Thingiverse

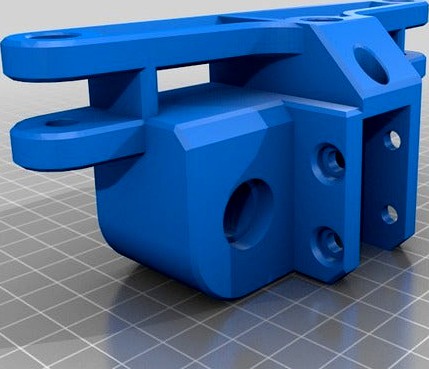

Tornado CR-10 Frame Brace Dual Z

by Thingiverse

Last crawled date: 4 years, 2 months ago

This is a full frame brace, & dual Z mod for Tevo Tornado, CR-10, and other variants. A few extra parts are needed : 2- leadscrew/shaft collar clamps, 2- 8mmx10mmx1mm washers for between the bearings and pulleys, 1- Smooth idler bearing for the belt tensioner(I used openbuilds), 8- M8 nuts & 4- 600mm M8 threaded rods(trim to fit, 5/16" also works fine), various M3, M4, & M5 screws/nuts & t-nuts, 5- 625-2RS bearings, 2- 600mm T8 2mm pitch 8mm lead leadscrews(trim to fit) I'm probably forgetting something else :)

This setup is a mashup of a few different mods edited to suit my needs. This is a VERY solid setup. a little tip : Take your time to line up the leadscrews and motor mount,and the Z axis wheels. These must be in PERFECT alignment & tension to stop Z banding/ringing. Also be sure to use the proper aluminum wheel spacers for the Gantry plates to keep proper alignment. This was based off a Creality printer first, so uses 8mm spacers(Original Tornado uses 7mm).

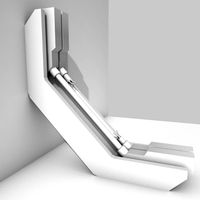

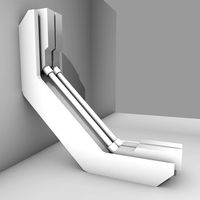

The "Frame_support" & "Frame_support_short" files are to stop the bottom frame from flexing between to rubber feet. The "short" file allows a 3mm thick piece of silicone sheet or 3mm printed TPU gasket to be installed between your table and the frame_support. This will help to stop external vibrations being transferred to the printer.

The "tie_rod" files have a bigger hole and smaller hole. The small hole version allows the threaded rods to thread into the tie rod. The big hole version allows the threaded rod to "slide" inside the tie rod, allowing tension adjustement of the frame brace. Use 1 of each type for each threaded rod. SuperGlue or Epoxy the M8 nuts into the BallNutM8 pieces.

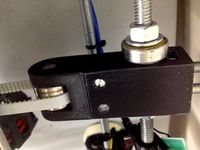

I use adjustable Z endstop for easy nozzle changes and nozzle height adjustments, so I included those files also. Epoxy the X_End_Stop_Nut into the X_End_Stop_Support. I'm not sure why the original designer left these pieces seperate, but Epoxy does the trick :)

Only 2 of these parts need to be printed with supports, Z_endstop_support_V2, and bearing_mount_625x2. Just be sure to put the proper face against the bed(sorry I'm too lazy to reorient the models :P)

This setup is a mashup of a few different mods edited to suit my needs. This is a VERY solid setup. a little tip : Take your time to line up the leadscrews and motor mount,and the Z axis wheels. These must be in PERFECT alignment & tension to stop Z banding/ringing. Also be sure to use the proper aluminum wheel spacers for the Gantry plates to keep proper alignment. This was based off a Creality printer first, so uses 8mm spacers(Original Tornado uses 7mm).

The "Frame_support" & "Frame_support_short" files are to stop the bottom frame from flexing between to rubber feet. The "short" file allows a 3mm thick piece of silicone sheet or 3mm printed TPU gasket to be installed between your table and the frame_support. This will help to stop external vibrations being transferred to the printer.

The "tie_rod" files have a bigger hole and smaller hole. The small hole version allows the threaded rods to thread into the tie rod. The big hole version allows the threaded rod to "slide" inside the tie rod, allowing tension adjustement of the frame brace. Use 1 of each type for each threaded rod. SuperGlue or Epoxy the M8 nuts into the BallNutM8 pieces.

I use adjustable Z endstop for easy nozzle changes and nozzle height adjustments, so I included those files also. Epoxy the X_End_Stop_Nut into the X_End_Stop_Support. I'm not sure why the original designer left these pieces seperate, but Epoxy does the trick :)

Only 2 of these parts need to be printed with supports, Z_endstop_support_V2, and bearing_mount_625x2. Just be sure to put the proper face against the bed(sorry I'm too lazy to reorient the models :P)

Similar models

thingiverse

free

Anet A8 Top Frame Brace by FredGenius

...nd nuts if you can't get hold of m8 in your area.

this goes well with my z sync mod:https://www.thingiverse.com/thing:2350350

thingiverse

free

Acrylic folgertech i3 clone diagonal front rod brace for rigidity by JamesCarpino

... needed are:

17.25" or 438-440mm.

you only need 3 nuts per side if using 5/16" rod because parts have internal threads.

thingiverse

free

Tarantula Z-Brace for 8mm threaded rod by Toxothrix

...ner braces. lower piece is unchanged.

works with 8mm or 5/16" threaded rod. 43cm per side. i've used 8 standard m8 nuts.

thingiverse

free

Anet A8 Z Axis CHUNK Reinforcement Top Mount & Z Motor Mount by TheWalkletts

...e job once the parts are printed.

top mounts take 1 x 608zz bearing each

join the two top mounts using m8 threaded rod & nuts

thingiverse

free

Belt Tensioner - Idle Pulley for Prusa Mendel I2 by Chris918

... old 608 bearing idler on the frame's threaded rod. it is acting as a washer on one side between the nut and the tensioner ;)

thingiverse

free

Tevo Tornado Lateral Frame Support by Markram94

...8 rod will be on the sides of the tornado so the z rod will not touched.

you need:

2 m8 rod

8 m8 nuts

8 m4x20 screws

8 t nuts m4

thingiverse

free

Z Stabilizer for Tornado/CR-10/... (608ZZ bearing) by cbaoth

...east on the tornado, these can't be used as bottom parts, since there are already screws in place holding the frame together.

thingiverse

free

TEVO Tornado and CR-10 belt driven dual Z mod with braces by PeroE30

...leys against top bearings) by gantry weight. the layers precision should be visibly improved.

if you have any questions just ask!

thingiverse

free

Graber I3 Y-Belt Tensioner by keinervonuns

...imple y-belt tensioner for graber i3.

parts list

608 skate bearing

m8 threaded rod or screw + nuts

m5 screw to adjust the tension

thingiverse

free

608 bearing to m4 threaded rod adapter by Antsurkov

...i use it with this z rod constraint for prevent z wobbing. http://www.thingiverse.com/thing:9864/

inner hole 4mm, outer size 8 mm

Tornado

3ddd

$1

диван Tornado

...диван tornado

3ddd

tornado

диван tornado

turbosquid

$20

Tornado

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

tornado

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$75

Tornado 3D Model

...tornado 3d model

3dexport

tornado low polygon

tornado 3d model mikemu 64260 3dexport

turbosquid

$20

Tornado Small

...yalty free 3d model tornado small for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1383489)

turbosquid

$100

Tornado GR4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tornado FumeFX

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Tornado

...

turbosquid

royalty free 3d model aletta for download as max on turbosquid: 3d models for games, architecture, videos. (1152155)

3d_export

$199

Tornado F3 3D Model

...tornado f3 3d model

3dexport

tornado f3 fighter aircraft airplane plane military

tornado f3 3d model drguz 67 3dexport

3d_ocean

$15

Panavia Tornado GR4

...t panavia plane soar tornado transport

low polygon and nicely detailed panavia tornado gr4 . check out my profile for more items!

Brace

archive3d

free

Bracing 3D Model

...

holder bracing strengthening

bracing 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...

bracing strengthening holder

bracing 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

brace PARIS

...osquid

royalty free 3d model brace paris for download as max on turbosquid: 3d models for games, architecture, videos. (1284415)

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Bracing 3D Model

...older fastening strengthening

bracing 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$20

Corner Brace Bracket

...oyalty free 3d model corner brace bracket for download as stl on turbosquid: 3d models for games, architecture, videos. (1322777)

turbosquid

$10

Craftsman Handtools - Brace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Degree Brace 4

...el degree brace 4 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205705)

turbosquid

$1

Degree Brace 3

...el degree brace 3 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205719)

turbosquid

$1

Degree Brace 2

...el degree brace 2 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205714)

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.