Thingiverse

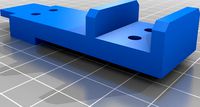

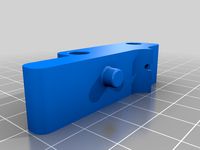

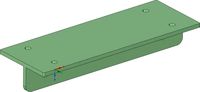

Tronxy X5SA Extruder and Filament Stop Mounting Plate by Toto-42

by Thingiverse

Last crawled date: 2 years, 11 months ago

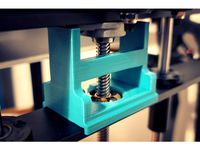

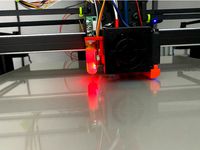

The original design of a Tronxy X5SA printer has the extruder and the filament stop detector mounted on two separate plates at the outer rear right vertical 2040 profile..

Unfortunately this results in maximum required length of the PTFE bowden tube.

Obviously not the best design.

The bowden tube can be shortened about 20% if the extruder is mounter in the middle of an upper horizontal frame part.

The rear seems usually to be the best place for this.

To overcome this, some re-work on the original mounting plates is required.

Here is the result...

It works for various extruders based on Nema 17 stepper motors,

but it is especially designed for the non-Titan original stock extruder (i.e. non-Pro X5SA) and the BMG extruder (and its clones). This is because of the position of the filament run out sensor.

Is was a design goal to position both devices in a straight vertical line regarding filament run. Therefore there are two sets of M3 mounting holes for this sensor.

At the time of designing this thing I still use(d) the stock sensor but have already ordered am BMG extruder clone. Each extruder has a different path for the filament, so the position of the sensor has to be be adapted correspondingly.

WARNING: the current 1st version has an issue interfering with the long diagonal brace! The upper mounting hole of the sensor is blocked by the brace. I will provide an updated version soon. If you don't use such a brace, then the issue doesn't affect you. Anyway, you can mount the sensor even with just one screw - it then self-aligns with the filament.

I have also designed a corresponding Tronxy X5SA Spool Holder in the Rear 2040-Profile Vertical Plane.

Unfortunately this results in maximum required length of the PTFE bowden tube.

Obviously not the best design.

The bowden tube can be shortened about 20% if the extruder is mounter in the middle of an upper horizontal frame part.

The rear seems usually to be the best place for this.

To overcome this, some re-work on the original mounting plates is required.

Here is the result...

It works for various extruders based on Nema 17 stepper motors,

but it is especially designed for the non-Titan original stock extruder (i.e. non-Pro X5SA) and the BMG extruder (and its clones). This is because of the position of the filament run out sensor.

Is was a design goal to position both devices in a straight vertical line regarding filament run. Therefore there are two sets of M3 mounting holes for this sensor.

At the time of designing this thing I still use(d) the stock sensor but have already ordered am BMG extruder clone. Each extruder has a different path for the filament, so the position of the sensor has to be be adapted correspondingly.

WARNING: the current 1st version has an issue interfering with the long diagonal brace! The upper mounting hole of the sensor is blocked by the brace. I will provide an updated version soon. If you don't use such a brace, then the issue doesn't affect you. Anyway, you can mount the sensor even with just one screw - it then self-aligns with the filament.

I have also designed a corresponding Tronxy X5SA Spool Holder in the Rear 2040-Profile Vertical Plane.

Similar models

thingiverse

free

Tronxy X5SA BMG Dual Drive Extruder and Filament Stop Mounting Plate by Toto-42

...stment in x direction too.

i have also designed a corresponding tronxy x5sa spool holder in the rear 2040-profile vertical plane.

thingiverse

free

X5SA titan extruder mount with filament sensor holder and filament guide by Nmosfet

...e mounted to the rear of the printer, allowing for more efficient bowden tube routing.

this was tested on an early 2019 x5sa-400

thingiverse

free

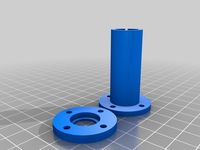

Tronxy X5SA Spool Holder in the Rear 2040-Profile Vertical Plane by Toto-42

... just provided here for completeness.

i have also designed a corresponding tronxy x5sa extruder and filament stop mounting plate.

thingiverse

free

tronxy x5sa pro bmg direct extruder mount by hongsoon

...mount by hongsoon

thingiverse

tronxy x5sa pro

bmg direct extruder mount

i remixed this.https://www.thingiverse.com/thing:4216647

thingiverse

free

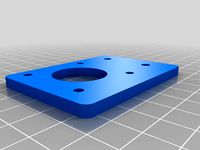

Tronxy X5SA Extruder Bracket by towguy87

...o avoid warping

4 walls for extra strength

attached filament sensor with the supplied 3mm bolts. bolts thread into the standoffs.

thingiverse

free

TronXY X5SA Bondtech Filament Sensor Spacer by AutoWiz

...han the titan. this simple part spaces the filament sensor out to the right location to line up with new filament inlet location.

thingiverse

free

TronXY X5SA Pro V6 Volcano Mount with Flex3Drive G5 and BLtouch by ChavasRegal

... be used with a remote extruder and bowden tube.

the fan duct is a modified version of https://www.thingiverse.com/thing:4620462.

thingiverse

free

Anycubic i3 Mega filament sensor adapter for BMG extruders

... mount this adapter to the printer. the m4 screw from the ball can be reused to connect the filament sensor to the adapter plate.

thingiverse

free

CR10S PRO Filament Run Out Adapter for BMG Bowden by jiahao_chen

...ament guide using a v-shaped pom wheel. you also need 3x 8mm m3 screws and the original 4x flat screws that come with the sensor.

thingiverse

free

Duet WiFi Laser filament sensor for direct Bondtech BMG

...erse bowden tube.case for this sensor you can find at: https://www.youmagine.com/designs/duet3d-laser-filament-monitor-housing-v2

X5Sa

thingiverse

free

Chain riser X5SA by xanatorium

...chain riser x5sa by xanatorium

thingiverse

chain risers for x5sa

thingiverse

free

Tronxy X5S X5SA Organizer

...tronxy x5s x5sa organizer

thingiverse

organizer for tronxy x5s; x5sa

thingiverse

free

Tronxy X5SA Z-Blocker by n02m4n

...tronxy x5sa z-blocker by n02m4n

thingiverse

a z-blocker for my x5sa.

thingiverse

free

Tronxy X5SA Fan Duct by Noobik4ever

...tronxy x5sa fan duct by noobik4ever

thingiverse

fun duct for tronxy x5sa

thingiverse

free

Tronxy X5S, X5SA linear rail

...tronxy x5s, x5sa linear rail

thingiverse

linear rail tronxy x5sa

thingiverse

free

Tronxy X5SA Filament holder Screw

...tronxy x5sa filament holder screw

thingiverse

better holder for tronxy x5sa filament as screw

thingiverse

free

TronXY X5SA PRO BLTouch Mount

...tronxy x5sa pro bltouch mount

thingiverse

a simple bltouch mount for the tronxy x5sa pro.

thingiverse

free

Tronxy X5SA Extruder TPU Upgrade

...tronxy x5sa extruder tpu upgrade

thingiverse

redesigned anycubic kossel extruder tpu upgrade for tronxy x5sa

thingiverse

free

X5SA Tronxy Towline by Daelin89

... towline by daelin89

thingiverse

broke the towline on my tronxy x5sa-400. so i remade it in fusion 360. have yet to test print

thingiverse

free

Tronxy X5SA Display Offset by Darkwulf3D

...tronxy x5sa display offset by darkwulf3d

thingiverse

tronxy x5sa pro display offset for the large table adjustment wheels

Toto

3ddd

$1

Toto

...toto

3ddd

toto

раковина toto

3ddd

$1

toto PPY1620W

...toto ppy1620w

3ddd

toto , ванна

toto ppy1620w

3ddd

$1

Toto sgabello

...toto sgabello

3ddd

барный

bar chair toto sgabello.

3ddd

$1

Toto VL10084C

...toto vl10084c

3ddd

смеситель

смеситель toto однорычажный серии мн.

3ddd

$1

Rainshower Toto PSU1000E.

...rainshower toto psu1000e.

3ddd

toto

rainshower toto psu1000e.

turbosquid

$8

Character Toto

...free 3d model character toto for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1312260)

3ddd

$1

Ванна TOTO PAY1740PWEE

...ливным и переливным гарнитуром и ножками для ванны

size (wxhxd in mm): 1700 x 850 x 640

material: acrylic resin

country: japan

3d_ocean

$5

TOTO Kiwami Renesse Faucet

...stic toto kiwami renesse deck-mount widespread model. no need any additional modeling and texturing. - only model - low-poly m...

turbosquid

$19

Bar Chair Toto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Автоматический унитаз-биде TOTO Neorest AH

... neorest

автоматический унитаз-биде toto neorest ahhttp://812vann.ru/?mode=product&product;_id=736217201

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

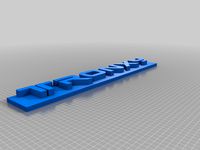

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

42

design_connected

$16

No.42

...no.42

designconnected

great dane no.42 computer generated 3d model. designed by kristiansen, kai.

design_connected

free

42

...42

designconnected

artek 42 free models computer generated 3d model. designed by alvar aalto.

design_connected

$16

Wogg 42

...wogg 42

designconnected

wogg wogg 42 computer generated 3d model. designed by boner, jörg.

3ddd

$1

PLANTS 42

...ants 42

3ddd

цветок , горшок

plants 42,, planters from rh vetro series,, enjoy the model

3d_ocean

$20

Maschinengewehr 42

...hine maschinengewehr mg mg-42 mg42 pistol ready rifle sniper weapon

low polygon and very well detailed maschinengewehr 42 (mg42).

turbosquid

$10

building 42

...urbosquid

royalty free 3d model building 42 for download as on turbosquid: 3d models for games, architecture, videos. (1362755)

turbosquid

$6

Bedcloth 42

...osquid

royalty free 3d model bedcloth 42 for download as max on turbosquid: 3d models for games, architecture, videos. (1522746)

turbosquid

$50

MG-42

...osquid

royalty free 3d model mg-42 3d model for download as on turbosquid: 3d models for games, architecture, videos. (1555634)

turbosquid

$12

Curtains 42

...royalty free 3d model curtains 42 for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1650289)

turbosquid

$7

RG-42

...quid

royalty free 3d model rg-42 for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1166505)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Stop

turbosquid

$5

Stop Stop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

stop

...stop

3dexport

classic stop.

3d_ocean

$12

Bus Stop

...bus stop

3docean

bus bus stop station

bus stop model

archibase_planet

free

Bus stop

...bus stop

archibase planet

bus stop bus-stop

bus stop n150111 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$10

stop valve

...stop valve

3dexport

stop valve

archibase_planet

free

Bus stop

...bus stop

archibase planet

bus stop bus-stop bus station

bus stop n070512 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bus stop

...bus stop

archibase planet

bus stop bus-stop bus station

bus stop n181213 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bus stop

...bus stop

archibase planet

bus stop bus-stop bus station

bus stop n120514 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$1

stop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Stopping Place

...in zip pack the following items: 3d file stopping plac pack/.max/.obj// material and textures. well we hope you enjoy it regards.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

plate

...plate

3dexport

plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate kitchen ware

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plates

...plates

archibase planet

plate plates and dishes crockery

plates 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plate

...plate

archibase planet

dinner-plate plate kitchen ware

plate n070808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$6

plate

...plate

3dexport

design of plate

3d_export

$5

plate

...plate

3dexport

plate lowpoly

archibase_planet

free

Plates

...plates

archibase planet

plate dish kitchen-ware

plate - 3d model for interior 3d visualization.

3ddd

$1

Plates

...plates

3ddd

полка , тарелка

african plates

archibase_planet

free

Plate

...plate

archibase planet

plate kitchen ware

plate - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mounting

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)