Thingiverse

Uber 180 Redesign -- No Supports Needed, VTX + Cam Mounts, Motor Guards by Light24bulbs

by Thingiverse

Last crawled date: 2 years, 12 months ago

This is a redesign to add features to the Uber and make it more printable.

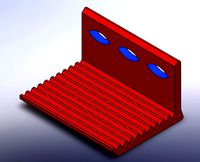

Mid:

Modifies the design for print-ability. No support is necessary. Original was hard to print and required support. It has been modified to have the cross spars for the battery strap at the bottom, so they can print right on your bed. The bottom has also been flattened, as the original had basically no surface area. Please let me know how these work for you.

Top:

Adds an SMA connection hole to the top plate of the Uber 180. Needed to protect your vtx and also a good way to mount the vtx without any other fasteners. Also removed rounded corners to make printing easier.

Top With Cam Mount:

Added a camera mounting hole for standard size FPV cams. It is angled at 40 or 30 deg, depending which file you choose. Please let me know if you want a different angle, or a different camera size. I tried to make it user configurable, but it just wasn't possible.

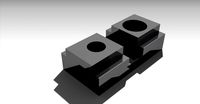

Motor Mount:

Added a small guard piece to the motor mount. Should protect the motors from most impacts from the side. They fit rs2205s and should fit any 220x motor.

Notes

Materials

Nylon 910 is the recommended material. Well printed PLA might be strong enough for some pieces some of the time, but Nylon is really the only material strong enough to make this frame viable.

Printing

Go slow and hot to insure good bonding. Thin layers are recommended for strength, depending on your material.

Assembly

You can refer to the original uber180(shown as the remix on this page) for cut lengths and assembly instructions.

I chose to dye my nylon orange with RIT dye.

I lightly glued motor mounts to tubes using superglue. Using less glue means you might actually be able to get it apart later.

Hardware: I used 20mm m3 button head screws and 10mm nylon standoffs with standard 35mm aluminum standoffs on top, from a ZMR kit. I recommend metal screws and standoffs all the way up for structure. I had some nylon screws and they sheared off on impact.

Mid:

Modifies the design for print-ability. No support is necessary. Original was hard to print and required support. It has been modified to have the cross spars for the battery strap at the bottom, so they can print right on your bed. The bottom has also been flattened, as the original had basically no surface area. Please let me know how these work for you.

Top:

Adds an SMA connection hole to the top plate of the Uber 180. Needed to protect your vtx and also a good way to mount the vtx without any other fasteners. Also removed rounded corners to make printing easier.

Top With Cam Mount:

Added a camera mounting hole for standard size FPV cams. It is angled at 40 or 30 deg, depending which file you choose. Please let me know if you want a different angle, or a different camera size. I tried to make it user configurable, but it just wasn't possible.

Motor Mount:

Added a small guard piece to the motor mount. Should protect the motors from most impacts from the side. They fit rs2205s and should fit any 220x motor.

Notes

Materials

Nylon 910 is the recommended material. Well printed PLA might be strong enough for some pieces some of the time, but Nylon is really the only material strong enough to make this frame viable.

Printing

Go slow and hot to insure good bonding. Thin layers are recommended for strength, depending on your material.

Assembly

You can refer to the original uber180(shown as the remix on this page) for cut lengths and assembly instructions.

I chose to dye my nylon orange with RIT dye.

I lightly glued motor mounts to tubes using superglue. Using less glue means you might actually be able to get it apart later.

Hardware: I used 20mm m3 button head screws and 10mm nylon standoffs with standard 35mm aluminum standoffs on top, from a ZMR kit. I recommend metal screws and standoffs all the way up for structure. I had some nylon screws and they sheared off on impact.

Similar models

thingiverse

free

Some Diatone Taycan build parts

...his.

air unit mount and standoff support

cam plates for dji cam (print of nylon, petg, etc.)

curved duct (i printed this of petg)

thingiverse

free

Über Design Ü120 TPU Parts - Uber Design U120 by theledman

...arm booties and cam mount need to be printed in tpu. i've been printing using this particular tpu and it's printed great!

thingiverse

free

Katana & Swissknife arm guard and motor soft mount by nracing

...ecommend filament : ninjaflex or cheetah, 0.1 layer thickness

you gonna need 10mm screw to mount the motors with this protection.

thingiverse

free

Realacc X210 Antenna mount by Rhymin

...as from crash damage. i used some additional 8mm washers under standoff screws for some additional support being printed in tpu.

thingiverse

free

Emax Babyhawk R 2" arm guard motor soft mount by TweetFPV

... recommend using some blue thread locker on your motor screws.

if you print this and like it please click "i made one"

thingiverse

free

Realacc XS220E top plate with VTX and Camera Mounts by FPV_Pilot

...ally get really hot)

anyway enough rambling... have fun printing and flying.

like and comment if you find this design useful.

thingiverse

free

FlexRC Mini Owl - Micro Swift Mount by DevJam

...king it vulnerable.

added some tabs to the standoffs so the camera is protected during a direct front impact.

i printed in nylon.

thingiverse

free

20x20mm Mount for the AKK Race VTX by ppetermann

... rest of the threaded part at the top.

use a zip tie to hold the vtx in place.

bonus points: i ziptied my rx on the bottom of it.

thingiverse

free

155 hex frame (hexacopter) by thumbs_fpv

... a full size cam+ flight controller. you need a m3 screw+ 30mm spacer. it does have 3 mounting holes for different kinds off vtx.

thingiverse

free

Hyperlow CG VTX Pigtail Mount W/ Capacitor Mount (TBS Unify style pigtail) by Fickert

...ecommend simplify3d as automatic supports tend to make too many.

i included a photo of the best orientation you will print with.

Light24Bulbs

thingiverse

free

Serotonin Earring by Light24bulbs

...ilament.

the picture is dopamine but that's just a reference image, the file is actually serotonin. it looks very similar.

thingiverse

free

Hook, flat bottom which glues on by Light24bulbs

...scale as needed, default scale is 5cm in diameter. i used it to glue to the top of a chickens waterbottle so we could hang it up

thingiverse

free

5/16ths and m8 nut by Light24bulbs

...course. stronger than you would think though.

recommended layer height: 0.1mm

recommended material: pla for dimensional accuracy

thingiverse

free

22xx Removable Countersunk Motor Mount - Wing reptile s800 by Light24bulbs

...motor to a plate, so that you can take the motor on and off as needed.

parts required:

m3 6mm cap head 4x

m3 6mm countersunk 4x

thingiverse

free

45mm Friction Fit Gas Cap for Craftsman Mower by Light24bulbs

...ler. simply friction fits on.

may not properly vent air into the tank but seems to work fine. probably simply leaks enough air.

thingiverse

free

LED Strip Shade and Holder for Standard 8mm strips by Light24bulbs

...ong led strips like these:

http://www.amazon.com/gp/product/b00hsf65mc?psc=1&redirect=true&ref_=oh_aui_detailpage_o02_s00

thingiverse

free

HammerHead Quadcopter 185mm 5inch X-frame CNC Carbon Fiber by Light24bulbs

...dcopter, the uber 180 redesign. available here with or without integrated camera mount: http://www.thingiverse.com/thing:1737107

thingiverse

free

Quanum v2 Goggles Glass Lens Mount from Harbor Freight by Light24bulbs

...upport when printing. they are the trickiest part. if they break off, you might as well just glue the lens in and call it good.

thingiverse

free

Iphone 8+, Galaxy s8/s9/s10 Wireless Charging Stand by Light24bulbs

...keywords=pleson+samsung+fast+wireless+charger

it has a cable slot to hide the cable and overall is nice to look at and works well

thingiverse

free

Enacfire E18 Earbuds battery extender case by Light24bulbs

...ot be necessary. by downloading this design you accept all responsibility, this design is provided without warranty of any kind.

Uber

turbosquid

$9

Uber tank

...d

royalty free 3d model 3d tank uber scetch for download as on turbosquid: 3d models for games, architecture, videos. (1699599)

3d_export

free

Download free Uber sword 3D Model

...download free uber sword 3d model

3dexport

youtoo32

uber sword 3d model bouchet 50494 3dexport

turbosquid

$10

Uber Super Spacey Dice Planet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

FN SCAR 3D Model

...obj weapon gun fn scar fn scar 3d model uber 19559...

3dfindit

free

UBER

...uber

3dfind.it

catalog: a&t

thingiverse

free

Uber Gnome by megane008

...uber gnome by megane008

thingiverse

my one of the kind gnome for the competition

renderosity

$9

Uber Suit for V4

.../>

- second skin suit,<br />

- helmet,<br />

- boots,<br />

- 5 materials for poser and daz studio</p>

thingiverse

free

Fast And Basic Clothing Hanger Divider (Uberized) by mofosyne

...ce think?

unlike the original design, this is not too practical. as the hole inside 20cm. unless you have a 20cm diameter hanger?

unity_asset_store

$35

Garage & Toolshed Prop Uber Pack by GameTextures

...hed prop uber pack by gametextures asset from gametextures.com. find this & other props options on the unity asset store.

thingiverse

free

Uber Bracker 2.0 by MDalton10

...he screw holes were too flimsy. i added a little big on length and a notch in the front to help you pry the print off of the bed.

Vtx

turbosquid

$1

FPV VTX Antenna

...e 3d model fpv vtx antenna for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1230317)

humster3d

$75

3D model of Toyota 86 GT VTX 2013

...tailed 3d model of toyota 86 gt vtx 2013 in various file formats. all our 3d models were created maximally close to the original.

thingiverse

free

Gnarlyfpv - Primo VTX adapter - Triangle VTX by Gnarlyfpv

...angle vtx by gnarlyfpv

thingiverse

tiny lightweight vtx adapter for the gnarlyfpv primo.

supports most triangle style vtx units.

thingiverse

free

FLOSS2 VTX MOUNT

...floss2 vtx mount

thingiverse

antenna vtx mount floss2

thingiverse

free

Drone vtx offset vtx stack mount by drvonhoss

... offset vtx stack mount by drvonhoss

thingiverse

offset vtx mount so the antenna clears the outer standoff on some drones/quads.

thingiverse

free

Vtx mount by kerst

...vtx mount by kerst

thingiverse

just a vtx mount for spceone 220

thingiverse

free

nano VTX mount 20x20

...nano vtx mount 20x20

thingiverse

for 20x20 stacks and mounts, nano vtx holder like eachine vtx nano or tbs nano vtx.

thingiverse

free

A01 VTX Mount

...ections/camera-vtx/products/a01-25-200mw-5-8g-vtx

and first of all it was design for a primo from gnarly fpv but fit on all tw fc

thingiverse

free

vtx sheath by mabadajo

...vtx sheath by mabadajo

thingiverse

this is to help hold the vtx mast more steady in a crash.

thingiverse

free

SWH210 vtx holder by Dubeswings

...swh210 vtx holder by dubeswings

thingiverse

vtx holder for swh210. fits rctimer micro 200mw vtx

Redesign

3d_ocean

$45

Hyundai SUV vehicle redesigned

...was redesigned by me. 3d model was created in blender3d.preview images were rendered with realistic plugin yafaray.side view o...

turbosquid

free

Colt M16 (Redesign)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

3D for Pose Scarlet Witch redesign\para Posar redesign Feiticeira Escarlate

... imprimir redesign feiticeira escarlate for download as blend on turbosquid: 3d models for games, architecture, videos. (1700850)

3d_export

$5

Gaz 21 redesign 3D Model

...gaz 21 redesign 3d model

3dexport

gaz 21 volga

gaz 21 redesign 3d model rossergorp 71511 3dexport

turbosquid

$55

Porsche Cayman 2015 redesign

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$55

Gallardo superleggera redesign

...model was made with blender3d 2.62.preview images were rendered with blender3d and yafaray 0.1.2 realistic rendering engine.ob...

3d_ocean

$55

Chevy Stingray 2013 redesign

...car.i gave my best to create accurate model,but without top view image it wasn’t possible for me.so when i lost a lots of nerv...

turbosquid

$30

Redesign Crash Bandicoot (c4d,obj,max,zpr)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Tango Floor Lamp

...3ddd andrey kole , tango , castlewerks andrey kole redesign tango floor lamp by castlewerks. 3dsmax2012 - corona...

3d_export

free

flexuous tweezers

...flexuous tweezers 3dexport i just wanted to redesign a tweezers that be more interesting.<br>you can see the...

Guards

3d_export

$5

guard

...guard

3dexport

very cool guard

turbosquid

$1

guard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Guard post

...base planet

guard post checkpoint building check point

guard post n191015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$5

phone guard

...phone guard

3dexport

phone guard. for cell phones the size of 68mm x 144mm

3d_export

$95

coast guard

...coast guard

3dexport

usa coast guard ship low poly. game ready fbx. obj. max 18. 3ds.

turbosquid

$20

Iron guard

...turbosquid

royalty free 3d model iron guard for download as on turbosquid: 3d models for games, architecture, videos. (1623465)

turbosquid

$7

Guard Light

...bosquid

royalty free 3d model guard light for download as ma on turbosquid: 3d models for games, architecture, videos. (1622828)

turbosquid

$5

card guard

...squid

royalty free 3d model card guard for download as blend on turbosquid: 3d models for games, architecture, videos. (1378924)

turbosquid

$5

Guard Tower

...quid

royalty free 3d model guard tower for download as blend on turbosquid: 3d models for games, architecture, videos. (1191976)

turbosquid

$20

Spaceship Guard

...ee 3d model spaceship guard for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1227837)

180

3ddd

$1

Ванная POLLSPA-Corazon-180-180

...dd

corazon , pollspa

ванная pollspa-corazon-180-180 примерно по каталогу. текстуры есть.

3ddd

$1

TENSO 180

...ddd

formina , ванна , джакузи

jakuzzi tenso 180

design_connected

$11

Bolero 180

...bolero 180

designconnected

poltrona frau bolero 180 computer generated 3d model. designed by lazzeroni, roberto.

design_connected

$20

Delta 180

...delta 180

designconnected

zanotta delta 180 2-seater computer generated 3d model. designed by emaf progetti.

design_connected

$27

Sayonara 180

...sayonara 180

designconnected

bbb emmebonacina sayonara 180 2-seater computer generated 3d model. designed by giorgio decursu.

turbosquid

$9

Office 180

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$25

La Mise 180

...la mise 180

designconnected

la mise 180 computer generated 3d model. designed by nichetto, luca.

3ddd

$1

Rishar R-180

...ar r-180

3ddd

rishar , стол

кабинет rishar

стол руководителя r-180

размеры: 1800х880х790

3ddd

free

Riho / MONTREAL 180

...и

ванна riho montreal 180

длина 180

ширина 90

высота 47,5

объем 275

цвет euro white (европейский белый)

страна голландия / чехия

design_connected

$18

FM-180 Armchair

...fm-180 armchair

designconnected

fsm fm-180 armchair computer generated 3d model. designed by heiliger, stefan.

Cam

archibase_planet

free

Cam

...cam

archibase planet

tv camera equipment

cam dolly - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

Cam and Follower

...ry to linear (reciprocating) motion. as the cam rotates, the follower rises and falls in a process known as reciprocating motion.

3d_ocean

$15

Studio Cam

...p. made in 3ds max 2013 1- 3dsmax with vray render included material and light 2- obj file 3- fbx file hope you like it please...

3d_export

$37

thermal cam

...thermal cam

3dexport

turbosquid

$19

Security cam

...oyalty free 3d model security cam for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1331128)

turbosquid

$40

Security Cam

...y free 3d model security cam for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1601103)

3d_export

$40

security cam

...security cam

3dexport

home security camera

turbosquid

$280

cam-bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$33

AT_minivan_(CAM)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

video cam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

archive3d

free

Motor 3D Model

...ine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mounts

3d_export

free

mounting bracket

...the part of a hinge, handle or latch that mounts the hardware to a cabinet. mounting plates make it...

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Supports

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon

Needed

3d_export

$5

I need a new job

...i need a new job

3dexport

i need a new job funny sign. include a *.obj file

3d_export

$10

Dog house that doesnt need laundry

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

free

the wall and the sidewalk i give it away for free but in return you need a comment whether it was

...dexport

the wall and the sidewalk, i give it away for free, but in return you need a comment whether it was useful to you or not

3d_export

$5

akm - unfinished project

...of akm, needs some work.<br>-no textures<br>-uv mapping needed<br>-geometry fixes needed ...

3d_export

$5

Boots

...

3dexport

does your character need flying boots to make their adventure even more memorable? then this is exactly what you need!

3d_export

$9

marantz sr7013

...; needs an emission shader with a light blue hue and lastly "readout" needs an emission shader in white.<br>enjoy

3d_export

free

nail

...nail 3dexport a nail for what is needed ...

3d_export

$5

oil can

...ort

can container for oil or any liquid. volume = 1200135 mm3 dimensions in mm ping me if need stl or need customize dimensions.

3d_export

$5

chess

...chess

3dexport

3 d chess is a ready-made project if you need to write right away what each chess piece needs in stl format

3d_export

$5

dragon 3d

...dragon 3d

3dexport

3 d chess is a ready-made project if you need to write right now what each chess piece needs in stl format