Thingiverse

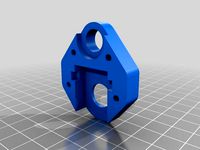

Threadless Ballscrew Nut (5 degree tilt for 16mm shaft) by palatis

by Thingiverse

Last crawled date: 3 years ago

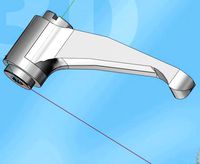

This is another design for threadless ballscrew nut.

The nut relies on friction of the shaft and bearings to grip, and move by turning the nut or the shaft.

You'll need:

M6 x 47mm screws x3

M6 x 20mm screw x1

M6 x 11mm x 1mm spacers x6

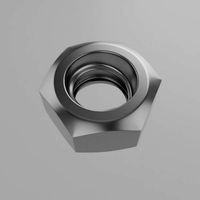

M6 nuts x3 (or x6 if you want to "lock" the nuts in place)

M6 square nut x1

626 bearings x6

You want to print 2 identical pieces and put the back-to-back, place the square nut in the slot for the adjustment screw, and screw the bearings and "tension adjustment screw" in.

To make spacers, I just pick up some M6 washers, secure a stack of them onto a M6 screw with nut, put them on a drill, and turn down the outer diameter with a grinder.

If you don't have a grinder, you can use some sandpaper to do the job.

You want the spacers to avoid the outer bearing ring (and maybe the sealing cap?) to grind against the printed ballscrew nut, and with some support under the bearing you can tighten the screws with greater force, thus better secure the nuts in place.

The 2 screw holes for the fixed bearings are a bit tight, you just tap them when you screw them in.

as a bonus, you can loosen the adjustment screws so you can slide the nut around the shaft, acts as a "quick release" like what you have on a lathe :-D

The tested nut

The nut I printed (shown in the picture) sustained my full body weight (approx 55kg), I can't get it to slip even I apply nearly my full weight onto it.

It's 5 degree tilt angle on a 16mm shaft, according to calculation it should travel about 4.397mm per revolution, with my (cheap Chinese) digital caliper it traveled around 4.66mm per revolution, I think the error is introduced by:

the play on the bearing

resolution of the printing (I'm printing with 0.2mm layer height on a Flashforge Creator Pro)

the cheap Chinese caliper... got it for like USD$15...... you can't really count on that.

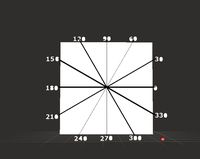

The math behind revolution and nut movement:

let the tilt angle of the ball bearing be ϴ

let the diameter of the shaft be D

the circumferences of the shaft be C = D x π

the movement of the nut after full revolution be H

given the angle ϴ and shaft diameter D

the movement of the nut per revolution is:H = tan(ϴ) x D x π

for example:

a 8mm shaft with 20 degree ball bearing angle will travelH= tan(20 degree) x 8mm * π ~= 0.364 x 8mm x 3.1415 ~= 9.147mm

after a full revolution.

a 8mm shaft with 10 degree ball bearing angle will travelH = tan(10 degree) x 8mm * π ~= 0.176 x 8mm x 3.1415 ~= 4.4315mm

after a full revolution.

a 16mm shaft with 10 degree ball bearing angle will travelH = tan(10 degree) x 16mm x π ~= 0.176 x 16mm x 3.1415 ~= 8.8631mm

after a full revolution.

given the shaft diameter D and desired travel distance H

the tilt angle of the ball bearing should beϴ = tan^-1(H / (D x π))

for example,

you want the nut to travel 4mm after a full revolution with a 16mm shaft, go forϴ = tan^-1(4 / (16 x π)) ~= tan^-1(0.00795) ~= 4.55 degree

The nut relies on friction of the shaft and bearings to grip, and move by turning the nut or the shaft.

You'll need:

M6 x 47mm screws x3

M6 x 20mm screw x1

M6 x 11mm x 1mm spacers x6

M6 nuts x3 (or x6 if you want to "lock" the nuts in place)

M6 square nut x1

626 bearings x6

You want to print 2 identical pieces and put the back-to-back, place the square nut in the slot for the adjustment screw, and screw the bearings and "tension adjustment screw" in.

To make spacers, I just pick up some M6 washers, secure a stack of them onto a M6 screw with nut, put them on a drill, and turn down the outer diameter with a grinder.

If you don't have a grinder, you can use some sandpaper to do the job.

You want the spacers to avoid the outer bearing ring (and maybe the sealing cap?) to grind against the printed ballscrew nut, and with some support under the bearing you can tighten the screws with greater force, thus better secure the nuts in place.

The 2 screw holes for the fixed bearings are a bit tight, you just tap them when you screw them in.

as a bonus, you can loosen the adjustment screws so you can slide the nut around the shaft, acts as a "quick release" like what you have on a lathe :-D

The tested nut

The nut I printed (shown in the picture) sustained my full body weight (approx 55kg), I can't get it to slip even I apply nearly my full weight onto it.

It's 5 degree tilt angle on a 16mm shaft, according to calculation it should travel about 4.397mm per revolution, with my (cheap Chinese) digital caliper it traveled around 4.66mm per revolution, I think the error is introduced by:

the play on the bearing

resolution of the printing (I'm printing with 0.2mm layer height on a Flashforge Creator Pro)

the cheap Chinese caliper... got it for like USD$15...... you can't really count on that.

The math behind revolution and nut movement:

let the tilt angle of the ball bearing be ϴ

let the diameter of the shaft be D

the circumferences of the shaft be C = D x π

the movement of the nut after full revolution be H

given the angle ϴ and shaft diameter D

the movement of the nut per revolution is:H = tan(ϴ) x D x π

for example:

a 8mm shaft with 20 degree ball bearing angle will travelH= tan(20 degree) x 8mm * π ~= 0.364 x 8mm x 3.1415 ~= 9.147mm

after a full revolution.

a 8mm shaft with 10 degree ball bearing angle will travelH = tan(10 degree) x 8mm * π ~= 0.176 x 8mm x 3.1415 ~= 4.4315mm

after a full revolution.

a 16mm shaft with 10 degree ball bearing angle will travelH = tan(10 degree) x 16mm x π ~= 0.176 x 16mm x 3.1415 ~= 8.8631mm

after a full revolution.

given the shaft diameter D and desired travel distance H

the tilt angle of the ball bearing should beϴ = tan^-1(H / (D x π))

for example,

you want the nut to travel 4mm after a full revolution with a 16mm shaft, go forϴ = tan^-1(4 / (16 x π)) ~= tan^-1(0.00795) ~= 4.55 degree

Similar models

thingiverse

free

Ball Screw Bed Mount & Top Bearing Mount (Old One) by mlbuxbaum

...r my hypercube. dual 16mm ballscrews instead of 8mm lead screws and guide rails. guide rails not required with these ball screws.

thingiverse

free

8mm bearing mount for 12mm Linear Rail support + 8mm Lead Screw by elufo

... x m3 nuts

bearings: 8mm inner, 16mm outer, 5mm thickness.

12mm linear shaft.

8mm lead screw.

nema 23 support + 10mm height base.

thingiverse

free

Ball thread for Machine Motion by ShuttleSpace

...'ve edited in orchard since it was so long.https://3dorchard.com/app/single/594d949b181a050bb3032964/5967cee7cb9d150cf298ed13

grabcad

free

Ball Bearing 16 x 8mm

...ball bearing 16 x 8mm

grabcad

ball bearing with 8mm inner diameter and 16mm outer diameter

grabcad

free

Rotating ballscrew nut assembly

...his if you want to use a ballscrew for large axis travel. own design. never tested, never used. but it may be helpfull to someone

thingiverse

free

CR-10 Spool Holder by jeeplvr

...if you want a 1/4 axle shaft

2ea. 608 bearings if you want an 8mm axle shaft

the axle slot in the holder is for a 1/4" shaft

thingiverse

free

Ball Screw assembly for RhinoPrinter by Rhinoprinter

... length machine screws

except bearing and ballscrew rest of the parts can be printed from abs, download the .stl files from here:

thingiverse

free

Dowel Jig by faris3474

...2x7

2x rod shaft 8mm length 75mm

1x screw hex m6 length 54mm

2x nut m6

1x washer m6

part print

quality 0.2

infill 20% or more

grabcad

free

Ball Screw

...llscrews, in contrast to traditional leadscrews, are typically substantial due to the need for a system to recirculate the balls.

thingiverse

free

Spool Holder with Bearings by Fire79

... you further need:

m6 screw

m6 nut

2 bearings 608

d8x60mm round steel for axis. for example an old linear guide with diameter 8mm

Threadless

3dfindit

free

Threadless Couplings

...threadless couplings

3dfind.it

catalog: abb installation products

3dfindit

free

Threadless Connectors - Nylon Insulated

...threadless connectors - nylon insulated

3dfind.it

catalog: abb installation products

3dfindit

free

Threadless Short Elbows - Nylon Insulated

...threadless short elbows - nylon insulated

3dfind.it

catalog: abb installation products

thingiverse

free

threadless M10 mixed nuts by L96sniperwolf

...threadless m10 mixed nuts by l96sniperwolf

thingiverse

i was messing with my 3d software and made this

3dfindit

free

S3131 Quick-release Coupling for Threadless Mounting

...s3131 quick-release coupling for threadless mounting

3dfind.it

catalog: wema

thingiverse

free

Y-ends for threadless ball screw. by jspark

...ot test yet.

the dimensions would be changed after the testing.

i'm now printing the parts.

i hope the results would not bad.

thingiverse

free

623 x 6mm Rod 10deg Threadless ball screw by natko

...verse

copy of msollack's "threadless ball screw. no more backlash"

but 623 bearings and 6mm rod, huxley sized ;)

thingiverse

free

Spiral Insert Threadless by vkalo

...gs concrete signs. added a light spiral to prevent it from coming loose. feel free to mix n match

dimensions 30mm height, od 15.9

thingiverse

free

Threadless ball screw Huxley X axis - Waiste of time - sorry by natko

...ed back

really drunk now

so peeps don't wast time with threadless ball screw unless threaded ..... my experience any way

thingiverse

free

bearing screw (no threadless, no ballscrew) by bigcnc

... axis

max speed 33mm/s

pitch 2.1

bearing 608z

threaded rod m12 (in testing real pitch measured is 2.1)http://youtu.be/b56dl4jdreu

Palatis

3d_export

$5

palaty bench-architect forms

...palaty bench-architect forms

3dexport

palaty bench/architect forms size: 100/35/25 size:200/40/30 design: palatystore

3d_ocean

$120

Doors Collection

...(3ds max 2010 for separate models) .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy obj...

3d_export

$15

wall wood boiserie paneling wallpaper

...atial, ornament, paneling, element, boiserie, wall, panel, wooden, wallpaper, pilasters, columns, cornice, plinth, molding, frame

3d_export

$15

wall wood boiserie paneling with wallpaper

...atial, ornament, paneling, element, boiserie, wall, panel, wooden, wallpaper, pilasters, columns, cornice, plinth, molding, frame

thingiverse

free

Gear cup by palatis

...gear cup by palatis

thingiverse

having fun with freecad :-d

can be used as a vase or pen holder or something like that.

thingiverse

free

Filament cleaner cap by palatis

...s the extruder!

should use some absorbent cotton which i just happends to not have at the moment, so used toilet paper instead.

thingiverse

free

Mjolnir (dual extrusion) by palatis

...=

emm... copied from http://www.thingiverse.com/thing:17637

sorry no relief, that's too difficult to be done in freecad.

thingiverse

free

snap-on filament cleaner by palatis

...filament when i just want to store them.

just snap the clip to the edge of the spool and you can put the spool back to the shelf.

thingiverse

free

Flashforge Creator X/Pro Filament Tube Holder remix by palatis

...ke.

i just replaced them with 2 60mm m3 screws...

add a little "horn-like" shape so it's easier to insert filament.

thingiverse

free

Cherry Key Cap by palatis

...e unknown-function lock key).

if you want some other labeled key, don't ask me to make them because i'll just ignore you.

Ballscrew

thingiverse

free

ballscrew by chiuyiming

...ballscrew by chiuyiming

thingiverse

ballscrew

thingiverse

free

DSG16 BallScrew Mount Block by Bahamuttg

...ightly smaller version of the dsg16h. it is the mount block for the ballscrew nut associated with the sfu1605 ballscrew assembly.

thingiverse

free

Bearing mount for 1605 ballscrew by Idegraaf

...bearing mount for 1605 ballscrew by idegraaf

thingiverse

bearing mount for 1605 ballscrew. bearing hole 26mm and 30mm.

thingiverse

free

grapa ballscrew eje X by sito_design

...llscrew eje x by sito_design

thingiverse

these staples are as my homemade cnc to join the mobile surfaces to each axis ballscrew

thingiverse

free

grapa ballscrew eje Y by sito_design

...llscrew eje y by sito_design

thingiverse

these staples are as my homemade cnc to join the mobile surfaces to each axis ballscrew

thingiverse

free

grapa ballscrew cnc eje Z by sito_design

...rew cnc eje z by sito_design

thingiverse

these staples are as my homemade cnc to join the mobile surfaces to each axis ballscrew

thingiverse

free

Cyrus V2 Spares; Ballscrew holder by Cyrus3D

...a spare part for the cyrus v2 printer, this spare is used holding the ballscrew and endstop

print it with minimum of 25% infill

thingiverse

free

ballscrew block holder 3030 by peanutwarrior

...m guide block to be mounted onto 3030 extrusion too lift the heatbed frame. you can buy the aluminium blocks cheap off aliexpress

thingiverse

free

Ballscrew 1605 End Support (Fixed Side) by Ezekeel

...1605 end support (fixed side) by ezekeel

thingiverse

china 1605 ballscrew end support for fixed side.

bearing: 7201 12x32x10 mm

thingiverse

free

Ballscrew

... print one of each part and extra cap.

openscad source: https://github.com/spegelius/3dmodels/blob/master/bearings/ballscrew.scad

16Mm

3d_export

$30

Parth ring2 16mm stl diamond price stl 3D Model

...arth ring2 16mm stl diamond price stl 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 105374 3dexport

3d_export

$10

Korona 3D Model

...korona 3d model 3dexport parth ring2 16mm stl diamond price korona 3d model download .c4d .max...

3d_export

$25

Film Reels 3D Model

...hollywood theater theatre reels realistic c4d 35mm movie spool 16mm cinema 3ds strip filmstrip celluloid vintage retro film reels...

3d_export

$30

Film reel 3D Model

...oscar academy awards projector camera spool theatre cinema imax 16mm 35mm hollywood movie panavision motion picture frames images film...

3d_export

$5

Computer desk

...top: width - 1544mm length - 1344mm thickness - 16mm bedside table for the system unit: width - 510mm...

3d_export

$5

Cartouche-016

...carving on cnc machines length: 336mm width: 106mm height: 16mm ...

3d_ocean

$5

Realistic Film Reel

...realistic film reel 3docean 16mm 35mm 3d model 3ds camera can celluloid cinema film...

3d_export

$14

Brazier 1105 - v2

...550 mm - thickness - 2,5mm - diameter - 16mm ...

3d_export

$7

ring of blades

...game dark souls.<br>there are 24 models in the archive.<br>ring diameter:<br>16mm 17mm 18mm 19mm 20mm 21mm 22mm 23mm<br>in the archive...

3d_export

$10

carved art nouveau

...(l * h * d): 563 x 70 x 16mmlt;br>* polys: 56 422<br>* .stl file included<br>3d model of modern...

Tilt

3ddd

free

TILT

...tilt

3ddd

tilt

http://www.graypants.com

tilt

gp-133 -size: o: 46cm | h: 35cm.

3ddd

$1

TILT

...tilt

3ddd

kenneth cobonpue

http://www.kennethcobonpue.com/collection/view/44/tilt

design_connected

$9

Tilt

...signconnected

photo-realistic 3d models of the tilt shelves from bonaldo for 3d architectural and interior design presentations.

turbosquid

$7

Tilt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Urban electric Tilt

...urban electric tilt

3ddd

urban electric , tilt

urban electric tilt

design_connected

free

Tilt 70

...tilt 70

designconnected

free 3d model of tilt 70 by nc möbler designed by andersson, peter.

3d_export

$5

tilt door knob

...tilt door knob

3dexport

tilt door knob

turbosquid

$65

Tilt scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Tilted Cross

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

tilt shape door knob

...tilt shape door knob

3dexport

tilt shape door knob

Shaft

3d_export

$5

shaft handle

...shaft handle

3dexport

shaft handle

3d_export

$5

shaft bracket

...shaft bracket

3dexport

shaft bracket

turbosquid

$3

Shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

crank shaft

...crank shaft

3dexport

crank shaft with piston with different materials

3d_export

$8

shaft bearing

...shaft bearing

3dexport

shaft bearing m10, m12,m16, m20 and m27

3d_export

$5

hexagonal shaft knob

...hexagonal shaft knob

3dexport

hexagonal shaft knob

3d_export

$5

shaft hand wheel

...shaft hand wheel

3dexport

shaft hand wheel

3d_export

$5

triangular shaft knob

...triangular shaft knob

3dexport

triangular shaft knob

3d_export

$5

octagonal shaft knob

...octagonal shaft knob

3dexport

octagonal shaft knob

Degree

design_connected

$13

Degree

...degree

designconnected

kristalia degree computer generated 3d model. designed by norguet, patrick.

3ddd

$1

Kristalia Degree

... kristalia , круглый

http://degree.kristalia.it/

turbosquid

$2

Degree Brace 4

...el degree brace 4 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205705)

turbosquid

$1

Degree Brace 3

...el degree brace 3 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205719)

turbosquid

$1

Degree Brace 2

...el degree brace 2 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205714)

turbosquid

$1

Degree Brace 1

...el degree brace 1 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205710)

design_connected

$13

30 Degrees Pendant L

...30 degrees pendant l

designconnected

hay 30 degrees pendant l computer generated 3d model. designed by van hengel, johan.

turbosquid

free

30 degrees Tridimensional grid

...free 3d model 30 degrees tridimensional grid for download as on turbosquid: 3d models for games, architecture, videos. (1383401)

turbosquid

$27

45 Degree Pipe Connection

...e connection for download as c4d, 3ds, stl, obj, wrl, and fbx on turbosquid: 3d models for games, architecture, videos. (1687847)

turbosquid

$8

Norway flag on 25 degree pole

...ee 3d model norway flag on 25 degree pole for download as c4d on turbosquid: 3d models for games, architecture, videos. (1158107)

Nut

3d_export

free

nut

...nut

3dexport

low poly

turbosquid

$13

Nut

...

royalty free 3d model nut for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1227126)

turbosquid

$12

nut

...

royalty free 3d model nut for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1175191)

3d_export

$5

nut handle

...nut handle

3dexport

nut handle

3d_export

$5

nut anchor

...nut anchor

3dexport

nut anchor

3d_export

$5

wing nut

...wing nut

3dexport

wing nut

3d_export

$5

butterfly nut

...butterfly nut

3dexport

butterfly nut

3d_export

$5

special nut

...special nut

3dexport

special nut

3d_export

$5

nut hook

...nut hook

3dexport

nut hook

3d_export

$5

nut ring

...nut ring

3dexport

nut ring

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.