Thingiverse

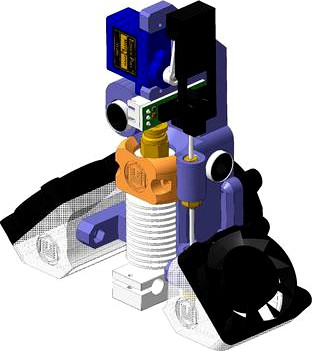

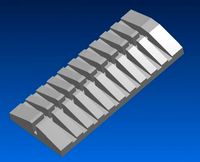

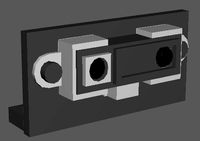

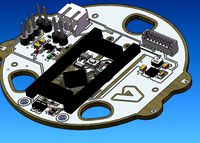

Ultimaker printhead with optical table-level auto-calibration sensor and servo

by Thingiverse

Last crawled date: 4 years, 1 month ago

One day, I wanted to make an automatic table calibration on my Ultimaker plywood.

Inductive, piezo, tenzo, and other sensors did not suit me because they either took up the workspace or caused problems with the installation of cooling fans for the printed part.

This also applies to BL-Touch, and its clones, the quality and reliability of which has recently left much to be desired.

As practice has shown, optical limit switches are the best solution in the implementation of precision positioning tools.

Based on it, it was decided to make a sensor for automatic calibration of the table level.

The principle of operation of this device is similar to the principle of the same BL-Touch.

Except that the sensor uses an optical limit switch, not a Hall sensor and a servo drive instead of a retracting solenoid.

Thanks to the long probe, the entire device was able to be placed on top of the print head.

As a probe used a bicycle needle. The thread is shortened to 5 mm, the length of the entire probe is 80 mm.

Guides for the probe are two Volcano nozzles, the holes of which were drilled up to 2 ... 2.2 mm.

You can use outdated nozzles. You can do without nozzles at all.

The archive has a printhead housing file with holes without thread - U5_AUTO_LEVEL_E3D_HOLDER_NO_NOOZLE.

https://www.youtube.com/watch?v=dzim4jhBjuYhttps://www.youtube.com/watch?v=yESJPz21lvs

Inductive, piezo, tenzo, and other sensors did not suit me because they either took up the workspace or caused problems with the installation of cooling fans for the printed part.

This also applies to BL-Touch, and its clones, the quality and reliability of which has recently left much to be desired.

As practice has shown, optical limit switches are the best solution in the implementation of precision positioning tools.

Based on it, it was decided to make a sensor for automatic calibration of the table level.

The principle of operation of this device is similar to the principle of the same BL-Touch.

Except that the sensor uses an optical limit switch, not a Hall sensor and a servo drive instead of a retracting solenoid.

Thanks to the long probe, the entire device was able to be placed on top of the print head.

As a probe used a bicycle needle. The thread is shortened to 5 mm, the length of the entire probe is 80 mm.

Guides for the probe are two Volcano nozzles, the holes of which were drilled up to 2 ... 2.2 mm.

You can use outdated nozzles. You can do without nozzles at all.

The archive has a printhead housing file with holes without thread - U5_AUTO_LEVEL_E3D_HOLDER_NO_NOOZLE.

https://www.youtube.com/watch?v=dzim4jhBjuYhttps://www.youtube.com/watch?v=yESJPz21lvs

Similar models

grabcad

free

CR Touch

...grabcad

cr touch:

metal probe

optical switch

independent solenoid

bl touch:

plastic probe

hall effect sensor

embedded solenoid

thingiverse

free

Anycubic Mega Zero BL Touch Mount by qystan

... values as follows:

nozzle_to_probe_offset{-37, -13, -2.195}

please note that the z will vary depending on your hot-end assembly.

thingiverse

free

Folgertech FT5 BL Touch Mount by 3D_Fabrication_Lab

...t can be calibrated using this really helpful video:https://www.youtube.com/watch?v=y_1kg45apko&ab_channel=breaks%27n%27makes

thingiverse

free

Crash Probe with optical switch by ANicolai

...ess of the crash probe http://reprap.org/wiki/crashprobe but using an optical switch.

https://www.youtube.com/watch?v=hqbf5s-abcq

thingiverse

free

Z Limit Switch Holder CR20 CR10 Ender 3

... bl touch. when i wanted to make it manual level without the bl touch i needed to design a limit switch base to hold it in place.

thingiverse

free

Wombot BL Touch Calibration Tool by Aurion55

...to 3mm from bed via z offset, while the bl touch will be 4mm off bed.

please do this calibration when your nozzle has cool down.

thingiverse

free

Openbeam Optical Limit Switch Mount by astfgl

...hing:431251 for the matching mgn12 carriage with integrated probe.

timelapse video: https://www.youtube.com/watch?v=xo8zvhpir4m

thingiverse

free

hypercube evolution BL touch adapter by Twigsnipperdave

...ozzle, just put the pin of blt in the hole and then adjust the height of the blt until the nozzle is touching the arm of the jig.

thingiverse

free

Rostock Z-Probe Automatic Bed Leveling with Hall-Effect by MarcoAntonini

...ll-effect by marcoantonini

thingiverse

automatic bed leveling with hall-effect sensorhttp://www.youtube.com/watch?v=upentweecww

thingiverse

free

BL Touch Holder by WordsFail

...induction sensor originally sat.

version 1 has 2.5mm holes to be tapped to m3. version 2 has 3.77mm holes and insets for m3 nuts.

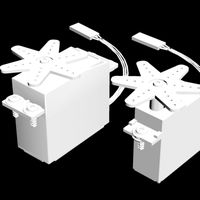

Printhead

3d_export

$24

mechanical spider

...to 3d-print complex structures using its integrated spool and printhead it can also be used for all your mechanical...

thingiverse

free

Ultimaker printhead cover by Gijs

...ultimaker printhead cover by gijs

thingiverse

printhead cover to protect the wires on top of the ultimaker printhead

thingiverse

free

Modified printhead clamp by Striffster

... the part that sits on the carriage to make it easier to change printhead. fits http://www.thingiverse.com/thing:793689 carriage.

thingiverse

free

full printhead by bouverat3dprint

...full printhead by bouverat3dprint

thingiverse

printer wanhao 5s. filament ø3mm

thingiverse

free

101hero printhead carrier e3d by workshoptinkerers

...or a 4mm push-fit pneumatic fitting with m6 threads if a non bowden printhead was purchased.

added carrier for e3d v5 printheads.

thingiverse

free

Diamond 3-1 printhead home bracket by robmink

...ngiverse

use to level your bed. only use while the printhead is cold. i used this for the chinese knock off diamond printhead.

thingiverse

free

FLSUN Cube Dual printhead Mount remix by ReneDriessen

...flsun cube dual printhead mount remix by renedriessen

thingiverse

dual printhead carriage for flsun cube

thingiverse

free

Fan-duct E3d Printhead by Straub

...e3d printhead.

the duct is designed for a 12v radial fan who is used in mankati printers.

(manufacturer number: bfb04512hha-dv52)

thingiverse

free

Voron Cablechain Printhead by 3d-workshop

... compartment to store the printhead-connectors.

unfortunately all parts need to be printed with supports except the chain itself.

thingiverse

free

Anycubic Predator effector for Stoneflower3D printhead v2

...flower3d printhead v2

thingiverse

anycubic predator effector to use with stoneflower3d printhead kit v2 for 3d ceramic printers.

Ultimaker

3d_export

$5

deer christmas 3

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

deer christmas 2

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

deer christmas

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

deer christmas 5

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

papa noel - santa claus

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

hippopotamus planter pot

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

decoration planter pot cute girl 15

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

decoration planter pot cute girl 14

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

deer christmas 6 3d print model

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

3d_export

$5

cute fat groot

...should use a good 3d printing software such as “ultimaker cura” with the option; “remove all holes” activated or...

Optical

design_connected

$9

Optic

...optic

designconnected

alessi optic computer generated 3d model. designed by colombo, joe.

3ddd

$1

обои OPTIC

...обои optic

3ddd

в архиве текстуры и фото обоев из коллекции optic.

archive3d

free

Optics 3D Model

...optics 3d model

archive3d

optics

optics - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$49

optical eyewear

...id

royalty free 3d model optical eyewear for download as max on turbosquid: 3d models for games, architecture, videos. (1592243)

3d_ocean

$5

optical mouses

...al mouses

3docean

3d models computer electronics mouse

optical mouses 3d models. realistic mouse model. custom and unique design.

turbosquid

$10

Optic cross

...yalty free 3d model optic cross for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1683403)

turbosquid

$7

OPTIC Mirror

... free 3d model optic mirror for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1223927)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$8

Mouse optical

...3d model mouse optical for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1504476)

turbosquid

free

Optical puzzle

... optical puzzle for download as max, ige, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1405925)

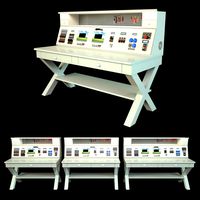

Calibration

turbosquid

$15

DEFIBRILLATOR CALIBRATORS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Calibration Test Benches

...libration test benches for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1355804)

turbosquid

$79

Tag Heuer Monaco Calibre 11

...free 3d model tag heuer monaco calibre 11 for download as max on turbosquid: 3d models for games, architecture, videos. (1634427)

turbosquid

$50

Smith & Wesson 50 Calibre Magnum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

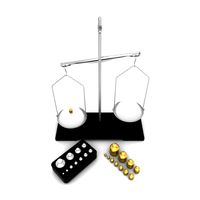

3d_export

$10

Laboratory Calibration Weight Set 1 3D Model

... 3d model

3dexport

laboratory lab science equipment weight set

laboratory calibration weight set 1 3d model bessoo 88084 3dexport

3d_export

$15

Laboratory Scale and Calibration Weight Set 3D Model

...port

laboratory lab science equipment weight set scale

laboratory scale and calibration weight set 3d model bessoo 88203 3dexport

3d_export

$5

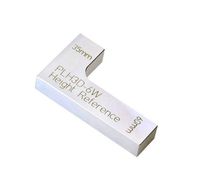

3D printer filament calibration tool 3D Model

...ernier

3d printer filament calibration tool 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl locoman 107942 3dexport

3d_export

$59

tag heuer link calibre 16 watch

...built to real-world scale. units used: centimeters. model is 18 centimeters tall.<br>scene objects are organized by groups.

3d_export

free

laser height reference calibration tool opt lasers

...ind out more about the engraving and cutting laser heads, this item was designed to work with, take a look at the following page:

3d_export

$99

Patek Philippe White Gold Calibre 89

...br>please note: this 3d model like all my other models cannot be used as nft, as is or modified<br>thank you for reading

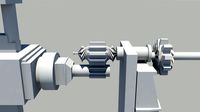

Servo

turbosquid

$30

Servo

...d model servo for download as obj, blend, dae, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1394011)

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

turbosquid

$1

Servo Moter

...quid

royalty free 3d model servo moter for download as blend on turbosquid: 3d models for games, architecture, videos. (1650816)

turbosquid

free

Motor/Servo

...osquid

royalty free 3d model motor/servo for download as obj on turbosquid: 3d models for games, architecture, videos. (1522522)

turbosquid

$60

Servo Skull

...

royalty free 3d model servo skull for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1318573)

3d_export

$5

Servo 3D Model

...rvo 3d model

3dexport

servo

servo 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl pasqualesiciliano 104590 3dexport

turbosquid

$50

Servo Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Servo Motor

...model servo motor for download as 3ds, max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1324153)

turbosquid

$29

Servo Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

machine servo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Auto

3d_export

$5

auto

...auto

3dexport

auto

3ddd

$1

auto

...auto

3ddd

max7

turbosquid

$69

AUTO

...to

turbosquid

royalty free 3d model auto for download as obj on turbosquid: 3d models for games, architecture, videos. (1453538)

3d_export

$10

Auto

...auto

3dexport

3d_export

free

auto

...auto

3dexport

3ddd

$1

Auto posters

...auto posters

3ddd

машина

auto posters

turbosquid

$50

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$28

Auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Level

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)

Table

3ddd

free

Table

...table

3ddd

table

table

archibase_planet

free

Table

...table

archibase planet

table glass-table round table glass table

table n240311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...e

archibase planet

table dining-room table dinner table round table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

table

...table

3dexport

table classic-table

archibase_planet

free

Table

...se planet

table glass table round table glass-table

table tonin habitat n280111 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table dining-room table dinner table

table - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table coffee table glass table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table glass-table coffee table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table writing table office table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Table

...table

3docean

dining table furniture home kitchen table

simple wooden table.