Thingiverse

Tunnelplan 3D printer by tunnelplan

by Thingiverse

Last crawled date: 3 years ago

20 August 2017

At a print length of 500 mm I need more support.

So I used a 10x2 mm carbon tube to support the two aluminium tubes.

You get a lot of stiffness with this triangle of tubes.https://www.thingiverse.com/thing:2491427

16 July 2017

I improved the hotend/ extruder support.

The two Z stepper motors are connected with one belt.

See https://www.thingiverse.com/thing:2437326

12 June 2017

The carbon tubes inside the aluminium tubes gave a lot of extra stiffness.

Waiting now for a 3D Touch autoleveling sensor.https://nl.aliexpress.com/item/Free-Shipping-Geeetech-Auto-Leveling-Sensor-3D-Touch-for-3D-Printer-Improve-Printing-Precision/32761924885.html?spm=2114.13010608.0.0.ounZPJ

03 June 2017

Changed the extruder/hotend drive and turned it 90 degree for more stability.

Use 6 mm wooden rods inside the aluminium tubes, that gave more stability.

Ordered 6/4mm x 500 mm carbon tubes from China for replacement wooden rods.

https://nl.aliexpress.com/item/3D-Printer-parts-for-Titan-Extruder-Fully-Kits-Titan-Extruder-for-1-75mm-3D-printer-extruder/32778467785.html?spm=2114.13010608.0.0.PpxZXkhttps://nl.aliexpress.com/item/4pcs-lot-3K-Carbon-Fiber-Tube-6-4-500mm-6mm-Tube-for-RC-Airplane-Aerobatics-Kite/32803570300.html?spm=2114.13010608.0.0.PpxZXk

Good results by printing 500x180x100mm parts.

03 May 2017

First print 450 mm x 50 mm.

Changed the extruder/hotend from bowden to a direct drive with a small motor.

01 April 2017

First print.

Used other type relays (not any noise).

Waiting for an other extruder/hotend from China.

12 March 2017

Double heated bed connected. Two temperature sensors at the bed (500 mm x 250 mm)

The relays are making to much noise. https://youtu.be/W7eudf0GQes

First run with 4 stepper motors.https://youtu.be/DfqCVCndlC8

Two Z- stepper motors are serial connected.

03 February 2017

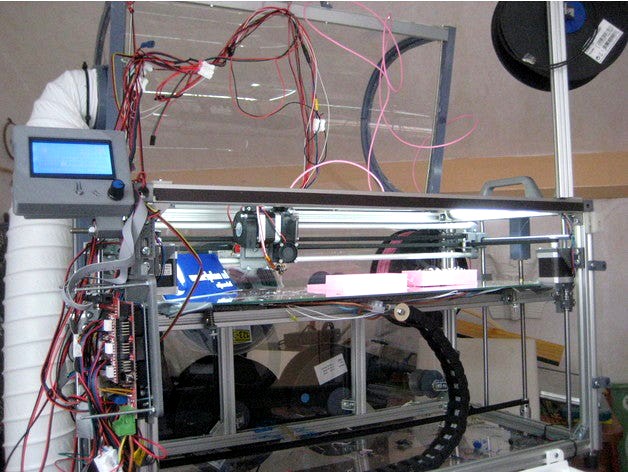

Baby incubator ??

On top a fan with hose to remove the gases.

At the transparent back side, space for 8 kg filament.

Zip file with all printed parts.

Now on wheels http://www.thingiverse.com/thing:2082928

21 January 2017

Led lights on top.

Two doors in front with magnetic tape.

Power supply and LCD display.

Used flexible hinges (http://www.thingiverse.com/thing:2023427 )

15 January 2017

Use a transparent cover for a controlled print environment .

Print space 500 x 250 x 200 mm

Heated bed with mirror 600 x 300 mm (Ikea Fullen euro 9.99)http://www.ikea.com/nl/nl/catalog/products/60189027/

Waiting for essential parts from China

12 January 2017

Waiting for essential parts from China.

30 December 2016

Waiting for essential parts from China.

Corner brackets and hammer nuts.

First impression with two lead screw outside for a 500mm long heated bed.

Printer standing on 4 bumpers.

27 December 2016.

Waiting for the parts from China.......

11 December 2016.

I'm starting to make a 3D printer with a print bed area of 500 x 200 x 200 mm based on thing:1752766 Tech2c (great design).

Waiting for the parts from China.......

In combination with http://www.thingiverse.com/thing:1725519

At a print length of 500 mm I need more support.

So I used a 10x2 mm carbon tube to support the two aluminium tubes.

You get a lot of stiffness with this triangle of tubes.https://www.thingiverse.com/thing:2491427

16 July 2017

I improved the hotend/ extruder support.

The two Z stepper motors are connected with one belt.

See https://www.thingiverse.com/thing:2437326

12 June 2017

The carbon tubes inside the aluminium tubes gave a lot of extra stiffness.

Waiting now for a 3D Touch autoleveling sensor.https://nl.aliexpress.com/item/Free-Shipping-Geeetech-Auto-Leveling-Sensor-3D-Touch-for-3D-Printer-Improve-Printing-Precision/32761924885.html?spm=2114.13010608.0.0.ounZPJ

03 June 2017

Changed the extruder/hotend drive and turned it 90 degree for more stability.

Use 6 mm wooden rods inside the aluminium tubes, that gave more stability.

Ordered 6/4mm x 500 mm carbon tubes from China for replacement wooden rods.

https://nl.aliexpress.com/item/3D-Printer-parts-for-Titan-Extruder-Fully-Kits-Titan-Extruder-for-1-75mm-3D-printer-extruder/32778467785.html?spm=2114.13010608.0.0.PpxZXkhttps://nl.aliexpress.com/item/4pcs-lot-3K-Carbon-Fiber-Tube-6-4-500mm-6mm-Tube-for-RC-Airplane-Aerobatics-Kite/32803570300.html?spm=2114.13010608.0.0.PpxZXk

Good results by printing 500x180x100mm parts.

03 May 2017

First print 450 mm x 50 mm.

Changed the extruder/hotend from bowden to a direct drive with a small motor.

01 April 2017

First print.

Used other type relays (not any noise).

Waiting for an other extruder/hotend from China.

12 March 2017

Double heated bed connected. Two temperature sensors at the bed (500 mm x 250 mm)

The relays are making to much noise. https://youtu.be/W7eudf0GQes

First run with 4 stepper motors.https://youtu.be/DfqCVCndlC8

Two Z- stepper motors are serial connected.

03 February 2017

Baby incubator ??

On top a fan with hose to remove the gases.

At the transparent back side, space for 8 kg filament.

Zip file with all printed parts.

Now on wheels http://www.thingiverse.com/thing:2082928

21 January 2017

Led lights on top.

Two doors in front with magnetic tape.

Power supply and LCD display.

Used flexible hinges (http://www.thingiverse.com/thing:2023427 )

15 January 2017

Use a transparent cover for a controlled print environment .

Print space 500 x 250 x 200 mm

Heated bed with mirror 600 x 300 mm (Ikea Fullen euro 9.99)http://www.ikea.com/nl/nl/catalog/products/60189027/

Waiting for essential parts from China

12 January 2017

Waiting for essential parts from China.

30 December 2016

Waiting for essential parts from China.

Corner brackets and hammer nuts.

First impression with two lead screw outside for a 500mm long heated bed.

Printer standing on 4 bumpers.

27 December 2016.

Waiting for the parts from China.......

11 December 2016.

I'm starting to make a 3D printer with a print bed area of 500 x 200 x 200 mm based on thing:1752766 Tech2c (great design).

Waiting for the parts from China.......

In combination with http://www.thingiverse.com/thing:1725519

Similar models

thingiverse

free

Tunnelplan Hotend support by tunnelplan

...truder-for-1-75mm-3d-printer-extruder/32778467785.html?spm=2114.13010608.0.0.ppxzxk

see https://www.thingiverse.com/thing:1959020

thingiverse

free

Tunnelplan carbon support by tunnelplan

...free-shiping-4pcs-x-10mm-x-6mm-x-1000mm-high-quality-3k-carbon-fiber-plain-fabric/32348177924.html?spm=a2g0s.9042311.0.0.gapjom )

thingiverse

free

Tunnelplan Tele Tracker by tunnelplan

...ker by tunnelplan

thingiverse

printed parts from https://www.thingiverse.com/thing:4167783

dummy lenght 450 mm, diameter 114 mm.

thingiverse

free

Tunnelplan 3D printing Robotic Arm AR2/eDO by tunnelplan

...om/watch?v=cdbzece0qgs)

learned a lot from the project (https://www.thingiverse.com/thing:1725519)

waiting for the ordered parts.

thingiverse

free

Carbon Fiber Christmas Tree

... down

gyroscopic snowflake (https://www.thingiverse.com/thing:2687377)

revolving ball (https://www.thingiverse.com/thing:1212209)

thingiverse

free

Tunnelplan Wind turbine with houses by tunnelplan

...ses by tunnelplan

thingiverse

a mix from https://www.thingiverse.com/thing:4816115 and https://www.thingiverse.com/thing:4178587

thingiverse

free

Wheel for 3D printer table by tunnelplan

...r 3d printer table by tunnelplan

thingiverse

wheels for my tunnelplan 3d printer table.

http://www.thingiverse.com/thing:1959020

thingiverse

free

Rotating 3D printing by tunnelplan

...nge bearings 8mm/22mm.

this is still onder construction.

see also http://www.thingiverse.com/thing:1725519 robot arm 3d printing.

thingiverse

free

dual bowden extruder carrier for reprap cube 3d printer by goaran

... where the hotends are plugd in is a milled aluminium part for extra cooling. i have not tried, but maybee it can be printed too.

thingiverse

free

Original Mendel upgrade to i3 X Axis by SysopJ

...usa mk2

x carriage & endstop: http://www.thingiverse.com/thing:1103976

hotend holder: http://www.thingiverse.com/thing:723803

Tunnelplan

thingiverse

free

Tunnelplan 3D-Art by tunnelplan

...tunnelplan 3d-art by tunnelplan

thingiverse

give me a hand please.

tunnelplan 3d- art

thingiverse

free

Tunnelplan Jolien by tunnelplan

...tunnelplan jolien by tunnelplan

thingiverse

play with letters and make your name.

jolien

thingiverse

free

Tunnelplan Violin by tunnelplan

...tunnelplan violin by tunnelplan

thingiverse

i made a small version of violin.http://www.thingiverse.com/thing:965261

thingiverse

free

Tunnelplan wine box by tunnelplan

...tunnelplan wine box by tunnelplan

thingiverse

birthday gift, 50 years!!

thingiverse

free

Tunnelplan box with lid by tunnelplan

...id by tunnelplan

thingiverse

box.

this box with lid is for three energy meters.

there is room for the instructions at the front.

thingiverse

free

Tunnelplan wine bottle holder by tunnelplan

...tunnelplan wine bottle holder by tunnelplan

thingiverse

as a gift, not only the wine bottle but also the holder.

thingiverse

free

Tunnelplan Tele Tracker by tunnelplan

...ker by tunnelplan

thingiverse

printed parts from https://www.thingiverse.com/thing:4167783

dummy lenght 450 mm, diameter 114 mm.

thingiverse

free

Tunnelplan Wind turbine with houses by tunnelplan

...ses by tunnelplan

thingiverse

a mix from https://www.thingiverse.com/thing:4816115 and https://www.thingiverse.com/thing:4178587

thingiverse

free

Object by tunnelplan

...object by tunnelplan

thingiverse

whats the object?

thingiverse

free

Tunnelplan carbon support by tunnelplan

...free-shiping-4pcs-x-10mm-x-6mm-x-1000mm-high-quality-3k-carbon-fiber-plain-fabric/32348177924.html?spm=a2g0s.9042311.0.0.gapjom )

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.