Thingiverse

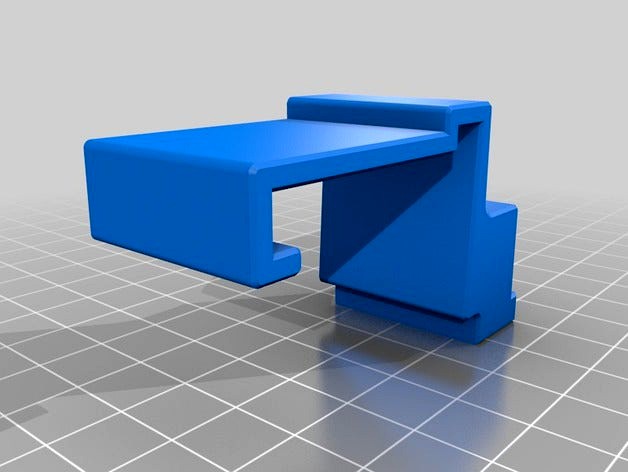

Spool holder (modular) base/clamp (for CTC and others) by brainwash

by Thingiverse

Last crawled date: 4 years, 4 months ago

This is the companion piece to the spool holder: https://www.thingiverse.com/thing:2543519

The mesh with each other using a T-Slot.

Designed for a CTC Dual (might fit i3 replicator, Makerbot Dual?) with 5mm laser-cut wood panels.

OnShape link: https://cad.onshape.com/documents/b18e4a474be7623d179a2956/w/786bb42a3f491a7321bdce8a/e/8b936b587468885eb7ab803d

Instructions:

You need the matching part: https://www.thingiverse.com/thing:2543519

Printed in PLA, 15-25% infill, no support or raft.

Rotate so the part sits on its side.

Choose 50x25 if you want the spool to sit attached to the top back side of the printer.

Choose 40x25 if you want the spool to sit attached to the front/left/right side of the printer.

Choose 50x85 if you want the spool to sit attached to the back side of the printer, but hanging lower.

Choose 10x25 if you want to reuse the old spool holder holes.

Obviously, you can customize the dimensions to match your printer.

Customizing:

This base is customizable using the OnShape link and change the variables: #TopLipDepth and #OffsetFromTop. #TopLipDepth sets the size of the top feature (lasered panel in my case) and is 50mm for a back-side clip 40mm for a front- or side-clip, and 9mm if you are using the spool holder hole (or minimum depth).

So, using these clamp designs, you can hang your spool on your printer on either side you want, or inside the spool holder hole.

You can offset to spools on top of each other or move the spool up/down, depending on needs. A spool sitting up will let the extruder see less filament resistance. A spool sitting down might let you stack two spools on top of each other. This is where the #OffsetFromTop variable comes into play. The minimum usable value is 9mm.

The part has been designed to register against a lip that's 3mm high and 3mm deep (laser-cut plywood). 0.2mm have been added for clearance, this allows for a nice 'snap' action. That part isn't going anywhere soon...

You can edit the "clip back side profile" sketch to set your custom printer dimensions, viewed from the side.

Design notes - boring read:

Most of the holders I've come across so far were printed across-the-grain, so the shearing stresses would break PLA easily. Especially with a full filament spool. On top of that, the spool holder often had supports (for the top spacer) and required a large height to be printed, almost impossible to do without cooling.

This design mitigates most problems by separating the spool holder and its base into two easily printable parts. You are looking at the spool [filament] holder part. This mates with a "clamp" by using a T-Slot.

The T-Slot is engineered to have an upwards angle to it (+3 deg), since printed parts are flexible and the spool would bog down otherwise. A higher angle would cause the filament to wind down against the base when the spool is getting empty.

The T-slot is engineered to have plenty of clearance for an easy slide-fit. A lot of the designs seen on Thingiverse don't take clearance into account, making it impossible to fit parts together without breaking them.

The holder has a lip at both ends, to keep the spool from sliding out or drag against the base [clamp].

Material use has been kept at a minimum, it can probably be reduced even more but I'm allowing for printer quality variance (i.e. incompletely adhered walls).

I've tried to keep the combined depth of the spool lip + base [clamp] to a minimum to avoid overhang, but haven't made structural calculations to see if it can be reduced even more. By reducing depth (distance between spool wall and printer wall) the integrity will also be reduced and I prioritized safety against minimalism.

Last but not least, I print my parts on a heated bed, at 80C, which also cures PLA. This makes parts stronger, so if you are printing without a HPB the parts might be under-dimensioned.

The mesh with each other using a T-Slot.

Designed for a CTC Dual (might fit i3 replicator, Makerbot Dual?) with 5mm laser-cut wood panels.

OnShape link: https://cad.onshape.com/documents/b18e4a474be7623d179a2956/w/786bb42a3f491a7321bdce8a/e/8b936b587468885eb7ab803d

Instructions:

You need the matching part: https://www.thingiverse.com/thing:2543519

Printed in PLA, 15-25% infill, no support or raft.

Rotate so the part sits on its side.

Choose 50x25 if you want the spool to sit attached to the top back side of the printer.

Choose 40x25 if you want the spool to sit attached to the front/left/right side of the printer.

Choose 50x85 if you want the spool to sit attached to the back side of the printer, but hanging lower.

Choose 10x25 if you want to reuse the old spool holder holes.

Obviously, you can customize the dimensions to match your printer.

Customizing:

This base is customizable using the OnShape link and change the variables: #TopLipDepth and #OffsetFromTop. #TopLipDepth sets the size of the top feature (lasered panel in my case) and is 50mm for a back-side clip 40mm for a front- or side-clip, and 9mm if you are using the spool holder hole (or minimum depth).

So, using these clamp designs, you can hang your spool on your printer on either side you want, or inside the spool holder hole.

You can offset to spools on top of each other or move the spool up/down, depending on needs. A spool sitting up will let the extruder see less filament resistance. A spool sitting down might let you stack two spools on top of each other. This is where the #OffsetFromTop variable comes into play. The minimum usable value is 9mm.

The part has been designed to register against a lip that's 3mm high and 3mm deep (laser-cut plywood). 0.2mm have been added for clearance, this allows for a nice 'snap' action. That part isn't going anywhere soon...

You can edit the "clip back side profile" sketch to set your custom printer dimensions, viewed from the side.

Design notes - boring read:

Most of the holders I've come across so far were printed across-the-grain, so the shearing stresses would break PLA easily. Especially with a full filament spool. On top of that, the spool holder often had supports (for the top spacer) and required a large height to be printed, almost impossible to do without cooling.

This design mitigates most problems by separating the spool holder and its base into two easily printable parts. You are looking at the spool [filament] holder part. This mates with a "clamp" by using a T-Slot.

The T-Slot is engineered to have an upwards angle to it (+3 deg), since printed parts are flexible and the spool would bog down otherwise. A higher angle would cause the filament to wind down against the base when the spool is getting empty.

The T-slot is engineered to have plenty of clearance for an easy slide-fit. A lot of the designs seen on Thingiverse don't take clearance into account, making it impossible to fit parts together without breaking them.

The holder has a lip at both ends, to keep the spool from sliding out or drag against the base [clamp].

Material use has been kept at a minimum, it can probably be reduced even more but I'm allowing for printer quality variance (i.e. incompletely adhered walls).

I've tried to keep the combined depth of the spool lip + base [clamp] to a minimum to avoid overhang, but haven't made structural calculations to see if it can be reduced even more. By reducing depth (distance between spool wall and printer wall) the integrity will also be reduced and I prioritized safety against minimalism.

Last but not least, I print my parts on a heated bed, at 80C, which also cures PLA. This makes parts stronger, so if you are printing without a HPB the parts might be under-dimensioned.