/designer/neri-hu/platform-sofa.html

размеры 230х92см

3ddd

$1

Табурет Neri & Ho

... nori & ho

табурет от neri & ho

материал : дерево, кожа

размеры : w 350 x d 350 x h 460 mm

3ddd

$1

Барный стул Neri & Ho

... neri&ho , табурет

высота 61 см

ширина 36,2 см

глубина 36,2 см

Consumer

turbosquid

$5

Consumer Unit

... free 3d model consumer unit for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1362377)

turbosquid

$1

Low consume bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

Storage box for consumables

...up. subscribe to the telegram channel to keep up to date with all the new products:) link:https://t.me/blog_engineer_designer ♥♥♥

3ddd

$1

Flos Consumer Taccia

... taccia

напольный светильник taccia фирмы flos

размеры: 19 х 49,5 х 54 см

полигоны: 33 507

3ddd

$1

FLOS

...flos 3ddd flos flos ktribe w/t1/f3/f1http://www.flos.com/consumeren/products/wall_ceiling_lighting/ktribe_w http://www.flos.com/consumer/en/products/table/ktribe_t http://www.flos.com/consumer/en/products/floor/ktribe_f ...

3ddd

$1

Flos 2097

...flos 2097 3ddd flos , gino sarfatti http://www.flos.com/consumeren/products/pendant/2097_30_50 ...

3ddd

$1

FLOS Guns - Bedside Gun

...flos guns - bedside gun 3ddd flos , guns http://www.flos.com/consumeren/products/table/guns-bedside_gun ...

3ddd

$1

Flos ARA

...3ddd flos , ara , starck ссылка на сайт производителя:http://www.flos.com/consumeren/products/table/ara ...

3d_export

$35

Nokia 9300 handphone 3D Model

...9300 handphone 3d model 3dexport nokia 9300 handphone electronics consumer product mobile cellphone nokia 9300 handphone 3d model capricorn...

3ddd

$1

Samsung AF9000

...af9000 3ddd кондиционер af9000 напольный кондиционер с технологией digital inverterhttp://www.samsung.com/kz_ru/consumerhome-appliances/air-conditioners/floor-standing/af27fssdawkner ...

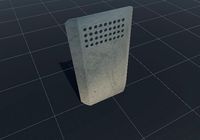

Shield

3d_export

$5

shield

...shield

3dexport

shield

3d_export

$5

Shield

...shield

3dexport

shield and a spear

3d_ocean

$6

Shield

...shield

3docean

game shield low polygon mei evil shild old shield shield

2048 texture obj,fbx,blend game ready.

3d_export

$5

Shield

...shield

3dexport

a shield that hasn't been made of materials will be available to everyone

3d_ocean

$4

Round Shield

...round shield

3docean

ancient battle fantasy knight medieval shield shields warrior

nice model of round shield.

3d_export

$5

shield

...shield

3dexport

old shield, damaged and covered in mold. every file have a zip folder in with textures.

3d_export

free

metal shield

...metal shield

3dexport

russian metal shield - anti-riot shield.

turbosquid

free

Shield

...shield

turbosquid

free 3d model shield for download as c4d on turbosquid: 3d models for games, architecture, videos. (1164800)

3d_export

$5

fire shield

...fire shield

3dexport

fire shield

turbosquid

$10

SHIELD

...

turbosquid

royalty free 3d model shield for download as obj on turbosquid: 3d models for games, architecture, videos. (1273553)

Fast

3d_export

$5

toilet fast

...toilet fast

3dexport

fast model toilet.<br>verts 21472<br>faces 21616

turbosquid

$13

fast food

...royalty free 3d model fast food for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1685616)

3ddd

free

rosenthal / Fast vase

...rosenthal / fast vase

3ddd

rosenthal

rosenthal fast vase

turbosquid

$20

Fast Food

...free 3d model fast food for download as ma, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1427379)

turbosquid

$65

table(fast)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Fast Food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

fast food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Fast Food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Fast table 3D Model

...fast table 3d model

3dexport

fast table

fast table 3d model modelix 59114 3dexport

turbosquid

free

Fast Food Cup

...turbosquid

free 3d model fast food cup for download as blend on turbosquid: 3d models for games, architecture, videos. (1206378)

Face

turbosquid

$100

face a face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Face To Face Swing

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Almerich Face to Face

... гибкостью материала, прозрачностью и тактом, чтобы создавать игры со светом и тенью.

размеры: 48 x 48 x 155 см

полигоны: 39 376

design_connected

$11

Face

...face

designconnected

montis face chairs computer generated 3d model. designed by gerard van den berg.

turbosquid

$15

Face

...ce

turbosquid

royalty free 3d model face for download as mud on turbosquid: 3d models for games, architecture, videos. (1178369)

turbosquid

$6

Face

...ce

turbosquid

royalty free 3d model face for download as max on turbosquid: 3d models for games, architecture, videos. (1409756)

turbosquid

$1

Face

...uid

royalty free 3d model face for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1288500)

turbosquid

$150

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ultra

3ddd

$1

ultra

...ultra

3ddd

ultra , кресло

офисное кресло руководителя, модель ultra

3ddd

$1

Стол Ultra

...стол ultra

3ddd

ogogo

стол ultra, интернет магазина ogogo обстановочка.

turbosquid

$10

ULTRA CHAIR_COMFORT

...royalty free 3d model ultra chair_comfort for download as max on turbosquid: 3d models for games, architecture, videos. (1256242)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

turbosquid

$3

Ultra Ball

...

royalty free 3d model ultra ball for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1510206)

turbosquid

$2

Ultra Greatsword

...ty free 3d model ultra greatsword for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1238281)

3ddd

$1

Galaxy Ultra

... ultra

реальная модель из жизни, текстуры в архиве есть, также имеется файл для макса 2010-го

turbosquid

$12

Ultra WebCam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Ultra Ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Ultra AP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...