Thingiverse

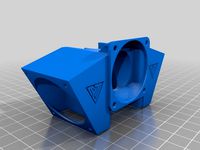

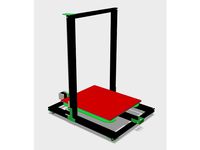

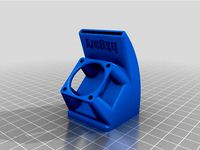

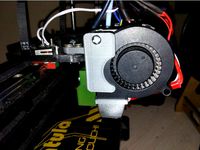

TEVO Tornado and CR-10 belt driven dual Z mod with braces by PeroE30

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a small remix of my favourite dual Z mod for Tevo Tornado and Creality CR-10 https://www.thingiverse.com/thing:2668969.

The design is symmetric so bearings used for upper holders are the same as bearing used for idler pulley. ( you will probably buy pack of 10 from china ;) )

You will need:

-600mm leadscrew and nut

-GT2 852mm Timing Belt

-3x 8/16/5 bearings

-2x M8 threaded rods

-8x M8 nuts

-7x M5x20 screws (idler and bottom holder)

-7x M5x35 screws (upper holder and gantry plate)

-11x M5 tee nuts

-8x M3x12 screw (leadscrew nut to gantry plate and bearing covers)

-4x M3 nut (leadscrew nut to gantry plate)

-4x 3mm washer (leadscrew nut to gantry plate)

-12x M3x8 screw (pulley and under bearing leadscrew locking ring)

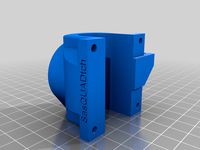

You will need to print:

-1x idler-holder.stl

-2x 8mm_leadscrew_bottom_fixing_ring.STL

-2x spacer_under_main_pulley.STL

-1x GantryPlate.stl

-1x pulley-idler40.stl

-2x bottom_holder.STL

-8x BallNutM8.stl (or 516_Nut.stl)

-2x pulley-64.stl

-2x top_holder.STL

-2x bearing_cover.STL

How to install:

Move z axis all the way up and then mount the left upper holder. Align the holder in X direction first and then in Y direction by tightening upper bearing holder (bearing has a 2mm play in Y direction so it can be adjusted). Do the same for right upper holder. The right leadscrew is fixed to the frame only on top so you have to carefully align it to be perfectly parallel to Z axis! Tighten things up only when the leadscrews are perfectly aligned and there is no leadscrew bending! At last, you put belt on and then adjust its tension with idler pulley. Measure distance from X-axis to the bottom on both sides. Make sure the left side is equal to the right side. ADJUST ALL Z GANTRY WHEELS! When force needed to rotate wheels is the same for all wheels then all gantry wheels are correctly adjusted! This step is very important because there can be some play in one of the leadscrews nuts caused by misalignment of the wheels. If everything is aligned correctly leadscrews nuts will be equally pressed against the leadscrew (also main pulleys against top bearings) by gantry weight. The layers precision should be visibly improved.

If you have any questions just ask!

The design is symmetric so bearings used for upper holders are the same as bearing used for idler pulley. ( you will probably buy pack of 10 from china ;) )

You will need:

-600mm leadscrew and nut

-GT2 852mm Timing Belt

-3x 8/16/5 bearings

-2x M8 threaded rods

-8x M8 nuts

-7x M5x20 screws (idler and bottom holder)

-7x M5x35 screws (upper holder and gantry plate)

-11x M5 tee nuts

-8x M3x12 screw (leadscrew nut to gantry plate and bearing covers)

-4x M3 nut (leadscrew nut to gantry plate)

-4x 3mm washer (leadscrew nut to gantry plate)

-12x M3x8 screw (pulley and under bearing leadscrew locking ring)

You will need to print:

-1x idler-holder.stl

-2x 8mm_leadscrew_bottom_fixing_ring.STL

-2x spacer_under_main_pulley.STL

-1x GantryPlate.stl

-1x pulley-idler40.stl

-2x bottom_holder.STL

-8x BallNutM8.stl (or 516_Nut.stl)

-2x pulley-64.stl

-2x top_holder.STL

-2x bearing_cover.STL

How to install:

Move z axis all the way up and then mount the left upper holder. Align the holder in X direction first and then in Y direction by tightening upper bearing holder (bearing has a 2mm play in Y direction so it can be adjusted). Do the same for right upper holder. The right leadscrew is fixed to the frame only on top so you have to carefully align it to be perfectly parallel to Z axis! Tighten things up only when the leadscrews are perfectly aligned and there is no leadscrew bending! At last, you put belt on and then adjust its tension with idler pulley. Measure distance from X-axis to the bottom on both sides. Make sure the left side is equal to the right side. ADJUST ALL Z GANTRY WHEELS! When force needed to rotate wheels is the same for all wheels then all gantry wheels are correctly adjusted! This step is very important because there can be some play in one of the leadscrews nuts caused by misalignment of the wheels. If everything is aligned correctly leadscrews nuts will be equally pressed against the leadscrew (also main pulleys against top bearings) by gantry weight. The layers precision should be visibly improved.

If you have any questions just ask!

Similar models

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount 2.0 by SaberShip

...ler pulley for 6mm wide gt2 belt

1x m5 x30 bolt

1x m5 nylon lock insert nut (regular m5 nut may work)

2x m3 x10 screws

2x m3 nuts

thingiverse

free

Tevo Tornado / CR10 Z top bracket by morgoth90

...he tevo tornado top z bracket, i used it to mount second z axis.

requirement:

standard skateboard bearing

2x m3 screw

2x m3 t nut

thingiverse

free

Dual Z & Frame Braces for Tevo Tornado and CR-10. Low cost high precision by pemic

...the titan_mount.

i'm new in 3d printing an my cad skills are limited. please tell me any flaws, may i can improve this thing.

thingiverse

free

TornadoCube - Tevo Tornado CoreXY Conversion by cransjadel

...0mm or 1360mm closed gt2 belt

longer bowden tube for 1.75mm filament, 4mm od

other parts i used:

jst wire connectors

tl smoothers

thingiverse

free

Adjustable bearing Z axis screw by zargo83

...earing for the t8 8mm z-axis screw

materials needed:

2x m3 30mm

2x m3 20mm

2x m3 nut

2x m3 t-slot nut

1x mini 608zz ball bearings

thingiverse

free

Belt driven Z upgrade by MarcusVoss

...idlers)

-two m5x8mm screws and two m5 nuts to mount the kfl008 bearing.

my rod holders: https://www.thingiverse.com/thing:2851231

thingiverse

free

Tevo Tornado X-Axis Pulley Wobble Fix by JohannesBerlin

...0 .f3d file is included if you need to make any adjustments.

parts needed:

m6 x 25mm screw (din912, din7984, iso7380)

m6 lock nut

thingiverse

free

Mendelmax 3.0 X-axis Tensioner by maddavo

...rts and install and test that - yes - it works better now. i have updated the parts and the pictures with the mirrored versions.

thingiverse

free

Hypercube Single Z motor, dual leadscrew

...+mm and you get 940, i just rounded up to 1000mm for a little extra. its better to have a belt slightly too long, than too short.

thingiverse

free

One Z-Motor / Filament holder solution for Prusa i3 Rework by WieMi

...t)

360mm m8 threaded rod (middle)

2x 380mm m8 threaded rod (right)

11x m3 nut

8x m3 - 8mm grub screw

8x m8 nut

5x 688zz bearing

Tornado

thingiverse

free

Tornado by 5665

...tornado by 5665

thingiverse

tornado with sharks

thingiverse

free

Tornado by AniMusic

...tornado by animusic

thingiverse

tornado con bucles

thingiverse

free

tornado by carsanarr

...tornado by carsanarr

thingiverse

esto es una simulación de la forma de un tornado

thingiverse

free

tornado oval by rortiz11

...tornado oval by rortiz11

thingiverse

tornado oval

thingiverse

free

Tornadoes Keychain by slms

...tornadoes keychain by slms

thingiverse

tornadoes keychain

thingiverse

free

A small tornado by dukeisi

...a small tornado by dukeisi

thingiverse

a model of a small tornado.

thingiverse

free

tornado in a bottle by kevinh6825

...tornado in a bottle by kevinh6825

thingiverse

tornado adapter for two bottles

thingiverse

free

Tornado in the city

...tornado in the city

thingiverse

daydeaming

thingiverse

free

tornado by slms

...tornado by slms

thingiverse

cool

thingiverse

free

FlyingBear Tornado by leucas

...flyingbear tornado by leucas

thingiverse

panello per modulo tft32 della tornado.

Driven

thingiverse

free

Servo Driven Valve by mikedeklerk

...ven valve by mikedeklerk

thingiverse

a valve for liquids, driven by a servo motor. this way you could automate a flow of liquid.

thingiverse

free

DRIVEN pocket series track

...eries-blind-packs/-/a-52182975

dynamic quality, 20% infill. print 'thin' walls to show the dividers and h on the helipad.

thingiverse

free

Z driven pulley with rims by MBC

...ys.

the “2c†version of this part has a gear-toothed “c†(as in mbc) engraved in the top and bottom faces of the part.

â

thingiverse

free

10013 Z axis driven sprocket pulley by unexpectedly

...se

this is a direct replacement for the rapman 3.1 arylic driven sprocket on the driven axes. 3 of these are used in the rapman.

thingiverse

free

Watermill Driven Ballerina by jochoi0707

...watermill driven ballerina by jochoi0707

thingiverse

will upload a build-video soon, sorry about the delay!

thingiverse

free

Windmill - Driven Model for steam engines by AmmoMike83

...this is a rebuild of a wilesco m68 windmill. you can print and use it as a driven model for steam engines or just for decoration.

thingiverse

free

T-Case and S-Case for ATTiny85-Driven Intervalometer by td0g

...ttiny85-driven intervalometer. more info at https://gerritsendesign.wordpress.com/2017/12/13/attiny85-driven-intervalometer-diy/

thingiverse

free

Heliodors driven out of the Temple by GeoffreyMarchal

...nhagen, denmark). made with memento beta (now remake) from autodesk.

for more updates, please follow @geoffreymarchal on twitter.

thingiverse

free

Balloon driven car by yuvalabou

...r by yuvalabou

thingiverse

toy balloon car for students shop course.

just put the balloon on top and inflate from the exhaust :)

thingiverse

free

Pulley & Idler for string driven Rostock by Hendrik

...out every now and then as updates and/or additions may be uploaded.

http://yarrp.blogspot.com

facebook.com/yarrp

@yarrp3dprinting

Braces

thingiverse

free

Wrist brace

...wrist brace

thingiverse

wrist brace

thingiverse

free

Brace by PearceCrocker19

...brace by pearcecrocker19

thingiverse

leg brace

thingiverse

free

brace by joestraws

...brace by joestraws

thingiverse

brace prototype

thingiverse

free

Brace

...brace

thingiverse

watch spies in disguise online

thingiverse

free

Brace

...brace

thingiverse

download frozen ii full movie

thingiverse

free

catwalk brace by NYC3D

...catwalk brace by nyc3d

thingiverse

catwalk brace

thingiverse

free

Pistol Brace

...pistol brace

thingiverse

pistol brace for commercial m4 buffer tubes

uses one bolt and lock nut to mount

thingiverse

free

Ivar Brace by alotto

...ivar brace by alotto

thingiverse

wip brace for kitten

thingiverse

free

Braces for teeth by WillandMrData2

...braces for teeth by willandmrdata2

thingiverse

braces to straighten teeth,

thingiverse

free

Camera Brace by aladisposition

...camera brace by aladisposition

thingiverse

a camera brace test. hope it works!

Tevo

thingiverse

free

TEVO Logo by limwenyao

...verse

tevo logo - for customizing your builds to look cooler with the tevo logo! pdf version is editable with adobe illustrator.

thingiverse

free

Tevo Tornado e3d Tevo Flash Style fan Mount by DemolitionX

...an mount by demolitionx

thingiverse

just messing around and made a tevo flash style fan mount for the e3d v6 on the tevo tornado

thingiverse

free

BODEN TUBE CLAMP FOR TEVO TARANTULA PRO AND TEVO TORNADO

... and tevo tornado

thingiverse

bodwen tube clamp. printable adjustable tension clamp for tevo tarantula pro and tornado extruder.

thingiverse

free

TEVO Tornado Model by JMDesigns

...tevo tornado model by jmdesigns

thingiverse

tevo tornado model

thingiverse

free

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

FAN TEVO TARANTULA by llprokall

...fan tevo tarantula by llprokall

thingiverse

fan tevo tarantula

thingiverse

free

Tevo Tarantula filament by Xbertus

...tevo tarantula filament by xbertus

thingiverse

suport for filamente tevo tarantula

thingiverse

free

TEVO Top Brackets by _Godoy_

...tevo top brackets by _godoy_

thingiverse

top brackets for tevo tarantula

thingiverse

free

Tevo Tarantula Spool Holder

...tevo tarantula spool holder

thingiverse

strong spool holder for tevo tarantula

thingiverse

free

tevo tarantula spacer by poundskinnyboy

...tevo tarantula spacer by poundskinnyboy

thingiverse

it's a tevo tarantula spacer

Cr

thingiverse

free

Creality CR-7 CR-8 CR-10 Filament holder by yyyfly

...creality cr-7 cr-8 cr-10 filament holder by yyyfly

thingiverse

creality cr-7 cr-8 cr-10 filament holder

thingiverse

free

Universal Z-Braces for CR-10 / CR-10S

...universal z-braces for cr-10 / cr-10s

thingiverse

universal z-braces for cr-10 / cr-10s

thingiverse

free

button cell adapter Cr 2430 of Cr 2032 by hardcoregamer

...button cell adapter cr 2430 of cr 2032 by hardcoregamer

thingiverse

button cell adapter cr 2430 of cr 2032

thingiverse

free

cr 10 by hugues1234

...cr 10 by hugues1234

thingiverse

cr 10

thingiverse

free

Cr-10 Cr-10s Cr-10 mini fan by nuggyblake

...ation. i wanted to aim the airflow better with this design. it lines up with the nozzle and is noticeably better (atleast to me).

thingiverse

free

attache cr-10

...attache cr-10

thingiverse

attache profiler cr-10

thingiverse

free

Cache courroie Y / CR-10 / CR-10S by DupeHart

...r-10 / cr-10s by dupehart

thingiverse

cache courroie y (belt holder) pour cr-10 / cr-10s.

version non personnalisée en partage.

thingiverse

free

CR-10 Addons by ermada

...cr-10 addons by ermada

thingiverse

cr-10 & cr-10s addons

thingiverse

free

Mini CR-10 by Liang0108

...mini cr-10 by liang0108

thingiverse

cr-10 printed mini cr-10

thingiverse

free

CR 10 (and CR X) TV Enclosure by pauliman

...cr 10 (and cr x) tv enclosure by pauliman

thingiverse

this is my new enclosure

Mod

thingiverse

free

HB-MOD-ETH Gehäuse RPI-RF-MOD by Dquantz

...hb-mod-eth gehäuse rpi-rf-mod by dquantz

thingiverse

case for hb-mod-eth with rpi-rf-mod

thingiverse

free

Dumbo ears mod

...dumbo ears mod

thingiverse

ears mod

thingiverse

free

YoYo Mod by 19pdansor

...yoyo mod by 19pdansor

thingiverse

a yoyo mod

thingiverse

free

Freecoaster mod by imbrid

...freecoaster mod by imbrid

thingiverse

freecoaster mod

thingiverse

free

mods by wtrduflo

...mods by wtrduflo

thingiverse

thingiverse

free

SapphirePro Cable Mod

...sapphirepro cable mod

thingiverse

a cable mod for the sapphire pro.

thingiverse

free

NLPWM Mod Box

...nlpwm mod box

thingiverse

my first mod mox

thingiverse

free

Silencer Mod by jakkal

...silencer mod by jakkal

thingiverse

silencer mod.

great sucess

thingiverse

free

eye mod

...eye mod

thingiverse

eye eye

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

Dual

thingiverse

free

Dual 4010

...dual 4010

thingiverse

dual fan 4010

thingiverse

free

dual color cone for testing dual extruders by lovethepirk

...dual color cone for testing dual extruders by lovethepirk

thingiverse

dual color cone for testing dual extruders

thingiverse

free

Dual hook by duxdhell

...dual hook by duxdhell

thingiverse

dual hook

thingiverse

free

Headsetholder dual by J3M

...headsetholder dual by j3m

thingiverse

dual headset holder

thingiverse

free

Dual extruder by gustavorpinheiro

...dual extruder by gustavorpinheiro

thingiverse

this is a support for dual extruders.

thingiverse

free

Dual Plate by Jaimemarie

...dual plate by jaimemarie

thingiverse

toggle and dual outlet plate

thingiverse

free

Dual IEC by mrkrash

...dual iec by mrkrash

thingiverse

dual hotend with fine regulation

thingiverse

free

Dual Spinner by AidanSandersSAN

...dual spinner by aidansanderssan

thingiverse

a dual spinner i made in class.

thingiverse

free

Dual Spinner by groman

...dual spinner by groman

thingiverse

a quick remix of the tri spinner. a dual spinner!

thingiverse

free

Dual stepper mount

...dual stepper mount

thingiverse

dual stepper mount. drill mounting holes for printer

Belt

thingiverse

free

belt

...belt

thingiverse

belt sleeve for 35mm wide..

use tpu or tpu95

gcode ready

thingiverse

free

Belt hanger for mission belt by maburke

...belt hanger for mission belt by maburke

thingiverse

hanger for mission belt- hangs belt nicely on the closet rod

thingiverse

free

Belt Hanger (For Belts With a Stud) by SamuelSVD

...belt hanger.

this belt hanger works by placing the stud on the belt in the hole, then hang the hanger.

yep, it's that simple.

thingiverse

free

Belt hanger for Trakline belt by tomasf

...belt hanger for trakline belt by tomasf

thingiverse

a hanger for a single trakline belt.

thingiverse

free

Belt clip for 9 mm belt by papat400

...belt clip for 9 mm belt by papat400

thingiverse

remix the belt lock gt2 for a 9mm belt

thingiverse

free

Belt Rack

...belt rack

thingiverse

belt hanger

thingiverse

free

Belt Holder

...belt holder

thingiverse

a simple belt holder.

thingiverse

free

Hermes belt buckle for 31mm belt by Hubiro

...hermes belt buckle for 31mm belt by hubiro

thingiverse

hermes belt buckle for 31mm belt

perfect to order as metal print :-)

thingiverse

free

Bugatti belt buckle for 31mm belt by Hubiro

...t buckle for 31mm belt by hubiro

thingiverse

bugati belt buckle made for 31mm hermes belt.

perfect to order as a metal print :-)

thingiverse

free

Belt tensioner for GT2 belts by Endlesscnc

...oner little different.

after print you will need a:

m3 nut

m3 x10+ (screw length your choice)

is for the gt2 belt with 6mm width

Z

thingiverse

free

Z Cam E1 Z-clip by zandoli

...z cam e1 z-clip by zandoli

thingiverse

the z-clip adds a shoe mount to the z cam e1.

thingiverse

free

Z-Wave Plus Z-Stick GEN5

...z-wave plus z-stick gen5

thingiverse

for the key : z-wave plus z-stick gen5

to put on the wall

thingiverse

free

z-mount

...z-mount

thingiverse

z axis steper motor mount

thingiverse

free

z.1.3.1 by coldboxpal

...z.1.3.1 by coldboxpal

thingiverse

pole: 5mm

hole: z.1.3.1.4 > z.1.3.1.3(recommend) > z.1.3.1.2 > z.1.3.1.1

thingiverse

free

![Test [Z] BedTest LEVEL [Z]. stl3dmodels.com by mtPrint](/t/8671393.jpg)

Test [Z] BedTest LEVEL [Z]. stl3dmodels.com by mtPrint

...test [z] bedtest level [z]. stl3dmodels.com by mtprint

thingiverse

test level bed [z] 100x100x1mm

thingiverse

free

Z-Crystal_Electrium Z by GameDirection

...m/theplatinumleague/

the platinum league is an ohio based group that was formed to host pokemon tournaments at local conventions.

thingiverse

free

Z-Crystal_Fightinium Z by GameDirection

...m/theplatinumleague/

the platinum league is an ohio based group that was formed to host pokemon tournaments at local conventions.

thingiverse

free

Z-Crystal_Steelium Z by GameDirection

...m/theplatinumleague/

the platinum league is an ohio based group that was formed to host pokemon tournaments at local conventions.

thingiverse

free

Z-Crystal_Rockium Z by GameDirection

...m/theplatinumleague/

the platinum league is an ohio based group that was formed to host pokemon tournaments at local conventions.

thingiverse

free

Z-Crystal_Icium Z by GameDirection

...m/theplatinumleague/

the platinum league is an ohio based group that was formed to host pokemon tournaments at local conventions.

10

thingiverse

free

the cube 10 x 10 x 10 mm by 3dluca

...the cube 10 x 10 x 10 mm by 3dluca

thingiverse

cube

10 x 10 x 10 mm

printing time < 5 minutes

thingiverse

free

A-10 Warthog

...a-10 warthog

thingiverse

a-10 warthog (the gun)

thingiverse

free

Stand for Voltcraft Devices SL-10, AN-10, LX-10 by Minfredus

...lmessgeraet_v1" has a "sound level meter sl-10"-branding. file "voltcraft_stand" comes without branding.

thingiverse

free

A-10 warthog

...a-10 warthog

thingiverse

a simple version of an a-10 warthog model

thingiverse

free

10 whisles

...10 whisles

thingiverse

10 whisles

if this is your design let me know

thingiverse

free

AT-10 by JARLANG

...at-10 by jarlang

thingiverse

at-10 british at - 1:72

paper project, but cool :)

thingiverse

free

Universal Z-Braces for CR-10 / CR-10S

...universal z-braces for cr-10 / cr-10s

thingiverse

universal z-braces for cr-10 / cr-10s

thingiverse

free

Fachwerkhaus 10 and 10S

...(original ~6x8m)

scale: optimized for 6mm (1:285)

format: stl

fachwerk / timberframe, optional base, 2 floors, roof with shingles

thingiverse

free

Cr-10s/10 first layer calibration by dilopsus

...cr-10s/10 first layer calibration by dilopsus

thingiverse

first layer calibration test for cr-10s/10 .

rotate model 90 degrees .

thingiverse

free

Creality CR 10 / 10s filament cleaner

...creality cr 10 / 10s filament cleaner

thingiverse

insert ptef tube in holes.