Thingiverse

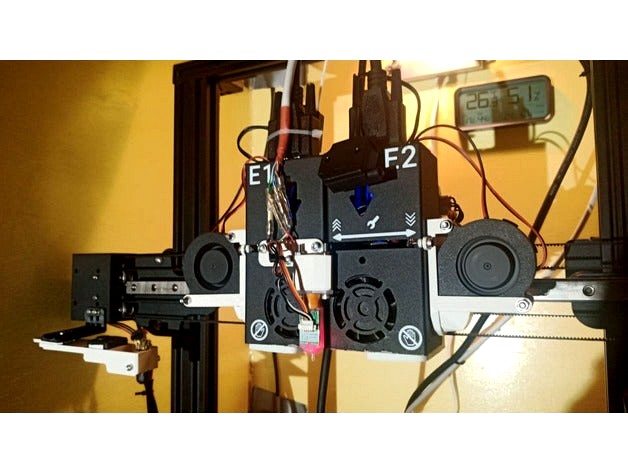

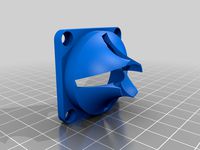

Tenlog TL-D3 Pro (Dual) 5015 Fan Mod for Stock Metal Shroud by Buriaku

by Thingiverse

Last crawled date: 2 years, 10 months ago

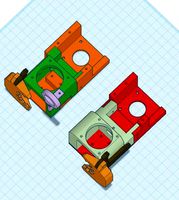

This is a modification for the stock metal shroud of the Tenlog TL-D3 Pro to use two (or one) 5015 fans per extruder. Air is sent to the back and front of the nozzle and distributed quite evenly. Airflow was examined using fluid simulation (Simscale) and water tests. For assembly, the metal shroud needs to be modified by removing the part sitting under the cooling fan by breaking or sawing it off.

The fans I used are from Winsinn.

Original Inventor files and exported STEP files of the whole assembly are provided.

Last two photos are printing examples of the "cooling fan torture test" by TeachingTech.

The single 5015 fanduct design was also used in the "Tenlog TL-D3 BMG Extruder V2" by andrewseago.

Printing:

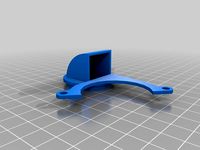

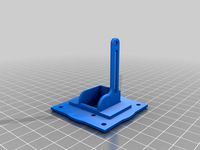

Print with supports on build plate and the flattest part laying on the build plate (side for fanholder, bottom for fanduct). Check, that there is no support inside the fanducts before printing. I used 0.2mm layer heights with 0.3mm initial layer height. Inner divider walls are 0.84mm, which is the recommended width in PrusaSlicer for two walls at 0.45mm outlines, so check whether there are actually two walls.

Assembly:

Remove the metal shroud, disconnect the fans from the board and unscrew both fans before modifying.

The fanduct parts go on the inside and the fanholder parts go on the outside of the shroud joined through the air intake hole of the original part cooling fan. No holes need to be bored into the shroud for assembly, but the metal "flap" sitting under the heatsink fan needs to be removed by breaking it off (flexing back and forth with pliers until the metal yields) or sawed off (after bending it down). To prevent injury, remove any sharp edges with a file after removal. The inside and outside parts are joined using two screws, one through the side hole of the shroud and one through the long slit on the front of the shroud. Two longer screws are used to fix the fans to the fanholder. All screw holes are designed for M3 screws.

If using two fans, they need to be connected in parallel. Search for examples, if unsure what that means. On the blue/yellow cable of the original Tenlog fan, blue is negative (black) and yellow is positive (red).

The fans I used are from Winsinn.

Original Inventor files and exported STEP files of the whole assembly are provided.

Last two photos are printing examples of the "cooling fan torture test" by TeachingTech.

The single 5015 fanduct design was also used in the "Tenlog TL-D3 BMG Extruder V2" by andrewseago.

Printing:

Print with supports on build plate and the flattest part laying on the build plate (side for fanholder, bottom for fanduct). Check, that there is no support inside the fanducts before printing. I used 0.2mm layer heights with 0.3mm initial layer height. Inner divider walls are 0.84mm, which is the recommended width in PrusaSlicer for two walls at 0.45mm outlines, so check whether there are actually two walls.

Assembly:

Remove the metal shroud, disconnect the fans from the board and unscrew both fans before modifying.

The fanduct parts go on the inside and the fanholder parts go on the outside of the shroud joined through the air intake hole of the original part cooling fan. No holes need to be bored into the shroud for assembly, but the metal "flap" sitting under the heatsink fan needs to be removed by breaking it off (flexing back and forth with pliers until the metal yields) or sawed off (after bending it down). To prevent injury, remove any sharp edges with a file after removal. The inside and outside parts are joined using two screws, one through the side hole of the shroud and one through the long slit on the front of the shroud. Two longer screws are used to fix the fans to the fanholder. All screw holes are designed for M3 screws.

If using two fans, they need to be connected in parallel. Search for examples, if unsure what that means. On the blue/yellow cable of the original Tenlog fan, blue is negative (black) and yellow is positive (red).

Similar models

thingiverse

free

Tenlog TL-D3 BMG Clone Extruders by andrewseago

...tock 40mm fan

2 stock d3 hotend assemblies

2 stock tenlog d3 vga breakout boards

1 capacitive probe (optional)

assorted 3mm bolts

thingiverse

free

Filament switch Tenlog TL-D3 Pro Dual by hirsch5

... tenlog tl-d3 pro dual v2

direct mount on extruder

mirror print for e1/e2

printed in 0.3mm pla 20% infill

2 screws m3 20mm + 30mm

thingiverse

free

Spool Holder for Tenlog TL-D3 Pro by BirdiesGalore

...o by birdiesgalore

thingiverse

spool holder for tenlog tl-d3 pro or any other printer that uses 20mm rails -- no support needed.

thingiverse

free

FanHolder for Printrbot Play by enhydra

...mm screws for mounting the fanholder to the extruder base.

4 pcs m3 by 16 screws for fixing fan and mini-shroud to the fanholder.

thingiverse

free

Diamond Hotend Fan Shroud by LHartmann

...diamond hotend fan shroud by lhartmann

thingiverse

part cooling fan mount and shroud for this mount, uses a 5015 radial fan.

thingiverse

free

Fanduct5015 for TenLOG D3 PRO by StikkaDesign

...grades (bltouch, led lights, etc.)

the rectangular holes are for the electrical clamps and the internal wiring of the fan cables.

thingiverse

free

V6 Extruder Heatsink Fan Duct for 5015 Centrifugal Fan by jammi

...o the shroud and the shroud itself snaps onto the heatsink.

print as-is, or with supports. bridging worked fine for me, but ymmv.

thingiverse

free

Tenlog TL-D3 Pro Fan Mount

...2 - strengthened the mount screw area

update - v3 for p2 shroud released - trimmed edge on left side down to give room for hotend

thingiverse

free

CR-10 5015 Radial Cooling Fan duct / shroud (original metal case) by sassymaker

...se) by sassymaker

thingiverse

cr-10 cooling fan mod using original metal case for extruder fan.

see photo for print orientation.

thingiverse

free

eB Fan Shroud - Remixed to use stock fan screws by mparker03

... the hotend fan and deleted the part cooling fan mounting holes.

printed in pla, 50% infill, print with cooling fan flange down.

Tenlog

thingiverse

free

Tenlog D3 Pro tool holder by shahfil

...tenlog d3 pro tool holder by shahfil

thingiverse

tool holder for tenlog printer

thingiverse

free

Tenlog D3 Filament Guide by akwerdesigns

...ent guide by akwerdesigns

thingiverse

filament guide for a tenlog d3 that keeps the filament from loosening on a full the spool.

thingiverse

free

Poignée Tenlog pour le plateau, Handle Bed TENLOG, tenlog tl-d3 pro by ArtDesChoix

...andle logo" et "handle single" que vous pourrez fusionner pour imprimer en é couleurs.

bonne impression

art3dchoix

thingiverse

free

Duet Tenlog TL D3 pro by denisvdb

...t tenlog tl d3 pro by denisvdb

thingiverse

replacing the tenlog motherboard with a duet 2 wifi + duex5. modification in progress

thingiverse

free

V-Slot Cover for Tenlog TLD3pro by jspivey13

...3pro by jspivey13

thingiverse

this is a remix of: https://www.thingiverse.com/thing:3379068 for the v-slots on my tenlog tld3pro

thingiverse

free

Tenlog Dial Indicator Mount by jammin32j

...he tenlog tl-d3 pro extruder. it holds the dial indicator and can be used for setting bed height and checking for a warped bed.

thingiverse

free

Tenlog / Hictop bmg+v6 by kanocz

...to onshape work: https://cad.onshape.com/documents/795ed0e8f7593bda6683f376/w/3a61c6ec6cc35afb6e159085/e/d0a1e93d030008aedf0c4812

thingiverse

free

Spool Holder for Tenlog TL-D3 Pro by BirdiesGalore

...o by birdiesgalore

thingiverse

spool holder for tenlog tl-d3 pro or any other printer that uses 20mm rails -- no support needed.

thingiverse

free

Tenlog TL-D3 Bed level and nozzle offset test by Samuelheiner1

...enlog tl-d3 bed level and nozzle offset test by samuelheiner1

thingiverse

economical bed level test for the tenlog idex printer.

thingiverse

free

ebox support pour Tenlog TLD3 Pro by jvida

...r tenlog tld3 pro by jvida

thingiverse

support pour ebox sur chassis de tenlog tl d3 pro

permet de fixer la ebox sur le portique

D3

turbosquid

$60

Albatros D3

...osquid

royalty free 3d model albatros d3 for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1206830)

turbosquid

$110

Albatros D3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

D3 Bookcase

...d3 bookcase for download as ma, 3ds, max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1339364)

3ddd

free

ODESD2 D3

...м шпонированная дубом фанера, мдф, фурнитура blum

размеры: ширина: 425мм, длина: 1200мм, высота: 800ммhttp://odesd2.com

3d_export

$5

Buggy d3 3D Model

...buggy d3 3d model

3dexport

buggy

buggy d3 3d model 1201314354 62357 3dexport

turbosquid

$20

Bowers & Wilkins HTM2 D3 Rosenut on FS HTM D3 Black

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Motorola RAZR D3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Bowers & Wilkins HTM2 D3 Satin White on FS HTM D3 Silver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Bowers & Wilkins HTM2 D3 Gloss Black on FS HTM D3 Black

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Osiris D3 Skate shoe

...ree 3d model osiris d3 skate shoe for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1403308)

Tl

design_connected

$13

TL

...tl

designconnected

bonaldo tl computer generated 3d model. designed by viganò, giuseppe.

3ddd

$1

felicita tl

...felicita tl

3ddd

торшер felicita tl

turbosquid

$15

TL symbol

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Tl Light

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

TL SYMBOL

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Pataviumart TL 2461

...pataviumart tl 2461

3ddd

pataviumart

модель pataviumart tl 2461/02nj41

размеры ш.в.г. - 31х56х20

+obj

3ddd

$1

SEDIA Traffic-TL

...sedia traffic-tl

3ddd

sedia

sedia traffic-tl

внимание!

в архиве имеются 2011 и 2014 версии!

приятного пользования!

humster3d

$75

3D model of Goggomobil TL 250 (TL 400) Transporter Van 1956

...bil tl 250 (tl 400) transporter van 1956 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$99

Acura TL 2009 3D Model

...acura tl 2009 3d model

3dexport

acura tl 2008 2009 2010 2011 sedan sporty usa honda

acura tl 2009 3d model squir 9457 3dexport

3d_export

$10

Solid Tl-1 3D Model

...solid tl-1 3d model

3dexport

solid tl-1 3d model slaz 97581 3dexport

5015

3ddd

$1

Скамья RUGIANO - COPERTINA BRONZA, 5015/130GL

...a bronza, 5015/130gl

3ddd

rugiano , скамья

скамья rugiano - copertina bronza, 5015/130gl

3d_export

$15

3d hair style for girl v94

...: 4811 - edges : 9836 - faces : 5015 - tris : 9642 - uvs : 5364 file...

thingiverse

free

5015 fan duct

...5015 fan duct

thingiverse

5015 fan duct

thingiverse

free

5015 Fan Guard

...5015 fan guard

thingiverse

5015 fan guard

3dfindit

free

294-5015

...294-5015

3dfind.it

catalog: wago

thingiverse

free

40MM to 5015 Adapter by 360alaska

...by 360alaska

thingiverse

this will adapt a 5015 fan to a 40mm fan mount. the 5015 fan mounts at a right angle and rotates fully.

thingiverse

free

Chiron 5015 blower by DK_Davis

...chiron 5015 blower by dk_davis

thingiverse

anycubic chiron 5015 blower

thingiverse

free

single 5015 to 50mnm by Kyledavis417

...single 5015 to 50mnm by kyledavis417

thingiverse

single 5015 to 50mm for tevo controller box

thingiverse

free

Cetus 3D 5015 Duct

...cetus 3d 5015 duct

thingiverse

twisted 5015 fan duct for cetus 3d mk2

thingiverse

free

Dual 5015 to 50mm by Kyledavis417

...dual 5015 to 50mm by kyledavis417

thingiverse

dual 5015 fan adapter for tevo tornado controller box

Shroud

3d_export

$500

Centrifugal pump volute casing with impeller

...casing with impeller 3dexport volute casing with impeller and shroud ...

3d_export

$35

The Holy Face base relief 3D Model

...the holy face base relief 3d model 3dexport shroud turin veronica veronica's veil gospel ikon jesus holy face...

3d_export

$20

present car cloth presentation transport transportation shape concepts show celebration cover showro

...transportation shape concepts show celebration cover showroom covered revealin shroudd cover covering tarp draped fabric cloth showroom reveal revealing...

3d_export

$5

Lockheed F-117 Nighthawk lowpoly stealth bomber

...initial operating capability status in 1983. the aircraft was shroudd in secrecy until it was revealed to the public...

3d_export

$49

kriss vector gen 2 sub-d

...rear flip sight.<br>- vector ejection port.<br>- vector crb square shroud / 16"" sliencer.<br>- ds150 stock.<br>- .ma (maya 2020 ascii)<br>-...

3d_export

$10

vichy dining table

...in oak, sycamore and walnut marquetry.<br>even if the restaurant shroud the vichy in a long table cloth, two slender...

3d_export

$500

us navy pcu sterett ddg-104 arleigh burke class destroyer flight iia max

...the position has been shifted.<br>q. where are the exhaust shroud for the stacks?<br>a. since ddg-89, the exhaust system was...

thingiverse

free

shroud by samshay317

...shroud by samshay317

thingiverse

shroud

thingiverse

free

Fan Shroud

...fan shroud

thingiverse

this is a fan shroud for a 140mm fan

thingiverse

free

40mm fan shroud

...40mm fan shroud

thingiverse

40mm fan shroud

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mod

design_connected

$13

MOD. 4233 - MOD. 4234 Table Lamp

...mod. 4233 - mod. 4234 table lamp

designconnected

arcahorn mod. 4233 - mod. 4234 table lamp computer generated 3d model.

design_connected

$11

MOD.1095

...mod.1095

designconnected

mod.1095 computer generated 3d model. designed by sarfatti, gino.

3ddd

$1

fireplaces mod Spec

...fireplaces mod spec

3ddd

камин

fireplaces mod spec 180x90x125h

3ddd

free

Flos Mod. 2129

... mod

фабрика: flos

модель: mod. 2129

описание: подвесной светильник, металл, белый, черный.

сайт: www.flos.com

turbosquid

$34

Mod Lamp.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Maars Mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mod 70..

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MOD Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Stock

turbosquid

$19

Stocks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$7

Christmas Stockings

...christmas stockings

3docean

christmas gift holiday present sock stocking

sock and 2 gift.

turbosquid

$30

Christmas Stocking

...

royalty free 3d model christmas stocking for download as fbx on turbosquid: 3d models for games, architecture, videos. (1660476)

turbosquid

$2

sexy stockings

...uid

royalty free 3d model sexy stockings for download as max on turbosquid: 3d models for games, architecture, videos. (1350546)

turbosquid

$2

sexy stockings

...uid

royalty free 3d model sexy stockings for download as max on turbosquid: 3d models for games, architecture, videos. (1354968)

turbosquid

$2

sexy stockings

...uid

royalty free 3d model sexy stockings for download as max on turbosquid: 3d models for games, architecture, videos. (1351029)

turbosquid

$3

Iron Stocks

...yalty free 3d model iron stocks for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1596546)

turbosquid

$6

Prison Stocks

...free 3d model prison stocks for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1454023)

turbosquid

$29

Christmas Stocking

...del christmas stocking for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1344671)

turbosquid

$5

Medieval Stocks

... model medieval stocks for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1291222)

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

Metal

3d_ocean

$10

Metal Barrel

...metal barrel

3docean

barrel barrels metal metal barrel wood barrel

metal barrel

turbosquid

$14

Metals

...als

turbosquid

royalty free 3d model metals for download as on turbosquid: 3d models for games, architecture, videos. (1486252)

3d_ocean

$18

Metal Furniture

...metal furniture

3docean

design desk indoor industrial metal metal furniture restoration table

metal furniture 3d model

3d_export

$5

metal table

...metal table

3dexport

metal table.blend

3d_export

$5

Metal Shelf

...metal shelf

3dexport

metal shelf

3d_export

free

metal detector

...metal detector

3dexport

metal detector

3ddd

$1

metal lux

...metal lux

3ddd

dedalo , metal lux

люстра и бра metal lux коллекция dedalo.

3ddd

$1

bonded metal

...bonded metal

3ddd

https://www.forms-surfaces.com/bonded-metal

boded tiled metal

3ddd

$1

Metal

...metal

3ddd

1280-1024 бесшовный 8-)

3d_export

$5

cgaxis metal

...cgaxis metal

3dexport

notebook cgaxis metal