Thingiverse

Threaded Tubes by booktinker

by Thingiverse

Last crawled date: 3 years ago

While working on an ambitious but unfinished design, that I decided not to submit for the Makerbot giveaway contest, I came up with a way to pretension tubes based upon the idea that was raised in Forest Higgs' blog entry demonstrating that pretensioned square tubes can take a relatively large sideways load.

http://technocraticanarchist.blogspot.com/2010/03/some-crude-load-tests.html

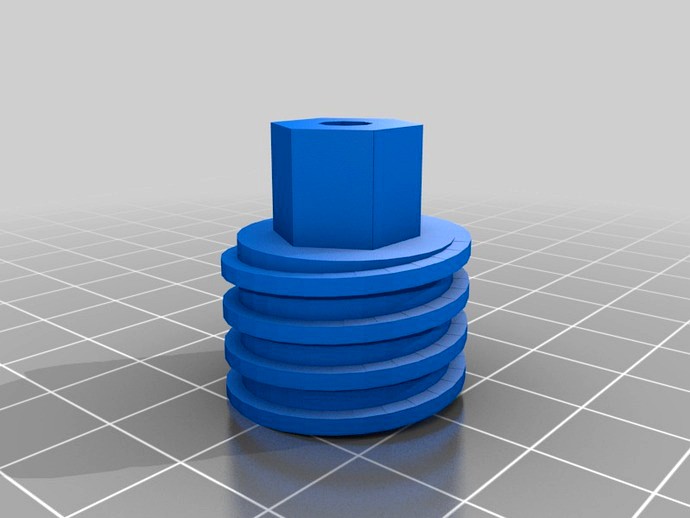

My idea involves internally threading the tubes. A setscrew with a hole through the center would be used to tension a cable or wire that is fed and tied off through the hole, thereby holding several tube sections together.

I have provided a square and round tube and two different types of setscrews. One is just a regular setscrew (tubescrew.scad). The other variation (capturednut.scad) involves two nested screws where the bottom nut is “captured†by the top screw when it is screwed upward through the tube. A gap exists between the screws when it is being advanced up the tube. When stationary, if tension or twist of the wire causes the top nut to screw back down, it will simply back up against the bottom screw after it rotates a quarter turn. (That's the theory at least.)

Both types of setscrews have a fifteen millimeter hex head to allows a deep throat socket with an extension arm fed down the tube to allow tightening. To help allow the screw to rotate independently of the wire, I would suggest using two plastic washers (PTFE, delrin?) between the knot of the wire and the setscrew.

I made my own script to create a screw since linear_extrude didn't yield favorable results for me. The downside is that rendering the screw takes quite a long time i.e. five minutes for the shorter tubescrew.scad.

When they didn't cause openscad to crash, rendering the tube sections took five hours (two hours running in Ubuntu)! I finally created an stl of a threads (cutthreads.stl) that I could use repeatedly to create the threading in the tubes. Once the initial three hour render of the plug was completed and exported, I used import_stl to replace the original makescrew module that took so long. Using difference to subtract the plug from the tube yielded quick results. The render then only took around a minute. I would appreciate any insights into optimization of the makescrew script.

Will the threads print? Will the nested set screws work? I am curious to see someone try printing these out. Whether they print or not is really just a curiosity since my main reason to post this is to try to further the effort of Reprap to print even more of its parts.

By the way, I used version 2010.05.10. There seems to be some difference in how includes are handled between the 2010.02 and this version. Also, I included Catarina Mota's shapes.scad script just in case you don't already have it.

http://technocraticanarchist.blogspot.com/2010/03/some-crude-load-tests.html

My idea involves internally threading the tubes. A setscrew with a hole through the center would be used to tension a cable or wire that is fed and tied off through the hole, thereby holding several tube sections together.

I have provided a square and round tube and two different types of setscrews. One is just a regular setscrew (tubescrew.scad). The other variation (capturednut.scad) involves two nested screws where the bottom nut is “captured†by the top screw when it is screwed upward through the tube. A gap exists between the screws when it is being advanced up the tube. When stationary, if tension or twist of the wire causes the top nut to screw back down, it will simply back up against the bottom screw after it rotates a quarter turn. (That's the theory at least.)

Both types of setscrews have a fifteen millimeter hex head to allows a deep throat socket with an extension arm fed down the tube to allow tightening. To help allow the screw to rotate independently of the wire, I would suggest using two plastic washers (PTFE, delrin?) between the knot of the wire and the setscrew.

I made my own script to create a screw since linear_extrude didn't yield favorable results for me. The downside is that rendering the screw takes quite a long time i.e. five minutes for the shorter tubescrew.scad.

When they didn't cause openscad to crash, rendering the tube sections took five hours (two hours running in Ubuntu)! I finally created an stl of a threads (cutthreads.stl) that I could use repeatedly to create the threading in the tubes. Once the initial three hour render of the plug was completed and exported, I used import_stl to replace the original makescrew module that took so long. Using difference to subtract the plug from the tube yielded quick results. The render then only took around a minute. I would appreciate any insights into optimization of the makescrew script.

Will the threads print? Will the nested set screws work? I am curious to see someone try printing these out. Whether they print or not is really just a curiosity since my main reason to post this is to try to further the effort of Reprap to print even more of its parts.

By the way, I used version 2010.05.10. There seems to be some difference in how includes are handled between the 2010.02 and this version. Also, I included Catarina Mota's shapes.scad script just in case you don't already have it.

Similar models

thingiverse

free

Mendel90 Y-belt Tensioner by bsbmx

...two-piece design that allows for tensioning of the y-belt similar to how the x-belt is tensioned. the existing bearings,...

thingiverse

free

RC plane firewall by bifi5590

...through the side holes.

i highly recommend printing this in abs because the pla version of this deformes when the motor gets hot.

thingiverse

free

Customizable Screw-to-Screw Connector by SpoonUnit

...e final printed object with it's intended use.

incidentally, the default values selected fit two uk colgate toothpaste tubes.

thingiverse

free

Quadcopter Cross Brace by voyager1713

...signed to be easily printed on a makerbot. i'm open to suggestions or ideas on improving the design. current model is ver4.

thingiverse

free

Fuse holder by boeingdude1

...ter fuses. i used an 8 gauge wire and fed it through the screw holes to the clips. the wires are the direct contacts to the fuse.

thingiverse

free

Threaded Tube by mphardy

...and tube and reduced the number of threads in the tube... now a 150mm tube + connector at 2 shells and 100% infill stands at 14g.

thingiverse

free

Flexible Filament Extruder Upgrade Threaded for Boden Tube Connectiion by ConfuseAcatLTD

...nkercad and added a thread to the hole that the boden tube connector screws into.

worked great and the boden tube stays in place.

thingiverse

free

MicroSafe (MicroSD Cardholder) by WillShelley

...

it took 8 hours to print all three components.

would love some pointers if anyone has any!

enjoy!

https://youtu.be/7jgnqouux8y

thingiverse

free

M3D Micro filament tube fitting clip by MrDanielGerber

...ent feed to be fed through a ptfe tube. two m2.5x6 socket head screws is needed in additional. should be easy to source via ebay.

thingiverse

free

M.B. Crystal Chamber v2. by joeymeckels

...en to show one wire. this unit has a threaded area and a threaded tube to allow the hilt to be split and screwed together. enjoy.

Booktinker

thingiverse

free

Coverplate Generator by booktinker

...ed to double check the measurements before you print.

it could also be easily adapted to work for ethernet, coax, telephone, etc.

thingiverse

free

Nintendo Switchplate by Fourofakind

...pasted some pieces onto a different switch plate by booktinker as well as creating some myself. i'm really new...

thingiverse

free

IPhone by Coin-op Tube by shivinteger

...[1] thing url : http://www.thingiverse.com/thing:3191 [1] thing author : booktinker [1] thing licence : gnu - gpl [2] thing...

Tubes

archibase_planet

free

Tube

...tube

archibase planet

paint tube stationery

tube - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

tube

...tube

turbosquid

free 3d model tube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1378271)

archibase_planet

free

Tube

...tube

archibase planet

mascara cosmetics make-up

tube 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Tube pants

...tube pants

3dexport

tube pants

3d_export

free

Tube

...tube

3dexport

turbosquid

free

TUBE

...

free 3d model tube for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672199)

turbosquid

$29

tube

...lty free 3d model tube for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442047)

3ddd

$1

perfume tube

...perfume tube

3ddd

тюбик

perfume tube, тюбик

3ddd

$1

Olivieri Tube

...olivieri tube

3ddd

olivieri

кровать olivieri tube

turbosquid

$22

Tube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Threaded

3d_export

$5

threaded handle

...threaded handle

3dexport

threaded handle

turbosquid

free

threaded

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Tangle of thread

... tangle thread triangles – 36 in one strand in scene 300 thread includes materials includes 3 colors tangle thread in psd for ...

3d_export

$5

threaded lock handle

...threaded lock handle

3dexport

threaded lock handle

3d_export

$5

threaded machine handle

...threaded machine handle

3dexport

threaded machine handle

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

3d_export

$5

threaded rope ring

...threaded rope ring

3dexport

threaded rope ring

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Thread Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.