GrabCAD

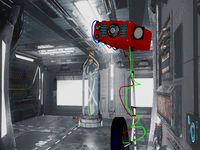

SRA100-H - Advanced Hollow Arm Robot

by GrabCAD

Last crawled date: 7 years, 1 month ago

Advanced Hollow Arm SRA100H

SRA-H

SRA100H

Nearly 20 years ago, Nachi was the pioneer of servo gun technology for spot welding. Today, Nachi continues to lead the industry in development of advanced robotic spot welding solutions – focused on making higher quality welds more quickly than in the past. With advanced industry leading hollow arm technology, the SRA-H series robots simplify cable routing by eliminating the need for external dress packages. Nachi's advanced hollow arm design improves cable life and neatly packages all pneumatic, power, and servomotor cables for turn key application success. Specifically designed for the fast paced automotive industry, SRA-H series robots will dramatically reduce cycle times, significantly improve productivity, and achieve cost reductions...achieve more with less robots! In your business "Time is Money", make the most of your money with the fastest robots available. Compare the Nachi SRA-H series against any competitor to see how much valuable time and money you can save with an SRA-H robot.

SRA series robots and their FD controllers are ideally suited to spot welding applications. The SRA-H robots are highly rigid and weight less, providing faster motion and less vibration. Advanced motion control from the FD controller provides top acceleration thereby shortening cycle-times. The FD also has 4th generation servo gun control software enabling higher motor speeds while maintaining gentle electrode contact to parts, optimizing spot welding performance. Finally, Nachi together with our welding partners, Obara and Art Hikari, are pushing the envelope in resistance welding with lightweight modular guns and spot welding solutions for aluminum parts.

Benefits & Features:

SRA-H Advanced Hollow Arm Design

Hollow arm desing neatly packages all pneumatic, power, and servomotor cables.

Eliminates the need for external dress packages

Permits extremely accurate offline programing and simulation studies

Internal dress eliminates cable snags with peripheral equipment

Improved cable life minimizes maintenance requirements

Improved Productivity

High speed gun motor control for fast open / close

High acceleration SRA-H robot for quickest movement between welds – SRA-H robots are the world’s fastest in their payload class

Extensive product line

SRA-H comes in various payloads from 100kg to 220kg

Standard floor mount models, invert mount model, long reach models over 3 meters.

New hollow arm series for internal dress of spot welding utilities provides extra protection and minimized stress for utility lines (cooling water, weld power, signals, servo gun cables)

Improved Weld Quality

Pressure calibration up to 10 points for more accurate pressure through the spot welding range

Nachi’s integrated spot weld timer – AC version available now, DC version from Jan-2014. Full programming from the robot teach pendant, weld results storage for traceability, full integration for fastest possible communication.

Spot weld solutions for aluminum parts

Long tip life between dress cycles (>400 welds)

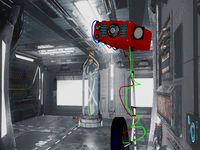

SRA-H

SRA100H

Nearly 20 years ago, Nachi was the pioneer of servo gun technology for spot welding. Today, Nachi continues to lead the industry in development of advanced robotic spot welding solutions – focused on making higher quality welds more quickly than in the past. With advanced industry leading hollow arm technology, the SRA-H series robots simplify cable routing by eliminating the need for external dress packages. Nachi's advanced hollow arm design improves cable life and neatly packages all pneumatic, power, and servomotor cables for turn key application success. Specifically designed for the fast paced automotive industry, SRA-H series robots will dramatically reduce cycle times, significantly improve productivity, and achieve cost reductions...achieve more with less robots! In your business "Time is Money", make the most of your money with the fastest robots available. Compare the Nachi SRA-H series against any competitor to see how much valuable time and money you can save with an SRA-H robot.

SRA series robots and their FD controllers are ideally suited to spot welding applications. The SRA-H robots are highly rigid and weight less, providing faster motion and less vibration. Advanced motion control from the FD controller provides top acceleration thereby shortening cycle-times. The FD also has 4th generation servo gun control software enabling higher motor speeds while maintaining gentle electrode contact to parts, optimizing spot welding performance. Finally, Nachi together with our welding partners, Obara and Art Hikari, are pushing the envelope in resistance welding with lightweight modular guns and spot welding solutions for aluminum parts.

Benefits & Features:

SRA-H Advanced Hollow Arm Design

Hollow arm desing neatly packages all pneumatic, power, and servomotor cables.

Eliminates the need for external dress packages

Permits extremely accurate offline programing and simulation studies

Internal dress eliminates cable snags with peripheral equipment

Improved cable life minimizes maintenance requirements

Improved Productivity

High speed gun motor control for fast open / close

High acceleration SRA-H robot for quickest movement between welds – SRA-H robots are the world’s fastest in their payload class

Extensive product line

SRA-H comes in various payloads from 100kg to 220kg

Standard floor mount models, invert mount model, long reach models over 3 meters.

New hollow arm series for internal dress of spot welding utilities provides extra protection and minimized stress for utility lines (cooling water, weld power, signals, servo gun cables)

Improved Weld Quality

Pressure calibration up to 10 points for more accurate pressure through the spot welding range

Nachi’s integrated spot weld timer – AC version available now, DC version from Jan-2014. Full programming from the robot teach pendant, weld results storage for traceability, full integration for fastest possible communication.

Spot weld solutions for aluminum parts

Long tip life between dress cycles (>400 welds)

Similar models

grabcad

free

Spot Welding System with Rotary jig. ( For Spot Electrical Box )

...em with rotary jig. ( for spot electrical box )

grabcad

spot welding system with c gun and x gun. ( use robot nachi sra166-01a.

grabcad

free

Nachi Robotics - MZ03EL 6-axis Industrial Robot

...s including palletizing, force sensing, vision sensing, line tracking conveyor synchronization, material handling, and many more.

grabcad

free

NACHI Spot Welding Robot SRA100H

...ware : solidworks 2021

3d cad: https://www.cgtrader.com/3d-models/industrial/industrial-machine/nachi-spot-welding-robot-sra100h

grabcad

free

Nachi Robotics - MZ04/04E 6-axis Industrial Robot - 4kg & Collaborative

...ing, vision sensing, line tracking conveyor synchronization, material handling, and many more.

http://www.nachirobotics.com/mz04

3d_export

$6

ABB Industrial Robot 3D Model

...a nachi mechanical assembly hydraulic cyborg claw plant construction welding

abb industrial robot 3d model dimafs 100520 3dexport

3d_export

$12

Industrial Robot 3D Model

...ruction welding cutting industrial hydraulic kr 100-3 titan robot arm kit armbot

industrial robot 3d model dimafs 100515 3dexport

grabcad

free

Robot Arm

...resembles the human arm motion. it is a 6-axis robot arm. servo motors are placed on each joint it controlled the various motion.

grabcad

free

Robotic Arm

...ensor based . everything works

incorporated with a servo mechanism, a gripper and various components. (layout ,mate controller).

grabcad

free

triflex RS TRC 70 robot dress kit

...;_blank">http://www.igus.co.uk/wpck/default.aspx?pagenr=3372&c=gb&l=en&wt.mc_id=grabcad</a>

grabcad

free

Nachi Robotics MZ07 & MZ07L 6-axis industrial robot

...://youtu.be/trgv_ak6dw4?list=plrghxr0atil62lpggukux6k5cvdhegokq

http://www.nachirobotics.com/images/brochures/mz07_brochure2.pdf

Nachi

3d_export

$22

Pagoda and Nachi Falls OBJ FBX

...r close up and distant renders. so take your characters on a vacation to japan and enjoy the vista of nature and ancient marvels.

3d_export

$12

Industrial Robot 3D Model

...industrial robot 3d model 3dexport robotic machine abb kuka nachi construction welding cutting industrial hydraulic kr 100-3 titan robot...

3d_export

$6

ABB Industrial Robot 3D Model

...model 3dexport robot robotic arm industrial machine abb kuka nachi mechanical assembly hydraulic cyborg claw plant construction welding abb...

3d_ocean

$39

Industrial Robot Arm

...claw cyborg factory hydraulic industrial machine max mechanical model nachi rig rigged robot vray industrial robot arm 3d model....

thingiverse

free

Wolf Nachi

...wolf nachi

thingiverse

meh

thingiverse

free

6202ZZE nachi bearing by snowboarder

...e nachi bearing by snowboarder

thingiverse

this is a profile of a nachi bearing 6202zze. it fits very snug inside this bearing.

thingiverse

free

Okuma Nachi hydraulics pump cover replacement. by Kuupeetje

...i hydraulics pump cover replacement. by kuupeetje

thingiverse

replacement cover for nachi pump in a okuma vr40ii pallet changer.

thingiverse

free

Bracket for nachi bearing 6202ZZE by snowboarder

...ze. it fits very tight, so if you decide to remove your bearing you may have to break the printed parted in order to remove it.

thingiverse

free

IJN Myoko by V4huni

...niigata prefecture. the other ships of the class were nachi ashigara, and haguro.myōkō was approved under the 1922 -1929...

grabcad

free

NACHI-MZ07L

...nachi-mz07l

grabcad

nachi 6-axis robot

Automation

turbosquid

$19

Automation for gates

... model automation for gates for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1600153)

turbosquid

$5

Automated Teller Machine

...tomated teller machine for download as c4d, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1677841)

turbosquid

$30

AUTOMATED GUARD STATION

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Drink Automate New

...w office old red retro rust soda store vending vintage

old rusty drink machine, and new shiny. xsi and lvo exported from blender.

evermotion

$10

home automation system 32 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 35 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 38 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 24 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 30 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 27 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

Hollow

3d_export

$20

hollow knight

...hollow knight

3dexport

this is a 3d version of the game character hollow knight

turbosquid

$5

Hollow Tree

...quid

royalty free 3d model hollow tree for download as blend on turbosquid: 3d models for games, architecture, videos. (1403446)

turbosquid

$3

Hollow Glass

...alty free 3d model hollow glass for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1555369)

3ddd

$1

Quail Hollow

...quail hollow

3ddd

журнальный

журнальный столик "quail hollow"(ар.01-0460-945). 30к полигонов. все текстуры в архиве.

turbosquid

$9

Hollowed Asteroids

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

the log with hollow

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

hollow cross

...hollow cross

3dexport

the cross has three parts and an eyelet for the chain.

turbosquid

$10

BMO figurine (hollow)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Hollow point bullet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Hollow Zig Zag

...el hollow zig zag for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1560240)

Advanced

turbosquid

$139

Carol (Advanced)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ADVANCED ROOM.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Explay Advance

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Advanced Crate

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Advanced Canister

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

automatic Advance Gun

...

royalty free 3d model automatic advance gun for download as on turbosquid: 3d models for games, architecture, videos. (1609069)

turbosquid

$4

Advanced Shower Equipment

...free 3d model advanced shower equipment for download as blend on turbosquid: 3d models for games, architecture, videos. (1282411)

turbosquid

$1

Advanced Sniper Rifle

...oyalty free 3d model advanced sniper rifle for download as obj on turbosquid: 3d models for games, architecture, videos. (720205)

3d_ocean

$32

Advanced Hospital Bed

...ds max 2010 or higher and many others. formats *.max scanline *.max vray *.max mentalray *.c4d advanced render *.c4d cinema 4d...

turbosquid

$17

Advance Rifle Patrol

...free 3d model advance rifle patrol for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1409260)

Robot

3d_ocean

$20

Robot

...robot

3docean

character metal robot robot robotic white

robot model for 3dsmax 2009 and greater

3d_ocean

$45

Robot

...robot

3docean

fighing machine robot

a fighting robot from the scrapyard.

3d_ocean

$18

Robot

...robot

3docean

machin robot science fiction

high poly robot.

3d_export

$7

Robot

...robot

3dexport

robot

3d_export

$5

robot

...robot

3dexport

robot

3d_export

free

Robot

...robot

3dexport

robot

turbosquid

$10

Robot/ Alien Robot

...

royalty free 3d model robot/ alien robot for download as max on turbosquid: 3d models for games, architecture, videos. (1442828)

3d_export

$5

robot

...robot

3dexport

robot in blender

3ddd

$1

robot

...robot

3ddd

робот

robot

3ddd

$1

Robot

...robot

3ddd

робот

robot

Robotic

3d_ocean

$20

Robot

...robot 3docean character metal robot robot robotic white robot model for 3dsmax 2009 and...

3d_ocean

$45

Robot

...robot

3docean

fighing machine robot

a fighting robot from the scrapyard.

3d_ocean

$18

Robot

...robot

3docean

machin robot science fiction

high poly robot.

3d_export

$7

Robot

...robot

3dexport

robot

3d_export

$5

robot

...robot

3dexport

robot

3d_export

free

Robot

...robot

3dexport

robot

turbosquid

$10

Robot/ Alien Robot

...

royalty free 3d model robot/ alien robot for download as max on turbosquid: 3d models for games, architecture, videos. (1442828)

3d_export

$5

robot

...robot

3dexport

robot in blender

3ddd

$1

robot

...robot

3ddd

робот

robot

3ddd

$1

Robot

...robot

3ddd

робот

robot

Arm

archibase_planet

free

Arm

...ase planet

arm hand right hand skeleton

arm human skeleton right arm n030515 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3ddd

$1

arm chair

...arm chair

3ddd

arm chair , пуф

arm chair

turbosquid

$5

arm

...arm

turbosquid

royalty free 3d model arm for download as obj on turbosquid: 3d models for games, architecture, videos. (1306158)

turbosquid

free

Arm

...arm

turbosquid

free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1346955)

turbosquid

$29

Arm

...osquid

royalty free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1382436)

3d_export

$5

coat of arms

...coat of arms

3dexport

coat of arms

3ddd

$1

ARM SOFA

...arm sofa

3ddd

arm sofa

3ddd

$1

Arm chair

...arm chair

3ddd

arm chair

3ddd

$1

Arm chair

...arm chair

3ddd

угловое

arm chair

3ddd

$1

ARM CHAIR

...arm chair

3ddd

arm chair clothes

Industrial

design_connected

$13

Industrial

...industrial

designconnected

dreizehngrad industrial computer generated 3d model.

3ddd

free

Industrial chair

...industrial chair

3ddd

industrial

industrial chair

3d_export

$5

industrial furniture - industrial table 01

...industrial furniture - industrial table 01

3dexport

"industrial table 01"

3ddd

free

Industrial table

...дустриальный , кофейный , стол

industrial table

3ddd

$1

L-Industry

...l-industry

3ddd

l-industry

промышленные светильники l-industry . диаметр × высота 320х492мм

3d_export

$5

industrial machine

...industrial machine

3dexport

industrial machine

3d_export

$5

industrial oven

...industrial oven

3dexport

industrial oven

3d_export

$5

industrial wheel

...industrial wheel

3dexport

industrial wheel

3ddd

$1

REFLECTOR INDUSTRIAL

...reflector industrial

3ddd

reflector industrial

3ddd

$1

Industrial light

...industrial light

3ddd

grange

industrial light.