Thingiverse

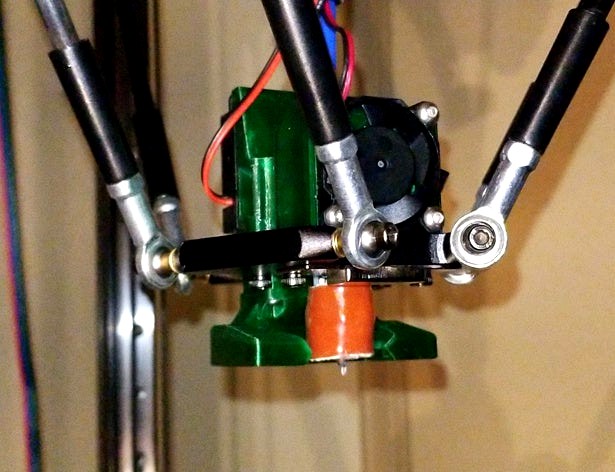

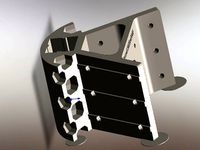

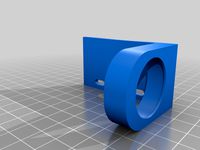

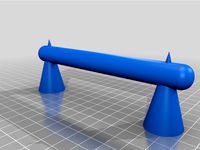

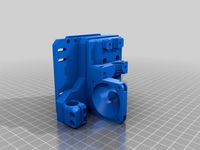

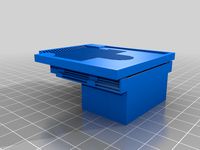

Ultra-compact ultra-light hotend for Anycubic Kossel

by Thingiverse

Last crawled date: 4 years, 2 months ago

Edit 2020/01/20: I just came across Thomas Sanladerer's video review of a hotend very similar to the one I cobbled together for this, so I guess I'm on the right track. :)

The one in his video looks like it has significantly different dimensions, but the same basic design. It's from a company called Deltaprintr. I like what I put together better as it uses standard threads for the nozzle, and has a variety of nozzles available.

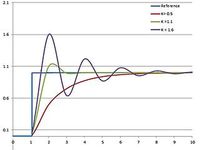

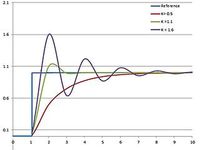

TL;DR: This knocked 51g off the effector. I was able to print 400mm/s with fairly nice results (very minimal ringing) using TMC2130 drivers (plus my other modifications) with this hotend using Klipper firmware. The limit turned out to be the TMC2130 drivers, as I ran into problems when I raised the current past 0.9A (the chip has a design-limit of 0.96A). I've since switched to TMC2208 drivers so I can raise the current further, but I've not yet run any more speed runs. I may upload a video later.

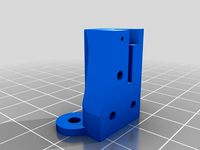

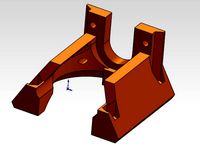

I wanted to try a combination of parts I had in my Anycubic Kossel Linear Plus, but it doesn't look like anyone else has put this combination together, so I made my own mount for it.

This uses the following parts:

Heatsink & heatbreak from Trianglelab.

It doesn't have a name, sadly, as I'd like to be able to refer to it by name. It's the external dimensions of the heatsink used in the Ender 3, but with fewer/thicker fins and a heatbreak closer to that of a MicroSwiss.https://www.aliexpress.com/item/4000083295807.html

Heatblock, heater, & nozzle from Trianglelab.

This also needs a name. It's miniscule and not much more than a piece of threaded aluminum tube with a cylindrical heater wrapped around it. If it's currently listed as "unavailable", check back. I asked them about this and they said they were improving the design and would be bringing it back soon.https://www.aliexpress.com/item/32697889176.html

3010 fan driven at 80% to reduce noise.

Various hardware, including 2x M3 nuts (pressed in the part cooler side), some longer M2.5 screws to mount the fan duct, and the rest (I think) were stock. I may have used screws 1-2mm shorter for the part cooler blower, but I'm not sure (I've been running this for a couple weeks now, haven't had to modify anything).

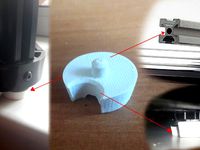

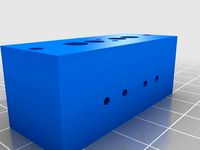

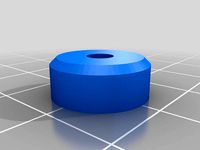

Note that this combination does lower the nozzle by a few millimeters, this is intentional (see below). Spacers are provided for moving your favorite part cooler duct down by 2.5mm or 3mm.

The one in his video looks like it has significantly different dimensions, but the same basic design. It's from a company called Deltaprintr. I like what I put together better as it uses standard threads for the nozzle, and has a variety of nozzles available.

TL;DR: This knocked 51g off the effector. I was able to print 400mm/s with fairly nice results (very minimal ringing) using TMC2130 drivers (plus my other modifications) with this hotend using Klipper firmware. The limit turned out to be the TMC2130 drivers, as I ran into problems when I raised the current past 0.9A (the chip has a design-limit of 0.96A). I've since switched to TMC2208 drivers so I can raise the current further, but I've not yet run any more speed runs. I may upload a video later.

I wanted to try a combination of parts I had in my Anycubic Kossel Linear Plus, but it doesn't look like anyone else has put this combination together, so I made my own mount for it.

This uses the following parts:

Heatsink & heatbreak from Trianglelab.

It doesn't have a name, sadly, as I'd like to be able to refer to it by name. It's the external dimensions of the heatsink used in the Ender 3, but with fewer/thicker fins and a heatbreak closer to that of a MicroSwiss.https://www.aliexpress.com/item/4000083295807.html

Heatblock, heater, & nozzle from Trianglelab.

This also needs a name. It's miniscule and not much more than a piece of threaded aluminum tube with a cylindrical heater wrapped around it. If it's currently listed as "unavailable", check back. I asked them about this and they said they were improving the design and would be bringing it back soon.https://www.aliexpress.com/item/32697889176.html

3010 fan driven at 80% to reduce noise.

Various hardware, including 2x M3 nuts (pressed in the part cooler side), some longer M2.5 screws to mount the fan duct, and the rest (I think) were stock. I may have used screws 1-2mm shorter for the part cooler blower, but I'm not sure (I've been running this for a couple weeks now, haven't had to modify anything).

Note that this combination does lower the nozzle by a few millimeters, this is intentional (see below). Spacers are provided for moving your favorite part cooler duct down by 2.5mm or 3mm.

Similar models

thingiverse

free

Fun duct 40 mm for hotend on effector kossel anycubic by Speedyluck

...verse

fun duct on 40mm fan to avoid cooling the aluminum heater block on kossel anycubic effector.

print right with 0.40 nozzle.

thingiverse

free

Anycubic 40x40 driver fan (Works with TMC2130) by Yakandu

...30) by yakandu

thingiverse

anycubic delta/kossel tri-gorilla board stepper motor driver cooler tunnel.

easy to print.

m3 screws.

thingiverse

free

Anycubic Kossel e3d v6 fan duct by teikjoon

...ify3d slicer settings, and a sample gcode file to print. currently using a 5015 fan and it only needs to be run at 60% fan speed.

thingiverse

free

Fan Duct for Anycubic i3 Mega with V6 Hotend and Sensor Holder by derhopp

...uct for the heatsink.

work in progress: the lower threaded holder is not yet in the right position... it should be a bit higher.

thingiverse

free

Anycubic Kossel Volcano Fan Duct by er1n

...anycubic kossel volcano fan duct by er1n

thingiverse

cooling duct for volcano hotend block at anycubic kossel.

grabcad

free

E3D V6 Hotend

...e3d v6 hotend

grabcad

e3d v6 hotend. includes heatsink, heatbreak, nozzle and heatblock.

thingiverse

free

Anycubic Delta Kossel Hotend Filament cooler by Rincewind123

... the fan nozzle. and you only need 2 screws like on picture, thats enought. the outher holes provided but to difficult to mount.

thingiverse

free

Part Cooler for Prometheus v2 Hotend by tinkerz

.... you'll likely set the fan speed higher for this model. this model will also then provide some additional heatsink cooling.

thingiverse

free

Anycubic Kossel Linear Plus E3d V6 Effector Threaded HeatSink by Havalok

...3d v6 effector threaded heatsink by havalok

thingiverse

this is a remix for the v6 threaded heatsink available from trianglelab.

thingiverse

free

Anycubic i3 Mega Ultrabase part cooling fan duct for E3D V6 hotend by roundisfunny

... amazon, that can run in variable speed).

for best cooling performance, update your firmware with 3d_rapid_de's 12v fan0 mod.

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

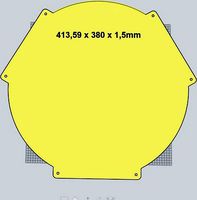

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Compact

3d_export

$5

compact freezer

...compact freezer

3dexport

the compact freezer is product about refrigeration machine

3d_ocean

$8

Compact Cassette

...

80s album analog audio cartridge cassette compact digital electronics lp mp3 music play record sound tape vinyl

compact cassette

design_connected

$20

Eames Compact

...eames compact

designconnected

herman miller eames compact computer generated 3d model. designed by eames, charles.

3d_ocean

$2

Compact Disc

...compact disc

3docean

album audio cd compact disc dvd laser disc movie music

a cd

3d_export

$10

land compacter

...land compacter

3dexport

turbosquid

$1

Compact knife

...quid

royalty free 3d model compact knife for download as obj on turbosquid: 3d models for games, architecture, videos. (1557900)

3d_export

$12

compact rotary broach

...compact rotary broach

3dexport

compact tool for drilling hexagonal holes in lathes!

turbosquid

free

Lada Compact

... 3d model lada compact for download as max, max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1623122)

turbosquid

$59

Compact Truck

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Compact kitchen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ultra

3ddd

$1

ultra

...ultra

3ddd

ultra , кресло

офисное кресло руководителя, модель ultra

3ddd

$1

Стол Ultra

...стол ultra

3ddd

ogogo

стол ultra, интернет магазина ogogo обстановочка.

turbosquid

$10

ULTRA CHAIR_COMFORT

...royalty free 3d model ultra chair_comfort for download as max on turbosquid: 3d models for games, architecture, videos. (1256242)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

turbosquid

$3

Ultra Ball

...

royalty free 3d model ultra ball for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1510206)

turbosquid

$2

Ultra Greatsword

...ty free 3d model ultra greatsword for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1238281)

3ddd

$1

Galaxy Ultra

... ultra

реальная модель из жизни, текстуры в архиве есть, также имеется файл для макса 2010-го

turbosquid

$12

Ultra WebCam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Ultra Ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Ultra AP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...