Thingiverse

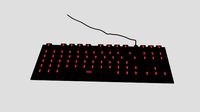

The Vampa - A 60% Stacked Acrylic Keyboard Case by BeagleChristo

by Thingiverse

Last crawled date: 3 years, 4 months ago

These are .svg files for a laser-cut 60% stacked acrylic keyboard case. The width and length of the case are 295.902mm and 105.402mm.

Several different variations can be cut from these files: (1) a high profile case with acrylic foot; (2) a high profile case with aluminum feet; (3) a low profile case with acrylic foot; and (4) a low profile case with aluminum feet.

High profile case with acrylic foot:

You will need at least ten 3mm-thick acrylic boards, twelve m2 x 25 screws (for the case), three m2 x 15 screws (for the foot), fifteen m2 lock nuts, and four adhesive rubber/silicone feet.

Print Layers 1-8, Layer 9(b), and Acrylic Foot.

High profile case with aluminum feet:

You will need at least nine 3mm-thick acrylic boards, twelve m2 x 25 screws, twelve m2 lock nuts, two aluminum feet (which usually include the necessary m3 screws), and two adhesive rubber/silicone feet.

Print Layers 1-8 and Layer 9(a).

Low profile case with acrylic foot:

You will need at least seven 3mm-thick acrylic boards, twelve m2 x 18 screws (for the case), three m2 x 15 screws (for the foot), fifteen m2 lock nuts, and four adhesive rubber/silicone feet.

Print Layers 4-8, Layer 9(b), and Acrylic Foot.

Low profile case with aluminum feet:

You will need at least seven 3mm-thick acrylic boards, twelve m2 x 18 screws, twelve m2 lock nuts, two aluminum feet (which usually include the necessary m3 screws), and two adhesive rubber/silicone feet.

Print Layers 4-8 and Layer 9(a).

The case is designed around the JM60S PCB. I settled on this PCB because it (1) allows for PCB-mounted stabilizers, which are necessary for plates of over 1.5mm (an alternate solution would be to design a plate that allows the switches and plate-mounted stabs to clip in); (2) is relatively inexpensive; and (3) is programmable.

The case is also designed around the use of 200 x 300 x 3mm, 300 x 300 x 3mm, or 300 x 400 x 4mm acrylic boards, which are relatively cheap and easy to source. The advantage of 300 x 300 x 3mm boards is that two layers can be cut from a single board, and the advantage of 300 x 400 x 3mm boards is that three layers can be cut from a single board.

I used the SwillKB plate builder to create the files and Inkscape to widen the stab cutouts and add holes for the feet. (I couldn't figure out how to cut polygons directly in SwillKB.) For those who want to modify the case, I used the following SwillKB parameters: Plate Layout = Default 60; Switch Type = Square MX; Stabilizer Type = Cherry Only; Case Type = Sandwich; USB Cutout = On; USB Cutout Location = -124.3; USB Cutout Width = 15; Mount Holes = 12; Mount Hole Diameter = 2.1; Mount Hole Edge Width = 5; Edge Padding = On; Top Padding = 5; Left Padding = 5; Right Padding = 5; Bottom Padding = 5; Plate Corners = On; Plate Corner Radius = 2.5; Kerf = 0.15.

MATERIALS SOURCING:

JM60S PCB:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=565005570287&_u=120rh52k2c4d

Acrylic Plates:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=561968534256&_u=120rh52kaed8

https://foxloveyou.world.taobao.com/search.htm?spm=2013.1.w5002-15935403892.1.2421777ePEAXoz&search=y

https://item.taobao.com/item.htm?spm=a1z0d.6639537.1997196601.151.59405886XQvpFF&id=534712487203

Aluminum Feet:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=564514011189&_u=120rh52k5f33

Several different variations can be cut from these files: (1) a high profile case with acrylic foot; (2) a high profile case with aluminum feet; (3) a low profile case with acrylic foot; and (4) a low profile case with aluminum feet.

High profile case with acrylic foot:

You will need at least ten 3mm-thick acrylic boards, twelve m2 x 25 screws (for the case), three m2 x 15 screws (for the foot), fifteen m2 lock nuts, and four adhesive rubber/silicone feet.

Print Layers 1-8, Layer 9(b), and Acrylic Foot.

High profile case with aluminum feet:

You will need at least nine 3mm-thick acrylic boards, twelve m2 x 25 screws, twelve m2 lock nuts, two aluminum feet (which usually include the necessary m3 screws), and two adhesive rubber/silicone feet.

Print Layers 1-8 and Layer 9(a).

Low profile case with acrylic foot:

You will need at least seven 3mm-thick acrylic boards, twelve m2 x 18 screws (for the case), three m2 x 15 screws (for the foot), fifteen m2 lock nuts, and four adhesive rubber/silicone feet.

Print Layers 4-8, Layer 9(b), and Acrylic Foot.

Low profile case with aluminum feet:

You will need at least seven 3mm-thick acrylic boards, twelve m2 x 18 screws, twelve m2 lock nuts, two aluminum feet (which usually include the necessary m3 screws), and two adhesive rubber/silicone feet.

Print Layers 4-8 and Layer 9(a).

The case is designed around the JM60S PCB. I settled on this PCB because it (1) allows for PCB-mounted stabilizers, which are necessary for plates of over 1.5mm (an alternate solution would be to design a plate that allows the switches and plate-mounted stabs to clip in); (2) is relatively inexpensive; and (3) is programmable.

The case is also designed around the use of 200 x 300 x 3mm, 300 x 300 x 3mm, or 300 x 400 x 4mm acrylic boards, which are relatively cheap and easy to source. The advantage of 300 x 300 x 3mm boards is that two layers can be cut from a single board, and the advantage of 300 x 400 x 3mm boards is that three layers can be cut from a single board.

I used the SwillKB plate builder to create the files and Inkscape to widen the stab cutouts and add holes for the feet. (I couldn't figure out how to cut polygons directly in SwillKB.) For those who want to modify the case, I used the following SwillKB parameters: Plate Layout = Default 60; Switch Type = Square MX; Stabilizer Type = Cherry Only; Case Type = Sandwich; USB Cutout = On; USB Cutout Location = -124.3; USB Cutout Width = 15; Mount Holes = 12; Mount Hole Diameter = 2.1; Mount Hole Edge Width = 5; Edge Padding = On; Top Padding = 5; Left Padding = 5; Right Padding = 5; Bottom Padding = 5; Plate Corners = On; Plate Corner Radius = 2.5; Kerf = 0.15.

MATERIALS SOURCING:

JM60S PCB:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=565005570287&_u=120rh52k2c4d

Acrylic Plates:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=561968534256&_u=120rh52kaed8

https://foxloveyou.world.taobao.com/search.htm?spm=2013.1.w5002-15935403892.1.2421777ePEAXoz&search=y

https://item.taobao.com/item.htm?spm=a1z0d.6639537.1997196601.151.59405886XQvpFF&id=534712487203

Aluminum Feet:https://item.taobao.com/item.htm?spm=a1z09.2.0.0.5ebc2e8dDe2NQ7&id=564514011189&_u=120rh52k5f33

Similar models

thingiverse

free

LED camp lamp by crota

...;_u=f27f148g9042

battery protectorhttps://item.taobao.com/item.htm?spm=a1z09.2.0.0.ly2j7b&id=531777228256&_u=f27f148g3456

thingiverse

free

Brushed drone 1020 motors FPV gen2 by Kargin_Makeit

...tem.htm?spm=a1z09.2.0.0.60b12e8dylmqn1&id=535566048449&_u=j289q3v7e925

diy controller and receiver:https://bit.ly/3bps7on

thingiverse

free

Micro quadcopter by CliffCliff

...motorshttps://item.taobao.com/item.htm?spm=a312a.7700838.0.0.pwyc5t&id=543240694980&_u=bce5bac6bcf it is designed to fit for micro camera similar to this...

grabcad

free

Ink bottle UV printer 1.5L direct float sensor, mixer.

...sensor, mixer.

grabcad

https://item.taobao.com/item.htm?spm=a1z09.2.0.0.d00c2e8d6dm07f&id=566506986544&_u=8207snbp5i555b

grabcad

free

Holder for batteries

...ttery-cell-3-7v-50ah-1

https://item.taobao.com/item.htm?spm=a1z09.2.0.0.17922e8dygmlfq&id=607720869759&_u=e207snbp5i472e

thingiverse

free

3D print photography light 55w by swanglei

...d the screws you will need

m6_50mm screws 2pics

m6 muts 2pics

m3_8mm screws 16pics

6mm rods l:110mm 4pics

cults

free

3D print photography light 55w

...;amp;_u=965kgh6a4b3

and the screws you will need

m6_50mm screws 2pics

m6 muts 2pics

m3_8mm screws 16pics

6mm rods l:110mm 4pics

thingiverse

free

Roller carriage stabilizer for Kossel 800 by jian

...162.y0xrcd&id=38749624507&_u=djifelu29e8

but longer (30mm) m6 screws are used.

-- remove support structures before using.

thingiverse

free

The YC66 Special (Bottom Mount Version) by BeagleChristo

...t bottom of case.

add case foam to bottom of tray.

sound tests:https://soundcloud.com/ogerrbogast/sets/typing-on-the-yc66-special

3dwarehouse

free

vodafone

...vodafone

3dwarehouse

http://item.taobao.com/item.htm?spm=a1z0d.1.1000638.89.qtolgu&id=13486128270

Vampa

cg_trader

$8

Bah - Broly - Dragon Ball | 3D

...3d print model bah - broly - dragon ball vampa animal bah, available in stl, ready for 3d animation...

cg_trader

$40

Horse ring | 3D

...jewel jewellery jewelry nature rhino ring silver zbrush art vampa printable engagem bridle diamond rings jewelry rings diamond...

cg_trader

$35

Mountain sheep ram pendant | 3D

...illegal jewelry nature silver ram goat mutton zodiac horoscope vampa muflon pets horn hoof wool animal barnyard zoo pendant...

Beaglechristo

thingiverse

free

The Mercédès - A Cherry MX-Style Beagle Switch Tester by BeagleChristo

... mx-style beagle switch tester by beaglechristo

thingiverse

this is a switch tester that can hold four cherry mx-style switches.

thingiverse

free

Low-Profile YC66 Foot by BeagleChristo

... is designed to fit a low-profile yc66 that is approximately 12.3 mm thick, so if your model is equivalent, the foot should work.

thingiverse

free

Mechanical Keyboard Spacer for 2011 MacBook Air by BeagleChristo

...ed this solution with my 2011 macbook air. i'm not sure whether it will work with other macbooks or other notebook computers.

thingiverse

free

The YC66 Special - Gasket Mount, Thin Bezel Version by BeagleChristo

...added an alternate version of the top layer that incorporates a blocker to cover the exposed top-right portion of the yc66 plate.

thingiverse

free

The Spada - A Bauhaus 60% Keyboard Case (Modified Tray or Ring Gasket Mount) by BeagleChristo

...auhaus school logo" by ktronik. many thanks to ktronik.

update sept. 7, 2020: added remarks regarding ring gasket mounting.

thingiverse

free

The YC66 Special (Bottom Mount Version) by BeagleChristo

...t bottom of case.

add case foam to bottom of tray.

sound tests:https://soundcloud.com/ogerrbogast/sets/typing-on-the-yc66-special

thingiverse

free

Thick Plate Model for Standard 60% Tray-Mount Keyboard Builds With PCB-Mounted Stabilizers by BeagleChristo

...s; and tinkercad to convert the .svg file to .stl format. (i couldn't figure out how to cut polygons using swillkb directly.)

thingiverse

free

The Herbault - A Sculpted 60% Modified-Tray-Mount Keyboard Case by BeagleChristo

... please note that i have not yet printed this model out, so cannot give any assurances about whether it is feasible or practical.

thingiverse

free

"Subtraction" Block for Use in the Design of 60% Keyboard Cases by BeagleChristo

... "subtraction" model for the usb port. if there is a need for those features, i will post another model on thingiverse.

thingiverse

free

The Faria - A Sculpted 60% Modified-Tray-Mount Keyboard Case by BeagleChristo

... please note that i have not yet printed this model out, so cannot give any assurances about whether it is feasible or practical.

Keyboard

3d_ocean

$9

Keyboard

...odels computer electronics keyboard peripheral / part

computer keyboard 3d models. it’s computer keyboard. render ready keyboard.

archibase_planet

free

Keyboard

...keyboard

archibase planet

input keyboard keyboard office equipment

pro keyboard - 3d model for interior 3d visualization

3d_export

$5

keyboard

...keyboard

3dexport

computer keyboard

3d_export

$11

Keyboard

...keyboard

3dexport

gaming keyboard with backlight 1:1

3d_export

free

keyboard

...keyboard

3dexport

keyboard blender stl obj fbx

archibase_planet

free

Keyboard

...keyboard

archibase planet

keyboard pc equipment

keyboard apple n130315 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

keyboard gaming

...keyboard gaming

3dexport

keyboard gaming include: 1 x keyboard gaming.blend 3 x keyboard gaming.png

archibase_planet

free

Keyboard

...keyboard

archibase planet

keyboar pc equipment

keyboard - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$9

keyboard USB

...models computer electronics keyboard peripheral / part

keyboard for computer 3d models. high detailed model of computer keyboard.

turbosquid

$24

Keyboard

...urbosquid

royalty free 3d model keyboard for download as max on turbosquid: 3d models for games, architecture, videos. (1710291)

Acrylic

turbosquid

$15

Acrylic Lectern For The Chruch - Podium Acrylic

...the chruch - podium acrylic for download as skp, obj, and 3ds on turbosquid: 3d models for games, architecture, videos. (1642137)

3ddd

free

Acrylic bathtub

...acrylic bathtub

3ddd

ванна

acrylic bathtub. size 170x110 cm

turbosquid

$24

Acrylic Stool

...3d model acrylic stool for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1311388)

turbosquid

$9

Acrylic Tables

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Acrylic Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Acrylic Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Table acrylic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Acrylic bath

... empire. originally created in 3ds max 2021 and v-ray next. materials v-ray mtl rubber; chromium; acrylic. modifiers: turbosmooth

3ddd

$1

Acrylic GM

...acrylic gm

3ddd

вентилятор

model is available in retail fanstar

3d_export

$17

Acrylic Chair 3D Model

...acrylic chair 3d model

3dexport

chair furniture acrylic

acrylic chair 3d model shalasaska 7623 3dexport

Stacked

3d_ocean

$12

Box Stacks

...n

barrel box box stack shards

this is model of box stack with texture that equipped with its shards around the box to add detail.

3ddd

$1

Triptych Stacks

...sa

triptych stacks

современный светильникhttp://curiousaandcuriousa.co.uk/index.php/home/chandeliers1/hayward-gallery1

3ddd

$1

Stacking D

...stacking d

3ddd

leucos

stacking

manufacturer leucos

designer rockwell group

3d_ocean

$5

Stack of Dollars

... realistic stack

ready to render! textured photorealistic dollars are animated. stack of dollars are falling down over and over…

3d_export

$5

dollar stack

...dollar stack

3dexport

turbosquid

$16

Stack of Wood

...quid

royalty free 3d model stack of wood for download as max on turbosquid: 3d models for games, architecture, videos. (1360320)

3d_ocean

$5

Money Stacks

... formats: c4d (textured) – obj (untextured) texture type: standard engine materials poly count per stack: 120 important: this ...

turbosquid

$5

stack machine

...lty free 3d model stack machine for download as ige and sldas on turbosquid: 3d models for games, architecture, videos. (1226834)

turbosquid

$19

Stack of Barrels

...3d model stack of barrels for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1472525)

turbosquid

$6

Brick Stack

...y free 3d model brick stack for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1239828)

60

3ddd

free

Life 60-60

...life 60-60

3ddd

life , часы

автор модели; aeroslon

design_connected

$29

60

...60

designconnected

restoration hardware 60" kensington leather sofa computer generated 3d model.

turbosquid

$1

60

...60

turbosquid

royalty free 3d model 60 for download as stl on turbosquid: 3d models for games, architecture, videos. (1158799)

3ddd

$1

ARKEL 60

...arkel 60

3ddd

arkel , круглый

arkel диаметр 60

design_connected

$13

60-0270

...60-0270

designconnected

christopher guy 60-0270 computer generated 3d model.

3ddd

$1

Pillows 60

...pillows 60

3ddd

подушка

pillows 60. i hope you like it. thank you !

design_connected

$13

Stool 60

...stool 60

designconnected

artek stool 60 computer generated 3d model. designed by aalto, alvar.

design_connected

$11

Mac 60

...mac 60

designconnected

linbrasil mac 60 computer generated 3d model. designed by rodrigues, sergio.

design_connected

$16

60-0246

...60-0246

designconnected

christopher guy 60-0246 armchairs computer generated 3d model. designed by n/a.

3ddd

$1

Pillows 60

...pillows 60

3ddd

подушка

pillows 60

new pillows .i hope you like it .thank you .

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.