Thingiverse

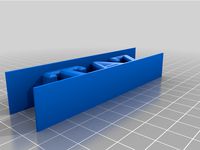

TAZ 6 Spool Holder Shaft by russell_i_brown

by Thingiverse

Last crawled date: 3 years, 1 month ago

I've been using https://www.thingiverse.com/thing:1608830 on my TAZ 6 for a while and it works very well... except... the spool often seems to hangup on the shaft and then go over centre with a loud CLUNK! :-( I even tried a bit of polished 22mm copper pipe as the shaft but that still went CLUNK! as the spool went round.

I don't like machines that make unexpected CLUNK! noises (and having a kilo of filament bouncing on the top of the printer doesn't sound like a great feature) so I designed this totally over-engineered bearing mounted shaft with tapered inserts to fit multiple spool sizes.

Using this shaft, the spool very gently rotates as the filament is pulled down by the extruder.

As well as the printed parts you'll also need:

2 x 10x26x8 bearings (I used 6000ZZ; very common and a couple of quid off EBay)

1 x 20mm OD, 17mm ID tube around 127mm long.

1 x M6x8 grub or set screw.

I say 'around' 127mm for the tube as that wasn't the original length I used (started at 130mm IIRC) and had to tweak it a bit as the upstands in the original design do have some flex along the shaft axis.

Anyway, I've includes links below for the Fusion 360 CAD files if you need to change anything.

Printing.

You need support turned on for both the spindle nut and the tube inserts but not for the other parts.

I used a 2mm wall thickness and 30% triangular infill for the tube inserts. 1mm and 20% for the other parts.

Assembly.

The tube inserts were designed to be a 'tight sliding' fit into the tube and bearing. This fit obviously depends on the accuracy of your printer. A slightly loose fit can be accomodated with a dab of bearing retainer (aka superglue). A tight fit means a bit of post-processing or tweak the model and reprint.

I would suggest you assemble the back tube insert (the left hand red bit in the rendering above) and tube then offer them up to your printer with the front tube insert held alongside so you can tweak the tube length if needed. I aimed for ~1mm clearance between the outside of each bearing and the upstand wall.

Before fitting the outer bearing, tap (M6) one or more of the 5mm holes in the threaded shaft and insert the m6x8 grub screw (setscrew in some parts of the world). Fit the threaded shaft onto the tube, nip down the grub screw and lastly fit the outer bearing.

The tapered cups and spindle nut just slide over the front bearing and front tube insert.

Drawings:

Tube Inserts: https://a360.co/2wrVHHm

Tapered Inserts: https://a360.co/2K2XuV3

Spool Nut: https://a360.co/2Klaals

Threaded Shaft: https://a360.co/2I283eN

Enjoy.

Updated the spool shaft to have a slightly thicker body after I had one split around the base of the threaded portion.

Nov '19 - Added holders for the Colorfabb 2Kg reels. These reels are not only larger diameter but thicker than the 1Kg reels. The inner fits to the shaft as normal and the nut has an integral 'cone' for the 52mm core together with a bit of reduced depth to accomodate the 2Kg reels.

You may also need high spool mounts so I've included a version of those too.

I don't like machines that make unexpected CLUNK! noises (and having a kilo of filament bouncing on the top of the printer doesn't sound like a great feature) so I designed this totally over-engineered bearing mounted shaft with tapered inserts to fit multiple spool sizes.

Using this shaft, the spool very gently rotates as the filament is pulled down by the extruder.

As well as the printed parts you'll also need:

2 x 10x26x8 bearings (I used 6000ZZ; very common and a couple of quid off EBay)

1 x 20mm OD, 17mm ID tube around 127mm long.

1 x M6x8 grub or set screw.

I say 'around' 127mm for the tube as that wasn't the original length I used (started at 130mm IIRC) and had to tweak it a bit as the upstands in the original design do have some flex along the shaft axis.

Anyway, I've includes links below for the Fusion 360 CAD files if you need to change anything.

Printing.

You need support turned on for both the spindle nut and the tube inserts but not for the other parts.

I used a 2mm wall thickness and 30% triangular infill for the tube inserts. 1mm and 20% for the other parts.

Assembly.

The tube inserts were designed to be a 'tight sliding' fit into the tube and bearing. This fit obviously depends on the accuracy of your printer. A slightly loose fit can be accomodated with a dab of bearing retainer (aka superglue). A tight fit means a bit of post-processing or tweak the model and reprint.

I would suggest you assemble the back tube insert (the left hand red bit in the rendering above) and tube then offer them up to your printer with the front tube insert held alongside so you can tweak the tube length if needed. I aimed for ~1mm clearance between the outside of each bearing and the upstand wall.

Before fitting the outer bearing, tap (M6) one or more of the 5mm holes in the threaded shaft and insert the m6x8 grub screw (setscrew in some parts of the world). Fit the threaded shaft onto the tube, nip down the grub screw and lastly fit the outer bearing.

The tapered cups and spindle nut just slide over the front bearing and front tube insert.

Drawings:

Tube Inserts: https://a360.co/2wrVHHm

Tapered Inserts: https://a360.co/2K2XuV3

Spool Nut: https://a360.co/2Klaals

Threaded Shaft: https://a360.co/2I283eN

Enjoy.

Updated the spool shaft to have a slightly thicker body after I had one split around the base of the threaded portion.

Nov '19 - Added holders for the Colorfabb 2Kg reels. These reels are not only larger diameter but thicker than the 1Kg reels. The inner fits to the shaft as normal and the nut has an integral 'cone' for the 52mm core together with a bit of reduced depth to accomodate the 2Kg reels.

You may also need high spool mounts so I've included a version of those too.

Similar models

thingiverse

free

PRUSA MMU2 Wall mount spool holder by ad_lamy

...two threaded mainshaft, with or without bearings, for the bearing version you need hk1012 needle rollers and rectified steel rod.

grabcad

free

Prusa i3 MK3 MMU2 Spool Holder

...two threaded mainshaft, with or without bearings, for the bearing version you need hk1012 needle rollers and rectified steel rod.

thingiverse

free

Dual Reel Adapter by backlash63

...do so with minimal materials. i included an insert for separation of the two reels if you feel it is necessary. fits 52mm spools.

thingiverse

free

Filament spool holder with bearings by dgeral

...mm spools.

you need a 5mm threaded shaft, 2 nuts and 2 bearings (16mm ext diameter).

you can attach a filament oiler at the base.

thingiverse

free

Fidget Spinner by Shinns

...ss the fusion 360 designs here:

2-6 bearing: http://a360.co/2qflz6z

7 bearing: http://a360.co/2qedxrm

cap: http://a360.co/2qn95at

thingiverse

free

Ultimate Spool Holder for Ultimaker by enur

...earing on the shaft and also reduces friction. you can manually adjust the how freely the reel is spinning by the nut at the end.

thingiverse

free

Duplicator 6 Spool Holder by leocov

...lls but not too fast.

screw the centering cone on all the way on and off a few times to chase the threads and make them smoother.

thingiverse

free

Tevo Little Monster filament spool replacement with bearings by mlinuxguy

...pool.

it reduces the friction quite a bit on the spool allowing for the flying extruder to easily pull new filament off the roll.

thingiverse

free

Solder Spool Sleeve

...ownloadable file that will allow the parameters to easily be changed to whatever size you need.

a360 fileshttps://a360.co/357iiph

thingiverse

free

CR-6 SE Spool Holder by pclapp19

... do not want any drag at all just replace the tension nut with a nylon nut and don't tighten the spindle to the mounting nut.

Russell

turbosquid

$10

Minotti RUSSELL

...id

royalty free 3d model minotti russell for download as max on turbosquid: 3d models for games, architecture, videos. (1563186)

turbosquid

$59

Jack Russel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Russel Dining Chair

...royalty free 3d model russel dining chair for download as max on turbosquid: 3d models for games, architecture, videos. (1363536)

turbosquid

$10

Minotti Russell Lounge

...alty free 3d model minotti russell lounge for download as max on turbosquid: 3d models for games, architecture, videos. (1563963)

3d_export

$59

Jack Russel 3D Model

...jack russel 3d model 3dexport jack russell dog terrier tail pet square isolated on white mammal...

turbosquid

$125

George Russell 2019

... russell 2019 for download as ma, 3ds, obj, c4d, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1481510)

turbosquid

$180

Jack Russell Terrier dog

...ty free 3d model jack russell terrier dog for download as c4d on turbosquid: 3d models for games, architecture, videos. (1333226)

turbosquid

$10

Minotti Russell Ottoman Set

...model minotti russell ottoman set for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1493341)

turbosquid

$25

Russel Wright Cocktail Set

... russel wright cocktail set for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1218482)

turbosquid

$14

Minotti Russell Armchair 1

... minotti russell armchair 1 for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1602745)

Taz

3d_ocean

$19

TAZ RIGGED

...ax version only texture is used only for wb logo, taz dont need texture no special render engine needed, just unzip and render...

3d_export

$5

Taz character 3D Model

...taz character 3d model

3dexport

taz toon character cartoon

taz character 3d model supercigale 22095 3dexport

cg_studio

$10

Taz 3D3d model

...taz 3d3d model

cgstudio

.3ds .max - taz 3d 3d model, royalty free license available, instant download after purchase.

cg_studio

$15

Taz Rigged3d model

...ged3d model

cgstudio

.3ds .fbx .max .obj - taz rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Taz Toy Calendar 3D Model

... 3d model

3dexport

taz toy calendar day month year looney tunes cartoon kid child

taz toy calendar 3d model nkfrds 49687 3dexport

3d_export

$10

Taz Tasmanian Devil RIGGED 3D Model

...y tunes anime bunny rigged material fantasy creature diable dessin

taz tasmanian devil rigged 3d model supercigale 28390 3dexport

3d_export

$19

Thylacine 3D Model

...animalia chordata mammalia marsupial dog extinct animals tiger tassie taz thylacine 3d model poly3dmodels 90790...

3d_export

$12

Bowl Decorated 3D Model

...bowl decorated 3d model 3dexport bowl tazn elements ceramics kitchen plastic cup container decorative cake biscuits...

3ddd

$1

Crate & Barrel Serveware

...crate & barrel поднос -http://www.crateandbarrel.com/feast-platter/s186961 набор ножей для сыра -http://www.crateandbarrel.com/tazcheese-knife-3-piece-set/s681377 бокал...

thingiverse

free

TAZ by Taz8373

...taz by taz8373

thingiverse

my 1st print

Shaft

3d_export

$5

shaft handle

...shaft handle

3dexport

shaft handle

3d_export

$5

shaft bracket

...shaft bracket

3dexport

shaft bracket

turbosquid

$3

Shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

shaft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

crank shaft

...crank shaft

3dexport

crank shaft with piston with different materials

3d_export

$8

shaft bearing

...shaft bearing

3dexport

shaft bearing m10, m12,m16, m20 and m27

3d_export

$5

hexagonal shaft knob

...hexagonal shaft knob

3dexport

hexagonal shaft knob

3d_export

$5

shaft hand wheel

...shaft hand wheel

3dexport

shaft hand wheel

3d_export

$5

triangular shaft knob

...triangular shaft knob

3dexport

triangular shaft knob

3d_export

$5

octagonal shaft knob

...octagonal shaft knob

3dexport

octagonal shaft knob

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Brown

3ddd

free

Dialma Brown

...dialma brown

3ddd

комод , dialma brown

dialma brown

3d_ocean

$9

Purple and Brown

...purple and brown

3docean

ballon brown cartoon purple

purple and brown

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown , комод

комод dialma brown

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown , камин

камин dialma brown

3ddd

$1

Dialma brown

...dialma brown

3ddd

dialma brown

диван dialma brown sofa

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown

итальянская фабрика dialma brown

www.dialmabrown.it

3ddd

$1

Dialma Brown

...3ddd

dialma brown , библиотека

библиотека итальянской фабрики dialma brown, арт.db001646

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown

dialma brown. элемент декора в современном стиле

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown

настенный светильник итальянской фабрики dialma brown. арт. db002647

3ddd

$1

Dialma Brown

...dialma brown

3ddd

dialma brown

настольный светильник итальянской фабрики dialma brown. арт. db002658

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

6

3d_export

$18

tulip 6

...tulip 6

3dexport

tulip 6

3d_export

$5

hinge 6

...hinge 6

3dexport

hinge 6

3ddd

$1

MASIERO / FLASHWOOD STL 6 + 6

...6

3ddd

masiero

торшер flashwood stl 6 + 6 фабрики masiero

http://www.masierogroup.com/c87_697/it/flashwood%20stl%206%20+%206.ashx

turbosquid

$110

Atmos Cannon 2000 6*6

...yalty free 3d model atmos cannon 2000 6*6 for download as skp on turbosquid: 3d models for games, architecture, videos. (1528591)

turbosquid

$1

ae 6 6 electric locomotive

... free 3d model ae 6 6 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707537)

turbosquid

$39

A-6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

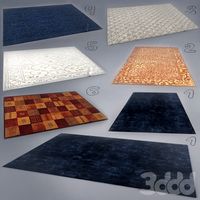

6 ковров

...6 ковров

3ddd

ковры , ковер

6 ковров

turbosquid

$12

Calligraphic Digit 6 Number 6

...hic digit 6 number 6 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389336)

turbosquid

$19

Case For Phone 6 Girl 6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Iphone 6 & 6 Plus All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.