Thingiverse

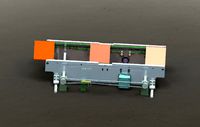

Tronxy/3DCStar P802 X-Axis Belt Tensioner by wypoon

by Thingiverse

Last crawled date: 3 years ago

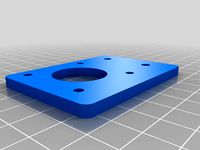

The Tronxy P802M X-Axis end-carriage is not a 'through' design, and traditional Anet A8 belt-tensioners, which rely on looping the belt past the end of the right end-carriage, will not work on it.

This compact design simply snaps on to the X-axis rail by the right carriage which:

adds more tension to your x-axis belt (e.g. when it stretches due to aging), and

has the added benefit of making the x-axis belt loop more run more 'parallel' to each other (the Tronxy uses a much larger bearing than the diameter of the stepper pinion gear).

Assembly:

Print all three parts and perform any clean-up or sanding required. Use a Q-Tip to clean the outside and inside cylindrical faces of the bearing with alcohol to remove any grease/oil.

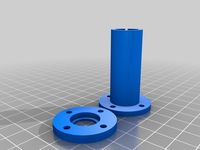

Test fit the pulley wheel cap (WheelB) to the pulley wheel (WheelA). Make sure the cap's groove is clear of debris and that the cap fits snug and the two circular guard flanges are parallel to each other.

Lightly coat the inside barrel of the pulley wheel with CA glue (be sure to wipe off any excess) and press a 5x11x4mm bearing into the wheel. Once flush in the wheel, use a dowel (a X-acto knife holder also works) that is >4mm to push the bearing all the way until it's completely seated within the pulley.

Lightly coat the i. rim of the pulley wheel (where it contacts the wheel cap), as well the ii. groove of the wheel cap with CA, and press the cap tightly onto the pulley. Let it set overnight.

Use a small butane torch (or cigarette-lighter) to heat up just the nub of the tensioner. Be very gentle (very quickly brush the flame across the nub 2-3x). Press the assembled pulley-wheel onto the nub. Make sure it's seated fully and while the nub is softened, adjust the plane of the pulley so that that it's straight and square and will not wobble as the pulley is rotated on the post.

Once the nub has cooled down, remove the pulley. Coat the cylindrical face of the nub with CA glue (be absolutely sure to wipe off any excess) and re-insert the pulley. Let it set overnight.

This compact design simply snaps on to the X-axis rail by the right carriage which:

adds more tension to your x-axis belt (e.g. when it stretches due to aging), and

has the added benefit of making the x-axis belt loop more run more 'parallel' to each other (the Tronxy uses a much larger bearing than the diameter of the stepper pinion gear).

Assembly:

Print all three parts and perform any clean-up or sanding required. Use a Q-Tip to clean the outside and inside cylindrical faces of the bearing with alcohol to remove any grease/oil.

Test fit the pulley wheel cap (WheelB) to the pulley wheel (WheelA). Make sure the cap's groove is clear of debris and that the cap fits snug and the two circular guard flanges are parallel to each other.

Lightly coat the inside barrel of the pulley wheel with CA glue (be sure to wipe off any excess) and press a 5x11x4mm bearing into the wheel. Once flush in the wheel, use a dowel (a X-acto knife holder also works) that is >4mm to push the bearing all the way until it's completely seated within the pulley.

Lightly coat the i. rim of the pulley wheel (where it contacts the wheel cap), as well the ii. groove of the wheel cap with CA, and press the cap tightly onto the pulley. Let it set overnight.

Use a small butane torch (or cigarette-lighter) to heat up just the nub of the tensioner. Be very gentle (very quickly brush the flame across the nub 2-3x). Press the assembled pulley-wheel onto the nub. Make sure it's seated fully and while the nub is softened, adjust the plane of the pulley so that that it's straight and square and will not wobble as the pulley is rotated on the post.

Once the nub has cooled down, remove the pulley. Coat the cylindrical face of the nub with CA glue (be absolutely sure to wipe off any excess) and re-insert the pulley. Let it set overnight.

Similar models

thingiverse

free

Tronxy X8 Belt tensioner x axis by GabrielePRG

...ith 60% infill is strong.

printed at 260c hot end, and 100c heated bed and no supports, with rafts and used simplify3d software.

thingiverse

free

Tronxy P802E X Axis Belt Tensioner by nipnbite

... than the large tronxy bearing.

you will need

(2) 4mm x40mm bolts

(4) 4mm nuts

(1) biqu-h303

(1) 5mm locknut

(1) 5mm x 25 bolt

thingiverse

free

Tronxy X5SA Belt Tensioner Y & X Axis by n02m4n

...tronxy x5sa belt tensioner y & x axis by n02m4n

thingiverse

a belt tensioner y & x axis for my tronxy x5sa.

thingiverse

free

Monoprice Select Mini X-Axis Belt Tensioner cap by justinschmitt

...m length (longer will work too)

an m3 nut to insert into the knob (nyloc preferred)

a washer to go between the nut and end cap

thingiverse

free

Afinibot A3 Y Axis Belt Pulley Wheel Assembly - With tensioner by Bartlby76

...mbly - with tensioner by bartlby76

thingiverse

a y axis belt pulley wheel assembly with a tensioner, for an afinibot a3 printer.

thingiverse

free

Tronxy p802m x axis belt tensioner by teesked

...m. might need to be heated with water and bended slightly depending on the quality of the x carriages. no need to buy a new belt.

thingiverse

free

Tevo tarantula PRO X axis belt tensioner

...y hands.

if you want to use 5mm bolts, you can print carriage from original design (they are swappable) and drill out the holles.

thingiverse

free

TronXY X8 X Carriage Belt Tension Mod by duodreamer

...rriage, plus two long m3 screws with nuts. can also use a smaller (625) bearing if you want and if your belt needs the clearance.

thingiverse

free

Tronxy p802 X axis belt tensioner by rtbuhler

...t;prusa i3 x axis belt tensioner" to fit tronxy p802e.

no need to replace the belt.

no need to print the parts with support.

thingiverse

free

X carrige belt idler for GEEETech prusa i3 x by sender86

...x by sender86

thingiverse

this is belt tensioning for x axies if pulley bearing fails. i designed it around two 624 zz bearings.

Wypoon

thingiverse

free

Tronxy/3DCStar P802 Thumbscrew/Thumbwheel Cap by wypoon

...nt with 100% infill.

be sure to add a drop or two of engine oil into the nut before re-installing -- makes a world of difference!

thingiverse

free

Tronxy/3DCStar P802 Z-Axis Endstop MicroSwitch Spacer by wypoon

...s properly aligned with the adjustment bolt. this is important for your z-axis homing to be accurate and reproducible every time!

thingiverse

free

Tronxy/3DCStar P802 Extruder Filament Guide by wypoon

...pooling the filament on the extruder's hobb wheel.

install by simply gluing it to the steel u-frame of the extruder carriage.

thingiverse

free

Tronxy PM802 Smooth rod holder and cap by kenbigt

...to compliment tronxy/3dcstar p802 z-axis threaded-rod bearing holder/stabilizer by wypoon published apr 14,...

thingiverse

free

Tronxy/3DCStar P802 Z-Axis Threaded-Rod Bearing Holder/Stabilizer by wypoon

...material.

update #2: the clearance for the bearing (as well as for the nub) has been reduced by 0.2mm to make it a more snug fit.

3Dcstar

thingiverse

free

Z_max endstop mount for Zonestar P802M / 3DCstar printer by Jagi

...x endstop, used in a cheap gearbest p802m printer (3dcstar acrylic). uses the same screw as the lid which covers the z-rail-hole.

thingiverse

free

M8 Mount for Tronxy 3DCSTAR P802-MHS by Miguel_Morales

... pieza en onshapehttps://cad.onshape.com/documents/cd7695b06ed63508cdba94c8/w/c6a10585002410ce8be7211d/e/84d79874b6ba7229ab8f8e7c

thingiverse

free

Clip for my Acrylic 3DCSTAR P802-MHS 3D Printer by mau21710

...ved the filament guide (go to the original file to take it)

. new measures for the clip (now fits well ot the printer, see photo)

thingiverse

free

3DCSTAR P802-MHS X-Tensioner by MarioVillani

...i've modified the original design to fit the hole in my printer. original top part was 8mm thick, i've reduced it to 6mm.

thingiverse

free

Tronxy/3DCStar P802 Thumbscrew/Thumbwheel Cap by wypoon

...nt with 100% infill.

be sure to add a drop or two of engine oil into the nut before re-installing -- makes a world of difference!

thingiverse

free

Tronxy/3DCStar P802 Z-Axis Endstop MicroSwitch Spacer by wypoon

...s properly aligned with the adjustment bolt. this is important for your z-axis homing to be accurate and reproducible every time!

thingiverse

free

Tronxy/3DCStar P802 Extruder Filament Guide by wypoon

...pooling the filament on the extruder's hobb wheel.

install by simply gluing it to the steel u-frame of the extruder carriage.

thingiverse

free

Tronxy/3DCStar P802 Motherboard 80mm Cooler Adapter by Sneakiest

...heating bed.

i could've designed it to use less filament, but i honestly couldn't be too bothered, it serves its purpose!

thingiverse

free

Tronxy P802 T-Bracket by astronauti

...a remix of the bracket to fit the tronxy p802/3dcstar just cut out a small hole for the screw...

thingiverse

free

Tronxy PM802 Smooth rod holder and cap by kenbigt

...kenbigt thingiverse these parts in red are to compliment tronxy/3dcstar p802 z-axis threaded-rod bearing holder/stabilizer by wypoon, published apr...

P802

thingiverse

free

Tronxy P802 Faceplate by Miziavelli

...tronxy p802 faceplate by miziavelli

thingiverse

tronxy p802 faceplate. wip!!

thingiverse

free

Brace for Tronxy P802

...for more stiffness of the frame

print the brace standing-up without support

printed on my tronxy p802

0.15mm hight and 20% infill

thingiverse

free

Copri elettronica prusa P802 by caspablog

...copri elettronica prusa p802 by caspablog

thingiverse

copri elettronica per prusa p802 ma

thingiverse

free

Tronxy P802 Filament Holder Clip by danzlrobert

...tronxy p802 filament holder clip by danzlrobert

thingiverse

clip for the tronxy p802 holder

thingiverse

free

Zonestar p802 mainboard + mofset holder by crimix73

...zonestar p802 mainboard + mofset holder by crimix73

thingiverse

zonestar p802 mainboard + mofset holder

thingiverse

free

prusa i3 p802 T corner by caillou333

...prusa i3 p802 t corner by caillou333

thingiverse

corner to reduce z-wobble for prusa i3 p802

thingiverse

free

P802-M button guide by BomanXIX

...802-m button guide by bomanxix

thingiverse

i've adapted these button guides to fit my printer from gearbest: tronxy p802-mhs

thingiverse

free

ZONESTAR P802 Filament feeder by HallyZhong

...ng

thingiverse

p802 filament feeder, it is can be applied to p802n p802q and p802c of zonestar 3d printer, support 1kg filament.

thingiverse

free

Zonestar P802 Prusa i3 Belt Clamp by tomausteltow

...zonestar p802 prusa i3 belt clamp by tomausteltow

thingiverse

zonestar p802 belt clamp

thingiverse

free

Filament_Dust_Filter__Guide_for_Prusa_I3 ZoneStar P802 edition 1 by harddrv1

... zonestar p802 edition 1 by harddrv1

thingiverse

remixed this to fit the frame of a zonestar p802 just made the clamp part wider

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

Tensioner

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$5

tension ring

...oyalty free 3d model tension ring for download as fbx and stl on turbosquid: 3d models for games, architecture, videos. (1553452)

turbosquid

$3

Tension Chair

...free 3d model tension chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1251503)

3d_export

$5

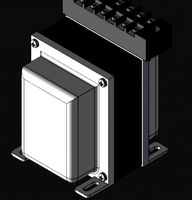

transformador de tension

...transformador de tension

3dexport

transformador de tension entrada 460vac salida 220vac marca audax

turbosquid

$20

Motorbike Chain Tensioner

...y free 3d model motorbike chain tensioner for download as stl on turbosquid: 3d models for games, architecture, videos. (1428322)

turbosquid

$25

TENSION-WOOD-CHAIR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

tension-bentwood-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Tension engagement ring

...n engagement ring for download as obj, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1491631)

3d_export

$10

Ruby Tension set Ring 3D Model

...ruby tension set ring 3d model

3dexport

tension set ruby ring in 18k

ruby tension set ring 3d model rehansheikh 25254 3dexport

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

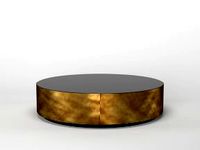

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award