Thingiverse

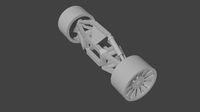

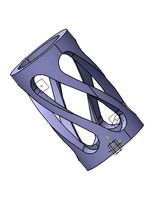

Traxxas Slash 2WD Part 2555 Modified Rear Suspension Arms by QuantumFlexGate

by Thingiverse

Last crawled date: 3 years ago

Update: Also see part 3631 for front suspension arms.

PLEASE READ ALL NOTES. I am very proud of this part. It took me several weeks to optimize. Any feedback of actual field testing and pictures of breakages will be GREATLY APPRECIATED. Please keep me in mind and help me improve this part for all the bashers out there.

Part v11 is an 11th generation part, taking into account breakage data and feedback from Karnite. It has fewer holes at the breakage points, plus the chassis screw encasement is just a bit reduced at the outer ranges of its swing.

Part v10 is a 10th generation, weight reduced part with the thickest ends possible around the chassis pins which has not yet been field tested but I believe it will be super durable. Part 10 has left and right versions. Its weight is close to factory weight but maybe 10% heavier. Part 82 is an older solid version, field tested, and quite a bit heavier than the Traxxas part. This part broke around the chassis pin when I did a 6' tall ramp, so I made version 10. Any thicker and you will need Aluminum or a different printing material.

I use this with the low gravity kit for the Traxxas Slash 2WD. I start by screwing the longest chassis pin in at the back end of the car (backwards from Traxxas), and start the shorter wheel pin at the front end of the car (same as Traxxas). This allows me to replace the part much easier when it breaks.

Please print this with PLA as solid (90% density) on high quality setting. Use supports to ensure the holes are round. Use a 1/8" drill bit to clean out the end holes for the pins and a 1/16" or 5/64" to clean out the middle suspension screw hole. DO NOT OVERSIZE the holes which weakens the part! If you use a 5/64" for the suspension hole and it is too big, then try heating around the hole for a couple of seconds with a lighter or small grill torch, then squeeze above and below the hole with pliers to make the hole smaller.

I created this part because the Traxxas original suspension hole kept stripping out. Filling the hole with super glue then re-drilling the hole nice and small can also work sometimes.

PLEASE READ ALL NOTES. I am very proud of this part. It took me several weeks to optimize. Any feedback of actual field testing and pictures of breakages will be GREATLY APPRECIATED. Please keep me in mind and help me improve this part for all the bashers out there.

Part v11 is an 11th generation part, taking into account breakage data and feedback from Karnite. It has fewer holes at the breakage points, plus the chassis screw encasement is just a bit reduced at the outer ranges of its swing.

Part v10 is a 10th generation, weight reduced part with the thickest ends possible around the chassis pins which has not yet been field tested but I believe it will be super durable. Part 10 has left and right versions. Its weight is close to factory weight but maybe 10% heavier. Part 82 is an older solid version, field tested, and quite a bit heavier than the Traxxas part. This part broke around the chassis pin when I did a 6' tall ramp, so I made version 10. Any thicker and you will need Aluminum or a different printing material.

I use this with the low gravity kit for the Traxxas Slash 2WD. I start by screwing the longest chassis pin in at the back end of the car (backwards from Traxxas), and start the shorter wheel pin at the front end of the car (same as Traxxas). This allows me to replace the part much easier when it breaks.

Please print this with PLA as solid (90% density) on high quality setting. Use supports to ensure the holes are round. Use a 1/8" drill bit to clean out the end holes for the pins and a 1/16" or 5/64" to clean out the middle suspension screw hole. DO NOT OVERSIZE the holes which weakens the part! If you use a 5/64" for the suspension hole and it is too big, then try heating around the hole for a couple of seconds with a lighter or small grill torch, then squeeze above and below the hole with pliers to make the hole smaller.

I created this part because the Traxxas original suspension hole kept stripping out. Filling the hole with super glue then re-drilling the hole nice and small can also work sometimes.

Similar models

3dwarehouse

free

Traxxas Slash Trophy Truck Chassis

...wed on our blog at ideal-rc.com . #110_scale #desert_racing #hpi #prerunner #rc #slash #traxxas #trophy_truck #truck #wheely_king

grabcad

free

Bulkhead for traxxas slash 2WD part 2530A

...bulkhead for traxxas slash 2wd part 2530a

grabcad

front part for traxxas slash 2wd

thingiverse

free

Traxxas Slash 2WD ESC Mount

...ed tape. if your esc has mounting holes then you could drill your own holes to fit your esc. nothing fancy here, it just works.

thingiverse

free

Castle Sidewinder SV3 ESC Mount for Traxxas Slash 2WD by tmoney315

...uck the wires underneath. there are tiny holes for screws to mount the switch, but it fits so tight you don't even need them!

thingiverse

free

traxxas slash 2wd front suspension arms 3631 - Right and Left by QuantumFlexGate

...it might work, it might not.

be careful to print it with the flat side down and the cut-outs up.

this is designed in cm as units.

thingiverse

free

Traxxas Slash 2WD Modified 3736 Front Steering Blocks (L & R) by QuantumFlexGate

... the thicker part tends to interfere with other parts of the steering or suspension and needs slight knotches cut out on the arm.

thingiverse

free

traxxas slash front by mardo

... front by mardo

thingiverse

the front to the traxxas slash 2wd model. i haven't printed it yet so please tell me if it works

cg_trader

$2

Traxxas turnbuckles for 2wd cars

...nother high impact material with 100% infill. i have them on my slash and i just that thing 30ft in the air and these dont break.

thingiverse

free

Traxxas slash 2wd aluminium LCG chassis design by PontiDude

...ut you can also mount it stock. this was designed to be cut out of aluminium but can also be laser cut out of wood or 3d printed.

3dwarehouse

free

Slash 2WD chassis

...slash 2wd chassis

3dwarehouse

slash 2wd chassis

Quantumflexgate

thingiverse

free

Door Knob Bumper by QuantumFlexGate

... the door knob from damaging the other door.

print with flex filament. i used sainsmart tpu at 220c nozzle temp and 50c print bed

thingiverse

free

tal coffee mug cap and seal by QuantumFlexGate

...or lid and the seal to a tal coffee mug. the od of the mug top is about 88.4mm or 3.5" for reference. please give me a like.

thingiverse

free

Spice Rack - Stackable by QuantumFlexGate

... and brand, but it works for most.

i think the top is slightly shorter in height and i would probably print them all this height.

thingiverse

free

Siphon pump for fish tank - tip replacement by QuantumFlexGate

...placement by quantumflexgate

thingiverse

my fish tank siphon pump broke, so i decided to make a replacement tip to glue onto it.

thingiverse

free

77T M0,53 spur gear with hexagonal pattern in center by QuantumFlexGate

...in center by quantumflexgate

thingiverse

this is a custom gear based on a picture send via email. i hope it is close to fitting.

thingiverse

free

Shower Curtain Clip Retainer by QuantumFlexGate

...ture say it all.

the v3 is very tight and a little difficult to put on, but it works the best. v4 is looser and easier to put on.

thingiverse

free

Bird Feeder Perch Hole for Cylindrical Birdhouse by QuantumFlexGate

...the birdhouse is about 75mm.

i printed it with the dome and the two pins facing up.

please give me a like if you like it. thanks!

thingiverse

free

Spur Gear 73 tooth 46p for Traxxas Slash 2WD by QuantumFlexGate

... it should work with a 23 tooth pinion or larger. i never used it yet so please leave me a comment or like if this works. thanks!

thingiverse

free

Traxxas Slash Pinion Gear 28t by QuantumFlexGate

...he throttle to avoid stripping the gears. thanks and enjoy. this part is posted as is with no warrantee - use at your own risk.

thingiverse

free

Samsung 60" smart TV Remove Cover by QuantumFlexGate

... do hold it in place, they are thin and break easily so i use a small piece of clear tape to make sure it doesn't come loose.

2555

3d_export

$7

Audi A3 (turning) lowpoly 3D Model

...model 3dexport audi a3 (turning) lowpoly 3d model $---serg---$ 2555 ...

3d_ocean

$19

Apartment House #72 Low Poly 3d Model

...interior. the 3d model includes a texture that is 1380×2555 in size. the objects are modeled using real world...

3d_export

$8

Isometric cliffs terrain

...positioned on colour pallette. blender stats verticies: 1285 tris: 2555 ...

3d_export

$120

Ripsaw from fast 8

...ordnance disposal.<br>model dimensions:<br>- length – 5237,5 mm<br>- width – 2555 mm<br>- height – 2493 mm<br>useful...

thingiverse

free

Cup Holder Garmin Nuvi 2555 GPS mount by rkxone

...39;t get to that until tomorrow afternoon/evening, so it's a wip until then, but the numbers are sound for tolerance.

enjoy!

thingiverse

free

Robo3D E3D Bowden Feed X Carriage by donhuevo

...a thread for this in the robo3d forums here... http://forums.robo3dprinter.com/index.php?threads/donhuevos-e3d-bowden-fed-x-carriage.2555 ...

3d_sky

free

ROOM & BOARD Ventura Extension Table

...board extension table room & board ventura extension table d1220xh740.http://www.roomandboard.com/rnb/product/detail.do?productgroup=2555amp;nbsp; *.max files in the archive, *.fbx and textures. file...

cg_trader

$25

Band ring - 2555 | 3D

...band ring - 2555 | 3d

cg trader

#bandring

#coupleband

cg_trader

$20

diamond bracelets 2555 | 3D

...diamond bracelets 2555 | 3d

cg trader

all information : brief description listed in photo .

2Wd

3d_export

$20

GMC Sierra 2500HD 2wd crew2009 rim 3D Model

...cle part of avto car gmc sierra 2500hd 2wd crew2009

gmc sierra 2500hd 2wd crew2009 rim 3d model creativeideastudio 63494 3dexport

3d_export

$30

Chevrolet Silverado 2500HD 2wd crew 2008 3D Model

... car chevrolet silverado 2500hd 2wd crew 2008

chevrolet silverado 2500hd 2wd crew 2008 3d model creativeideastudio 62600 3dexport

3d_ocean

$18

GMC Sierra 2500HD 2wd crew2009 rim

... model has got physically accurate materials. it is separated on parts and they are correctly named. so it is easy to use and ...

cg_studio

$33

Chevrolet Silverado 2500HD 2wd crew 20083d model

...b .obj .xsi - chevrolet silverado 2500hd 2wd crew 2008 3d model, royalty free license available, instant download after purchase.

cg_studio

$20

Chevrolet Silverado 2500HD 2wd crew 20083d model

...b .obj .xsi - chevrolet silverado 2500hd 2wd crew 2008 3d model, royalty free license available, instant download after purchase.

cg_studio

$33

GMC Sierra 2500HD 2wd crew 2009 wheel3d model

... .mb .obj .xsi - gmc sierra 2500hd 2wd crew 2009 wheel 3d model, royalty free license available, instant download after purchase.

3d_ocean

$20

GMC Sierra 2500HD 2wd crew 2009 wheel

...del is created in real units of measurement. model with physically accurate materials. model is separated on parts and correct...

3d_export

$30

GMC Sierra 2500HD 2wd crew 2009 wheel 3D Model

...or choosing our 3d models.we look forward to continuously dealing with you.good luck with your project.creative idea studio team.

3d_export

$49

Motorbike 3D Model

...motorbike 3d model 3dexport bmw sidecar motorbike motorcycle 2wd atv vintage retro bike imz dnepr chopper custom vehicle...

3d_export

$99

Daihatsu Terios 2009 3D Model

...model 3dexport daihatsu terios 2008 2009 2010 2011 4wd 2wd awd suv crossover mini wagon 4-door compact zotye family...

Slash

3d_export

$15

Slash

...

modelo de slash tipo cartoon, realizado en zbrush con cortes y encastres para su facil impresion, armado y pintado de la figura.

turbosquid

$10

Slash Lamp

...bosquid

royalty free 3d model slash lamp for download as max on turbosquid: 3d models for games, architecture, videos. (1524877)

3d_export

$12

slash hat

...slash hat

3dexport

slash hat 3d model, very high detail, made in 3dsmax 2016, rendered in vray 3.0, high resolution texture.

turbosquid

$4

Slash Web Icon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

Bamax Slash Night bed

...ee 3d model bamax slash night bed for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1454828)

3d_export

$80

Slash Les Paul Guitar Top Hat 3D Model

...ment jimi hendrix metal top hat photorealistic detailed textures

slash les paul guitar top hat 3d model 3dhorizon 44785 3dexport

3d_ocean

$45

Slash Les Paul Guitar & Top Hat

...es paul guitar. polygons 45186 vertices 48016 epiphone les paul guitar polygons 45405 vertices 48269 top hat 1 polygons 27984 ...

turbosquid

$35

Bamax Slash dining room set with table setting and decor

...ith table setting and decor for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1337198)

3d_export

$5

Winter Sword 3D Model

...winter sword 3d model 3dexport winter sword steel weapon slash cut winter sword 3d model davidmlopez 85025...

3d_export

$25

Beyblade Driger MS 3D Model

...driger ms 3d model 3dexport beyblade driger ms metal slash ray kon beyblade driger ms 3d model alexsikdar 94763...

Traxxas

thingiverse

free

TRAXXAS UDR Panel

...traxxas udr panel

thingiverse

traxxas udr panel

thingiverse

free

Traxxas logo by JCETech

...traxxas logo by jcetech

thingiverse

this traxxas logo was made on inventor

thingiverse

free

traxxas bulkhead by rayman9076

...traxxas bulkhead by rayman9076

thingiverse

traxxas bulkhead part 2530

thingiverse

free

Traxxas skis by rbrutsky

...traxxas skis by rbrutsky

thingiverse

skis for 1/10 traxxas cars

thingiverse

free

traxxas Adapter

...traxxas adapter

thingiverse

use it for what you wish

thingiverse

free

traxxas slash arm by rayman9076

...traxxas slash arm by rayman9076

thingiverse

a-arm for a traxxas slash

thingiverse

free

Traxxas body mount

...traxxas body mount

thingiverse

replace part for traxxas 8215 - body mount.

higher version to raise up trx6 body

thingiverse

free

Traxxas Funnycar Exhaust by Uforic

...traxxas funnycar exhaust by uforic

thingiverse

this is a dummy exhaust for the traxxas funny car

thingiverse

free

Traxxas TRX6 stand

...traxxas trx6 stand

thingiverse

stable stand for traxxas trx6 mercedes-benz g63 6x6.

splitted into 12 patrs - easy to print.

thingiverse

free

Traxxas Shockstand 1/16 cars

...traxxas shockstand 1/16 cars

thingiverse

traxxas shockstand for traxxas 1/16 size shocks(10 mm shockbody)

Suspension

3ddd

free

Circolo Suspension

...circolo suspension

3ddd

circolo , suspension

this is the circolo led suspension

3d_export

$20

suspension

...pension

3dexport

suspension it is used in bicycle, motorcycle; and many more object<br>rendering is done in photo view 360

3ddd

$1

Fieltebek suspension

...fieltebek suspension

3ddd

fieltebek , suspension

fieltebek

3d_export

free

suspension

...suspension

3dexport

3ddd

$1

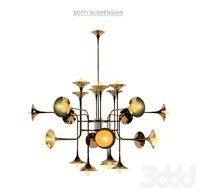

Botti Suspension

...botti suspension

3ddd

botti

люстра botti suspension

turbosquid

$25

suspension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

suspension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

SUSPENSION

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

DELIGHTFULL MATHENY | SUSPENSION

... matheny , suspension

delightfull matheny | suspension

design_connected

$16

Vaeder Suspension

...vaeder suspension

designconnected

modular lighting instruments vaeder suspension computer generated 3d model.

Rear

3d_export

$48

engine case rear

...re efficient as it eliminates the need for the propeller shaft while the differential merges with the transmission to save space.

turbosquid

$39

rear rim

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Rear Suspension 3D Model

... suspension 3d model

3dexport

rear suspension spring sport car disc brake chasis

rear suspension 3d model bayazoff 30675 3dexport

turbosquid

$20

Rear sport wheel

...del rear sport wheel for download as ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1227527)

turbosquid

$99

Rear tyre set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Wet Rear tyre

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Hard rear tyre

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Medium Rear tyre

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Supersoft Rear tyre

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

tractor rim rear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Arms

archibase_planet

free

Arm

...ase planet

arm hand right hand skeleton

arm human skeleton right arm n030515 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3ddd

$1

arm chair

...arm chair

3ddd

arm chair , пуф

arm chair

turbosquid

$5

arm

...arm

turbosquid

royalty free 3d model arm for download as obj on turbosquid: 3d models for games, architecture, videos. (1306158)

turbosquid

free

Arm

...arm

turbosquid

free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1346955)

turbosquid

$29

Arm

...osquid

royalty free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1382436)

3d_export

$5

coat of arms

...coat of arms

3dexport

coat of arms

3ddd

$1

ARM SOFA

...arm sofa

3ddd

arm sofa

3ddd

$1

Arm chair

...arm chair

3ddd

arm chair

3ddd

$1

Arm chair

...arm chair

3ddd

угловое

arm chair

3ddd

$1

ARM CHAIR

...arm chair

3ddd

arm chair clothes

Modified

turbosquid

$5

modify car

...bosquid

royalty free 3d model modify car for download as max on turbosquid: 3d models for games, architecture, videos. (1390511)

turbosquid

$35

Soleste modified

...e 3d model soleste modified for download as 3dm, stl, and jpg on turbosquid: 3d models for games, architecture, videos. (1646606)

turbosquid

$35

Screwdriver-Modified

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

APS modified

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Modified skull

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Maruti 800 Modified

...obile engineers. this concept will also helpful to modified car enthusiast. this is made in solidworks & rendered in keyshot.

3d_ocean

$5

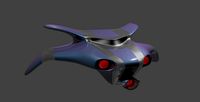

Spacecraft with Subdivision Modifier

...raft with subdivision modifier

3docean

fantasy spacecraft vehicle

the model was created in blender using the subdivision modifier

turbosquid

$10

Modified 9mm pistol

...royalty free 3d model modified 9mm pistol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560956)

3d_export

$10

ak-47 modified

...ak-47 modified

3dexport

turbosquid

$10

modified evo x

...ree 3d model modified evo x for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1461606)

Part

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)