GrabCAD

Swashplateless rotor head

by GrabCAD

Last crawled date: 1 year, 11 months ago

https://pocharitechnologies.com/2019/03/01/electronic-actuated-rotor-head/

Many mistakenly assume slip rings are required to achieve electric IBC, this is incorrect. Pochari Technologies has solved the long-standing issue facing IBC which was the need fo either hydraulic slip rings or electric slip rings. A simple solution is where a permanent magnet generator is mounted on the rotating assembly, a shaft passes through the drive system to the fixed assembly, providing constant power as long as the rotor system is spinning. The system provides a comparable if not higher level of redundancy than traditional swashplate-pitch link hydraulic rotor control systems while eliminating all their disadvantages. IBC provides up to an 80% reduction in vibration and significant reduction in acoustic signature as well as reduced power consumption. IBC also increases rotorcraft agility and maneuverability.

“Rotorcraft such as helicopters commonly make use of a complex mechanical device known as a “swashplate” to control collective pitch (for providing a change in altitude) and cyclic pitch (for providing change in attitude, and thus maneuvering). By actuating the angles of attack of the rotor blades, each of which is capable of rotating at its root, where it connects to the rotor head, the collective and cyclic pitch of the helicopter can be controlled”

The swashplate, which comprises a non-rotating lower plate movably connected to a rotating upper plate by bearings, is typically located just below the rotor head on the axis of the main rotor shaft, and is itself typically actuated by hydraulic cylinders mounted to the chassis. When rotorcraft controls actuate the hydraulic cylinders, the hydraulic cylinders move and pitch the non-rotating lower plate up and down and at an angle with respect to the plane of the main rotor. This up-and-down movement and/or pitch is transferred to the rotating half of the swashplate. The rotating half of the swashplate thereby transmits the motion of the stationary actuators to the several rotating pitch links, which connect the upper plate of the swashplate to the blade roots and act as lever arms, increasing or decreasing the blades’ angle of attack.

A swashplate, however, disadvantageously adds weight and aerodynamic drag to a rotorcraft, which can in turn reduce power, speed, maneuverability, and increase cost of flight. Another major disadvantage of a swashplate is that it limits control inputs to one per revolution of the rotor blades (except in the case of a three-bladed rotor). In addition, because of its mechanical complexity and the fact that it provides a single point of critical failure, swashplates necessitate many hours of inspection and preventative maintenance. The pitch links of a swashplate, which occupy a relatively large volume on the upper side of a rotor shaft and are therefore difficult to shield, also introduce significant ballistic vulnerability, as from missile attack, flak, and other flying debris. Damage to any one of the pitch links results in a loss of rotorcraft control.

Many mistakenly assume slip rings are required to achieve electric IBC, this is incorrect. Pochari Technologies has solved the long-standing issue facing IBC which was the need fo either hydraulic slip rings or electric slip rings. A simple solution is where a permanent magnet generator is mounted on the rotating assembly, a shaft passes through the drive system to the fixed assembly, providing constant power as long as the rotor system is spinning. The system provides a comparable if not higher level of redundancy than traditional swashplate-pitch link hydraulic rotor control systems while eliminating all their disadvantages. IBC provides up to an 80% reduction in vibration and significant reduction in acoustic signature as well as reduced power consumption. IBC also increases rotorcraft agility and maneuverability.

“Rotorcraft such as helicopters commonly make use of a complex mechanical device known as a “swashplate” to control collective pitch (for providing a change in altitude) and cyclic pitch (for providing change in attitude, and thus maneuvering). By actuating the angles of attack of the rotor blades, each of which is capable of rotating at its root, where it connects to the rotor head, the collective and cyclic pitch of the helicopter can be controlled”

The swashplate, which comprises a non-rotating lower plate movably connected to a rotating upper plate by bearings, is typically located just below the rotor head on the axis of the main rotor shaft, and is itself typically actuated by hydraulic cylinders mounted to the chassis. When rotorcraft controls actuate the hydraulic cylinders, the hydraulic cylinders move and pitch the non-rotating lower plate up and down and at an angle with respect to the plane of the main rotor. This up-and-down movement and/or pitch is transferred to the rotating half of the swashplate. The rotating half of the swashplate thereby transmits the motion of the stationary actuators to the several rotating pitch links, which connect the upper plate of the swashplate to the blade roots and act as lever arms, increasing or decreasing the blades’ angle of attack.

A swashplate, however, disadvantageously adds weight and aerodynamic drag to a rotorcraft, which can in turn reduce power, speed, maneuverability, and increase cost of flight. Another major disadvantage of a swashplate is that it limits control inputs to one per revolution of the rotor blades (except in the case of a three-bladed rotor). In addition, because of its mechanical complexity and the fact that it provides a single point of critical failure, swashplates necessitate many hours of inspection and preventative maintenance. The pitch links of a swashplate, which occupy a relatively large volume on the upper side of a rotor shaft and are therefore difficult to shield, also introduce significant ballistic vulnerability, as from missile attack, flak, and other flying debris. Damage to any one of the pitch links results in a loss of rotorcraft control.

Similar models

grabcad

free

Bell-206 Main Rotor Blades Pitch Angle Control System

....

one of the modules of main rotor blades steering system is a swashplate. this project concentrates on the swashplate assembly.

grabcad

free

HELICOPTER ROTOR BLADES

...ed by a swashplate connected to the helicopter flight controls. helicopters are one example of rotary-wing aircraft (rotorcraft).

grabcad

free

Helicopter Rotor

...arboxes along the tail boom. the blade pitch is typically controlled by a swashplate connected to the helicopter flight controls.

grabcad

free

Helicopter transmission system

...helicopter transmission system

grabcad

rotorcraft transmission with hydraulic servos and rotor head system.

grabcad

free

5 Blade RC Helicopter Swash Head

.... power is supplied from a large gas engine or turbine to a large primary pulley (not shown) at the bottom of the primary shaft.

grabcad

free

Tail rotor with swash plate

...main constant and when a rotor shaft is rotating, you will see how is changing a angle of blades of tail rotor within one cycle.

thingiverse

free

Blade 230s Rotor Head Pitch Link by kingdallen

...ing whatever slicer you prefer. petg filament is recommended but pla may work. print with the wide end of the hole facing down.

grabcad

free

Hydrogen powered turbine helicopter

...ydrogen is the world's first company developing freighter aircraft and rotorcraft powered by liquid hydrogen-fueled turbines.

3dwarehouse

free

Sketchyphysics Helicopter Swashplate Model

... rotor head of helicopter blade movement #aircraft #animation #blade #copter #heli #helicopter #rotor #sketchyphysics #swashplate

grabcad

free

MECHANICAL GRIPPER ACTUATED BY HYDRAULIC SYSTEM

...h is for study purpose. gripper has 3 hydraulic double acting cylinder and spring control gripper.

good renders are welcome...

Swashplateless

thingiverse

free

Hings for Swashplateless Hellicopter by minedge

...hings for swashplateless hellicopter by minedge

thingiverse

software : https://github.com/minedge/swashplateless-hellicopter

grabcad

free

Swashplateless Variable Pitch Propeller (Design Concept)

...grabcad.com/library/vpp-brushless-motor

my freelancing (3d modeling services) at fiver:

https://www.fiverr.com/users/mohd_abdin/

Rotor

design_connected

$4

Rotor

...rotor

designconnected

bellato international rotor coffee tables computer generated 3d model. designed by luciano bertoncini.

3ddd

free

Cassina / Rotor

...assina / rotor

3ddd

cassina , обеденный

стол cassina/rotor

габаритные размеры 303x123x74

turbosquid

$5

Brake Rotor

...3d model brake rotor for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1288076)

turbosquid

$3

Brake rotor

...e 3d model brake rotor for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1318483)

turbosquid

$30

rotor disk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Rotor Slide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Brake Rotor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Brake Rotor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Brakr Rotor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

helicopter rotor system

...oyalty free 3d model helicopter rotor system for download as on turbosquid: 3d models for games, architecture, videos. (1598497)

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

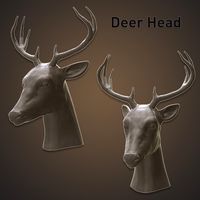

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

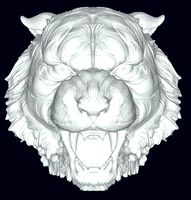

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear