Thingiverse

Spool Cover Box Corner Brackets for Lack Enclosures by Charixfox

by Thingiverse

Last crawled date: 3 years ago

Cats.

They love things that move. They love to break stuff. They love to play with skinny string-like objects. Like spools of filament.

So when we put our printer in a Lack Enclosure (Which is an awesome thing, by the way), we decided we also needed to protect the spool and filament going in.

One Eket "Cabinet" from Ikea ($15-$20 depending on size at the time of this writing) and some guiding corner holders later and we have a good solution. These are the corner holders. The will work for pretty much any box that should be set down onto something and kept from sliding around as long as they can be attached.

Two options, so don't print everything.

Option 1: Inner Corners. You can use the inner corners on the front, or the back, or both, or neither. The inner corners are much more difficult to position though.

Option 2: Outer corners. You can mix and match inner and outer corners. Outer corners are much easier to place with tight tolerance.

You can hold outer corner brackets in place against the box when screwing them down for the tightest tolerance and fit. The angle of all the brackets helps guide the box into place.

A tiny, tiny piece of putty or clay can be used to hold the inner brackets close to in position but slightly too far outwards and then slide the box over them very slowly to pull them in. Then take the box off very carefully and screw them down. You can measure for the inner corner brackets, however I found that the rounded corners of the boxes involved make that a challenge and even a millimeter of leeway will allow wiggle in the end result. Sub-millimeter fit is good in this.

Bonus points for air-tight filament system:

Use silicone caulk around the top (back) of the cabinet box and the inside corners edges to make it air-tight.

Use a silicone membrane with an tight hole for a bowden tube to feed through

Put an even bead of soft silicone caulk around the open side of the box and let it half-dry so its surface is dry, then place it on top to form fit.

Use a filament holder and/or bowden tube holder (even with a direct feed extruder) to feed the filament into the tube and down into the box through the silicone membrane. The bowden tube can still slip up and down through the membrane as the print head moves.

Some desiccant in the box and you're set.

They love things that move. They love to break stuff. They love to play with skinny string-like objects. Like spools of filament.

So when we put our printer in a Lack Enclosure (Which is an awesome thing, by the way), we decided we also needed to protect the spool and filament going in.

One Eket "Cabinet" from Ikea ($15-$20 depending on size at the time of this writing) and some guiding corner holders later and we have a good solution. These are the corner holders. The will work for pretty much any box that should be set down onto something and kept from sliding around as long as they can be attached.

Two options, so don't print everything.

Option 1: Inner Corners. You can use the inner corners on the front, or the back, or both, or neither. The inner corners are much more difficult to position though.

Option 2: Outer corners. You can mix and match inner and outer corners. Outer corners are much easier to place with tight tolerance.

You can hold outer corner brackets in place against the box when screwing them down for the tightest tolerance and fit. The angle of all the brackets helps guide the box into place.

A tiny, tiny piece of putty or clay can be used to hold the inner brackets close to in position but slightly too far outwards and then slide the box over them very slowly to pull them in. Then take the box off very carefully and screw them down. You can measure for the inner corner brackets, however I found that the rounded corners of the boxes involved make that a challenge and even a millimeter of leeway will allow wiggle in the end result. Sub-millimeter fit is good in this.

Bonus points for air-tight filament system:

Use silicone caulk around the top (back) of the cabinet box and the inside corners edges to make it air-tight.

Use a silicone membrane with an tight hole for a bowden tube to feed through

Put an even bead of soft silicone caulk around the open side of the box and let it half-dry so its surface is dry, then place it on top to form fit.

Use a filament holder and/or bowden tube holder (even with a direct feed extruder) to feed the filament into the tube and down into the box through the silicone membrane. The bowden tube can still slip up and down through the membrane as the print head moves.

Some desiccant in the box and you're set.

Similar models

thingiverse

free

Filament Spool Holder- no bearings needed by Sc0rpio

...ortant to remove any imperfections in the print so that it can rotate freely. a little bit of wd40 or other lubricant would help.

thingiverse

free

Filament Feed Tube Holder for i3's by Perdurable

...ilament feed such as a dry box!

please feel free to contact me with any advice, ideas, or complaints. tips are much appreciated!

thingiverse

free

2020 UNIVERSAL SPOOL HOLDER SLIM VERSION V2 by chaoren

...e can slide completely through and the tube can take the turn into the arms. the pneumatic fitting will lock the tube into place.

thingiverse

free

Bowden bracket for FT-5 by Ishampadron

... right side.

to load filament simply slide the mount up and feed the filament. then slide it down over the extruder when its fed.

thingiverse

free

Filament Spool Holder (Brackets) for IKEA 365+ Drybox

...opened.

filament is guided through a lack filament guide (https://www.thingiverse.com/thing:1895060) and a glued-in teflon tube.

thingiverse

free

Dry Box with PTFE Tube Fittings by SubSite

...teel pipe a had lying around.

update: added a stopper to prevent air from leaking into the ptfe tubes when no filament is loaded.

cults

free

Creatr Side-car Spool Holder with Filament Guide

... assuming the dimensions of the top plate on the printer are the same on all of them (45 mm wide). please check before printing.

thingiverse

free

Creatr Side-car Spool Holder with Filament Guide by Festus440

...m assuming the dimensions of the top plate on the printer are the same on all of them (45 mm wide). please check before printing.

thingiverse

free

Filament Feed Tube Bracket by minutiae

...filament feed tube bracket by minutiae

thingiverse

keeps the filament feed tube fixed firmly in place.

thingiverse

free

Prusa Mk2 Mk3 8 up Dry Box Filament Guide by TheClarkJB

...nage the bowden tubes and filament from a dry box to your mk3. the bowden tube stops in the holder, the filament passes through.

Lack

3d_export

$5

LACK LACK Coffee table white 90x55 cm IKEA

..., white, 90x55 cm ikea<br>https://www.ikea.com/ru/ru/p/lack-lakk-zhurnalnyy-stol-belyy-50449907/?ysclid=l8zshj49w6656165430

turbosquid

$4

Ikea Lack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

IKEA Lack Coffee Table

... кофейный

ikea lack coffee tablehttp://www.ikea.com/gb/en/catalog/products/00104291

turbosquid

$5

IKEA Lack Table

...ack table for download as blend, blend, unitypackage, and fbx on turbosquid: 3d models for games, architecture, videos. (1623135)

turbosquid

$10

Ikea Lack Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

IKEA Lack Library

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

IKEA LACK TABLE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

IKEA Lack Shelf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Ikea Table 5 Lack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

IKEA Lack Side Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Enclosures

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

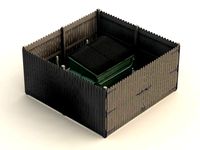

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Brackets

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket n280911 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder corbel bracket

bracket 9 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel console bracket

bracket 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder console bracket

bracket 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 13 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Corner

archibase_planet

free

Corner

...corner

archibase planet

nook corner

corner n030708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Corner

...corner

archibase planet

corner post rack

fp corner wh - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Country Corner

...country corner , комод , прованс

country corner

3ddd

$1

Corner 8140

... corner

corner 8140 - 16,5 x 17,4 (cm)

corner 8141 - 16,5 x 29,5 (cm)

corner 8142 - 16,5 x 41,5 (cm)

corner 8143 - 28 x 28 (cm)

archibase_planet

free

Corner

...corner

archibase planet

seat easy chair furniture

havanna corner - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Country corner

... country corner , romance

рамка country corner, romance,

артикул cc0141

3ddd

$1

Country corner

...country corner

3ddd

country corner , журнальный

country corner pbth размеры 169*69*49

3d_export

$5

Corner

...corner

3dexport

3ddd

$1

Table-Corner

...table-corner

3ddd

круглый

table,corner

3ddd

$1

Table,Corner

...table,corner

3ddd

журнальный

table,corner

Cover

archibase_planet

free

Cover

...cover

archibase planet

cover place setting

cover n170807 - 3d model for interior 3d visualization.

3ddd

$1

cover

...cover

3ddd

ковер , круглый

cover decor

archibase_planet

free

Cover

...cover

archibase planet

cover place setting setting

servis-cafe1930 - 3d model for interior 3d visualization.

turbosquid

free

Coverings

...rings

turbosquid

free 3d model coverings for download as dwg on turbosquid: 3d models for games, architecture, videos. (1279391)

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

turbosquid

$25

Covers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

manhole cover

...manhole cover

3dexport

manhole cover gost, stl, step

turbosquid

$5

Street Gas Cover Manhole Cover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Bed cover

...bed cover

3ddd

постельное белье

very useful bed cover

3d_export

$5

cpu cover

...cpu cover

3dexport

cpu cover, cpu box, sheet metal container

Box

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

carton cardboard box box

box 1 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$6

box

...box

3dexport

box

3d_export

$5

Box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

archibase_planet

free

Box

...box

archibase planet

box box for paper notebook pencil

box - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n170111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n050411 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boxes

...boxes

archibase planet

boxes box case bin

boxes n281213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.