Thingiverse

Spider-Bot from the movie Runaway by rkxone

by Thingiverse

Last crawled date: 3 years, 3 months ago

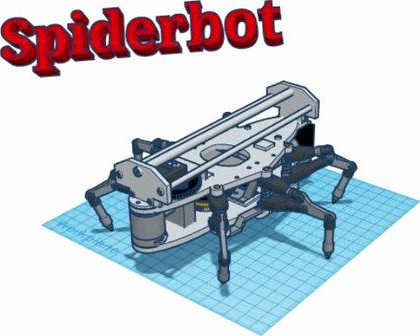

Spider-Bot from the movie Runaway

(November-15-2020: Check out my new Lock-On Bot from the movie here also: https://www.thingiverse.com/thing:4654995 )

Hello all, over the last week I have been sinking all my time into this prop reproduction from the movie Runaway (Tom Sellek and Gene Simmons 1984 - https://www.imdb.com/title/tt0088024/ ). I have always had a love for the killer robot spiders, so I decided to go looking for a print. Oddly enough there are none modelled off this amazing killer spider! So I decided to start toying with this. Slowly but surely over the course of 5 full days of modelling 16 hours a day I have what I consider a 90% faithful looking kit. I went through many versions of printing to get this to just the right level of building and look. I will continue to add some greebles to this as I finish the final building, but this is the base kit.

There are outside parts you will want/need to complete this.

Flexible cable conduit (for the top level, see the actual prop photos)

Misc wiring (for all over)

small Zip ties (for all over securing the wiring etc)

Optional (If you want more strength on the top rods): 2x 3mm Tubes or dowels (200 mm length each), steel for strength (a coat hanger may work here I have not tested that yet), 5mm tube for the main support

Wooden skewers from the grocery store will likely also work here as they are long enough and 3mm thick.

Superglue.

Assortment of M3 socket head cap screws (https://www.amazon.ca/gp/product/B06ZY36VDP/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1) (These are optional as you can glue it all together, but the extra realism you get with these and the ability to take this apart to add to it or work on it I find is well worth the upgrade)

Paint - Aluminum, or silver. Detail Paint: flat black, white, and any other touches you might like.

Optional: Instead of printing the battery pack I recommend just making one yourself from old AA or AAA batteries, this will add some nice weight, and cuts an hour from the print time ;)

Considerations

I am trying to make this as easy a print as possible while being faithful to the onscreen prop from the movie, you should be able to look at it and know exactly where it is from if you've seen it before :)

The legs are moveable strictly side to side, not the joints.

The gears go nowhere but do spin :), yes I know, this is not a working model kit, but to give the best approximation and to keep simplicity. they will never go anywhere, there are also some linkages missing and some small liberties taken so that the print looks right and will display nicely, yet giving you the options to explore adding your own greebles.

This is my first mega type build of this degree. It's not going to be perfect. And it's all designed in tinkercad. And I have now rebuilt almost all of the original to increase details, and improve the print quality. a few times over now :P

By the time this gets to thingaverse it will be fully printed and and issues I can't correct will be documented and explained. (see above :P )

This kit is meant to be printed on a 200mm bed. it's scaled for every part to fit, It's very close to the movie prop in size

Not all the print times are listed, there were a lot of changes and variations as I was trying to both write up this guide and get things done ;) It will likely take a day to print this at .2, 35mm/s and 20-80% fill.

Assembly:

While you can just glue everything together I used a mix of gluing some parts and bolting the frames together.

Sand edges (or exacto) to remove all elephants foot expansion and fill/sand to your desire. Then paint pretty much all silver and weather it with black wash. I barely had to sand anything, not much more than 10 minutes for the whole kit. A lot of thought went into fit here :)

Install pictures are below

General print settings

.20 quality (each part group is detailed so if something is different it is listed there)

Infill will vary from 20-80% and will be listed

35mm Print speed

Hot end temp: 205 degrees

Bed Temp 60 degree first layer 55 degree and gradating down to 0 depending on height

Ironing is on top layer only

other settings as best suits your style

Parts Breakdowns

Legs:

Grouped together for the middle sets and the end legs, all are split

Print the end legs twice for the right number (this is because I am impatient :P )

1.5 hour print for each pair of legs

Support everywhere at 60degrees

these print clean, the supports come off well, had to redesign these to make the springs prominent. this version works well, the posts are black, I would silver accent the spring edges

short legs go on the front and back, holes face the front, a very light sanding of the posts top and bottom so they are smooth. They are supposed to protrude from the top and bottom of the plates to mimic the prop mounting bolts. paint the top and bottom protrusions black

Radio box:

no support

30 minute print time

holes are included for attaching wiring,

this is a free mount part on the top deck on the riser above the top gear pack glue in place

Control arms

No support needed

15 minute print

Prints without issue as is

These are under/over control arms

a dab of glue on the top of the lower and the underside of the top with the bolt head.

if there is a fit issue (I had to change the dimension thickness of the chassis) hot water bend these to fit but mine fit perfect

Lower box and rod

No support needed

20 minute print

free mount for the base of the box, the rod will connect to the front motor in the hole, slight sanding will be required for fit

you can glue the box to the base or just leave it as a friction fit part

Lower back plate

7 minute print time on horizontal, 30 minutes vertical

print with support (unless printing vertical)

A bolt screws in through this, through the base plate, and through the servo hosing and into the servos.

Lower Main Plate

No Supports

printed at 40% infill

print time 3 hours

Increased the infill to 40% as I also thickened the plate from 1mm to 4mm, this gives a better quality print and a more realistic feel, I will be changing the gears to 3mm as I feel they were a bit thin also.

Slightly file the mounting holes for the legs only. the other holes should be left alone so the threads can grab.

Lower Gear Pod

No supports

50 minute print time

80% fill for rod strength

Minor filing of the holes may be required so they free spin

the base gear fits into the main plate indent and should be glued, and the gears will just stack on top

the main gear shaft will line up into the top plate hole (do not glue the rod to the top if you glued the bottom!)

Upper Gear Pod

No supports

50 minute print time

80% fill for rod strength

Minor filing of the holes may be required so they free spin

the base gear fits into the top plate indent and should be glued, and the gears will just stack on top

the main gear shaft will line up into the top riser hole (do not glue the rod to the top if you glued the bottom!)

Back Servos

no support

1 hour print time

colour black with white top gears

feel free to add linkages to other areas

mounted upside down in the servo holder via screws top and bottom

front motor

support is needed here but you can likely get away without it

1 hour print

front location, line up with the plate edging and top and bottom plate holes

add a zip tie around the top for the authentic prop look

run wiring and add holes to mount if you like (future version may get this)

Rods

No Support

80% fill

1 hour print

print horizontally (for strength)

These came out very well and I have high hopes for strength, sand the ends to insert into the fore and aft vertical plates, there will be a bit of a flat spot on the bottom, face that down if you glue these in (no glue required if bolting this together. rods are flush to the back when complete.

Vertical Support

print horizontal with support

40% fill as it's structural

the short end of this mounts in the box on the main bottom plate, you can glue the base or I used bolts from the bottom to add to the bottoms look, do not over tighten any bolts!

Upper and lower risers

40% fill

1 hour print time

Support as your preference

Upper riser has a hole for the upper gear pod

lower riser has no hole.

lower riser butts up against the vertical support holder, upper support butts up against the front plate, glue these down. (for the upper riser paint the area and gears first)

Top plates

40% fill

half hour print

both align to the front and back edges, either screw down with m3 bolts or glue directly

Server housing

40% fill

30 minute print

no support needed

line up the mounting holes, make sure the servos are inside (should move freely) bolt in place with longer m3 screws

I have about 100 hours of design time and 2 days of print time into this to create something cool! If you make one please post it as I would love to see it, if you have any questions please ask. :)

Enjoy! If you enjoy my prints please consider donating, even a dollar helps :) it's always appreciated :) https://www.paypal.me/RychardK

(November-15-2020: Check out my new Lock-On Bot from the movie here also: https://www.thingiverse.com/thing:4654995 )

Hello all, over the last week I have been sinking all my time into this prop reproduction from the movie Runaway (Tom Sellek and Gene Simmons 1984 - https://www.imdb.com/title/tt0088024/ ). I have always had a love for the killer robot spiders, so I decided to go looking for a print. Oddly enough there are none modelled off this amazing killer spider! So I decided to start toying with this. Slowly but surely over the course of 5 full days of modelling 16 hours a day I have what I consider a 90% faithful looking kit. I went through many versions of printing to get this to just the right level of building and look. I will continue to add some greebles to this as I finish the final building, but this is the base kit.

There are outside parts you will want/need to complete this.

Flexible cable conduit (for the top level, see the actual prop photos)

Misc wiring (for all over)

small Zip ties (for all over securing the wiring etc)

Optional (If you want more strength on the top rods): 2x 3mm Tubes or dowels (200 mm length each), steel for strength (a coat hanger may work here I have not tested that yet), 5mm tube for the main support

Wooden skewers from the grocery store will likely also work here as they are long enough and 3mm thick.

Superglue.

Assortment of M3 socket head cap screws (https://www.amazon.ca/gp/product/B06ZY36VDP/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1) (These are optional as you can glue it all together, but the extra realism you get with these and the ability to take this apart to add to it or work on it I find is well worth the upgrade)

Paint - Aluminum, or silver. Detail Paint: flat black, white, and any other touches you might like.

Optional: Instead of printing the battery pack I recommend just making one yourself from old AA or AAA batteries, this will add some nice weight, and cuts an hour from the print time ;)

Considerations

I am trying to make this as easy a print as possible while being faithful to the onscreen prop from the movie, you should be able to look at it and know exactly where it is from if you've seen it before :)

The legs are moveable strictly side to side, not the joints.

The gears go nowhere but do spin :), yes I know, this is not a working model kit, but to give the best approximation and to keep simplicity. they will never go anywhere, there are also some linkages missing and some small liberties taken so that the print looks right and will display nicely, yet giving you the options to explore adding your own greebles.

This is my first mega type build of this degree. It's not going to be perfect. And it's all designed in tinkercad. And I have now rebuilt almost all of the original to increase details, and improve the print quality. a few times over now :P

By the time this gets to thingaverse it will be fully printed and and issues I can't correct will be documented and explained. (see above :P )

This kit is meant to be printed on a 200mm bed. it's scaled for every part to fit, It's very close to the movie prop in size

Not all the print times are listed, there were a lot of changes and variations as I was trying to both write up this guide and get things done ;) It will likely take a day to print this at .2, 35mm/s and 20-80% fill.

Assembly:

While you can just glue everything together I used a mix of gluing some parts and bolting the frames together.

Sand edges (or exacto) to remove all elephants foot expansion and fill/sand to your desire. Then paint pretty much all silver and weather it with black wash. I barely had to sand anything, not much more than 10 minutes for the whole kit. A lot of thought went into fit here :)

Install pictures are below

General print settings

.20 quality (each part group is detailed so if something is different it is listed there)

Infill will vary from 20-80% and will be listed

35mm Print speed

Hot end temp: 205 degrees

Bed Temp 60 degree first layer 55 degree and gradating down to 0 depending on height

Ironing is on top layer only

other settings as best suits your style

Parts Breakdowns

Legs:

Grouped together for the middle sets and the end legs, all are split

Print the end legs twice for the right number (this is because I am impatient :P )

1.5 hour print for each pair of legs

Support everywhere at 60degrees

these print clean, the supports come off well, had to redesign these to make the springs prominent. this version works well, the posts are black, I would silver accent the spring edges

short legs go on the front and back, holes face the front, a very light sanding of the posts top and bottom so they are smooth. They are supposed to protrude from the top and bottom of the plates to mimic the prop mounting bolts. paint the top and bottom protrusions black

Radio box:

no support

30 minute print time

holes are included for attaching wiring,

this is a free mount part on the top deck on the riser above the top gear pack glue in place

Control arms

No support needed

15 minute print

Prints without issue as is

These are under/over control arms

a dab of glue on the top of the lower and the underside of the top with the bolt head.

if there is a fit issue (I had to change the dimension thickness of the chassis) hot water bend these to fit but mine fit perfect

Lower box and rod

No support needed

20 minute print

free mount for the base of the box, the rod will connect to the front motor in the hole, slight sanding will be required for fit

you can glue the box to the base or just leave it as a friction fit part

Lower back plate

7 minute print time on horizontal, 30 minutes vertical

print with support (unless printing vertical)

A bolt screws in through this, through the base plate, and through the servo hosing and into the servos.

Lower Main Plate

No Supports

printed at 40% infill

print time 3 hours

Increased the infill to 40% as I also thickened the plate from 1mm to 4mm, this gives a better quality print and a more realistic feel, I will be changing the gears to 3mm as I feel they were a bit thin also.

Slightly file the mounting holes for the legs only. the other holes should be left alone so the threads can grab.

Lower Gear Pod

No supports

50 minute print time

80% fill for rod strength

Minor filing of the holes may be required so they free spin

the base gear fits into the main plate indent and should be glued, and the gears will just stack on top

the main gear shaft will line up into the top plate hole (do not glue the rod to the top if you glued the bottom!)

Upper Gear Pod

No supports

50 minute print time

80% fill for rod strength

Minor filing of the holes may be required so they free spin

the base gear fits into the top plate indent and should be glued, and the gears will just stack on top

the main gear shaft will line up into the top riser hole (do not glue the rod to the top if you glued the bottom!)

Back Servos

no support

1 hour print time

colour black with white top gears

feel free to add linkages to other areas

mounted upside down in the servo holder via screws top and bottom

front motor

support is needed here but you can likely get away without it

1 hour print

front location, line up with the plate edging and top and bottom plate holes

add a zip tie around the top for the authentic prop look

run wiring and add holes to mount if you like (future version may get this)

Rods

No Support

80% fill

1 hour print

print horizontally (for strength)

These came out very well and I have high hopes for strength, sand the ends to insert into the fore and aft vertical plates, there will be a bit of a flat spot on the bottom, face that down if you glue these in (no glue required if bolting this together. rods are flush to the back when complete.

Vertical Support

print horizontal with support

40% fill as it's structural

the short end of this mounts in the box on the main bottom plate, you can glue the base or I used bolts from the bottom to add to the bottoms look, do not over tighten any bolts!

Upper and lower risers

40% fill

1 hour print time

Support as your preference

Upper riser has a hole for the upper gear pod

lower riser has no hole.

lower riser butts up against the vertical support holder, upper support butts up against the front plate, glue these down. (for the upper riser paint the area and gears first)

Top plates

40% fill

half hour print

both align to the front and back edges, either screw down with m3 bolts or glue directly

Server housing

40% fill

30 minute print

no support needed

line up the mounting holes, make sure the servos are inside (should move freely) bolt in place with longer m3 screws

I have about 100 hours of design time and 2 days of print time into this to create something cool! If you make one please post it as I would love to see it, if you have any questions please ask. :)

Enjoy! If you enjoy my prints please consider donating, even a dollar helps :) it's always appreciated :) https://www.paypal.me/RychardK

Similar models

thingiverse

free

6:1 Stackable Planetary Gear by DbC

...density

cover: 1 hour 42 minutes, 8.13 meters

ring gear: 1 hour 48 minutes, 8.43 meters

100% fill

sun gear: 7 minutes 0.46 meters

thingiverse

free

Drone stand which fits every drone! by Ratner

...per_part_example1"

3)glue the upper and lower part together

tip: use 0% infill and fill the stand after the print with sand.

thingiverse

free

pumpkin happy halloween

...al and energy.

printing

layer height 0.2 mm

filling density 20%

filling pattern, lines

no supports

the cura program

regards

lefan

thingiverse

free

Q450 Quad Landing Legs Gear Quadcopter by Imaginator3D

...unts. you will need slightly longer frame screws to attach the legs to the bottom of the frame. i used a 50% fill for strength.

thingiverse

free

Spinning Top by AKRAM3D

...equired if printing the "split" model. you can glow the upper and lower part together.

spins for more than two minutes!

thingiverse

free

Headphone Stand by Riven02

... the support up to match the top.

the accent pieces lightly snap together but i suggest a drop of superglue on all of the joints.

thingiverse

free

New gear for Star Tracker by martin_au by TTRCmedia

...den the hole for the threaded rod in the bottom plate to ~10mm and glue or screw the part "axis" onto the bottom plate.

thingiverse

free

Turkey Foot Prosthesis by RickDIY

...aused by this design. please consult a medical professional if your bird has sustained an injury, and prior to using this device.

thingiverse

free

lower ring bracket by bobbyshomerul

...ned a bracket to link it to the big gear.

you need to print 4 pcs and glue them to big gear and use upperring instead of lowering

thingiverse

free

Furniture Risers by w1ebr

...e5b6

i printed this using 20% fill of esun abs+ with fast honeycomb interior fill and approx 1mm top, bottom and shell thickness

Runaway

3d_export

$5

IAI Sparrow X lowpoly concept fighter

...also enables short take off and landing on smaller runaway to operate even from the streets. it is equipped...

thingiverse

free

mk3s fan shroud to prevent thermal runaway

...ting at higher temperatures. this modification has so far fixed the problem for me. i could only find the stl, not the step file.

thingiverse

free

Runaway heart by DuncanShadow

...ureshttps://www.instagram.com/duncanlouca

i also have a website where i have other sculpts for sale.https://www.duncanshadow.com/

thingiverse

free

GASLANDS RC BOMB- RUNAWAY STYLE (LOCK-ON)

... resin printer.

update: modded them to have the target part removed..since it may not even print with some printers at its size.

thingiverse

free

Runaway Replacement Headband by AdamoRobinson

...ou'll need:

2x 20mm m2 bolts

2x m2 nuts

the m2 nut traps along the band itself are for bolting a cushion to, once i model it.

thingiverse

free

Runaway Island Christmas Village House by JmsDwh

...translucent filament. if you mask the windows and paint the model, the light from an led tealight will shine through the windows.

thingiverse

free

Ender 3 Pro filament runaway sensor, z axis endstop salvage - remix by Tse_Tso

...eems that creality had changed the design slightly. anyway, original design is not working for ender 3 pro.

print and enjoy :)

thingiverse

free

Lock-On Bot From the movie Runaway by rkxone

...u enjoy my prints please consider donating, even a dollar helps :) it's always appreciated :) https://www.paypal.me/rychardk

thingiverse

free

Runaway Blimp aka Raytheon JLENS by mstyle183

...y-military-2015-10 http://foxtrotalpha.jalopnik.com/this-giant-sensor-packed-balloon-is-about-to-watch-over-1635655334/1739241144

thingiverse

free

staff of one by Silkburrito27

...the staff of one nico minoru wields in the runaway hulu series will upload more pictures when i'm able...

Rkxone

thingiverse

free

Militech by rkxone

...militech by rkxone

thingiverse

militech sign

for more of my wall art: https://www.thingiverse.com/rkxone/collections/wall-art

thingiverse

free

Avengers Bookmark by rkxone

...kxone

thingiverse

avengers bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Atari Bookmark by rkxone

...y rkxone

thingiverse

atari bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Viper Bookmark by rkxone

...y rkxone

thingiverse

viper bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Ghostbusters Bookmark by rkxone

...e

thingiverse

ghostbusters bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Punisher Bookmark by rkxone

...kxone

thingiverse

punisher bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Shadowrun Bookmark by rkxone

...kxone

thingiverse

shadowrun bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Shadowhunter Bookmark by rkxone

...e

thingiverse

shadowhunter bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Stormtrooper Bookmark by rkxone

...e

thingiverse

stormtrooper bookmark

check out my other bookmarks here: https://www.thingiverse.com/rkxone/collections/bookmarks

thingiverse

free

Biotechnica Sign by rkxone

...hingiverse

biotechnica sign from cyberpunk 2077

for more of my wall art: https://www.thingiverse.com/rkxone/collections/wall-art

Bot

turbosquid

$19

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

scanner bot

...scanner bot

3dexport

cool scanner bot who scans for fixing things...

3d_ocean

$9

Apc Bot

...n bot games toys

an all-purpose-constructo-bot. for cartoon purposes. the model is not rigged. please use vray adv for rendering.

3d_export

$75

Bot 3D Model

...bot 3d model

3dexport

robot bot man kiborg character

bot 3d model evgen 19504 3dexport

turbosquid

free

Eye Bot

...eye bot

turbosquid

free 3d model eye bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1514059)

turbosquid

$29

Gorill-bot

...bosquid

royalty free 3d model gorill-bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1239456)

turbosquid

$25

Lamp Bot

...bosquid

royalty free 3d model lamp bot for download as blend on turbosquid: 3d models for games, architecture, videos. (1230121)

turbosquid

$10

Spectre Bot

...osquid

royalty free 3d model spectre bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1616378)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

Spider

3d_export

$15

spider

...spider

3dexport

spider

3d_export

$5

Spider

...spider

3dexport

"the spider wants you to accept it." spider made in blender 3.0 from spheres and cylinders

3d_export

free

spider

...spider

3dexport

spider 3d 3dmodel animal free pack collection fbx

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$11

Spider

...spider

designconnected

oluce spider floor lights computer generated 3d model. designed by joe colombo.

3d_export

$24

SPIDER ROBOT

...spider robot

3dexport

spider robot

3d_export

$5

metallic spider

...metallic spider

3dexport

spider formats

3d_export

$5

spider robot

...spider robot

3dexport

spider robot

turbosquid

$100

spider

...r

turbosquid

royalty free 3d model spider for download as ma on turbosquid: 3d models for games, architecture, videos. (1205083)

turbosquid

$10

Spider

...

turbosquid

royalty free 3d model spider for download as obj on turbosquid: 3d models for games, architecture, videos. (1674135)

Movie

3d_ocean

$9

Movie Theater

...movie theater

3docean

movie theater

movie theater building model

3ddd

$1

OFME / MOVIE

...ofme / movie

3ddd

ofme , movie

в архиве 8 моделей

3d_export

$5

movie clapboard

...xport

movie clapboard. lowpoly. here is video: >>>> https://rumble.com/vrjkbb-lowpoly-movie-clappboard-3d-model.html

3d_export

$5

syprocom movie

...5 mm length 320 mm https://svetsupermarket.ru/spoty/potolochnie-i-nastennie-spoty/potolochnye-spoty/movie-mv-movie_mv_181_18.html

design_connected

$16

2045 Movie

...2045 movie

designconnected

intertime 2045 movie computer generated 3d model. designed by crea team intertime .

turbosquid

$29

Movie Popcorn

...quid

royalty free 3d model movie popcorn for download as fbx on turbosquid: 3d models for games, architecture, videos. (1238386)

turbosquid

$10

Movie Slate

...ty free 3d model movie slate for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1265231)

turbosquid

free

movie Screen

... 3d model movie screen for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1452759)

3ddd

free

MOVIE 1 VISI

...movie 1 visi

3ddd

стул

стул офисный. movie 1 visi

turbosquid

$50

Movies Animation

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.