Thingiverse

Tronxy/3DCStar P802 Z-Axis Threaded-Rod Bearing Holder/Stabilizer by wypoon

by Thingiverse

Last crawled date: 3 years, 1 month ago

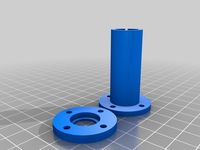

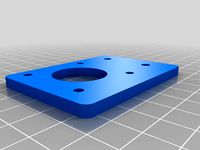

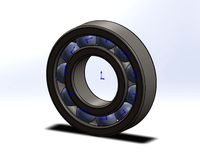

This is a great, easy upgrade to stabilize the Z-Axis threaded rod. Simply press-fit a 8x22x7 bearing into the holder, glue (solvent is best if printed in ABS) on the nub, and fit the holder into the existing threaded-rod hole in the acrylic chassis.

The holder is designed to be a snug interference-fit, so simply heat the bearing to 70C (for PLA) and then press the bearing into the holder. Do not overheat or the holder will deform!

There is built-in compensation for FDM printing clearance of 0.8mm between the nub and the centering socket on the holder, to allow for +0.4mm of oversize on the nub, and +0.4mm undersize on the receiving socket.

Wrap one layer of Kapton tape around the threaded-rod to make it fit snugly into the bearing (i.e. you want to bearing inner race to rotate with the rod).

No drilling of the chassis or cutting of rods need to be done. The bearing holder is designed to have a low profile when installed, so simply loosen the set screws on the Z-coupler to accept the holder. Make sure to push up on the threaded rod to butt the holder up tight against the top acrylic frame plate before tightening the set screws.

UPDATE #1: A single-piece .STL and .GCODE have been added ... if you are comfortable with printing and removing supports. The .GCODE is pre-sliced with supports, and I recommend using this as it can be difficult to get the settings right for supports (that you can actually remove) -- just be sure to modify the three temperatures lines to suit your material.

UPDATE #2: The clearance for the bearing (as well as for the nub) has been reduced by 0.2mm to make it a more snug fit.

The holder is designed to be a snug interference-fit, so simply heat the bearing to 70C (for PLA) and then press the bearing into the holder. Do not overheat or the holder will deform!

There is built-in compensation for FDM printing clearance of 0.8mm between the nub and the centering socket on the holder, to allow for +0.4mm of oversize on the nub, and +0.4mm undersize on the receiving socket.

Wrap one layer of Kapton tape around the threaded-rod to make it fit snugly into the bearing (i.e. you want to bearing inner race to rotate with the rod).

No drilling of the chassis or cutting of rods need to be done. The bearing holder is designed to have a low profile when installed, so simply loosen the set screws on the Z-coupler to accept the holder. Make sure to push up on the threaded rod to butt the holder up tight against the top acrylic frame plate before tightening the set screws.

UPDATE #1: A single-piece .STL and .GCODE have been added ... if you are comfortable with printing and removing supports. The .GCODE is pre-sliced with supports, and I recommend using this as it can be difficult to get the settings right for supports (that you can actually remove) -- just be sure to modify the three temperatures lines to suit your material.

UPDATE #2: The clearance for the bearing (as well as for the nub) has been reduced by 0.2mm to make it a more snug fit.

Similar models

thingiverse

free

Anycubic Prusa i3 Z-Axis Stabilizer by jdonegan

...ing diameters 22x8x7mm. replaces the current top supports. might fit other models such as geeetech that use an 8mm acrylic frame.

thingiverse

free

Ender 3 Pro z-axis rod stabilization bearing

...e bearing to the exact right spot for vertical accuracy- bearing is designed to keep the rod the correct distance from the frame.

thingiverse

free

Bianca - Nema 17 Motor mount with Z-Axis Stabilizer and Matching threaded rod bearing mount by Tabris25

...earing mount by tabris25

thingiverse

bianca - nema 17 motor mount with z-axis stabilizer and matching threaded rod bearing mount

thingiverse

free

Prusa i3 Z threaded rod stabilizer by stoto

...ed for the assembly. it is a very tight fit, use a soldering iron to heat up the bearing for an easier fit into the plastic part.

thingiverse

free

Z Rod Stabilizer by JulioRadesca

...he threaded rods is 29.2mm. it is half the axial distance of the threaded rods that support the z motor mount of a prusa mendel.

thingiverse

free

TronXY X1 Z-Axis rod holder/stabilizer for 12mm bearing by Ozziemandias

...zziemandias

thingiverse

based on jayarr model. designed to hold 12mm bearing (8mm internal diameter). needs longer threaded rod.

thingiverse

free

Anet A8 Z-axis support by Autro

...is support. comes in 2 parts for easy lubrication of the leading rods.

[update] make sure you turn it correctly before printing.

thingiverse

free

Tronxy PM802 Smooth rod holder and cap by kenbigt

...arts in red are to compliment

tronxy/3dcstar p802 z-axis threaded-rod bearing holder/stabilizer

by wypoon, published apr 14, 2017

thingiverse

free

Sunhokey Acrylic z axis recessed rods with screw stabilizer by zpeedster

...he srew rods and to lower the guide rods into the motor mounts.

please be awere of the spacing between rod holes before printing!

thingiverse

free

Robo3D Z Rod Constraint by galaxius

...still has to slide onto the smooth rod.

slide onto the smooth rod and adjust so the threaded z rod is verticle.

tighten the bolt.

Wypoon

thingiverse

free

Tronxy/3DCStar P802 Thumbscrew/Thumbwheel Cap by wypoon

...nt with 100% infill.

be sure to add a drop or two of engine oil into the nut before re-installing -- makes a world of difference!

thingiverse

free

Tronxy/3DCStar P802 Z-Axis Endstop MicroSwitch Spacer by wypoon

...s properly aligned with the adjustment bolt. this is important for your z-axis homing to be accurate and reproducible every time!

thingiverse

free

Tronxy/3DCStar P802 Extruder Filament Guide by wypoon

...pooling the filament on the extruder's hobb wheel.

install by simply gluing it to the steel u-frame of the extruder carriage.

thingiverse

free

Tronxy PM802 Smooth rod holder and cap by kenbigt

...to compliment tronxy/3dcstar p802 z-axis threaded-rod bearing holder/stabilizer by wypoon published apr 14,...

thingiverse

free

Tronxy/3DCStar P802 X-Axis Belt Tensioner by wypoon

...indrical face of the nub with ca glue (be absolutely sure to wipe off any excess) and re-insert the pulley. let it set overnight.

3Dcstar

thingiverse

free

Z_max endstop mount for Zonestar P802M / 3DCstar printer by Jagi

...x endstop, used in a cheap gearbest p802m printer (3dcstar acrylic). uses the same screw as the lid which covers the z-rail-hole.

thingiverse

free

M8 Mount for Tronxy 3DCSTAR P802-MHS by Miguel_Morales

... pieza en onshapehttps://cad.onshape.com/documents/cd7695b06ed63508cdba94c8/w/c6a10585002410ce8be7211d/e/84d79874b6ba7229ab8f8e7c

thingiverse

free

Clip for my Acrylic 3DCSTAR P802-MHS 3D Printer by mau21710

...ved the filament guide (go to the original file to take it)

. new measures for the clip (now fits well ot the printer, see photo)

thingiverse

free

3DCSTAR P802-MHS X-Tensioner by MarioVillani

...i've modified the original design to fit the hole in my printer. original top part was 8mm thick, i've reduced it to 6mm.

thingiverse

free

Tronxy/3DCStar P802 Thumbscrew/Thumbwheel Cap by wypoon

...nt with 100% infill.

be sure to add a drop or two of engine oil into the nut before re-installing -- makes a world of difference!

thingiverse

free

Tronxy/3DCStar P802 Z-Axis Endstop MicroSwitch Spacer by wypoon

...s properly aligned with the adjustment bolt. this is important for your z-axis homing to be accurate and reproducible every time!

thingiverse

free

Tronxy/3DCStar P802 Extruder Filament Guide by wypoon

...pooling the filament on the extruder's hobb wheel.

install by simply gluing it to the steel u-frame of the extruder carriage.

thingiverse

free

Tronxy/3DCStar P802 Motherboard 80mm Cooler Adapter by Sneakiest

...heating bed.

i could've designed it to use less filament, but i honestly couldn't be too bothered, it serves its purpose!

thingiverse

free

Tronxy P802 T-Bracket by astronauti

...a remix of the bracket to fit the tronxy p802/3dcstar just cut out a small hole for the screw...

thingiverse

free

Tronxy PM802 Smooth rod holder and cap by kenbigt

...kenbigt thingiverse these parts in red are to compliment tronxy/3dcstar p802 z-axis threaded-rod bearing holder/stabilizer by wypoon, published apr...

P802

thingiverse

free

Tronxy P802 Faceplate by Miziavelli

...tronxy p802 faceplate by miziavelli

thingiverse

tronxy p802 faceplate. wip!!

thingiverse

free

Brace for Tronxy P802

...for more stiffness of the frame

print the brace standing-up without support

printed on my tronxy p802

0.15mm hight and 20% infill

thingiverse

free

Copri elettronica prusa P802 by caspablog

...copri elettronica prusa p802 by caspablog

thingiverse

copri elettronica per prusa p802 ma

thingiverse

free

Tronxy P802 Filament Holder Clip by danzlrobert

...tronxy p802 filament holder clip by danzlrobert

thingiverse

clip for the tronxy p802 holder

thingiverse

free

Zonestar p802 mainboard + mofset holder by crimix73

...zonestar p802 mainboard + mofset holder by crimix73

thingiverse

zonestar p802 mainboard + mofset holder

thingiverse

free

prusa i3 p802 T corner by caillou333

...prusa i3 p802 t corner by caillou333

thingiverse

corner to reduce z-wobble for prusa i3 p802

thingiverse

free

P802-M button guide by BomanXIX

...802-m button guide by bomanxix

thingiverse

i've adapted these button guides to fit my printer from gearbest: tronxy p802-mhs

thingiverse

free

ZONESTAR P802 Filament feeder by HallyZhong

...ng

thingiverse

p802 filament feeder, it is can be applied to p802n p802q and p802c of zonestar 3d printer, support 1kg filament.

thingiverse

free

Zonestar P802 Prusa i3 Belt Clamp by tomausteltow

...zonestar p802 prusa i3 belt clamp by tomausteltow

thingiverse

zonestar p802 belt clamp

thingiverse

free

Filament_Dust_Filter__Guide_for_Prusa_I3 ZoneStar P802 edition 1 by harddrv1

... zonestar p802 edition 1 by harddrv1

thingiverse

remixed this to fit the frame of a zonestar p802 just made the clamp part wider

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

Stabilizer

3d_export

$5

Stabilizer 3D Model

...stabilizer 3d model

3dexport

stabilizer dashpot

stabilizer 3d model gaj15 60446 3dexport

turbosquid

$1

Steadicam Stabilizer

...oyalty free 3d model steadicam stabilizer for download as ipt on turbosquid: 3d models for games, architecture, videos. (1306615)

3d_export

free

Download free Stabilizer 3D Model

...download free stabilizer 3d model

3dexport

stabilizer electronics

stabilizer 3d model umairahmad555 35737 3dexport

3d_export

$23

stabilized moss and mirrors

...smoothing modifier is turned off by default. for close-ups, apply turbosmooth 1 iteration (turbosmooth is in the modifiers stack)

3d_export

$13

stabilized moss - world map

...level in the anti-aliasing modifier. the stack is open.<br>file export for anti-aliasing. apply the anti-aliasing modifier.

3d_export

$12

stone panels and stabilized moss

...in the scene).<br>all elements are made as separate objects, you can place them in any order<br>good renders for you!

3d_export

$13

wooden panels and stabilized moss

...r a particular frame. the anti-aliasing modifier is turned on (display in the viewport - 0 iterations, on the render 1 iteration)

3d_export

$13

stabilized moss 2

...or a particular frame. the anti-aliasing modifier is enabled (display in the viewport - 0 iterations, on the render 1 iteration).

3d_export

$13

stabilized moss 3

...level in the anti-aliasing modifier. the stack is open.<br>file export for anti-aliasing. apply the anti-aliasing modifier.

3d_export

$18

bouquet collection of dried flowers in a vase 181

...atural decor dry reed dried flowers, dry grass. dry, stabilized, painted stems, dried pods, natural decor cyperus papyrus cyperus

Rod

archibase_planet

free

Rod

...rod

archibase planet

shank rod

so rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spinning rod

...g rod

archibase planet

spinning rod spinning rod fishing-rod

spinning rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

rod handle

...rod handle

3dexport

rod handle

3ddd

$1

bench with rods

...bench with rods

3ddd

скамейка

bench with rods

3ddd

$1

диван ROD

...диван rod

3ddd

rod , living divani

http://www.livingdivani.it/

3ddd

$1

кресло ROD

...кресло rod

3ddd

rod , living divani

http://www.livingdivani.it/

design_connected

$18

Rod Armchair

...rod armchair

designconnected

living divani rod armchair computer generated 3d model. designed by lissoni, piero.

archive3d

free

Rod 3D Model

...rod 3d model

archive3d

shank rod

so rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$15

Fishing rod

...urbosquid

royalty free 3d model fishing rod for download as on turbosquid: 3d models for games, architecture, videos. (1684756)

turbosquid

free

Heating Rod

...rod

turbosquid

free 3d model heating rod for download as obj on turbosquid: 3d models for games, architecture, videos. (1482690)

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Threaded

3d_export

$5

threaded handle

...threaded handle

3dexport

threaded handle

turbosquid

free

threaded

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Tangle of thread

... tangle thread triangles – 36 in one strand in scene 300 thread includes materials includes 3 colors tangle thread in psd for ...

3d_export

$5

threaded lock handle

...threaded lock handle

3dexport

threaded lock handle

3d_export

$5

threaded machine handle

...threaded machine handle

3dexport

threaded machine handle

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

3d_export

$5

threaded rope ring

...threaded rope ring

3dexport

threaded rope ring

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Thread Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.