Thingiverse

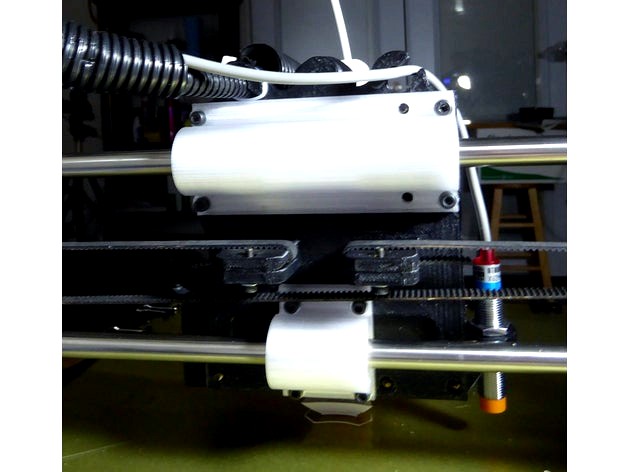

Taz 4 or 5 Bearing and Extruder Holder Mods by jaln

by Thingiverse

Last crawled date: 3 years ago

This mod addresses the slop in Taz 4 (or Taz 5, 3, etc.) bearings and extruder holders.

The slop translates into uneven surfaces which are readily apparent on large flat horizontal surfaces, but also affect every other print in some way.

There are a few mods here and you can try all or one at a time.

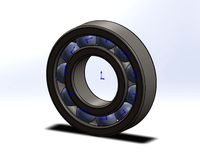

First off, the bearing holders on the X carriage. You will notice that on a Taz 6 that Lulzbot started using bearing holder without a break in the circumference. There are two replacements here that fit existing inserts. Also, the bearings are changed out for the precision versions of the 10mm Igus bearings. I used the RJ4JP-01-10 version. Lulzbot uses a different precision bearing version on the bed of the Taz 6 which will also work. The 'P' in the part number is for 'precision' which has a tighter tolerance than the ones they used on the Taz 4 and 5 stock. I got mine on eBay for a decent price.

This mod alone will noticeably help with the X carriage slop.

The bearings can be difficult to install. I used a small vice for the single bearing with rubber protectors and a 7/16 long socket and a rawhide mallet for the double bearings. Do not use metal hammers and un-faced vices. The Igus bearing are soft and can be damaged if not handled properly. Slow and steady and light tapping only! If you need to get the bearings out of the double holder, cut the holder in half in the middle first. The single bearing can be a bit difficult without the right tools. You can remove some of the retainer ring at the insertion end to make it easier to install the bearing. It really only takes 1/4 to 1/2 of the ring to retain the bearing so you can use and X-Acto knife to cut some of the locking ring away to make the insertion easier. However the bearing will press into the one without modification if you just take it slow and use a c-clamp or small vice with rubber protection, or a long 7/16 (10mm) socket for a driver with a light mallet over a hole or bridged in a vice.

The next part is to stiffen up the extruder holder. if you grab the stock holder or large gear you will see that it moves around too much without much effort. The stiffened holder will stop that. You will need to replace the existing screw with an m3 x 30mm screw, using the old washer. This design makes it easier to install the nuts for the latch. You will have to use some supports on the bearing socket that faces the printer bed. I used sight support inside the nut chambers and struggled a bit with getting the support out through the small holes.

If I were to do it again, I would forego the supports in those slots and chambers. Make sure not to over-tighten the 3/8 lock nut on reassembly and remember the two washers outside of the rear bearing.

I also changed the bearings on the Y-axis bed, but did not use the newer bearing holders and only two of the precision bearings instead of all four because I could not get the bed to slide easily with all of those thing changed. I suspect is was because the two 10mm rails were not parallel, and I did not try adjusting the frame. That may have allowed changing out all the bearings and holders. I just settled for using the stock single bearing holders and two of four precision bearings which improved the slop in the bed. Changing everything out without adjusting the frame was binding too much to be used.

The slop translates into uneven surfaces which are readily apparent on large flat horizontal surfaces, but also affect every other print in some way.

There are a few mods here and you can try all or one at a time.

First off, the bearing holders on the X carriage. You will notice that on a Taz 6 that Lulzbot started using bearing holder without a break in the circumference. There are two replacements here that fit existing inserts. Also, the bearings are changed out for the precision versions of the 10mm Igus bearings. I used the RJ4JP-01-10 version. Lulzbot uses a different precision bearing version on the bed of the Taz 6 which will also work. The 'P' in the part number is for 'precision' which has a tighter tolerance than the ones they used on the Taz 4 and 5 stock. I got mine on eBay for a decent price.

This mod alone will noticeably help with the X carriage slop.

The bearings can be difficult to install. I used a small vice for the single bearing with rubber protectors and a 7/16 long socket and a rawhide mallet for the double bearings. Do not use metal hammers and un-faced vices. The Igus bearing are soft and can be damaged if not handled properly. Slow and steady and light tapping only! If you need to get the bearings out of the double holder, cut the holder in half in the middle first. The single bearing can be a bit difficult without the right tools. You can remove some of the retainer ring at the insertion end to make it easier to install the bearing. It really only takes 1/4 to 1/2 of the ring to retain the bearing so you can use and X-Acto knife to cut some of the locking ring away to make the insertion easier. However the bearing will press into the one without modification if you just take it slow and use a c-clamp or small vice with rubber protection, or a long 7/16 (10mm) socket for a driver with a light mallet over a hole or bridged in a vice.

The next part is to stiffen up the extruder holder. if you grab the stock holder or large gear you will see that it moves around too much without much effort. The stiffened holder will stop that. You will need to replace the existing screw with an m3 x 30mm screw, using the old washer. This design makes it easier to install the nuts for the latch. You will have to use some supports on the bearing socket that faces the printer bed. I used sight support inside the nut chambers and struggled a bit with getting the support out through the small holes.

If I were to do it again, I would forego the supports in those slots and chambers. Make sure not to over-tighten the 3/8 lock nut on reassembly and remember the two washers outside of the rear bearing.

I also changed the bearings on the Y-axis bed, but did not use the newer bearing holders and only two of the precision bearings instead of all four because I could not get the bed to slide easily with all of those thing changed. I suspect is was because the two 10mm rails were not parallel, and I did not try adjusting the frame. That may have allowed changing out all the bearings and holders. I just settled for using the stock single bearing holders and two of four precision bearings which improved the slop in the bed. Changing everything out without adjusting the frame was binding too much to be used.

Similar models

thingiverse

free

Lulzbot Universal Filament holder by mde091234

...eed 4 - m3-.5 3.8mm heatset insert and 4 m3 socket head cap screws. insert the heatset inserts into the spool holder attachment.

thingiverse

free

Single Bearing Holder Lulzbot taz by slashed_wings

...sion (which i broke twice trying to fit these bearings) also as the screw is supported all the way though they are a tighter fit.

thingiverse

free

12mm Y rod mounting hardware for the Lulzbot Taz 6 printer by piercet

... bearings, whatever the one in the taz 12mm single bearing holder on the carriage is

2 500mm long 12mm rods (preferably hardened)

thingiverse

free

Taz 6 Mod - Revised 10mm Y-Axis Bearing Holder from the Taz Pro

...he pro and that it can be bolted onto the 6 without mods.

voids warranty, use at your own risk, yadda yadda yadda.

happy modding!

thingiverse

free

Non-intrusive PCB Mill Vice Bed Mod for Lulzbot TAZ by solarnetone

...nserted in the provided holes, securing each pair of rails together. you will need to print two of each file for a complete set.

thingiverse

free

12mm LM12UU Bearing Holder for Lulzbot TAZ 6 by ant0ny

...side diam of 21mm.

i have not changed the outer dimensions of the housing, so it should just bolt onto the original lulzbot taz 6

thingiverse

free

Spool holder for Lulzbot Taz 6 by MuchHat

...he orientation on the files: the bearing with the wider part flat on the bed, and the "u" bar vertically when printing.

thingiverse

free

TAZ 5 Strengthened Hexagon Extruder Body by wantmys2000

...9.

all the base models used in this change were based on the freecad drawings included by lulzbot on the sd card with my taz 5.

thingiverse

free

Lulzbot Extruder Mod for Printing Flexible Filaments by CheeseJam

... ex for the mini: https://devel.lulzbot.com/print-profiles/cura/mini_flexystruder_v2/ change the nozzle size from 0.6mm to 0.5mm!

thingiverse

free

Custom Taz X Ends and X Carriage based off Lulzbot Mini by TechsavvyCNC

...ount can be downloaded from the lulzbot website: http://devel.lulzbot.com/easy_taz_mini/daffodil/production_parts/printed_parts/

Jaln

thingiverse

free

Vase-X3 by jaln

...awn.

there are two sizes of this triangle to hex transition.

they are printed upside to insure that they stay stuck to the bed.

thingiverse

free

AmanteVase by jaln

...is especially useful when you are using pause to change filament colors. pausing on the inner wall will help conceal the change.

thingiverse

free

Vase-X4 by jaln

...t 100mm.

the smaller one is printed upside down for stability while printing.

this design is my favorite of this series.

enjoy!

thingiverse

free

Turbowlz II by jaln

...r the other designs to make your own designs.

lid knob made bigger on 01/22/15. deleted old file-- new file has a designation.

thingiverse

free

Turbo-Bowl: Turbo-Vase+, the Sequel Continues by jaln

...the sequel continues by jaln

thingiverse

here's some matching bowls for vase10a.

(turbo-vase+, the sequel).

scaled 1x and 2x

thingiverse

free

TurBowlz I by jaln

...ed .33mm layers, i am amazed that this even printed with no support!

a testament to lulzbot taz4 and gizmo dorks transparent abs.

thingiverse

free

BublaVase by jaln

... print job. not intentional, but i often recommend printing partial prints to make bowls from vases. some look great both ways.

thingiverse

free

Vase-X2 three versions by jaln

...previous vases were rotations, sweeps along splines, and boolean functions.

scale em, stretch em. have fun.

show us your work.

thingiverse

free

FlamoVase by jaln

...nt at about 30% of its full height, it makes a great screw on lid for the full print of the same scale. see the last two photos.

thingiverse

free

Vase-X1 by jaln

...ave slots. x3 is thicker.

the x1 in the photo was printed right side up and decided to leave the heated bed prior to completion.

Taz

3d_ocean

$19

TAZ RIGGED

...ax version only texture is used only for wb logo, taz dont need texture no special render engine needed, just unzip and render...

3d_export

$5

Taz character 3D Model

...taz character 3d model

3dexport

taz toon character cartoon

taz character 3d model supercigale 22095 3dexport

cg_studio

$10

Taz 3D3d model

...taz 3d3d model

cgstudio

.3ds .max - taz 3d 3d model, royalty free license available, instant download after purchase.

cg_studio

$15

Taz Rigged3d model

...ged3d model

cgstudio

.3ds .fbx .max .obj - taz rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Taz Toy Calendar 3D Model

... 3d model

3dexport

taz toy calendar day month year looney tunes cartoon kid child

taz toy calendar 3d model nkfrds 49687 3dexport

3d_export

$10

Taz Tasmanian Devil RIGGED 3D Model

...y tunes anime bunny rigged material fantasy creature diable dessin

taz tasmanian devil rigged 3d model supercigale 28390 3dexport

3d_export

$19

Thylacine 3D Model

...animalia chordata mammalia marsupial dog extinct animals tiger tassie taz thylacine 3d model poly3dmodels 90790...

3d_export

$12

Bowl Decorated 3D Model

...bowl decorated 3d model 3dexport bowl tazn elements ceramics kitchen plastic cup container decorative cake biscuits...

3ddd

$1

Crate & Barrel Serveware

...crate & barrel поднос -http://www.crateandbarrel.com/feast-platter/s186961 набор ножей для сыра -http://www.crateandbarrel.com/tazcheese-knife-3-piece-set/s681377 бокал...

thingiverse

free

TAZ by Taz8373

...taz by taz8373

thingiverse

my 1st print

Mods

design_connected

$13

MOD. 4233 - MOD. 4234 Table Lamp

...mod. 4233 - mod. 4234 table lamp

designconnected

arcahorn mod. 4233 - mod. 4234 table lamp computer generated 3d model.

design_connected

$11

MOD.1095

...mod.1095

designconnected

mod.1095 computer generated 3d model. designed by sarfatti, gino.

3ddd

$1

fireplaces mod Spec

...fireplaces mod spec

3ddd

камин

fireplaces mod spec 180x90x125h

3ddd

free

Flos Mod. 2129

... mod

фабрика: flos

модель: mod. 2129

описание: подвесной светильник, металл, белый, черный.

сайт: www.flos.com

turbosquid

$34

Mod Lamp.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Maars Mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mod 70..

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MOD Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

turbosquid

$1

re 4-4 electric locomotive

... free 3d model re 4 4 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707845)

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло