Thingiverse

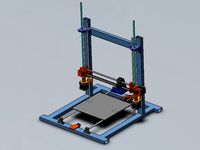

StrongPrint - The DIY Metal 3D Printer by kolergy

by Thingiverse

Last crawled date: 3 years ago

Design & Built with the support of the Artilect Fablab in Toulouse France

Affordable DIY metal 3d Printer based on TIG process

For more details in English: http://reprap.org/wiki/StrongPrint

Pour plus de details en Francais: http://reprap.org/wiki/StrongPrint/fr

Article on 3Dprint.com: http://3dprint.com/4787/3d-metal-printer-600-euros/

For the french speakers there is an article on 3D Natives:http://www.3dnatives.com/strong-print-3d-metal/

Videos:

Lift arc ignition test: https://www.youtube.com/watch?v=HJQUvF1kOV0

3 Layers line test: http://youtu.be/ro6W5TgIXXA

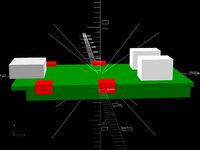

It consists of the Enlarged Rostock modified with a magnetic effector & coupes to a cheap 160Amps inverter MMA power source.

Spool Holder available from Iron_Momo: http://www.thingiverse.com/thing:335662/#files

Wire feed was one of the most difficult item to get right (and at the time being is not fully stabilized). What seems to work the best is to rapidly extrude & retract the metal wire to make sure it only melt where you want it to melt

Wire is 0.6mm steel. for MIG.

This machine is still very experimental & will evolve.

Setup & test phase activities:

Done: Arc ignition, process to reliably ignite the arc with the lift arc technique

Done: Arc Power & speed control to identify adequate settings to perform surface fusion of the baseplate

Done: initial metal deposition identify wire nozzle angle & position

Done: initial metal deposition identify speed wire feed quantity.

Done: Initial metal deposition identify preferencial directions

Done: initial few Layers stack-up test

On Going: identify adequate speed & power profile for layers stack-up

On Going: manage layer height

On Going: large number of layers stack-up test

Printer design & make:

Working: Printer movement mechanism, cinematics from Enlarged Rostock with added magnetic bearings. (a slightly larger magnet size could be beneficial)

Working: Fixed torch & nozzle holder

Working: Wire feed motor (Extruder)

Working: Wire nozzle holder & positioning device

Working: Tig torch modification

Working: Power source coupled with TIG torch

Working: Shielding of all wirerings to prevent electromagnetic interferences

Working: Wire roll holder including brake & wire damping mechanism

Working: Shilding of the control board

Working: Implemented Ignition GCode command & automatic lift arc ignition

Working: New 160A power source 80A was clearly to weak

Working: Arduino controlled Solenoid valve for argon

To Do: Arduino controlled power source

To Do: HF ignition system

Made in Fablab Artilect: https://artilect.fr/

Design Details to be provided on http://reprap.org/wiki/StrongPrint

(Page still in construction)

Affordable DIY metal 3d Printer based on TIG process

For more details in English: http://reprap.org/wiki/StrongPrint

Pour plus de details en Francais: http://reprap.org/wiki/StrongPrint/fr

Article on 3Dprint.com: http://3dprint.com/4787/3d-metal-printer-600-euros/

For the french speakers there is an article on 3D Natives:http://www.3dnatives.com/strong-print-3d-metal/

Videos:

Lift arc ignition test: https://www.youtube.com/watch?v=HJQUvF1kOV0

3 Layers line test: http://youtu.be/ro6W5TgIXXA

It consists of the Enlarged Rostock modified with a magnetic effector & coupes to a cheap 160Amps inverter MMA power source.

Spool Holder available from Iron_Momo: http://www.thingiverse.com/thing:335662/#files

Wire feed was one of the most difficult item to get right (and at the time being is not fully stabilized). What seems to work the best is to rapidly extrude & retract the metal wire to make sure it only melt where you want it to melt

Wire is 0.6mm steel. for MIG.

This machine is still very experimental & will evolve.

Setup & test phase activities:

Done: Arc ignition, process to reliably ignite the arc with the lift arc technique

Done: Arc Power & speed control to identify adequate settings to perform surface fusion of the baseplate

Done: initial metal deposition identify wire nozzle angle & position

Done: initial metal deposition identify speed wire feed quantity.

Done: Initial metal deposition identify preferencial directions

Done: initial few Layers stack-up test

On Going: identify adequate speed & power profile for layers stack-up

On Going: manage layer height

On Going: large number of layers stack-up test

Printer design & make:

Working: Printer movement mechanism, cinematics from Enlarged Rostock with added magnetic bearings. (a slightly larger magnet size could be beneficial)

Working: Fixed torch & nozzle holder

Working: Wire feed motor (Extruder)

Working: Wire nozzle holder & positioning device

Working: Tig torch modification

Working: Power source coupled with TIG torch

Working: Shielding of all wirerings to prevent electromagnetic interferences

Working: Wire roll holder including brake & wire damping mechanism

Working: Shilding of the control board

Working: Implemented Ignition GCode command & automatic lift arc ignition

Working: New 160A power source 80A was clearly to weak

Working: Arduino controlled Solenoid valve for argon

To Do: Arduino controlled power source

To Do: HF ignition system

Made in Fablab Artilect: https://artilect.fr/

Design Details to be provided on http://reprap.org/wiki/StrongPrint

(Page still in construction)

Similar models

thingiverse

free

Marlin Update for Strong Print by kolergy

...tested on delta printer should work on cartesian but untested.

designed for strongprint http://www.thingiverse.com/thing:329498

thingiverse

free

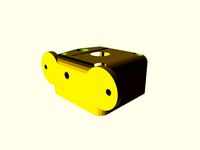

MiniStruder V0.3 by kolergy

...llerblades with m8 screw

print with 3 outside layers, 15% fill ratio & supports

made in fablab artilect: https://artilect.fr/

grabcad

free

WP-20 TIG TORCH

...wp-20 tig torch

grabcad

external parts of a 200 amp water cooled tig torch

grabcad

free

Deltapi 3D printer with STEP files

...deltapi 3d printer with step files

grabcad

http://reprap.org/wiki/delta-pi

grabcad

free

Rostock MAX - Delta 3D printer

...rostock max - delta 3d printer

grabcad

rostock max - delta 3d printer

http://seemecnc.com/

http://reprap.org/wiki/rostock_max

thingiverse

free

box for ramps 1.4 with smart controller by jfpion

...p://reprap.org/wiki/reprapdiscount_smart_controller but could do with other ultipanel (with some adjustement for the lcd fitting)

grabcad

free

Kossel 3D printer

...be.com/watch?feature=player_detailpage&v=do3ciyycxnc

http://www.youtube.com/watch?feature=player_detailpage&v=b_xfvaumqbq

thingiverse

free

Lutz 3D Printer by gabrielmini

...printer by gabrielmini

thingiverse

multimaterial, medium volume 3d printer lutz (http://reprap.org/wiki/lutz)

under construction

cg_trader

$8

TIG Torch

...tig torch

cg trader

tig torch 3d metal autodesk, formats include obj, fbx, stl, sldprt, iam, stp, ready for 3d animation and ot

grabcad

free

Torch TIG welding

...torch tig welding

grabcad

torch for tig and mig welding

Strongprint

thingiverse

free

StrongPrint spool holder by Iron_Momo

...giverse.com/thing:329498)

v1.1 - notch added for easier spool replacement, now only one type of screw is required for assembly.

thingiverse

free

Simple GCode Generator in Python by kolergy

...simple pyton script to generate gcode to test the strongprint 3d metal printer http://www.thingiverse.com/thing:329498 latest version always available on...

thingiverse

free

Marlin Update for Strong Print by kolergy

...printer should work on cartesian but untested. designed for strongprint ...

thingiverse

free

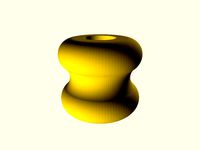

Magnetic Carriage V0.3 by kolergy

...magnetic carriage v0.3 by kolergy thingiverse magnetic carriage for strongprint http://www.thingiverse.com/thing:329498 based on supermagnete 15 mm donut magnethttp://www.supermagnete.fr/eng/r-15-06-06-n the...

thingiverse

free

MiniStruder V0.3 by kolergy

...single printed part. this extruder is part of the strongprint the metal 3d printer http://www.thingiverse.com/thing:329498 designed in openscad to:...

Kolergy

thingiverse

free

AirForce Tip by kolergy

...airforce tip by kolergy

thingiverse

end bit to be 3d printed

thingiverse

free

WireGuide V0.9 by kolergy

...wireguide v0.9 by kolergy

thingiverse

wire guide for strong print: http://www.thingiverse.com/thing:329498

thingiverse

free

MiniStruder for uDelta by kolergy

...er for udelta by kolergy

thingiverse

the ministruder adapted to the udelta printer

made in fablab artilect: https://artilect.fr/

thingiverse

free

Frabjous 3mm by kolergy

...jous 3mm by kolergy

thingiverse

a scaled version of http://www.thingiverse.com/thing:12271 to use 3mm plywood or other materials

thingiverse

free

DTE by kolergy

...t;dronons tous ensembles"

aimed at providing access to drone to persons with various handicaps

https://artilect.fr/dronelab/

thingiverse

free

Ball Holder for Magnetic Bearing by kolergy

...ball holder for magnetic bearing by kolergy

thingiverse

to comme soon

thingiverse

free

Tool Holder for the Magnetic Platform by kolergy

...tool holder for the magnetic platform by kolergy

thingiverse

soon to come

thingiverse

free

SR17 Torch Holder V0.9 by kolergy

...sr17 torch holder v0.9 by kolergy

thingiverse

to come soon

thingiverse

free

Springy Clip for uDelta by kolergy

...springy clip for udelta by kolergy

thingiverse

springy clip to reduce play on delta printers adapted to the udelta

thingiverse

free

Micro Scisky Board by kolergy

...micro scisky board by kolergy

thingiverse

open scad model of the naze32 based micro scisky board

Diy

3d_export

free

DIY 3D Printer

...diy 3d printer

3dexport

diy 3d printer model

turbosquid

$10

Diy tiered

...l diy tiered for download as max, max, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1603709)

turbosquid

$3

Diy Desk to Bench

...odel diy desk to bench for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1506589)

turbosquid

$2

DIY Moon Light

...model diy moon light for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1501170)

3d_export

$8

DIY CNC Router 3D Model

...diy cnc router 3d model

3dexport

cnc; router; diy; homemade

diy cnc router 3d model maikeru86 58463 3dexport

turbosquid

$5

Diy Kitchen Cabinets

...itchen cabinets for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1197373)

3d_export

free

Download free Diying Plant 3D Model

...download free diying plant 3d model

3dexport

diying plant blender

diying plant 3d model visitorsama 98607 3dexport

3ddd

$1

DIY coffee table + decor

... рамка для фото

кофейный столик diy 400х350х600(h) мм. моделился по фото. внимание: материалы - corona.

turbosquid

$3

Diy Wire Lamp Shade

...free 3d model diy wire lamp shade for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1347605)

cg_studio

$12

DIY MONGOLIAN LAMB STOOLS3d model

... hair soft pile white

.max - diy mongolian lamb stools 3d model, royalty free license available, instant download after purchase.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Metal

3d_ocean

$10

Metal Barrel

...metal barrel

3docean

barrel barrels metal metal barrel wood barrel

metal barrel

turbosquid

$14

Metals

...als

turbosquid

royalty free 3d model metals for download as on turbosquid: 3d models for games, architecture, videos. (1486252)

3d_ocean

$18

Metal Furniture

...metal furniture

3docean

design desk indoor industrial metal metal furniture restoration table

metal furniture 3d model

3d_export

$5

metal table

...metal table

3dexport

metal table.blend

3d_export

$5

Metal Shelf

...metal shelf

3dexport

metal shelf

3d_export

free

metal detector

...metal detector

3dexport

metal detector

3ddd

$1

metal lux

...metal lux

3ddd

dedalo , metal lux

люстра и бра metal lux коллекция dedalo.

3ddd

$1

bonded metal

...bonded metal

3ddd

https://www.forms-surfaces.com/bonded-metal

boded tiled metal

3ddd

$1

Metal

...metal

3ddd

1280-1024 бесшовный 8-)

3d_export

$5

cgaxis metal

...cgaxis metal

3dexport

notebook cgaxis metal