GrabCAD

The Orbiter" 140g direct dual drive Extruder with 10 kg pushing force

by GrabCAD

Last crawled date: 3 years, 5 months ago

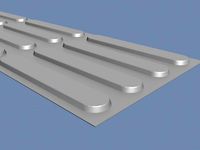

Hi everyone! This is my latest design, a high precision direct extruder using a planetary gearbox plus the big (12mm diameter) dual drive bondtech style gear-set.

Short spek:

Gear ratio - 7.5 and 7.2

Filament pushing force 120Ncm (max theoretical) - 12.4 Kg (Wantai stepper)

Filament pushing force 103Ncm (max. theoretical) - 10.5 Kg (LDO stepper)

Filament acceleration up to 660mm/s^2

Retraction speed: 60mm/s

Overall weight is about 140g

The extruder is driven by a small round nema 14 stepper.

The orbiter printing @ 200mm/s on my MachCube 2.1:

https://youtu.be/aZolOWtBbME

In the last months I have experimented with worm gear based extruders with very good results, however not perfect so I decided to go for a different approach.

What I have learned is that the worm gears are not the best choice for extruders. Although high gear ratio gives a good theoretical filament pushing force in reality this is not always true, mainly because the worm gear efficiency is pretty low.

The plastic printed gears are even worse, at high torque their efficiency is well below 50%. The plastic worm gears tooth's are bending a little causing pressure variation in the nozzle which leads to some tiny wavy artifacts on the printed surface.

20-30:1 gear ratio reduces a lot this effect but the stepper will not be able to provide decent filament acceleration slowing your printed drastically down because it has to wait for the extrusion (this is the case for the Zesty Nimble, the flex3drive drive with Nema8 and my previous worm gear based extruders as well, acceleration below 100mm/s^2).

Because of the above arguments I decided to go with a different approach, using a planetary gearbox (efficiency over 96%). In the same time I have changed from the small dual hubs (5mm) to the bigger ones (8mm) because the depth to which the hub tooth bites in the filament is more constant over different materials. More teeths comes in touch with the filament. There is a slightly better grip on the filament resulting a more accurate extrusion. On the downside the bigger hubs ad more weight.

Short spek:

Gear ratio - 7.5 and 7.2

Filament pushing force 120Ncm (max theoretical) - 12.4 Kg (Wantai stepper)

Filament pushing force 103Ncm (max. theoretical) - 10.5 Kg (LDO stepper)

Filament acceleration up to 660mm/s^2

Retraction speed: 60mm/s

Overall weight is about 140g

The extruder is driven by a small round nema 14 stepper.

The orbiter printing @ 200mm/s on my MachCube 2.1:

https://youtu.be/aZolOWtBbME

In the last months I have experimented with worm gear based extruders with very good results, however not perfect so I decided to go for a different approach.

What I have learned is that the worm gears are not the best choice for extruders. Although high gear ratio gives a good theoretical filament pushing force in reality this is not always true, mainly because the worm gear efficiency is pretty low.

The plastic printed gears are even worse, at high torque their efficiency is well below 50%. The plastic worm gears tooth's are bending a little causing pressure variation in the nozzle which leads to some tiny wavy artifacts on the printed surface.

20-30:1 gear ratio reduces a lot this effect but the stepper will not be able to provide decent filament acceleration slowing your printed drastically down because it has to wait for the extrusion (this is the case for the Zesty Nimble, the flex3drive drive with Nema8 and my previous worm gear based extruders as well, acceleration below 100mm/s^2).

Because of the above arguments I decided to go with a different approach, using a planetary gearbox (efficiency over 96%). In the same time I have changed from the small dual hubs (5mm) to the bigger ones (8mm) because the depth to which the hub tooth bites in the filament is more constant over different materials. More teeths comes in touch with the filament. There is a slightly better grip on the filament resulting a more accurate extrusion. On the downside the bigger hubs ad more weight.

Similar models

grabcad

free

The Orbiter" 140g direct dual drive Extruder with up to 10 kg pushing force

...re is a slightly better grip on the filament resulting a more accurate extrusion. on the downside the bigger hubs ad more weight.

thingiverse

free

Planetary extruder with 12mm dual geared hubs

...tly better grip on the filament resulting leading to a more accurate extrusion. on the downside the bigger hubs ads more weight.

grabcad

free

The Orbiter Extruder

...power supply)

– 30mm/s (12v power supply)

overall weight is about 140g

design by robert lorincz

thingiverse.com/thing:4223085

thingiverse

free

Extruder for planetary stepper and MK7 filament gear by dvjcodec

...xtruder for planetary stepper and mk7 filament gear by dvjcodec

thingiverse

extruder for planetary stepper and mk7 filament gear

thingiverse

free

The Orbiter F2.85 Dual Direct Drive Extruder for 2.85mm Filament by lorinczroby

...rint with the upcoming orbiter v2.

i have published 2 design versions, one is for sls / mjf printing and second for fdm printing.

thingiverse

free

Double Pinch Extruder idea by michthom

...n idea to take nophead's stepper-driven worm gear extruder and extend it to drive pinch wheels on both sides of the filament.

thingiverse

free

XAS Worm Gear Extruder Adapter for MK8 extruder by sm4xas

...needs to be grinded down so that the gear fits.

this is a work in progress, and i haven't tested it yet! only in simulations.

thingiverse

free

D-bot mk7 extruder by Masterjuggler

... better filament grip and less grinding due to the increased surface area contacting the filament from the larger outer diameter.

grabcad

free

2 cim gear

...good mix of acceleration and top speed.

drive train gear (cim motor) with ratio 1:7.55, with that ratio we drive in 16.58 ft/s.

thingiverse

free

Saturn Extruder - A compact 3mm planetary geared bowden extruder by alexspeller

...geared bowden extruder with a roughly 5:1 gear ratio (similar to a wade extruder) but far more compact. there...

140G

turbosquid

$14

Mondelez Milka Choco Chunks 140g Box

...odel mondelez milka choco chunks 140g box for download as max on turbosquid: 3d models for games, architecture, videos. (1446733)

turbosquid

$24

Lays Potato Chips Salted 140g 2020

...ays potato chips salted 140g 2020 for download as max and max on turbosquid: 3d models for games, architecture, videos. (1597472)

thingiverse

free

Disc Golf Driver by Donotseemyself

...disc golf driver by donotseemyself thingiverse 210mm, 140g ...

thingiverse

free

Cap for Simmenthal (Metal Container) by andysus

...container) by andysus thingiverse recycle your simmenthal 90g or 140g with this...

thingiverse

free

"The Orbiter CR" 140g direct dual drive Extruder for Creality CR 10 printer types by lorinczroby

...0318.html?spm=2114.12010615.8148356.7.7db82f4fx2kk5u

if you have any comments/questions please let me know in the comments below.

3d_sky

free

55 "FRENCH ROUND TABLE

...round table from curations dimensions: 140sh x 76b x 140g ...

thingiverse

free

Stackable Fabric Pattern Weight (tighter fit) by SuperIngo

...washer) don't rattle. with two washers the weight is 140g one washer costs...

thingiverse

free

Orbiter adapter for TEVO Flash and Tarantula PRO by lorinczroby

...adapter design i've made to fit "the orbiter" light (140g direct extruder on tevo tarantula pro and flash 3d...

thingiverse

free

Kitchen/Spice Rack 3-4 Shelves with wood by raphstar

...4 shelves especially designed to fit reused "zwergenwiese" containers. (https://www.zwergenwiese.de/produkte/smoerrebroed-gemuese-140g) size of model is 290x75x9,3mm shelves are fixed through...

thingiverse

free

Star Wars Scout Trooper Helmet by SteveZZR

...design saved me approximately 9 hours print time and 140g of filament (as i'd already printed part 2) ,...

Orbiter

3ddd

free

Orbit

...ь - orbit 6225

габарит - 1450*400*310

сайт производитель -http://www.garsnas.se/en-gb/products/screens-lamps/orbit-6225

design_connected

$16

Orbital

...orbital

designconnected

modus furniture orbital lounge chairs computer generated 3d model. designed by christophe pillet.

3d_ocean

$5

Benzene Orbitals

...l arrangement. orbitals represent electronic cloud around atoms involved in benzene particle. red-green lobes of p-orbitals cr...

3ddd

$1

Dedon / Orbit

...dedon / orbit

3ddd

dedon

dedon / orbit

3ddd

$1

orbit lamps

...t lamps

3ddd

orbit

new modern orbit lamp.

it is a ceiling lamp, every element is parent father - child, and dummy. easy control.

3ddd

free

Dedon / Orbit

...d

dedon , германия , круглая

dedon orbit daybed

3ddd

$1

Люстра ORBITAL SP10

...люстра orbital sp10

3ddd

orbital

люстра orbital sp10

3ddd

$1

Foscarini Orbital

...foscarini orbital

3ddd

foscarini , orbital

дизайнер ferruccio laviani, 1992 г.

3ddd

$1

Dandelion Orbit Chandelier

...dandelion orbit chandelier

3ddd

dandelion , orbit

dandelion orbit chandelier

3ddd

$1

Orbit Chandelier

...orbit chandelier

3ddd

orbit

manufacturer:

townsend design, usa

www.townsenddesign.net

designer:

patrick townsend

Kg

turbosquid

$5

Kettlebell 10 kg

...ll 10 kg for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1583701)

turbosquid

$5

Kettlebell 7.5 kg

...l 7.5 kg for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1583699)

turbosquid

$5

Kettlebell 5 kg

...ell 5 kg for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1583695)

turbosquid

$5

Kettlebell 2 kg

...ell 2 kg for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1583690)

turbosquid

$5

Kettlebell 1 kg

...ell 1 kg for download as blend, blend, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1583687)

3ddd

$1

SIEMENS KG 49NS50

...siemens kg 49ns50

3ddd

siemens , холодильник

текстуры в архиве.

turbosquid

$30

Wouxun KG-UVD1P radio

...ouxun kg-uvd1p radio for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1198344)

turbosquid

$39

Gorilla Kettlebell 20 Kg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Gas LPG 3 Kg

...odel gas lpg 3 kg for download as c4d, 3ds, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1327329)

turbosquid

$5

Fixed Barbell 5 kg

... barbell 5 kg for download as blend, blend, 3ds, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1584064)

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Pushing

3ddd

$1

Pushe

...pushe

3ddd

pushe

pushe

3ddd

$1

Pushe

...pushe

3ddd

pushe

диван pushe

3ddd

$1

PUSHE

...pushe

3ddd

pushe , угловой

размер 320x260 см

3ddd

$1

Pushe / Hilton

...pushe / hilton

3ddd

om , pushe

pushe / hilton

3ddd

$1

Pushe / Enio

...pushe / enio

3ddd

om , pushe

pushe / enio

3ddd

$1

Pushe / Volana

...pushe / volana

3ddd

om , pushe

pushe / volana

3ddd

$1

Pushe / Адорес

...pushe / адорес

3ddd

om , pushe

pushe / адорес

3ddd

$1

Pushe / Kosta

.../ kosta

3ddd

om , pushe , угловой

pushe / kosta

3ddd

$1

Pushe / Narciss

...rciss

3ddd

om , pushe , угловой

pushe / narciss

3ddd

$1

Pushe / Grande

...grande

3ddd

om , pushe , угловой

pushe / grande

Force

3d_export

$5

us air force

...us air force

3dexport

u.s air force logo cutting plan

3d_export

$10

van - force traveler

...van - force traveler

3dexport

turbosquid

$100

Force Security helicopter

...ty free 3d model force security helicopter for download as ma on turbosquid: 3d models for games, architecture, videos. (1211745)

turbosquid

$390

SPANISH NAVAL FORCES

...ree 3d model spanish naval forces for download as max and max on turbosquid: 3d models for games, architecture, videos. (1592474)

3d_export

$10

van force traveler

...van force traveler

3dexport

3d_export

$10

air force kooala

...air force kooala

3dexport

bigboy slattt

turbosquid

$199

Force India VJM09

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$89

Taiwan Military Force

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Special Force Soldier

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$47

force 3500.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.