Thingiverse

Spool Winder

by Thingiverse

Last crawled date: 4 years, 2 months ago

Spool Winder

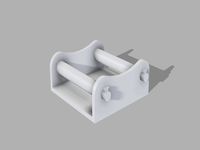

Spool winder for filament and other spools with a maximum dimension of 210mm in diameter and 76mm wide. If the spool axle is inset then wider spools may be accommodated. Spools should be a minimum of 30mm wide with an axle hole not smaller than 16mm diameter.

One turn of the handle gives two turns of the spool.

The winder is parts compatible with my spool holder which also includes jointing pieces to join multiple spool holders together. See my thing:3823334.

Printing

I provide files for the frame to suit either right or left handed people (the right-hand configuration is shown in the images). All the other files need to be printed except the centring discs where you inly need to print ones which correspond with (or are slightly smaller than) your spool's axle hole.

Also I provide an optional filament guide and pivot however I find that windings are generally satisfactory without using this.

I recommend PLA for printing this, alternatively PETG or a plastic which has good layer adhesion.

If you must print in a plastic which does not bond well, such as ABS or nylon then there is a hole through the spool axle to take an optional M4 x 60mm machine screw to strengthen the layers forming the threads to reduce the chances of them snapping off.

Assembly

The spool axle gear and spool axle pin should be glued onto the spool axle. Use a melt glue for ABS or Superglue for most other plastics.

Ensure that the round crank axle fits into the frame properly and rotates reasonably freely. You may need to trim any printing artefacts from around the holes in the frame with a sharp knife.

The handle of the crank should rotate on its shaft. You may meed to break it free if it has stuck during printing.

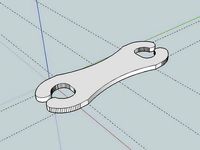

Put the crank gear into the recess in the frame then push the crank axle into the frame and through the gear as illustrated in the image.

Glue the hexagonal pin into the crank axle and optionally clue the crank handle onto the hexagonal pin taking care not to get glue on the moving parts.

I design these things for myself but I have published them for you. If they make your life easier or save you money then please do not forget to "Tip Designer"! Thank you.

Spool winder for filament and other spools with a maximum dimension of 210mm in diameter and 76mm wide. If the spool axle is inset then wider spools may be accommodated. Spools should be a minimum of 30mm wide with an axle hole not smaller than 16mm diameter.

One turn of the handle gives two turns of the spool.

The winder is parts compatible with my spool holder which also includes jointing pieces to join multiple spool holders together. See my thing:3823334.

Printing

I provide files for the frame to suit either right or left handed people (the right-hand configuration is shown in the images). All the other files need to be printed except the centring discs where you inly need to print ones which correspond with (or are slightly smaller than) your spool's axle hole.

Also I provide an optional filament guide and pivot however I find that windings are generally satisfactory without using this.

I recommend PLA for printing this, alternatively PETG or a plastic which has good layer adhesion.

If you must print in a plastic which does not bond well, such as ABS or nylon then there is a hole through the spool axle to take an optional M4 x 60mm machine screw to strengthen the layers forming the threads to reduce the chances of them snapping off.

Assembly

The spool axle gear and spool axle pin should be glued onto the spool axle. Use a melt glue for ABS or Superglue for most other plastics.

Ensure that the round crank axle fits into the frame properly and rotates reasonably freely. You may need to trim any printing artefacts from around the holes in the frame with a sharp knife.

The handle of the crank should rotate on its shaft. You may meed to break it free if it has stuck during printing.

Put the crank gear into the recess in the frame then push the crank axle into the frame and through the gear as illustrated in the image.

Glue the hexagonal pin into the crank axle and optionally clue the crank handle onto the hexagonal pin taking care not to get glue on the moving parts.

I design these things for myself but I have published them for you. If they make your life easier or save you money then please do not forget to "Tip Designer"! Thank you.

Similar models

thingiverse

free

Dryer pipe holder by Kveri

...#39;t needed.

the holes at the side are used to provide better grip for the glue/heated plastic. i recommend uses melted plastic.

thingiverse

free

Spool Winder modified Gear, Pinion and Pin by Gorbi-Gnome

...ngiverse.com/thing:3918099

tooth profile optimized according to standard. slightly reduced filament usage. pin clearance reduced.

thingiverse

free

Filament Winder Handle, Crank and gear assembly by LizHavlin

...nge is to interface with an outside power supply.

i also have a solar powered motor on the table ready to be experimented with!

thingiverse

free

5lb (large) filament spool carrier by jmcskixc

...f some kind through the whole thing. i used an old screwdriver for an axle, but i also modeled a quick axle that should work ok.

thingiverse

free

Filament Spool Winder V3 by hlyman

... winder from the first one is that the spool gear motor is mounted at the bottom of the spool, thus eliminating the rotating arm.

thingiverse

free

LYMAN FILAMENT SPOOL WINDER by hlyman

...ccessory to the lyman filament extruder, wherein the winder winds onto a spool the filament as it is extruding from the extruder.

thingiverse

free

Spool Filament Winder

... filament winder for drill. uses 3/8 threaded rod and nuts. may need to glue nuts in place depending on your printers tolerances.

thingiverse

free

Dremel Spool Winding Station by TperroneDesign

...nd keep the spool inserts in place, i used a countersink drill bit to countersink the fasteners.

share a picture if you make one!

thingiverse

free

Base plate and axle for Triple gear by henryseg

...mooth. possibly some improvements could be made to the shape of the baseplate and/or axle and/or triple gear to make it smoother.

thingiverse

free

Filament Guide Wheel for Wanhao i3 Plus by SnickerdoodleFP

... and the axle and assemble. depending on your printer's tolerances, you may need to sand the axle for the smoothest rotation.

Winder

thingiverse

free

Side Winder by airdronez

...side winder by airdronez

thingiverse

side winder

thingiverse

free

Earphone winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Earphone Winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Spool Winder by Verohomie

...spool winder by verohomie

thingiverse

spool winder for a cordless drill

thingiverse

free

Cable Winder by kazsoft

...cable winder by kazsoft

thingiverse

just a simple cable winder.

thingiverse

free

Watch Winder by neilzeg

...watch winder by neilzeg

thingiverse

diy watch winder

youtube:

thingiverse

free

Wire Winder by FJAW

...wire winder by fjaw

thingiverse

winder for sota coax / wire (with freecad).

thingiverse

free

Ukulele Winder by GearWalker

...ukulele winder by gearwalker

thingiverse

hand crank strings winder for ukulele.

thingiverse

free

plate for winder by giovannire

...plate for winder by giovannire

thingiverse

manual winder for plotter roland versacamm

thingiverse

free

Rope winder

...rope winder

thingiverse

for fishing

Spool

thingiverse

free

Spool Support For Anycubic Spool Holder and AMZ3D Spools by Kobaratsu

... amz3d spools by kobaratsu

thingiverse

spool axis support to avoid jerks on spool, using anycubic spool holder and amz3d spools

thingiverse

free

Spool adapter for Warhorse spool

...spool adapter for warhorse spool

thingiverse

a simple spool adapter to use abs warhorse spool with a 72 mm hole diameter.

thingiverse

free

Spool holder for 1KG Spools by angkor

...spool holder for 1kg spools by angkor

thingiverse

spool holder for 1kg spools

thingiverse

free

Spool holder

...spool holder

thingiverse

i use this spool holder for up to 1kg spools and should fit all spools.

thingiverse

free

Spool assembler

... empty spool with this spool assembler

just cut an empty spool in half , put your filament and assemble with this spool assembler

thingiverse

free

Small Spool and Spool Stand by Beckman13

...ool holder are meant for 50 gram flexible filaments. the two sides of the spool holder are meant to slide together and interlock.

thingiverse

free

spool spindle cap for 25mm spools by Seadevil

...spool spindle cap for 25mm spools by seadevil

thingiverse

spool spindle cap for 25mm spools

thingiverse

free

spool ! by St0rmingBr4in

...spool ! by st0rmingbr4in

thingiverse

this is a spool !

thingiverse

free

Spool Holder for large spools by dmonkey

...y

thingiverse

a spool holder that you can attach to the back of a makerbot replicator that can hold large filament spools (1kg)

thingiverse

free

Spool roll

...spool roll

thingiverse

spool roll