Thingiverse

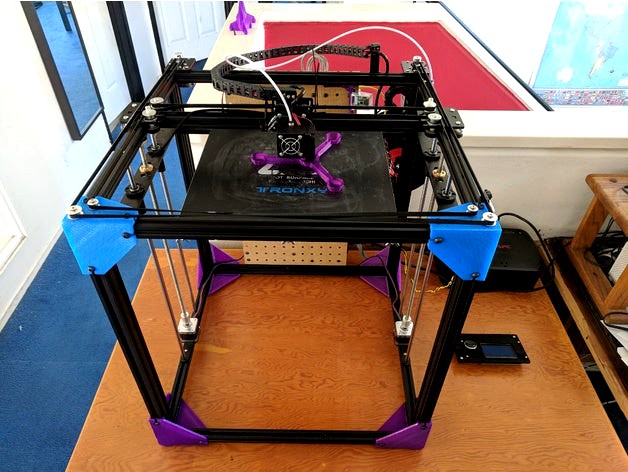

TronXY X5S upgrades by pbannister

by Thingiverse

Last crawled date: 3 years ago

Bought a cheap Chinese Core-XY printer with a lot of shortcomings. With a number of upgrades, this is a much much better printer.

Ended up replacing the rollers for X-motion of the print head with solid printed-plastic bearing, with much better result.

Note the theme here is a minimal upgrade. Addressed only the worst flaws, and stopped when I had a decent printer. Did not need to replace the motor mounts. Did not need to replace the Y-motion frame and rollers. Kept the funky belt "pulleys", except for the front corners, as they work well enough.

Insulating and reinforcing (flattening) the print bed was critical. Stiffening, dampening, and forcing frame alignment with the large corners was critical. Routing the belts in one plane removed asymmetric forces from the gantry. Replacing the X-rollers with a solid bearing was critical to force more exact head positioning. Putting all the electronics on a single backplane made the wiring much cleaner. Entirely removed the control panel (with the horrid Marlin UI), as the OctoPrint web-based control panel was much(!) better.

And at this point I stopped. This is a now very serviceable PLA (mostly) printer.

Also note the large plastic corners are superior to metal brackets, as they force exact frame alignment, dampen vibration, and are more than sufficiently stiff.

Update 2018/05/13

Slightly updated the X-sliders to be even more precise. Tightened up tolerances and added a slight slope to the bearing surface. The result is improved. The prior iteration had less "give" than the stock bearings, but there was still a slight amount of play. Eliminated the play with these changes.

Update 2018/06/10

Again, in the theme of minimal upgrades ... added a simple support tower for the cable chain. Tie-wrapped the filament tube to the cable chain (after losing a print, due to the tube snagging on one of the clips). Nothing fancy, but works.

Update 2018/08/11

The printed-PLA bearing for X-motion continues to perform well. No noticeable wear or "play". Note that I took advantage of the slightly porous nature of 3D printed parts, and soaked the bearing with a generic oil spray (from the local hardware store, which also claims to contain Teflon and silicone). Sprayed a (Telfon-based) mold release on the rail (though this may not be needed). This just works. Weights less than the original X-motion bearing (wheels) and has no perceptible "play" (thus more precise).

Ended up replacing the rollers for X-motion of the print head with solid printed-plastic bearing, with much better result.

Note the theme here is a minimal upgrade. Addressed only the worst flaws, and stopped when I had a decent printer. Did not need to replace the motor mounts. Did not need to replace the Y-motion frame and rollers. Kept the funky belt "pulleys", except for the front corners, as they work well enough.

Insulating and reinforcing (flattening) the print bed was critical. Stiffening, dampening, and forcing frame alignment with the large corners was critical. Routing the belts in one plane removed asymmetric forces from the gantry. Replacing the X-rollers with a solid bearing was critical to force more exact head positioning. Putting all the electronics on a single backplane made the wiring much cleaner. Entirely removed the control panel (with the horrid Marlin UI), as the OctoPrint web-based control panel was much(!) better.

And at this point I stopped. This is a now very serviceable PLA (mostly) printer.

Also note the large plastic corners are superior to metal brackets, as they force exact frame alignment, dampen vibration, and are more than sufficiently stiff.

Update 2018/05/13

Slightly updated the X-sliders to be even more precise. Tightened up tolerances and added a slight slope to the bearing surface. The result is improved. The prior iteration had less "give" than the stock bearings, but there was still a slight amount of play. Eliminated the play with these changes.

Update 2018/06/10

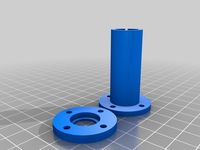

Again, in the theme of minimal upgrades ... added a simple support tower for the cable chain. Tie-wrapped the filament tube to the cable chain (after losing a print, due to the tube snagging on one of the clips). Nothing fancy, but works.

Update 2018/08/11

The printed-PLA bearing for X-motion continues to perform well. No noticeable wear or "play". Note that I took advantage of the slightly porous nature of 3D printed parts, and soaked the bearing with a generic oil spray (from the local hardware store, which also claims to contain Teflon and silicone). Sprayed a (Telfon-based) mold release on the rail (though this may not be needed). This just works. Weights less than the original X-motion bearing (wheels) and has no perceptible "play" (thus more precise).

Similar models

thingiverse

free

FLSUN COREXY Z Mount replacement by Willg77

...nd the z axis rods under this creation. same alignment distance applies.

update: 20 jul 18 - added z axis limit switch mount (m4)

thingiverse

free

Andersen Plastic Screen Frame Corner by Raspbian

...replacement part at lowes, but i would have the similar complaint:...

thingiverse

free

Vibration Dampener for Prusa Bear Upgrade by Slyph

...hem on the bear upgrade as well. i do get a noticeable reduction in noise using these.

update 2018-09-10

added the thick versions

grabcad

free

Roller Bearings

...s to desirable motion. it prevents undesirable motion by controlling the vectors of normal forces that bear on the moving parts.

grabcad

free

Tapered roller bearing

...his geometry makes the motion of the cones remain coaxial, with no sliding motion between the raceways and the od of the rollers.

thingiverse

free

Filament cleaner /roller guide for Ender 3 by ihsjepsen

...a very tight press fit in the ring. see https://www.thingiverse.com/thing:3061551 for additional detail and non bearing options.

thingiverse

free

Ultimaker Original LM6LUU replacement with linear copper bashing by barelkodotcom

...and after:

before upgrade: https://www.youtube.com/watch?v=re_j6eljlyk

after upgrade: https://www.youtube.com/watch?v=5kponvoyd-w

thingiverse

free

Anet A8 Y Axis Rework by viktor3d

...2351450

top reinforcement: https://www.thingiverse.com/thing:2646309

nema 17 stepper motor dampener: https://tinyurl.com/yalhohrr

thingiverse

free

Marble Machine by cowger

... bearing, two of which are used to keep things aligned.

finally, my motor cover is slightly smaller to fit the base a bit better.

thingiverse

free

Slew bearing with crossed cylinder rollers by Isi3d

...its go to thegoofy and his slew bearing (see remix note). i just rebuilt it in openscad and designed the cage/spacer as one part.

Pbannister

thingiverse

free

Desktop tools organizer by pbannister

...desktop tools organizer by pbannister

thingiverse

simple holder for tools (files, mostly in my use) kept near my 3d printer.

thingiverse

free

Oumuamua by pbannister

...have as evidence is a single wavering colored pixel.

discussion: https://plus.google.com/u/0/+prestonbannister/posts/l1zty5pxcg4

thingiverse

free

Spooler holder by pbannister

...he common size for skateboards. should fit most any size spool.

could print the inner and outer bits separately, or as one print.

thingiverse

free

Hinge (meant for printer enclosure) by pbannister

... number of iterations to get a hinge (for a printer enclosure) that prints well.

will update this once the enclosure is finished.

thingiverse

free

Clips for TV tray by pbannister

...ined.

the caveat is that i do not (yet) know if they work! shipped the printed parts off to a relative, who needed replacements.

thingiverse

free

Pegboard upgrade for TronXY X5S by pbannister

...xibility, with better appearance, while at least seeming more organized. (added a raspberry pi running octopi ... so more wires.)

thingiverse

free

Spooler holder (by pbannister) Remix by cntryder

...nter bearing spacer i printed with 10% infill.

a couple of the parts may require supports in a few areas. just use you judgement.

thingiverse

free

Steve from Minecraft by pbannister

...ructure, and you should have a working toy. (suggest you print face-up. painting the face and/or body is up to you.)

have fun. :)

thingiverse

free

Archimedes screw by pbannister

...ernatively, you could remove the crank and turn the screw with an 8mm allen key - perhaps attached to an electric motor or drill.

thingiverse

free

Rockets!! by pbannister

...iralized" (or "vase mode") prints. also, if you push speed, they seem good for finding the faults in your printer.

X5S

3ddd

$1

топор Fiskars X5

...топор fiskars x5

3ddd

топор

точная модель топора fiskars-x5

3d_export

$25

Bmw x5 3D Model

...bmw x5 3d model

3dexport

bmw x5

bmw x5 3d model alex.fox 914 3dexport

turbosquid

$9

Smartband X5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$89

BMW X5 2011

...r detailed detailed german german luxury luxury model model sport sport suv suv vehicle vehicle x5 x5

bmw x5 2011 detailed model

3d_export

$39

BMW X5 3D Model

...bmw x5 3d model

3dexport

bmw x5 car transport

bmw x5 3d model bumart 406 3dexport

3d_export

$28

BMW X5 3D Model

...bmw x5 3d model

3dexport

car bmw x5 vray 3ds max high poly

bmw x5 3d model spwar 2 3dexport

3d_export

$60

BMW X5 3D Model

...bmw x5 3d model

3dexport

bmw bmw x5 suv german car transportation automovile tuning

bmw x5 3d model pati3nt 19059 3dexport

3d_export

$69

BMW-X5 2023

...bmw-x5 2023

3dexport

turbosquid

$10

fruit and vegetable x5

...yalty free 3d model fruit and vegetable x5 for download as ma on turbosquid: 3d models for games, architecture, videos. (1653791)

turbosquid

$10

fruit and vegetable x5

...yalty free 3d model fruit and vegetable x5 for download as ma on turbosquid: 3d models for games, architecture, videos. (1653839)

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

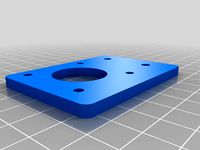

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

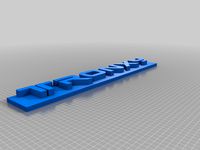

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

Upgrades

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.